Methods and apparatus for controlling ion fraction in physical vapor deposition processes

A physical vapor deposition, magnetron technology, applied in the direction of ion implantation plating, metal material coating process, electrical components, etc., can solve problems affecting the uniformity of substrate deposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

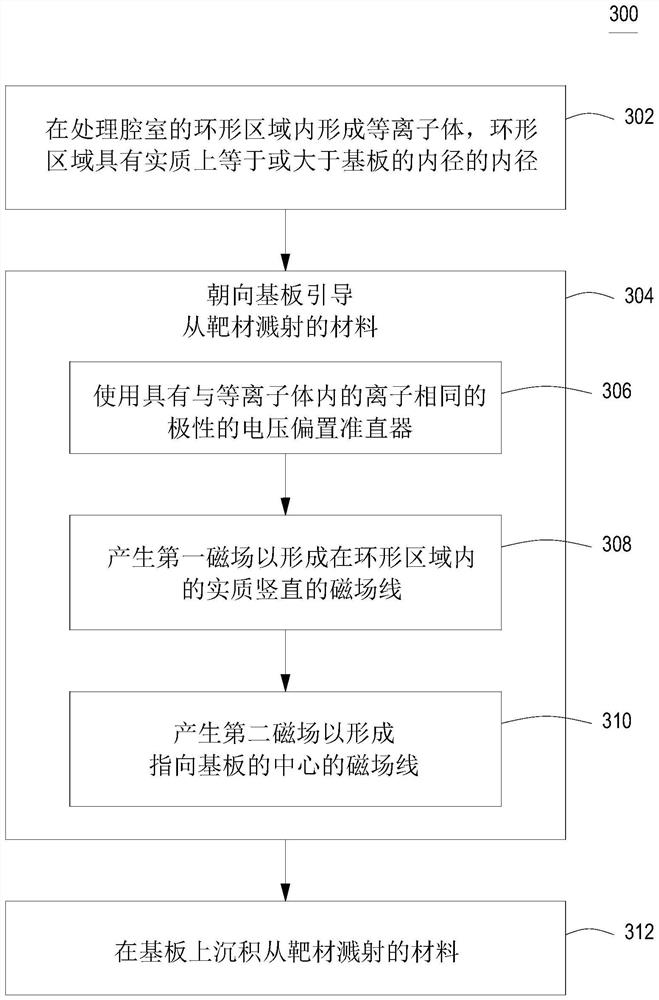

[0016] Embodiments of methods and apparatus for controlling ion fractions in physical vapor deposition processes are disclosed herein. The method and apparatus of the present invention advantageously provide better control of ions in a PVD process, thereby further advantageously facilitating control of deposition results such as the uniformity of deposition of material on a substrate. Embodiments of the apparatus and methods of the present invention may also advantageously improve deposition in features in a substrate and reduce the necessary deposition rate by increasing the number of ions and reducing the amount of neutral species deposited on the substrate.

