Assembly type building construction fence convenient to mount and dismount

A building construction and prefabricated technology, applied in the direction of building, building type, building structure, etc., can solve the problems of brick masonry, such as self-heavy, difficult to achieve bending, waste of resources, etc., to achieve simple and convenient installation and disassembly, stability and reliability. The effect of strong applicability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

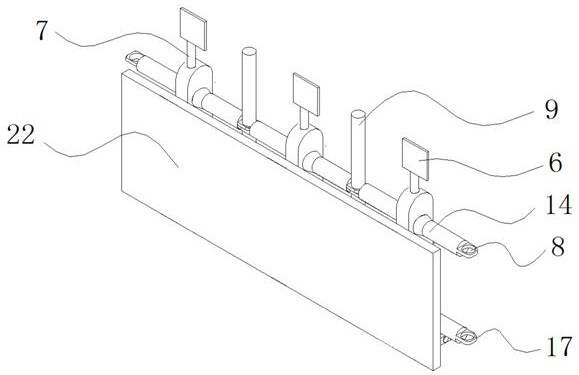

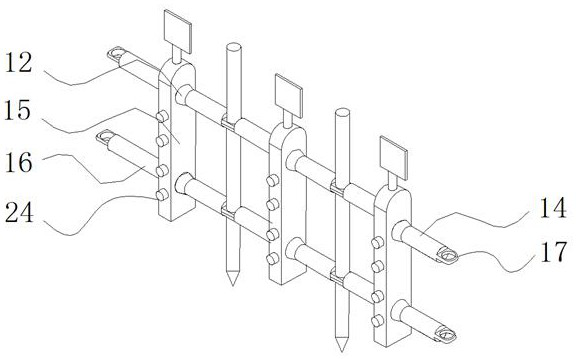

[0029] refer to Figure 1-5, a prefabricated building construction enclosure that is easy to install and disassemble, including a support plate 15, the support plate 15 is the main support part of the device, the support plates 15 are evenly arranged and the number is set to an odd number greater than 1, a complete device There is a support plate 15 in the middle position and several support plates 15 at both sides that are symmetrical to each other, and the support plates 15 at the two sides are symmetrically distributed along the support plate 15 in the middle position, so that the angle and height of the construction enclosure can be realized. The change of length...

no. 2 example

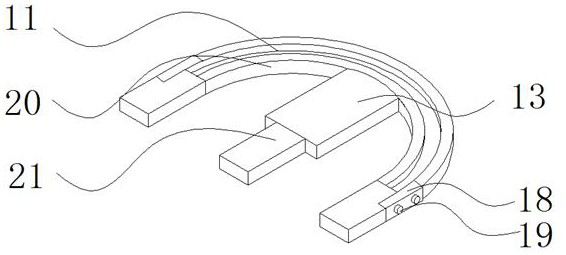

[0035] Based on a prefabricated building construction enclosure that is easy to install and disassemble based on the first embodiment, the rotation angles of the support plates 15 at the two sides cannot be precisely controlled during operation, resulting in the elastic protective barriers 22 at the two sides. The degree of bending is different, resulting in an irregular shape of the elastic protective barrier plate 22, which increases the difficulty of assembly. In order to solve this problem, a combination of Figure 5 , a prefabricated building construction enclosure that is easy to install and disassemble can be changed to a fixed connection between the bottom of the support plate 15 and the support base plate 21, the bottom of the support base plate 21 is fixedly connected with the arc-shaped anti-skewing base plate 20, and one side of the electric control telescopic rod 24 is connected to the The elastic protective barrier plate 22 is hinged, and when the electric control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com