Using method of concrete cutting saw

A cutting saw and concrete technology, which is applied in the field of construction engineering, can solve the problems of economic loss, waste of screws, and difficult cutting in corners, etc., and achieve the effect of reducing workload, facilitating work, and precise cutting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

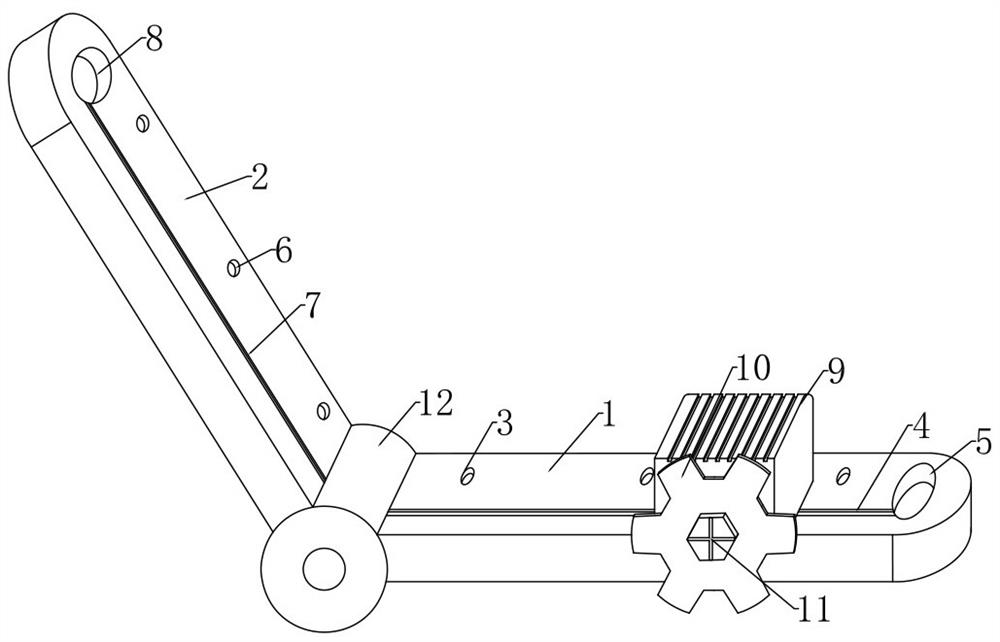

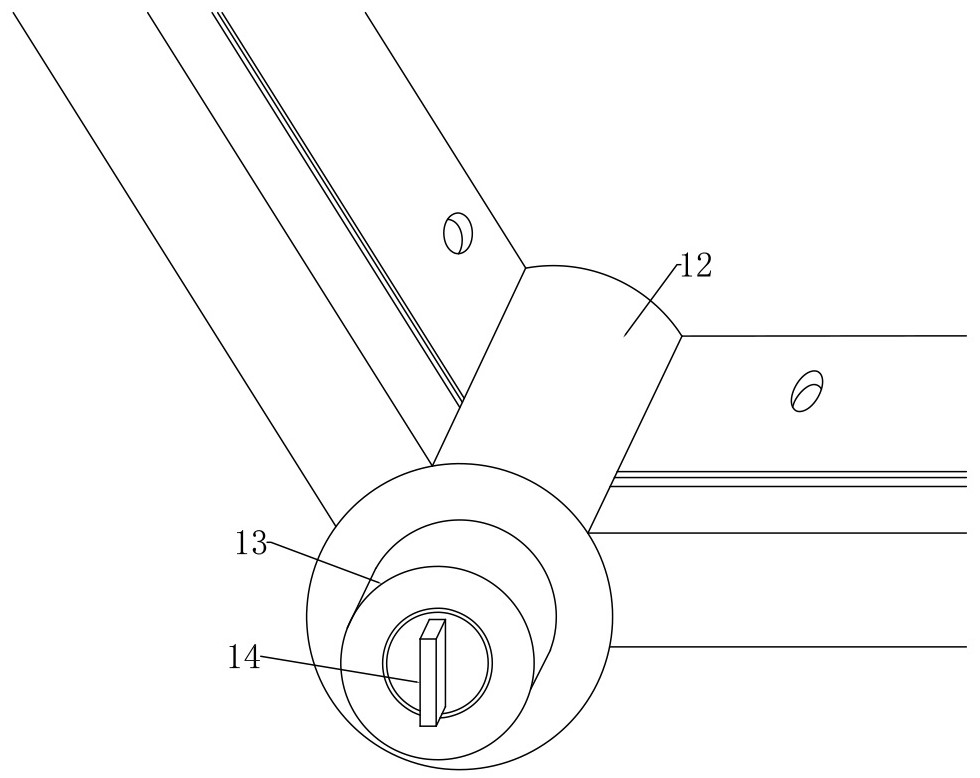

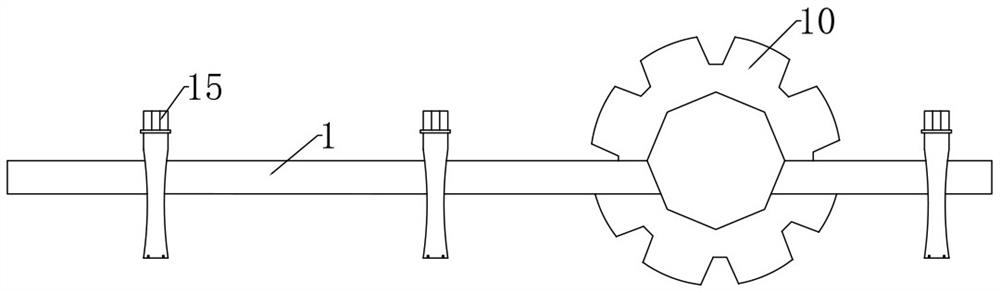

[0027] see Figure 1-4 , a method of using a concrete cutting saw, comprising a longitudinal fixing frame 2, a horizontal fixing frame 1 and a rotating shaft 12, one end of the longitudinal fixing frame 2 is provided with a rotating shaft 12, and one side of the rotating shaft 12 is provided with a horizontal fixing frame 1, and The horizontal fixed frame 1 and the vertical fixed frame 2 are hinged by a rotating shaft 12, the top of the horizontal fixed frame 1 is provided with a first fixed guide rail 4, and the top of the first fixed guide rail 4 is provided with a motor 9, and the motor 9 One side is provided with cutting saw blade 10, and described cutting saw blade 10 is socketed on the rotating shaft of motor 9, and described cutting saw blade 10 is connected with motor 9 rotating shafts, and described cutting saw blade 10 side is provided with fixing screw 11. The fixing screw 11 is closely attached to and fixed to the rotating shaft of the motor 9 , a rotary fixed swit...

Embodiment 2

[0029] A method for using a concrete cutting saw, comprising a longitudinal fixing frame 2, a horizontal fixing frame 1 and a rotating shaft 12, one end of the longitudinal fixing frame 2 is provided with a rotating shaft 12, and one side of the rotating shaft 12 is provided