A long glass fiber reinforced lightweight thermoplastic composite material for preparing a full-length underbody protection plate of a passenger car and a preparation method thereof

A bottom guard, thermoplastic technology, applied in the field of composite materials for automotive exterior parts, can solve the problems of long fiber wear and tear, reduce the ratio of vertical and horizontal strength, excellent formability, improve breaking strength and elongation at break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

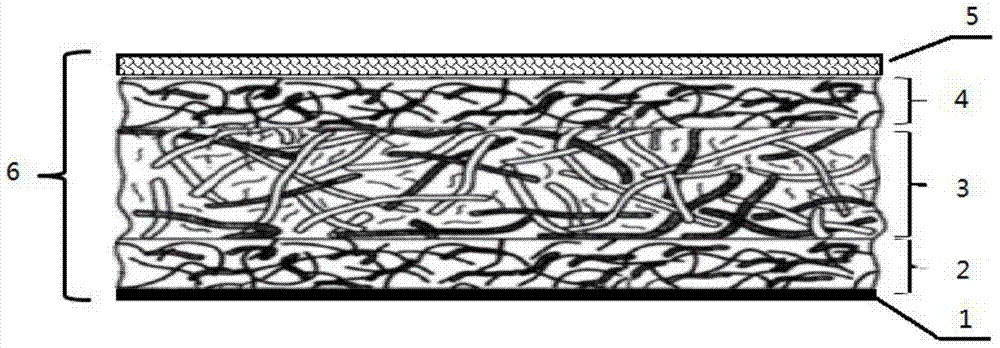

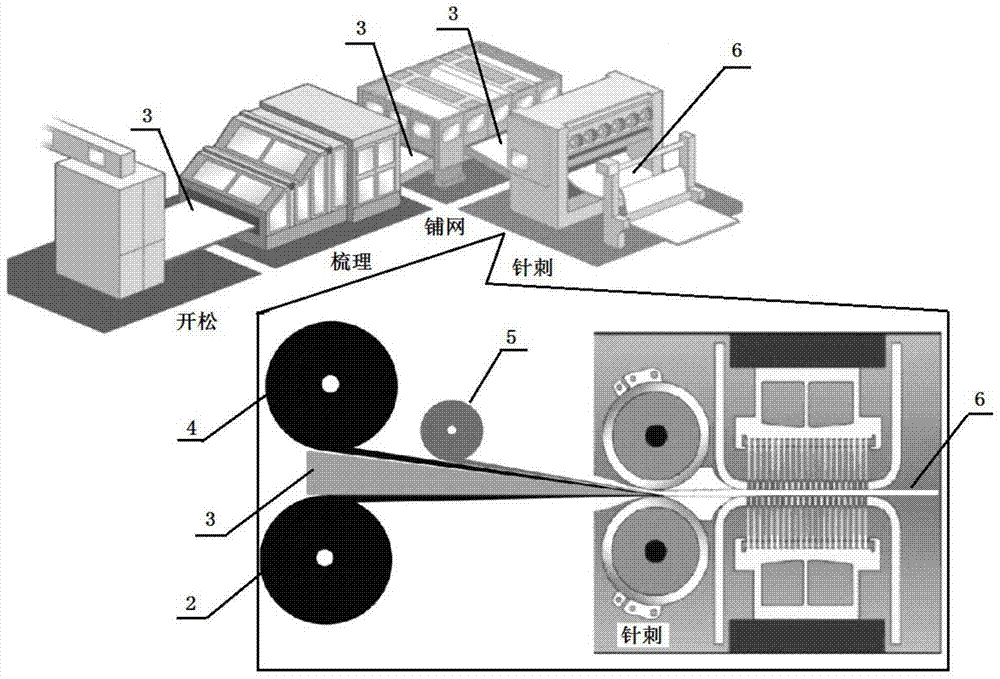

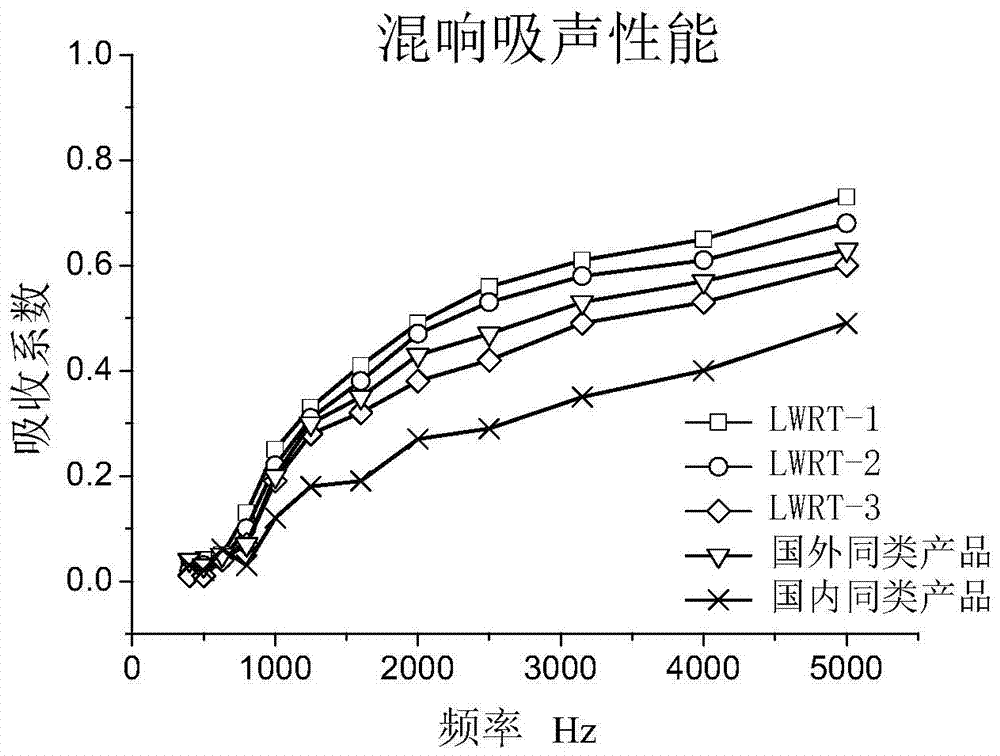

[0034] figure 1 It is a schematic structural view of the long-fiber reinforced lightweight thermoplastic composite sheet used to prepare the full-length underbody protection plate of a passenger car according to the present invention. From bottom to top, it is an anti-seepage and scratch-resistant layer 1, a toughened impact-resistant layer 2, and a rigid skeleton Layer 3, sound-absorbing and noise-reducing layer 4 and hydrophobic and oil-repellent layer 5, wherein the toughened and impact-resistant layer 2 and the sound-absorbing and noise-reducing layer 4 use thermoplastic polypropylene fiber (fiber length 60mm / denier 7D) as the bonding matrix, polyester fiber ( Fiber length 60mm / fineness 1.5D / cross-section shape) is a composite fiber mat made by uniformly mixing reinforcing materials in a ratio of 35:65, and the surface density is 300g / m 2 The rigid skeleton layer 3 is based on thermoplastic polypropylene fiber (fiber length 100mm / denier 9D) as a bonding matrix, and glass f...

Embodiment 2

