Solar photovoltaic panel with self-cleaning function

A solar photovoltaic panel and self-cleaning technology, which is applied in the field of solar photovoltaic panels, can solve the problems of solar photovoltaic panels consuming a lot of effort, and achieve the effect of increasing cleaning efficiency and strengthening cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

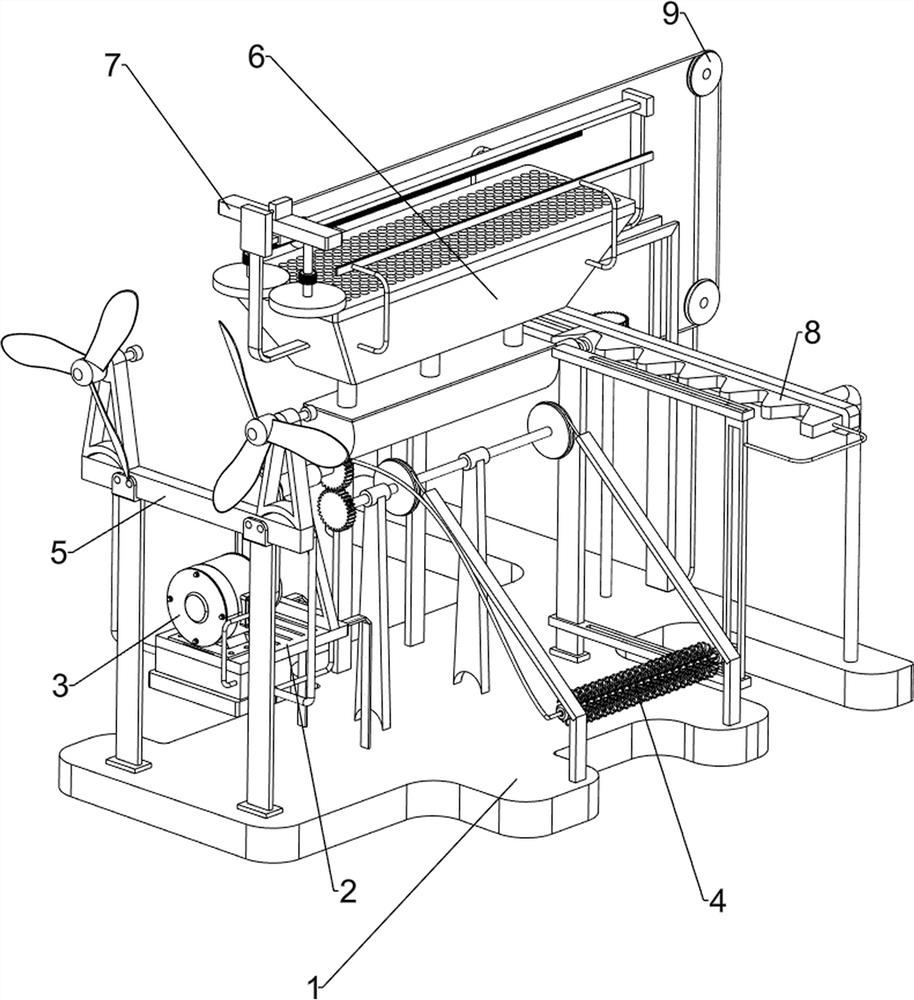

[0058] A self-cleaning solar photovoltaic panel such as figure 1 As shown, it includes a base plate 1, a supporting plate 2, an induction motor 3, a cleaning mechanism 4 and a wind power generating mechanism 5. The supporting plate 2 is welded on the left side of the top of the base plate 1, and the induction motor 3 is fixed on the top of the supporting plate 2 through bolts. 1. A cleaning mechanism 4 is arranged on the front side of the top, and a wind power generating mechanism 5 is installed on the left part of the top of the base plate 1. The wind power generating mechanism 5 is connected with the induction motor 3 through a line.

[0059] When workers need to clean the solar photovoltaic panels, the induction motor 3 rotates at regular intervals, the rotation of the induction motor 3 will drive the cleaning mechanism 4 to rotate, the cleaning mechanism 4 will slide up and down, and the cleaning mechanism 4 will move up and down to clean the solar photovoltaic panels. The...

