Improved structure of lower temperature measuring opening of polymerization kettle and polymerization kettle adopting same

A polymerization kettle and temperature measuring port technology, applied in chemical/physical/physical chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve unfavorable safety hazards in production management, unplanned shutdowns, and production safety hazards and other problems, to achieve the effect of improving service life and performance, relieving axial stress, and high safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

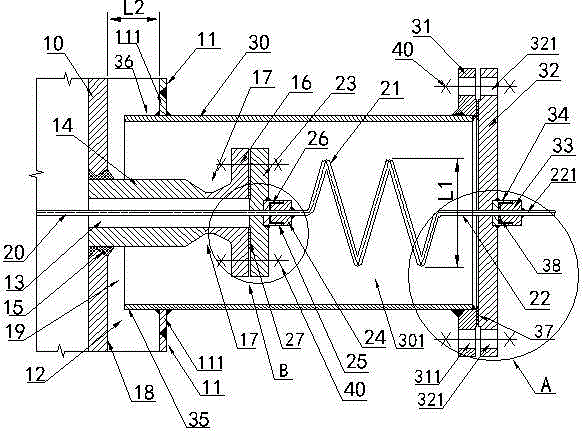

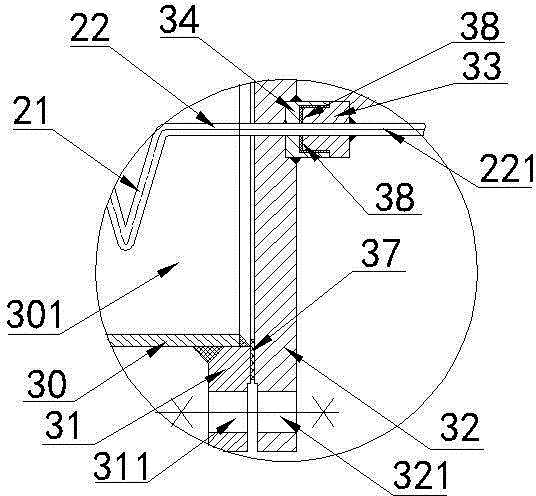

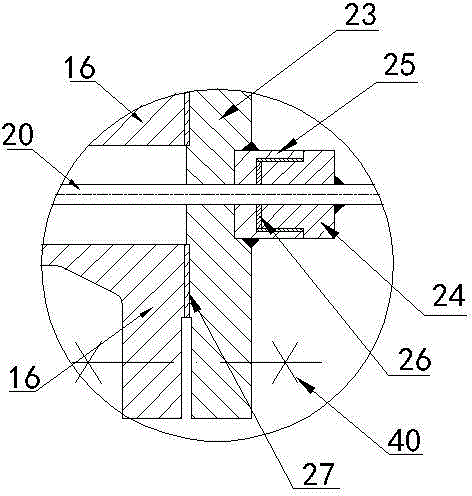

[0027] The thermal resistance is connected with a spiral spring type thermal resistance section 21 continuously between the thermal resistance front section 20 and the thermal resistance tail section 22. In the cavity space between the sealing ends of the resistance outer protection tube body 30 . The spring-type thermal resistance section 21 adopts a coil-shaped spiral section with 2 coils. Of course, a coil-disc coil segment with 2 to 5 coils can also be used according to the actual situation, so as to improve the axial stress of the polymerization kettle and prevent the thermal resistance from falling out to a greater extent. The phenomenon of weld cracking between the protective tube body 30 and the jacket 11 of the kettle body occurs, and also improves the problem of preventing the phenomenon of cracking at the temperature measuring port under the polymerization kettle, so as to improve the thermal resistance of the outer protective tube body 30 and the kettle body. The e...

Embodiment 3

[0029] A polymerization kettle adopts the improved structure of the lower temperature measuring port of the polymerization kettle described in one of the above-mentioned embodiment 1 or embodiment 2, and other structures are the same or similar to the structure of the polymerization kettle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com