Device and method for enhancing condensation heat exchange by utilizing ionic wind

A technology of condensation heat exchange and ion wind, applied in indirect heat exchangers, cooling/ventilation/heating renovation, lighting and heating equipment, etc., can solve the problems of complex production process, poor stability, poor durability, etc. Small loop current, the effect of overcoming instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

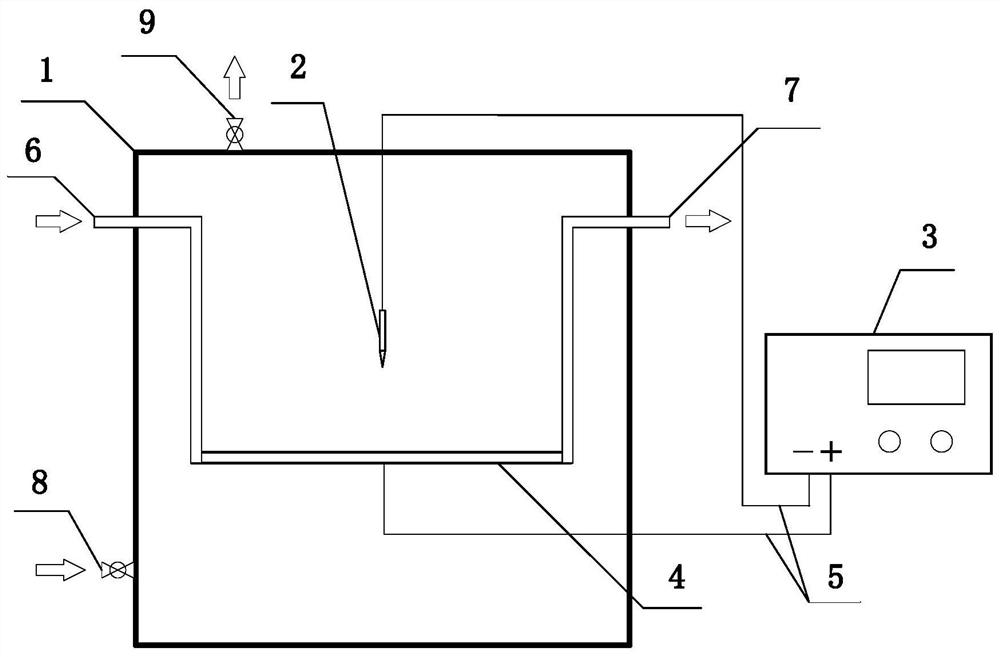

[0026]Such asfigure 1As shown, a device that utilizes ion wind strengthens condensed heat transfer, the main structure includes a vacuum coagulating cavity body 1, provided in the needle tip electrode 2 in the vacuum coagulating cavity 1, a horizontal metal tube 4 vertically disposed with the needle tip electrode 2, connection The water pipe 6 and the water pipe 7 on both ends of the horizontal metal pipe 4, respectively connect the needle tip electrode 2 and the negative pressure high voltage power source 3 of the horizontal metal pipe 4, and the intake valve 8 and the air valve 9 of the vacuum condensed cavity 1, the The needle tip electrode 2 is connected to the negative electrode of the negative pressure high voltage power source 3, and the horizontal metal pipe 4 is connected to the positive electrode of the negative pressure high voltage power source 3, and the tip of the needle electrode 2 points to the horizontal metal tube 4. The vacuum coagulating cavity 1 is a square stru...

Embodiment 2

[0031]A method of using ion-wind-intensified condensation heat transfer, the flow rate is 0.5 l / min, the temperature is 20 ° C (temperature range is 10 to 60 ° C; the flow range is 0.1 L / min ~ 5L / min, the present embodiment is preferably 0.5L. / min, 20 ° C) circulating cooled water flows from the intake pipe 6 of the vacuum condensed cavity 1, flowing out from the water pipe 7; temperature is 110 ° C, the pressure is 0.14 MPa (temperature range 90 ° C ~ 150 ° C; pressure range 0.07 MPA ~ 0.5 MPa, the aerosolic temperature of the present embodiment is 110 ° C, the pressure is 0.14 MPa), from the intake valve 8 of the vacuum coagulating cavity body 1, the air condensed cavity 1 of the air-condensed cavity 1 is only used The remaining gas release after the work. The gaseous working pressure is 0.01 MPa, the temperature is 46 ° C (temperature range is from 30 ° C to 80 ° C; the pressure range is 0.004 MPa ~ 0.05 MPa, the present embodiment is preferably 0.01 MPa, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com