Method and system for calibrating laser swinger

A laser leveling instrument, laser technology, applied in the field of intelligent surveying and mapping, can solve problems such as unsuitable laser leveling instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

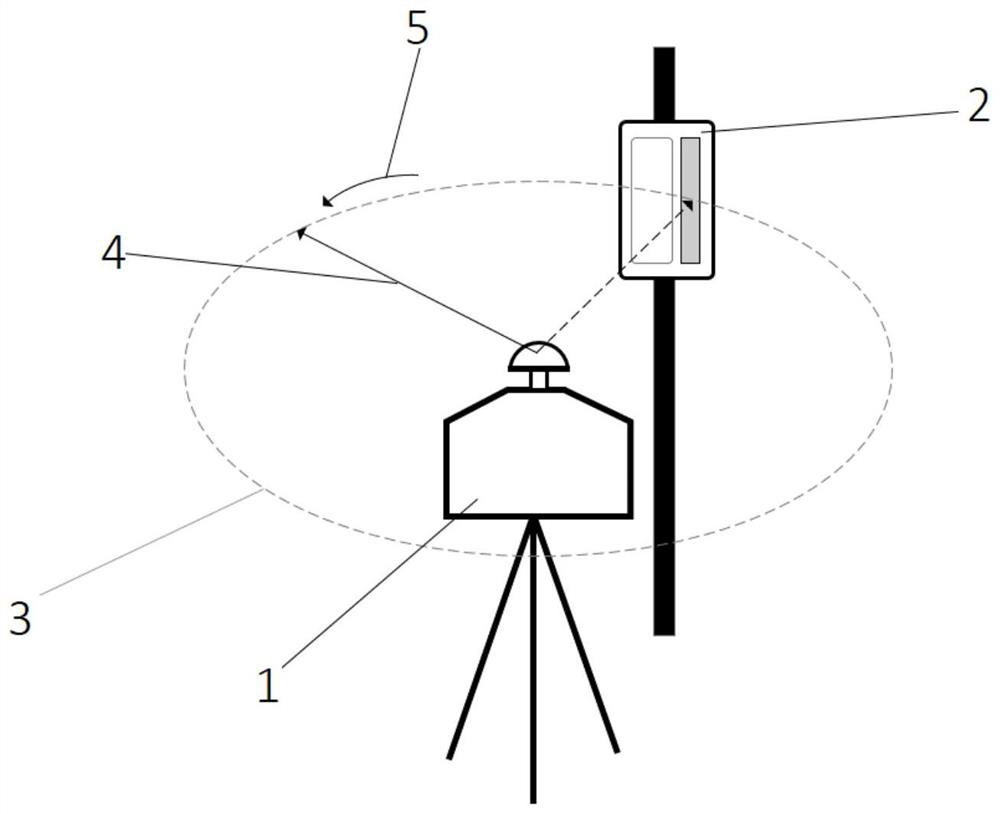

[0068] Such as figure 1 As shown, a laser tracking system is disclosed, which includes a laser leveling device 1 and a detector 2 spaced apart from the laser leveling device 1 on the same horizontal plane. Before calibrating the laser leveling instrument 1 , it is necessary to realize the tracking of the laser leveling instrument 1 to the detector 2 , so that the detected position of the laser leveling instrument 1 can be determined.

