Intelligent bush hammer

A kind of chisel machine, intelligent technology, applied in the direction of erecting/assembling bridges, stone processing tools, working accessories, etc., can solve the problems of high thrust, high labor intensity of construction personnel, low construction efficiency, etc., to ensure stability and improve chiseling Hair effect, the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

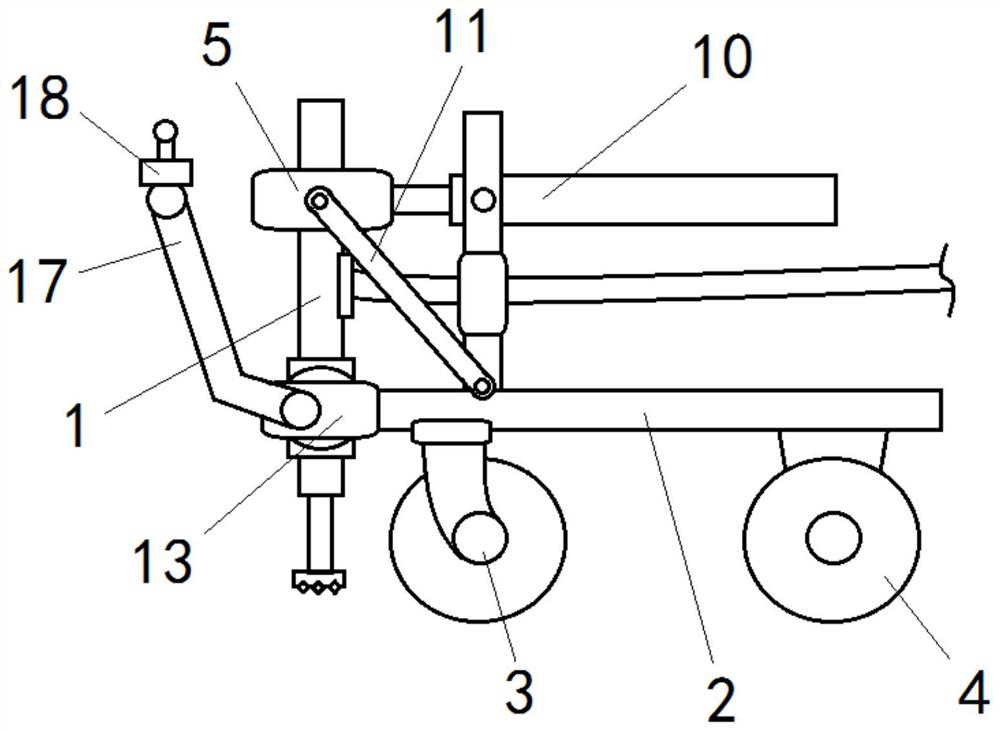

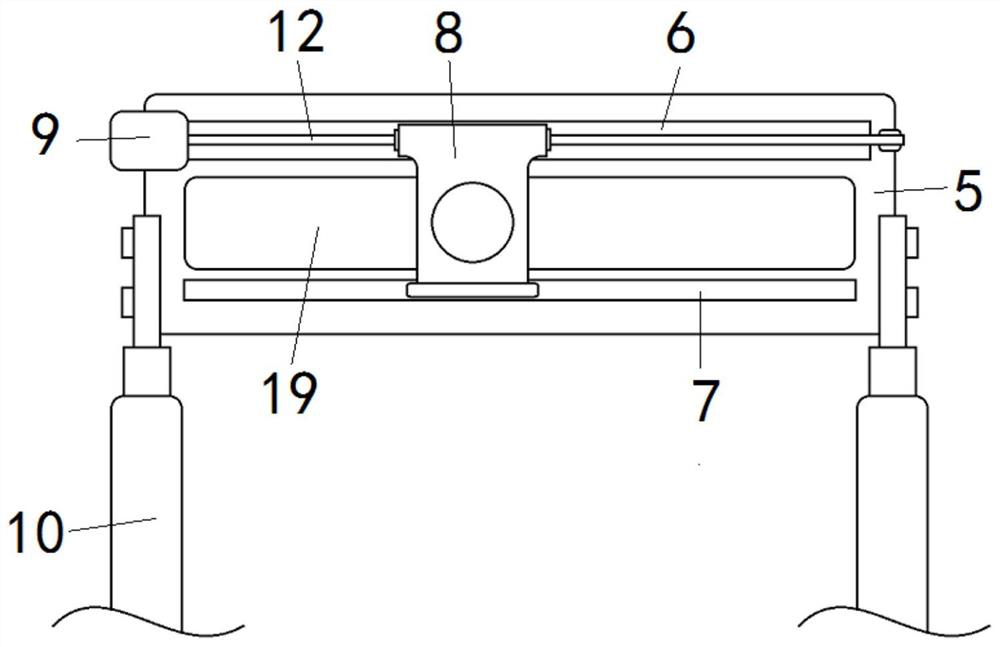

[0019]according tofigure 1 ,figure 2 ,image 3As shown, an intelligent chiseling machine is composed of a rock drill 1 and a body 2 for mounting the rock drum 1, the body 2 is a tube structure, and the body 2 is provided with a carrier, the drilling machine 1 is vertically attached to any end of the body 2 via a tilt control system; the tilt control system includes a horizontal lane 5 having a transverse channel 19, the transverse channel 19 is up and down Set, and the upper half of the rock drill 1 is located within the lateral channel 19; the inner wall of the lateral channel 19 is provided with a first slide 6, and the first slide 6 is provided with a fork 8. The fork 8 constrains the outer diameter of the rock drill 1, further comprising a first driver that drives the first slide 6 in the first slide 6; the rock driver 1 passes through the bottom Set with the body 2. The horizontal homage seat 5 is fitted to the body 2 by a push mechanism, and the push mechanism includes a level ...

