Deflection wheel sorting unit, deflection wheel sorting machine, deflection wheel sorting system and package supply system

A deflecting wheel and sorting machine technology, applied in sorting and other directions, can solve the problems of limited size, insufficient flexibility, and complex module structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

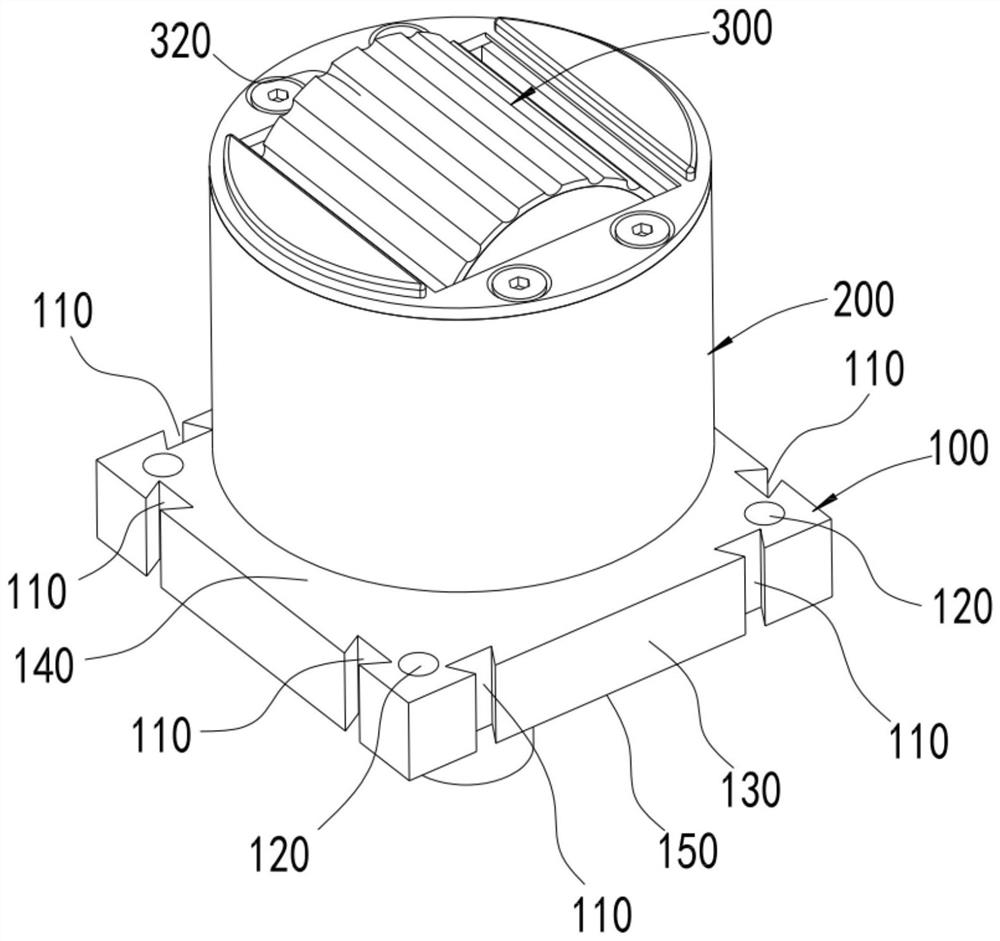

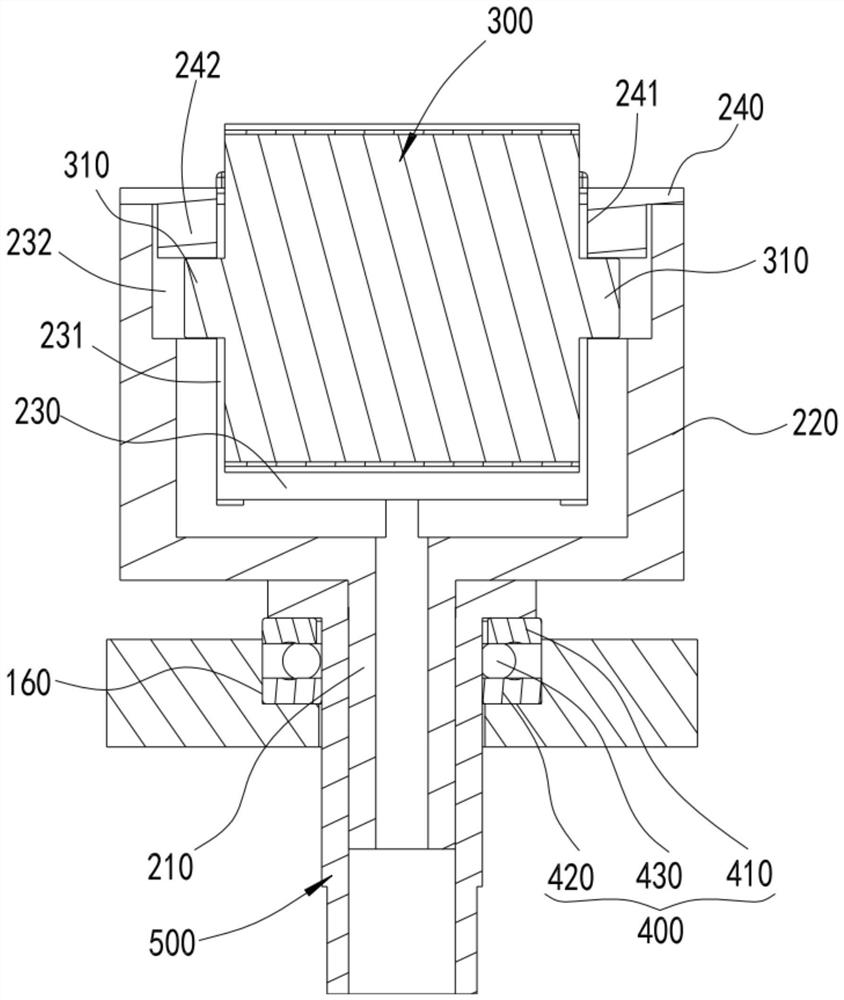

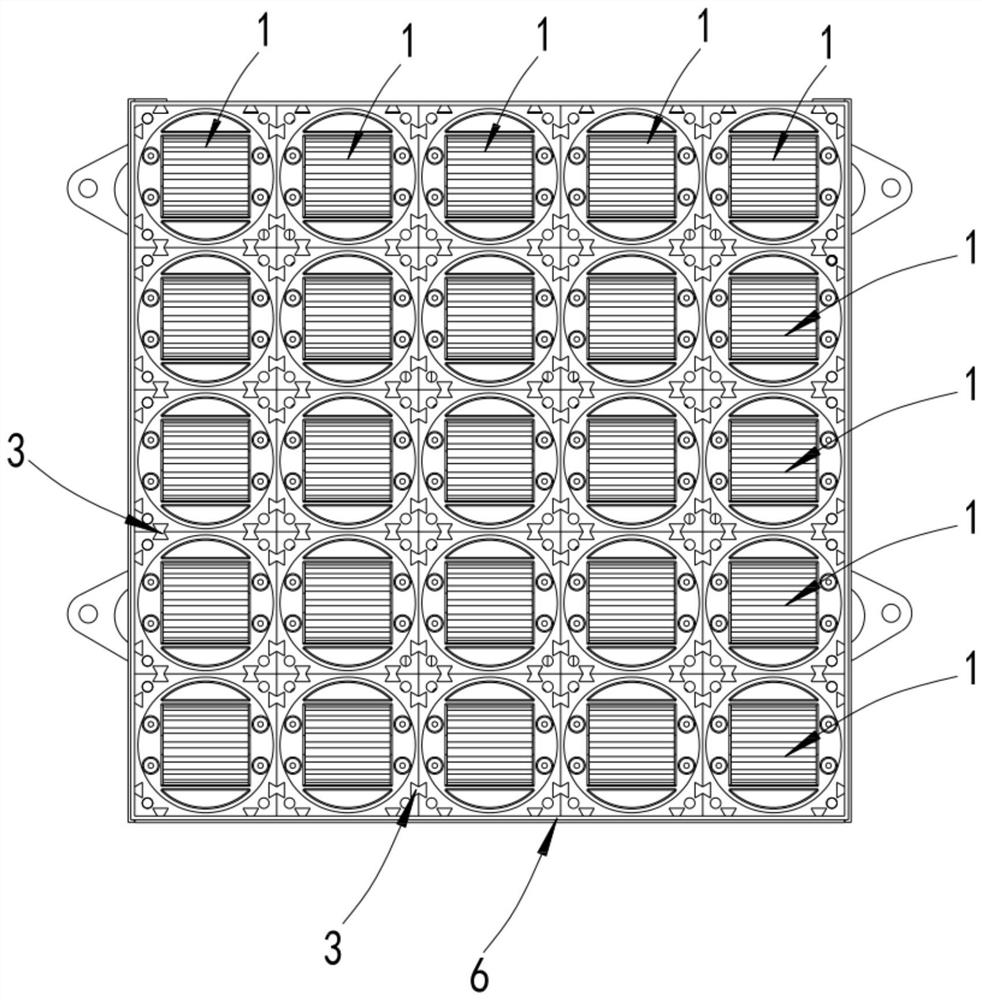

[0045] This embodiment discloses a deflection wheel sorter, as attached image 3 - attached Figure 4 As shown, it includes a set of deflection wheel sorting unit 1 of the above-mentioned embodiment and a swing driving mechanism 2 for driving the deflection wheel sorting unit 1 to swing. The number and layout of multiple deflection wheel sorting units 1 can be designed according to needs. In this embodiment, the deflection wheel sorting units 1 are arranged in five rows and five columns, so that the conveying surface of the entire deflection wheel sorter is square.

[0046] as attached Figure 4 As shown, the deflection wheel sorting unit 1 and the swing driving mechanism 2 are arranged on the frame 6, and the frame 6 can be various feasible structures. In a preferred embodiment, the frame 6 includes four A pillar 61, a beam 65 is arranged between two pillars 61 on the same side, four L-shaped plates 62 surrounded by a square are arranged on the four pillars 61, and a top cov...

Embodiment 3

[0053] This embodiment discloses a deflection wheel sorting system, as attached Figure 7 As shown, any deflection wheel sorter 1000 described above is included. There are multiple deflection wheel sorters 1000, and the adjacent deflection wheel sorters 1000 are connected by a conveyor 2000, and the input end of the first deflection wheel sorter is connected to the input line 3000, and each of the deflection wheel sorters The two sides of the adjacent deflection wheel sorters are respectively provided with chutes 4000.

Embodiment 4

[0055] This program further reveals a kind of package supply system, as attached Figure 8 As shown, the deflection wheel sorter 30 of the above-mentioned embodiment is included, the three output ends of the deflection wheel sorter 30 are connected to three supply platforms 10, and the input ends of the deflection wheel sorter 30 are connected to six Surface scanning code conveyor line 40.

[0056] as attached Figure 8 , attached Figure 9 As shown, the three package supply platforms 101, 102, and 103 are arranged in parallel and with the same length, and each package supply platform 10 can be a known multi-stage package supply platform, but compared with the existing package supply platform, this The code scanning device can be omitted at 10 positions of the package supply platform of the scheme, and other structures are consistent with the existing package supply platform, so they will not be described here. In a preferred embodiment, the weighing section can be omitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com