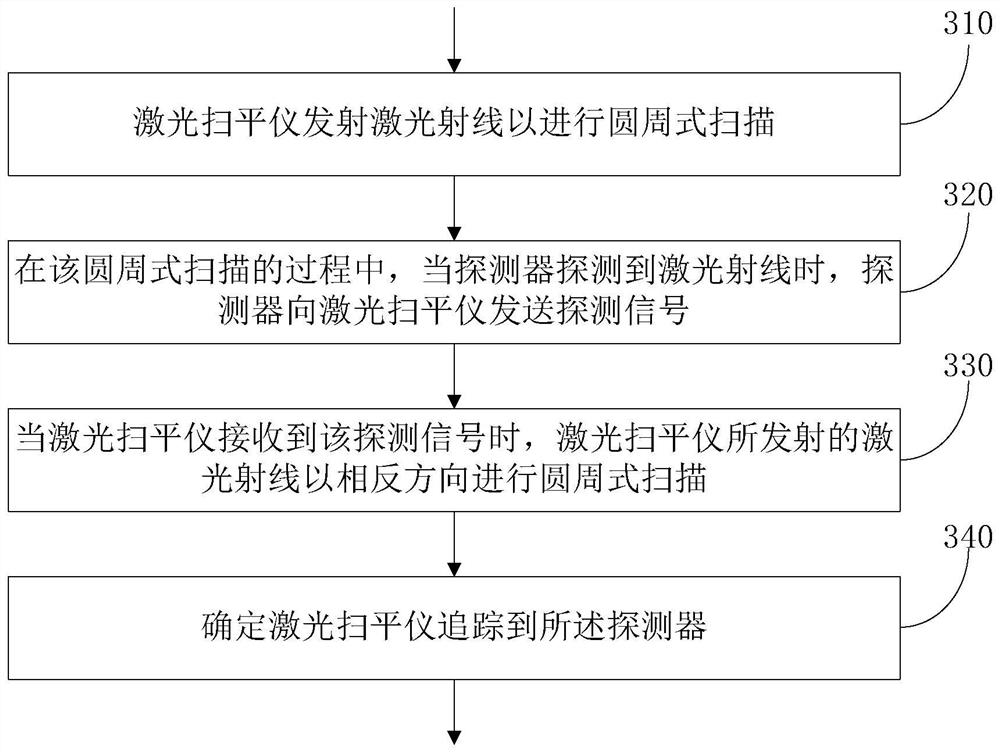

[0069] In this embodiment, the laser leveling device 1 is at least used to emit laser rays for circular scanning, and the detector 2 is at least used to receive the laser rays. Further, the detector 2 includes a first wireless communication module, and the laser leveling instrument 1 includes a second wireless communication module; wherein, when the detector 2 detects a laser ray, the first wireless communication module sends a second wireless communication module to the laser leveling instrument 1. The communication module sends a probe signal...

Embodiment 2

[0087] Such as figure 1 As shown, a system for calibrating a laser scanner is disclosed, which includes: a laser scanner 1 for generating a laser beam for calibration in a calibration state and a detector 2 for acquiring the laser beam for calibration. Wherein, the laser leveling instrument 1 and the detector 2 are arranged on the same horizontal plane, so that the laser leveling instrument 1 is in the detected position; and the laser leveling instrument 1 is set in a dot pattern or a sector pattern.

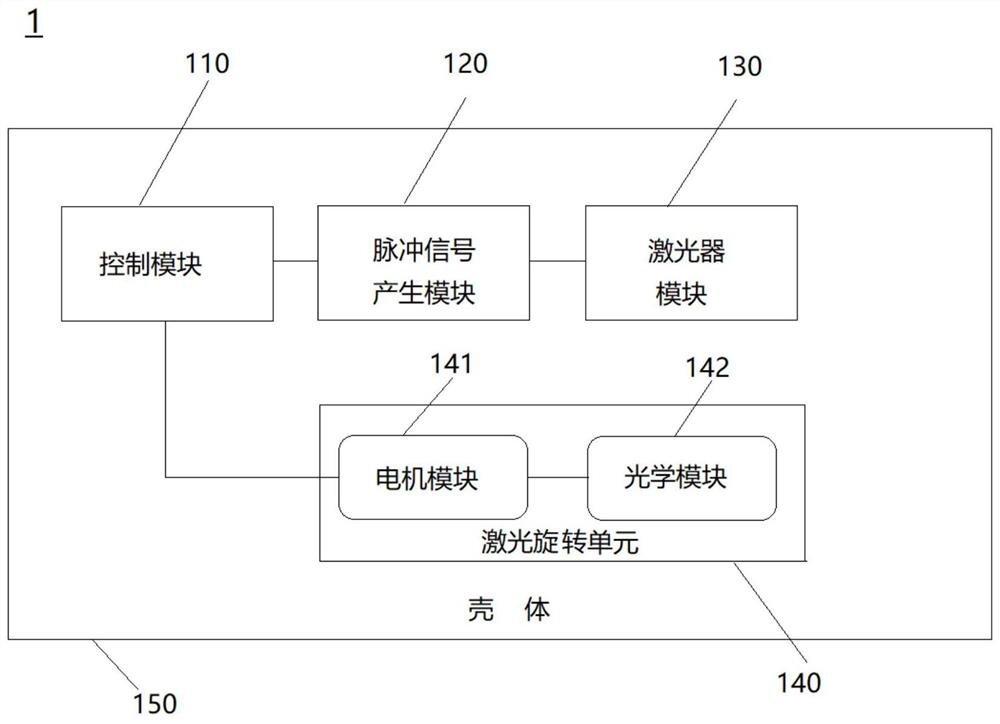

[0088] In addition, if figure 2 The shown laser leveling instrument 1 includes: a housing 150 , a control module 110 , a pulse signal generation module 120 , a laser module 130 and a laser rotation unit 140 . Wherein, the control module 110 is arranged in the casing 150, the pulse signal generating module 120 is arranged in the casing 150 and is electrically coupled with the control module 110, so as to be controlled by the control module 110 to generate a pulse signal; the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com