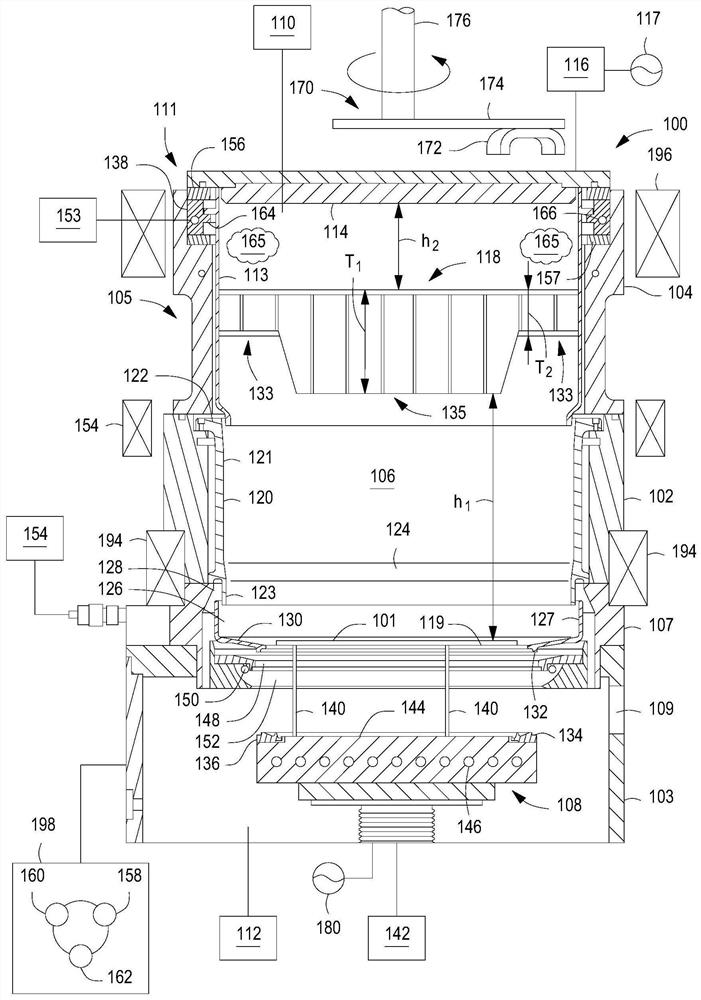

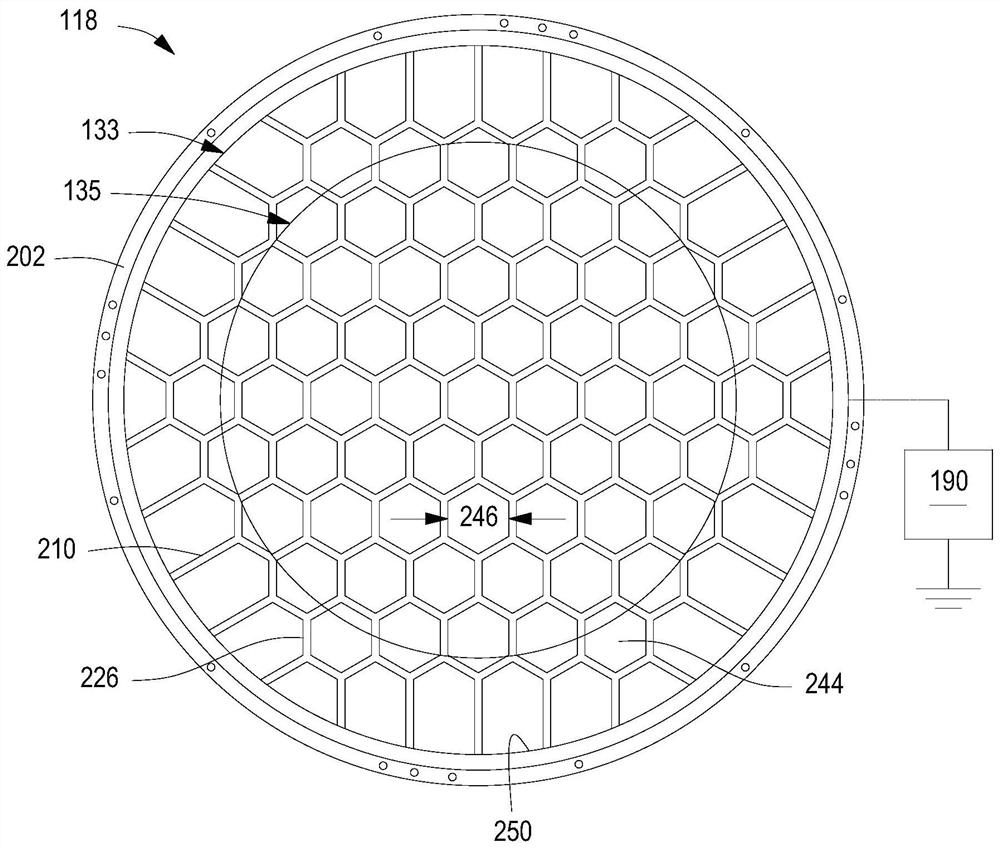

[0017] Embodiments of the disclosure are illustratively described herein with reference to a physical vapor deposition (PVD) chamber. However, the methods of the present invention may be used in any processing chamber modified in accordance with the teachings disclosed herein. figure 1 A PVD chamber (processing chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap