Filament dividing device for slit drawing device

A technology of stretcher and filament separation, which is applied in the field of nonwoven fabrics, can solve the problems of high vertical and horizontal strength ratio of nonwoven fabrics, affect product quality, and uneven web laying, so as to reduce the vertical and horizontal strength ratio and smooth horizontal movement , The effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

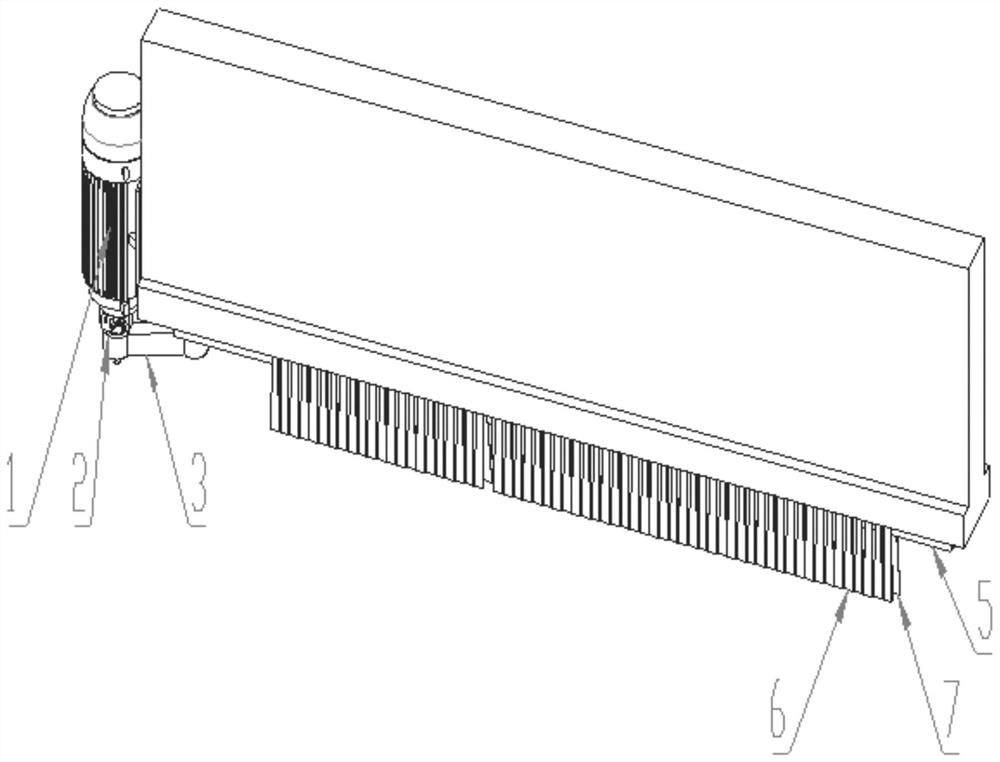

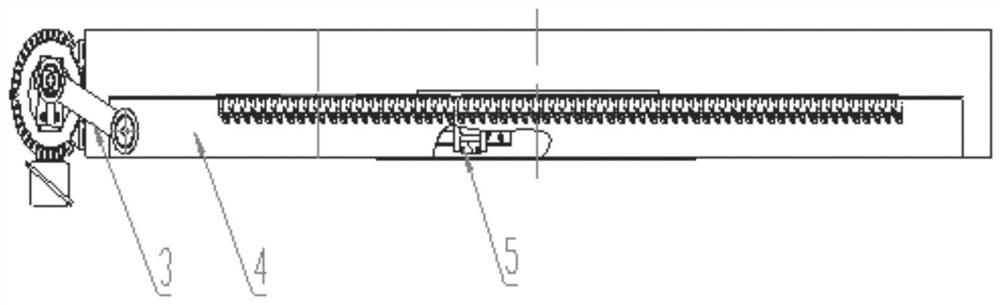

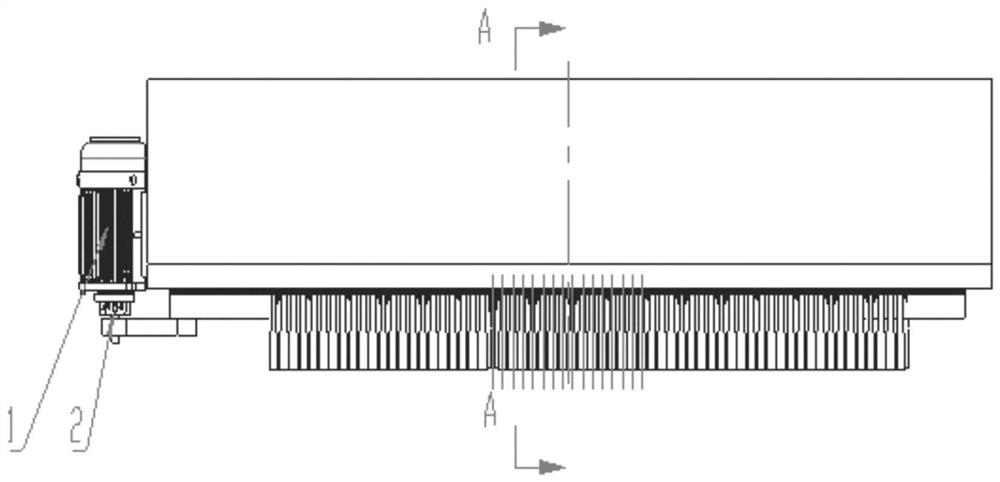

[0028] exist Figure 1 to Figure 7 In the schematic diagram of the present invention shown, the sub-filament matrix 4 is connected to the drafter through a linear bearing 5 fixed at the bottom of the drafter, and one side of the sub-filament matrix is passed through the transmission mechanism 3 and the eccentric mechanism 2, frequency conversion The motor 1 is connected, and the frequency conversion motor is set on the drafting device, which drives the splitter body to move left and right. The traverse frequency is adjusted by frequency conversion, and the adjustment range is 200 times / min. The traverse amplitude is adjusted by the eccentric mechanism, and the adjustment range is 10mm. The length of the main body of the splitter is equal to the outlet of the wide slit positive pressure drafter. There are front and rear staggered slideways on the mother body of the wire splitter, and the angle between the slideway and the level of the mesh surface is 60° 0 to 100 0 , each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com