[0045] A long-fiber-reinforced lightweight thermoplastic composite sheet used to prepare a full-length underbody guard for a passenger car consists of an anti-seepage and scratch-resistant layer 1, a toughened impact-resistant layer 2, a rigid skeleton layer 3, and a sound-absorbing and reducing layer from bottom to top. The noise layer 4 and the hydrophobic and oil-repellent layer 5, wherein the toughened and impact-resistant layer 2 and the sound-absorbing and noise-reducing layer 4 use thermoplastic polypropylene fibers (fiber length 60mm / denier 7D) as bonding matrix, and glass fibers (fiber length 100mm / diameter 30μm) is a composite fiber mat prepared by uniformly mixing reinforcing materials in a ratio of 60:40, 70:30 or 80:20, and the surface density is 300g / m2 ; Rigid skeleton layer 3 is made of thermoplastic polypropylene fiber (fiber length 100mm / denier 9D) as a bonding matrix, glass fiber (fiber length 150mm / diameter 50μm) as a reinforcing material uniformly mixed in a...

Embodiment 3

[0055] A long-fiber-reinforced lightweight thermoplastic composite sheet used to prepare a full-length underbody guard for a passenger car consists of an anti-seepage and scratch-resistant layer 1, a toughened impact-resistant layer 2, a rigid skeleton layer 3, and a sound-absorbing and reducing layer from bottom to top. The noise layer 4 and the hydrophobic and oil-repellent layer 5, wherein the toughened and impact-resistant layer 2 and the sound-absorbing and noise-reducing layer 4 use thermoplastic polypropylene fibers (fiber length 60mm / denier 7D) as bonding matrix, polyester fibers (fiber length 60mm / denier 7D) 1.5D / cross-sectional shape is triangular) is a composite fiber mat made by uniformly mixing reinforcing materials in a ratio of 35:65, and the surface density is 300g / m 2 ; Rigid skeleton layer 3 is made of thermoplastic polypropylene fiber (fiber length 100mm / denier 9D) as a bonding matrix, glass fiber (fiber length 100mm / diameter 50 μm) as a reinforcing material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com