Embodiment 2

[0022]The horizontal lane 5 is further provided with a second slide 7 relative to the first slide 6, and the fork 8 is facing one end of the first slide 6 and the second The slide 7 mates; also includes a hinge arm 11, which is hinged to the outer wall of the rock drill 1 and the bottom of the body 2.

[0023]In the above setting, the slider in the second slide 7 is responsible for stabilizing the movement of the fork 8 within the transverse channel 19, thereby improving the stability and reliability of the fork 8 operation. The hinge arm 11 constrains the longitudinal motion range between the rock drill 1 and the body 2, so that the weight of the body 2 can be applied to the rock drill 1, thereby improving the chiseling effect.

Embodiment 3

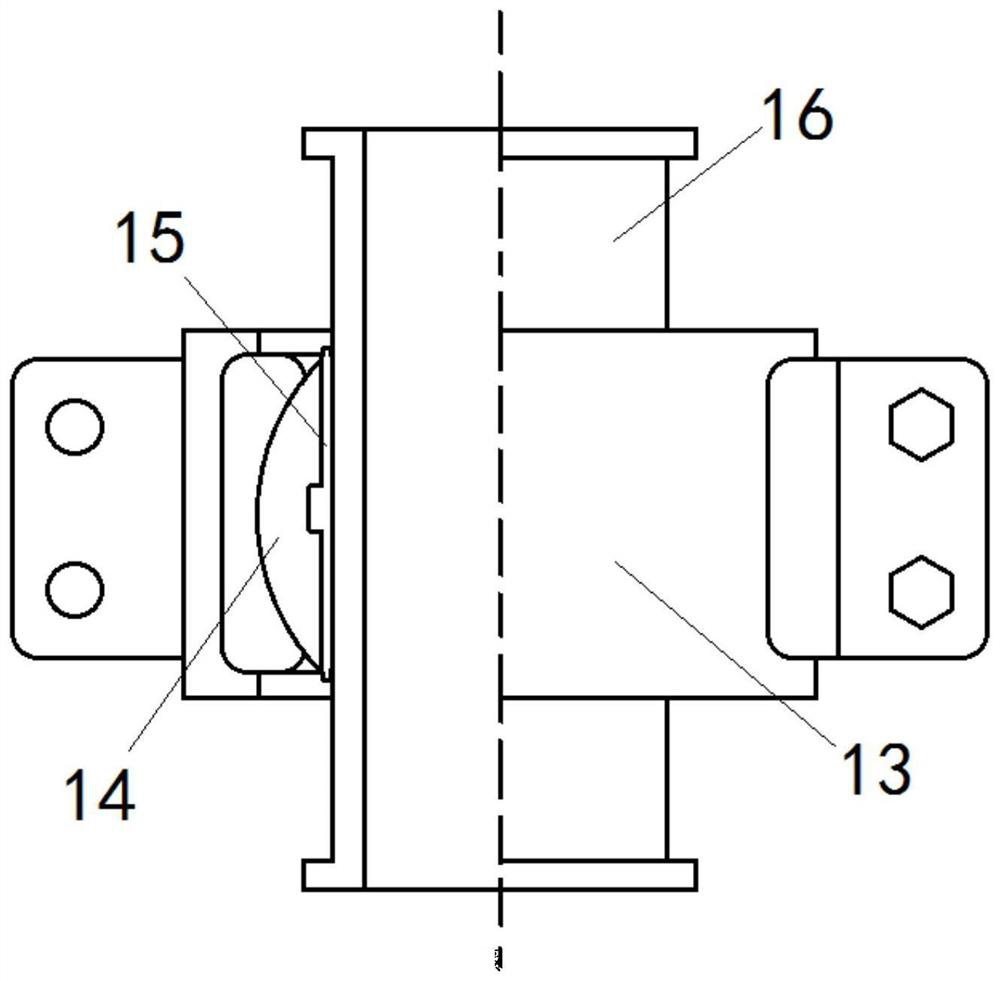

[0025]The universal slide includes a fixed ring 13 that is fixedly coupled to the body 2, and a core ball 14 in which the core ball 14 is fitted in the fixing ring 13, and the core ball 14 is fitted in the fixed ring. The free rotation is free, and the core ball 14 is provided with an axial hole through and down, the rock drill 1 coaxial nested in the shaft hole of the core ball 14. The inner side wall ring of the shaft hole of the core ball 14 is circumferentially provided with a slit, which is nested in the shaft hole of the core ball 14, and a bushing 15 is provided, and the outer side wall of the bushing 15 is provided with the slot. The mating projection; the outer wall fixed nested nested nested nested nested nested in the bottom of the drilling machine 1, the sliding sleeve 16 slides together.

[0026]In the above arrangement, the fixed ring 13 with the rigid connection of the body 2 forms a rigid fulcrum on the rock drill 1, so that the stability of the tilt angle of the rock d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com