with a horizontal fixing frame 1, and the The horizontal fixed frame 1 and the vertical fixed frame 2 are hinged by a rotating shaft 12, the top of the horizontal fixed frame 1 is provided with a first fixed guide rail 4, and the top of the first fixed guide rail 4 is provided with a motor 9, and the motor 9 is a A cutting saw blade 10 is provided on the side, and the cutting saw blade 10 is sleeved on the rotating shaft of the motor 9, and the cutting saw blade 10 is connected to the rotating shaft of the motor 9 in rotation, and a fixing screw 11 is provided on one side of the cutting saw blade 10 , the fixing screw 11 is closely attached to and fixed to the rotating shaft of the motor 9 , a rotary fixed ...

Embodiment 3

[0032] A method for using a concrete cutting saw, comprising a longitudinal fixing frame 2, a horizontal fixing frame 1 and a rotating shaft 12, one end of the longitudinal fixing frame 2 is provided with a rotating shaft 12, and one side of the rotating shaft 12 is provided with a horizontal fixing frame 1, and the The horizontal fixed frame 1 and the vertical fixed frame 2 are hinged by a rotating shaft 12, the top of the horizontal fixed frame 1 is provided with a first fixed guide rail 4, and the top of the first fixed guide rail 4 is provided with a motor 9, and the motor 9 is a A cutting saw blade 10 is provided on the side, and the cutting saw blade 10 is sleeved on the rotating shaft of the motor 9, and the cutting saw blade 10 is connected to the rotating shaft of the motor 9 in rotation, and a fixing screw 11 is provided on one side of the cutting saw blade 10 , the fixing screw 11 is tightly fitted and fixed to the rotating shaft of the motor 9 , a rotary fixed switc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com