Web former with rotatable main air duct

A technology of web forming machine and main air duct, which is applied in the direction of textiles, papermaking, and non-woven fabrics. It can solve the problems of single and unadjustable width and index parameters, and achieve the goal of reducing the vertical and horizontal strength ratio and saving manufacturing and labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

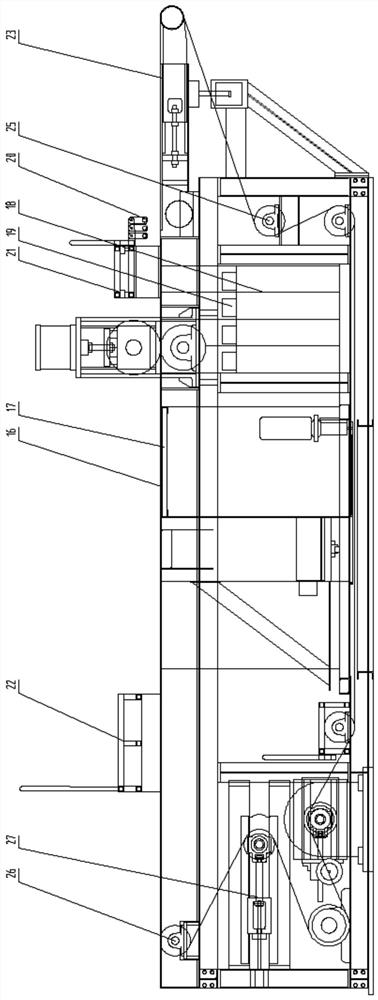

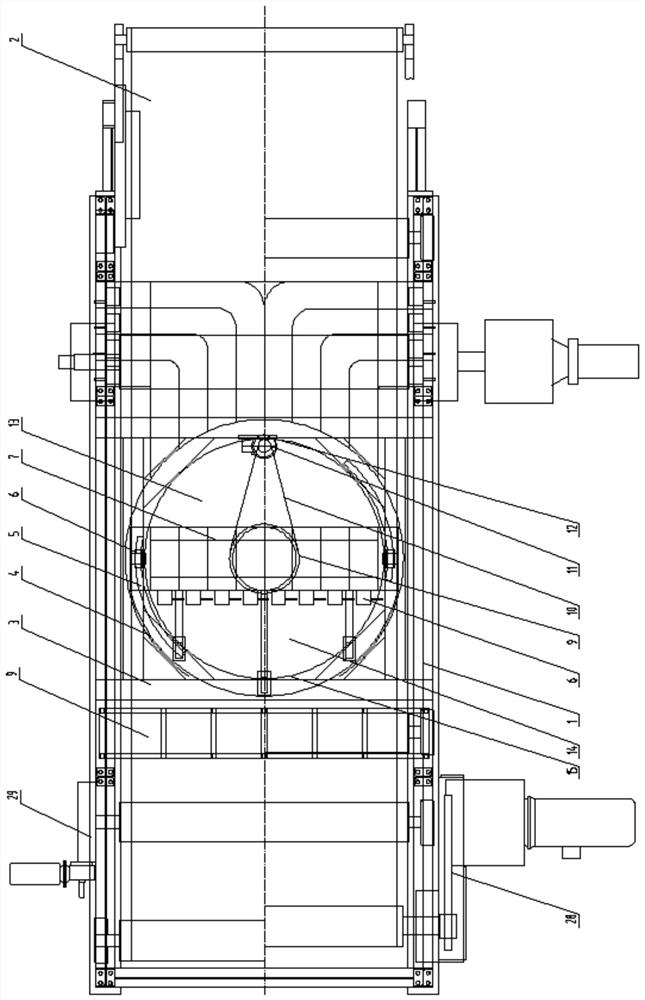

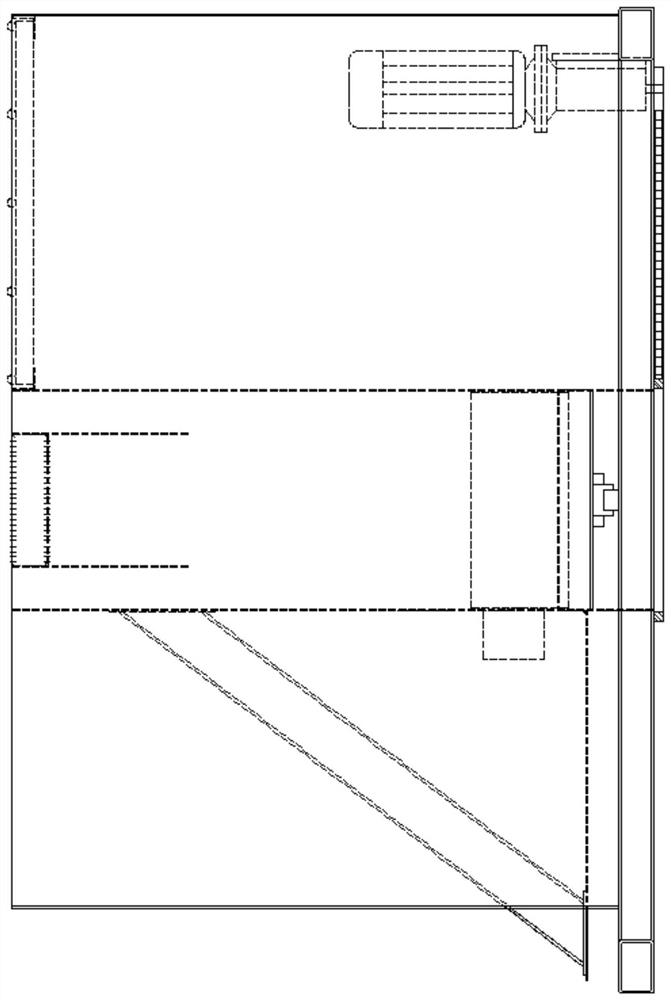

[0020] exist Figure 1 to Figure 6 In the shown schematic diagram of the present invention, the web forming machine frame 1 is a frame frame, and a net curtain 2 is laid on the upper surface of the frame, and the tow is received above the web forming machine, and the wire is formed in the web forming machine frame. The lower part of the bundle and fiber web is equipped with a main suction mechanism and a secondary suction air channel mechanism. The main suction area is where the tow falls to the web forming machine, and the secondary suction area is to enable the fiber web to transition smoothly on the mesh curtain. , the main suction mechanism, the secondary suction air channel mechanism are connected with the fan trench. The main suction mechanism includes the main air duct bracket, annular sleeve, main air duct air volume regulating valve, arc slide rail, slider, ring gear, main air duct, toothed belt, motor, gear, windshield, nylon gang and perforated plates. The main ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com