Embodiment 2

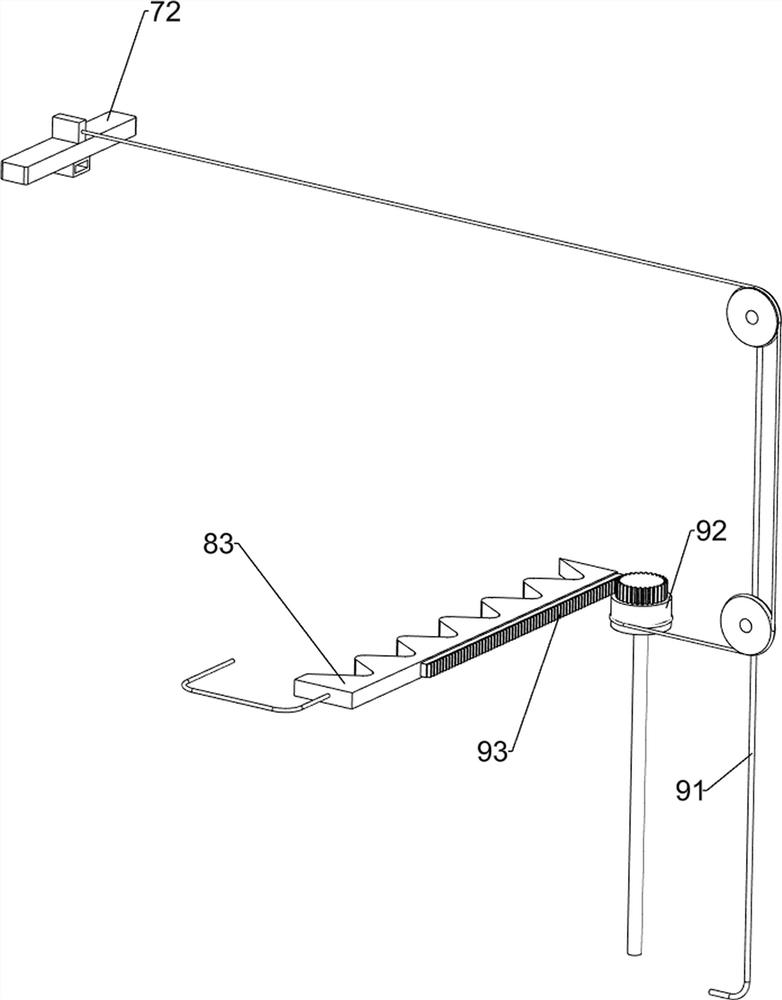

[0061] In a preferred embodiment of the present invention, as figure 2 As shown, the cleaning mechanism 4 includes a first guide sleeve 41, a cleaning assembly 42, a first rotating sleeve 43, a first pulling assembly 44, a second rotating sleeve 45, a gear set 46 and a transmission assembly 47. The first guide sleeve 41 is symmetrically provided, and the cleaning assembly 42 is slidingly provided between the two first guide sleeves 41. The top of the bottom plate 1 is fixed with the first rotating sleeve 43, and the top of the first rotating sleeve 43 is symmetrically rotated. A pulling assembly 44, the first pulling assembly 44 is connected with the corresponding cleaning assembly 42, a second rotating sleeve 45 is fixedly connected to the right side of the top of the pallet 2, and a transmission assembly 47 is rotatably arranged inside the second rotating sleeve 45, and the transmission assembly 47 It is connected with the output shaft of the induction motor 3 , and a gear ...

Embodiment 3

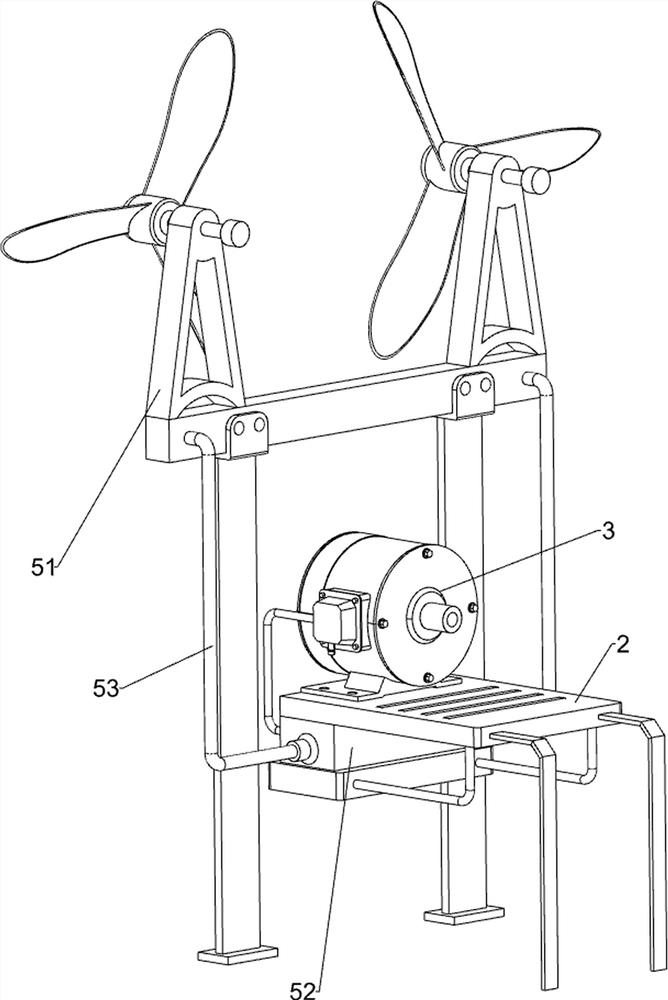

[0064] In a preferred embodiment of the present invention, as figure 1 with Figure 3-Figure 7 As shown, the wind power generation mechanism 5 includes a wind power generation group 51, a storage battery group 52 and an incoming line 53, a wind power generation group 51 is installed on the left side of the top of the bottom plate 1, a storage battery group 52 is installed on the bottom of the supporting plate 2, and the wind power generation group 51 An incoming line 53 is connected to the storage battery pack 52 .

[0065] When the external power supply cannot be connected in a relatively remote place, the wind will blow the wind power generation unit 51 to rotate, and the electric energy generated by the rotation of the wind power generation unit 51 will be transmitted to the storage battery pack 52 for storage through the incoming wire 53, and the storage battery pack 52 can provide power to the induction motor. 3 provides electric energy, so that the induction motor 3 wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com