Visual carton production and operation system

An operation system and cardboard box technology, applied in the field of carton manufacturing, can solve problems affecting the efficiency of use, inconvenient production planning, and inability to grasp product dynamics well, and achieve the effect of improving the interaction effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

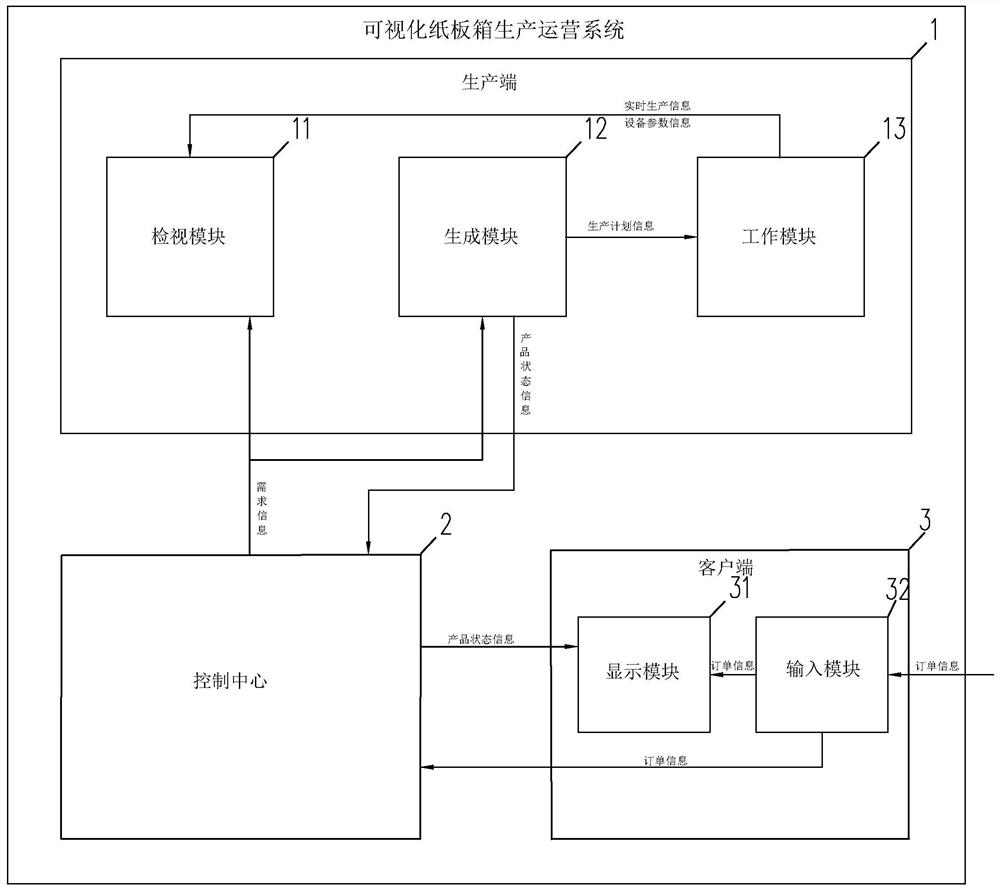

[0019] The embodiment of the visualized carton production and operation system of the present invention is as follows figure 1 Shown: includes client 3, production end 1 and control center 2, described client 3 and production end 1 are connected with control center 2 respectively, and described client 3 includes input module 32 and display module 31, and described production Terminal 1 includes a working module 13, a viewing module 11 and a generating module 12;

[0020] The input module 32 is used to generate order information, the order information includes order number, product specification and product quantity, and is used to send the order information to the control center 2 and the display module 31;

[0021] The display module 31 is used to receive and display order information and product status information;

[0022] The control center 2 is used to receive status information and order information, and is used to summarize the order information according to product sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com