Water pump bearing

A water pump bearing and bearing technology, which is applied in the field of water pump bearings, can solve the problems of shortening the practical life of the bearing, large pressure difference of the bearing, and large bearing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

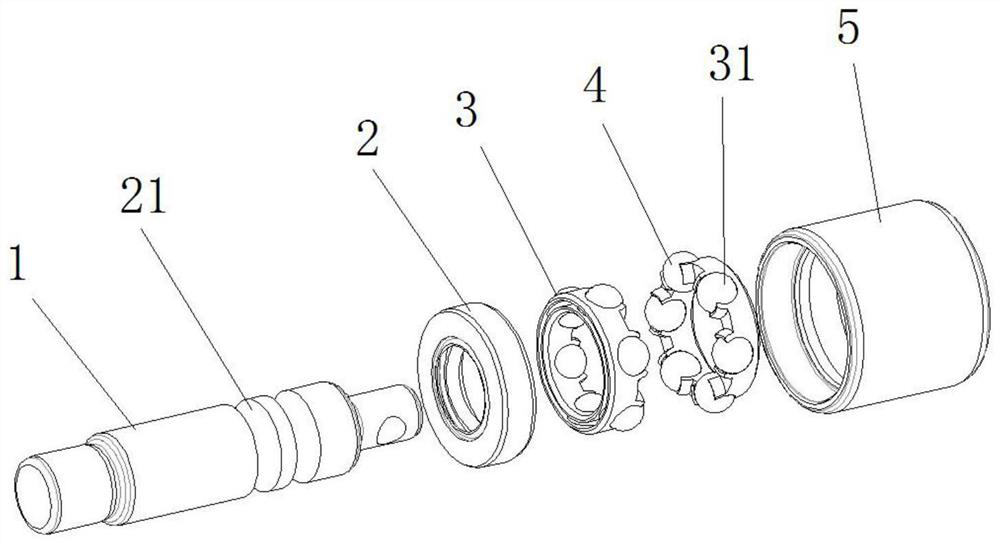

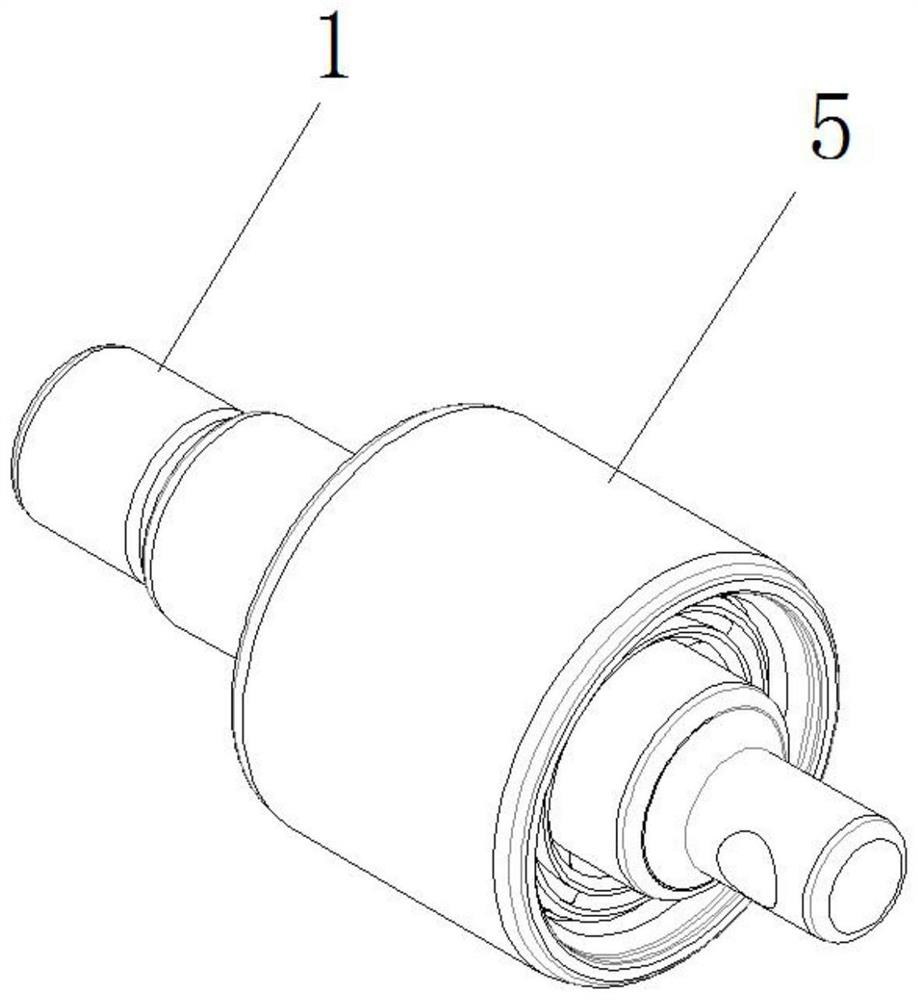

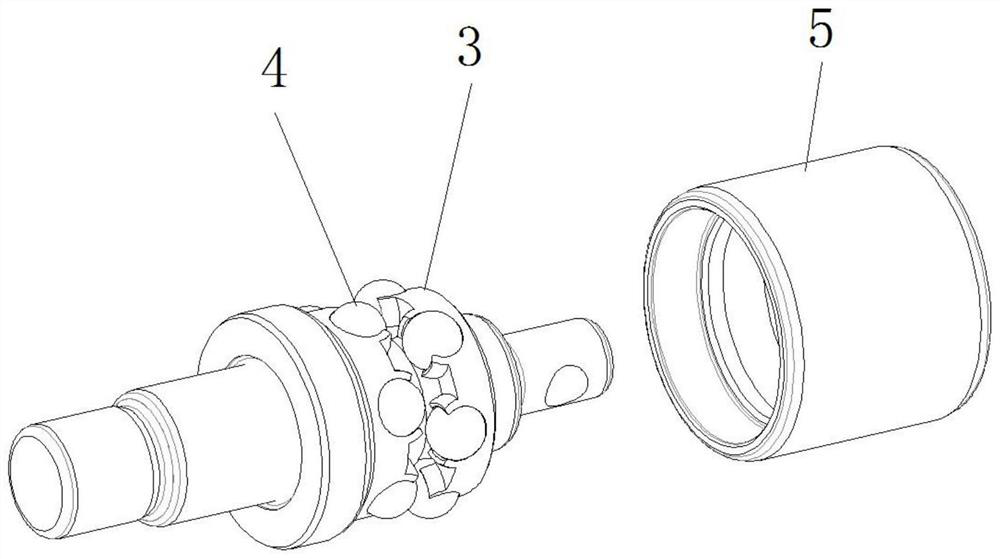

[0028] Depend on Figure 1 to Figure 8 It can be seen that the present invention discloses a water pump bearing, including a bearing mandrel 1, the outer surface of the bearing mandrel 1 is covered with a bearing ring 2, and the inside of the bearing ring 2 is provided with a ring raceway 21 , the outer surface of the bearing ring 2 is provided with a steel ball cage 3, the steel ball body 4 is placed on the inner surface of the steel ball placement groove 31 in the steel ball cage 3, and the steel ball body 4 is filled with In the bearing mandrel 1 and the ring raceway 21 provided inside the bearing ring 2, the outer surface of the steel ball cage 3 is covered with a bearing housing 5, and the bearing housing 5 With the clearance fit of the steel ball cage 3, the above scheme can effectively reduce the internal complexity of the bearing in the cooling system of the motorcycle engine, and has the effects of transmitting kinetic energy, running smoothly, and having a small volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com