Track type inspection robot navigation positioning module and coarse and fine composite positioning method

An inspection robot, navigation and positioning technology, applied in the field of navigation and positioning, can solve the problems of increasing use and maintenance costs, and the lack of observation data of track tilt settlement by the inspection robot of the pipe gallery, so as to achieve the effect of reducing the use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The invention will be described in detail below with reference to the accompanying drawings and specific examples, and illustrative of the invention, but is not limited thereto.

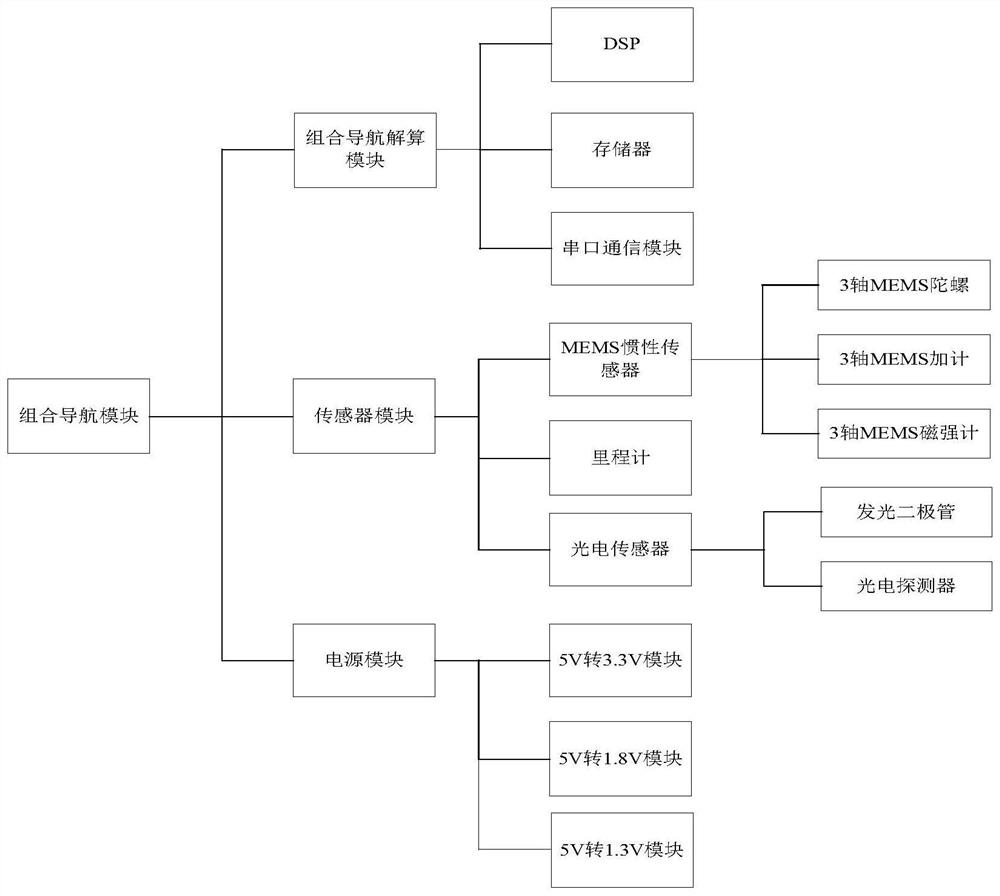

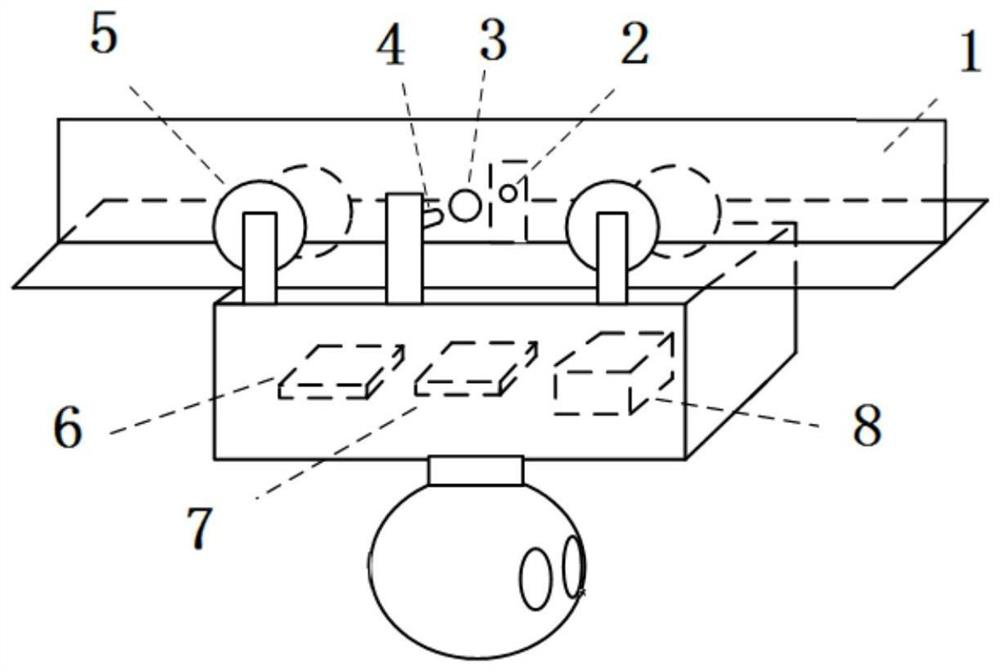

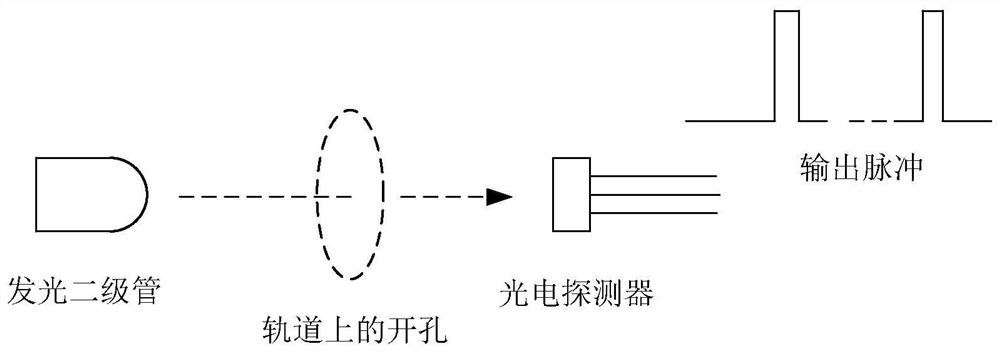

[0050]Such asfigure 1 As shown, the track type patrol robot of the present invention includes: sensor module, including a plurality of sensors, including MEMS inertial sensors, milemeter, and photoelectric sensors, positioning holes in a plurality of sensors, The information obtained is passed to the combination navigation decision module.

[0051]The combination navigation decisor module is mainly used by the DSP core circuit, the memory, and serial port communication module. It is used to solve the data of the sensor, data fusion, and the decisions are sent to the external control center through the serial port communication module RS232 port. The control center stores a gallery map with navigation data to display the vehicle position.

[0052]The power module is mainly supplied to the power supply. It can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com