High-speed rail platform antiskid ground paving structure and paving method thereof

A platform and pavement technology, which is applied to the anti-slip floor pavement structure of high-speed railway platforms and its pavement field, can solve the problems of damage to anti-slip floor tiles, inconvenient removal of anti-slip floor tiles, and loss of workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

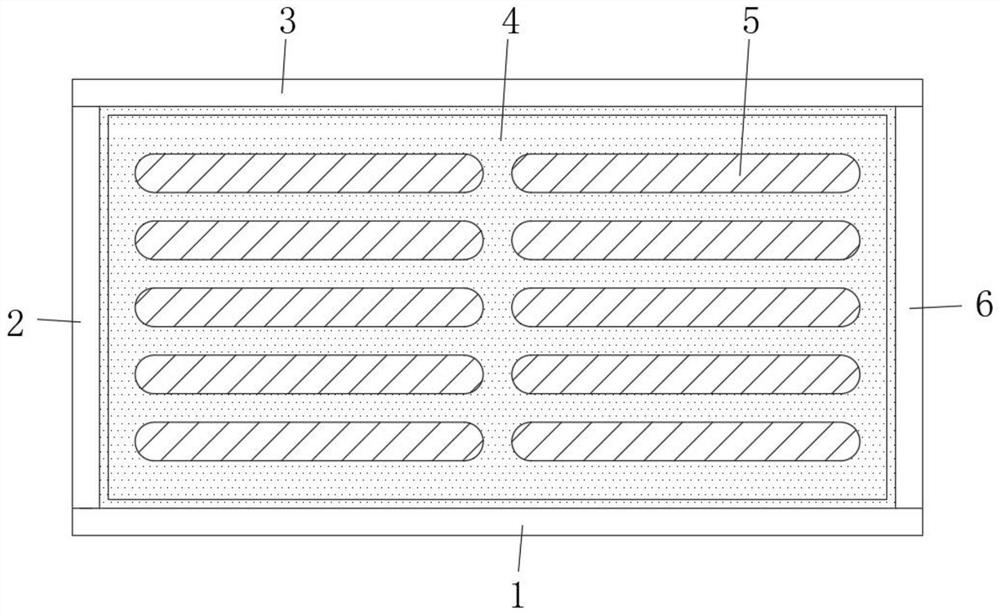

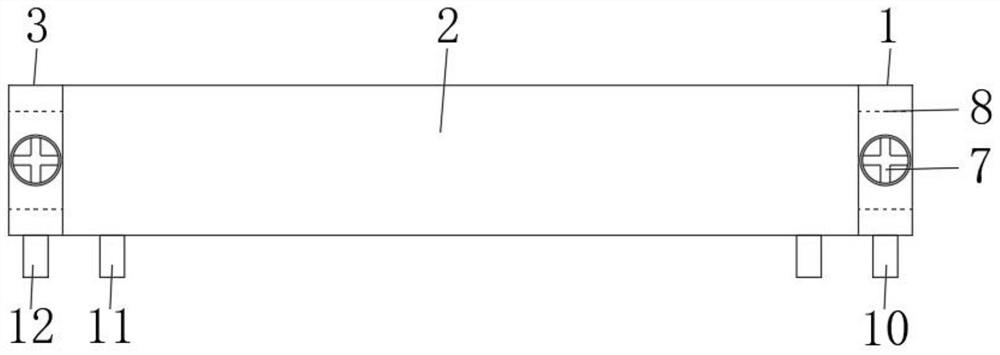

[0032] see Figure 1 to Figure 7 , an embodiment provided by the present invention: a high-speed rail platform anti-slip ground pavement structure, including a first partition 1, a second partition 2, a third partition 3, non-slip floor tiles 4, a fourth partition 6 and screws 7. Both sides of the first partition 1 and the third partition 3 are respectively provided with insertion holes 17 , and the insertion holes 17 run through the front and rear surfaces of the first partition 1 and the third partition 3 . The middle of the two ends of the first partition 1 and the third partition 3 are respectively provided with a first screw hole 18, and the middle of the two ends of the second partition 2 and the fourth partition 6 are respectively fixed with a plug-in block 8, and on the plug-in block 8 A second screw hole 19 is opened. The size of the first dividing plate 1, the second dividing plate 2, the third dividing plate 3 and the fourth dividing plate 6 can be selected accordi...

Embodiment 2

[0035] see Figure 4, an embodiment provided by the present invention: a high-speed rail platform anti-slip ground pavement structure, the first flat plate 13 is fixed on the bottom of the back of the first partition 1, and the bottom of the side of the second partition 2 opposite to the third partition 3 A second flat plate 14 is fixed, a third flat plate 15 is fixed at the bottom of the side of the third partition 3 opposite to the second partition 2 , and a fourth flat 16 is fixed at the bottom of the front of the fourth partition 6 . The bottom end surfaces of the first dividing plate 1, the second dividing plate 2, the third dividing plate 3 and the fourth dividing plate 6 are respectively connected with the bottom end surfaces of the first flat plate 13, the second flat plate 14, the third flat plate 15 and the fourth flat plate 16. Evenly, the first flat plate 13, the second flat plate 14, the third flat plate 15 and the fourth flat plate 16 are spliced end to end in ...

Embodiment 3

[0037] see figure 2 , image 3 , Figure 5 , Figure 6 and Figure 7 , an embodiment provided by the present invention: a high-speed rail platform non-slip ground pavement structure, the first nail post 10 is respectively fixed on both sides of the bottom end surface of the first partition 1, and the two sides of the bottom end surface of the second partition 2 are respectively fixed with The second nail column 11, the third nail column 12 is respectively fixed on both sides of the bottom end surface of the third partition 3, and the fourth nail column 9 is respectively fixed on both sides of the bottom end surface of the fourth partition plate 6. The frame composed of the first partition 1, the second partition 2, the third partition 3 and the fourth partition 6 is embedded in the uncured cement, the first nail post 10, the second nail post 11 and the third nail post 12 and the fourth nail post 9 nailed into the uncured cement, after the cement is solidified, the first n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com