Power transmission wire sag adjusting device

A technology for adjusting devices and transmission wires, applied in the direction of adjusting/maintaining mechanical tension, overhead lines/cable equipment, etc., which can solve the problems of inability to guarantee sag accuracy, time-consuming and labor-intensive sag, and easily guaranteed sag design values. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

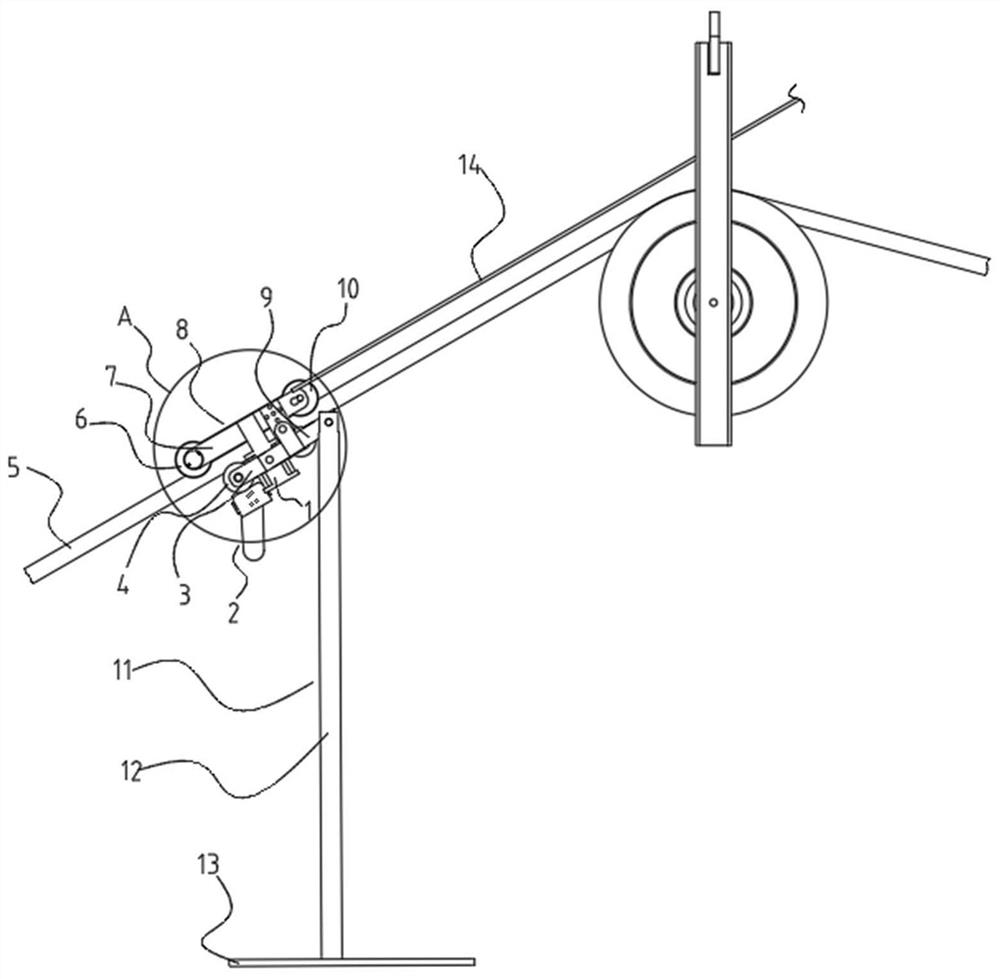

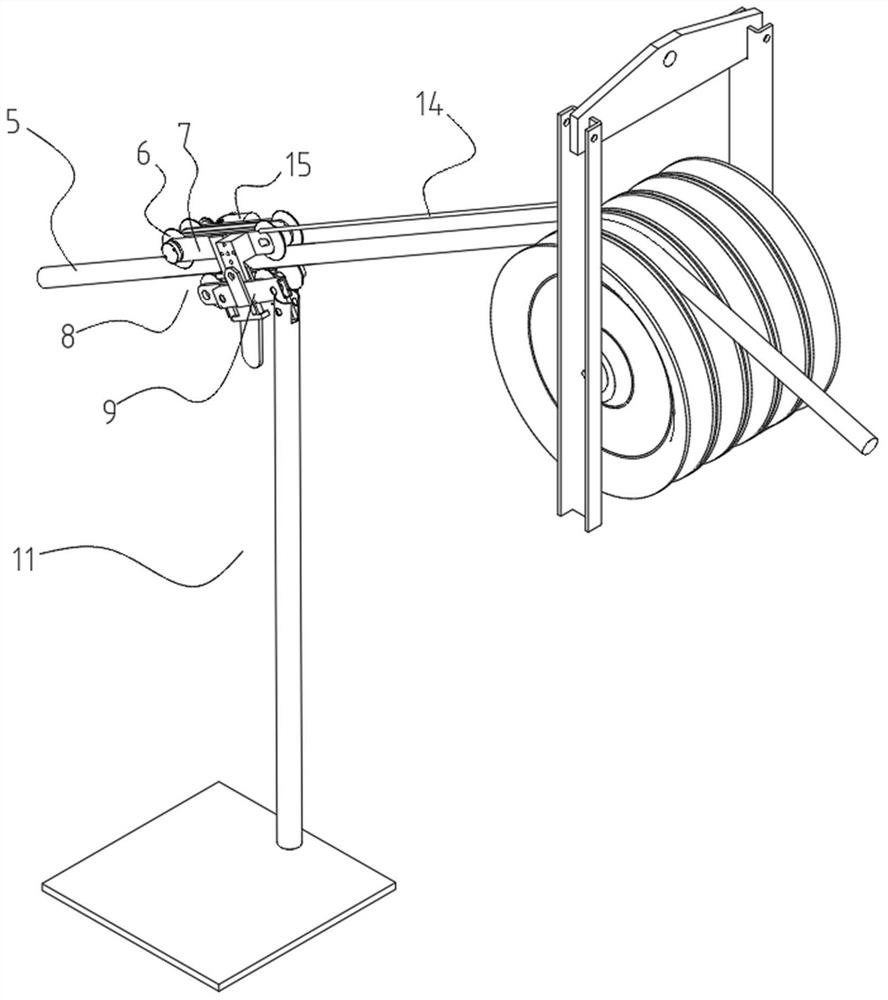

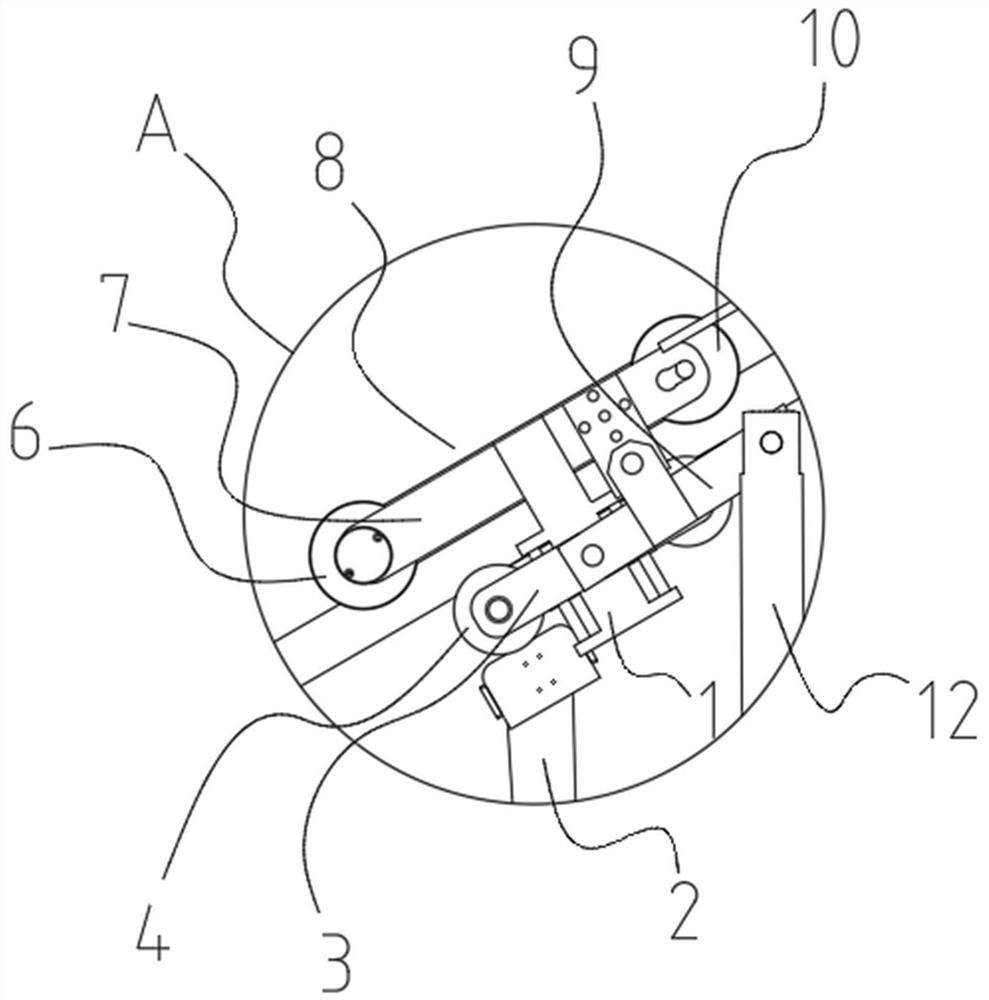

[0023] Embodiments of the transmission wire sag adjustment device in the present invention are as follows: Figure 1~7 Shown: includes wire feeder 8, wire feeder includes wire feeder bracket, wire feeder bracket includes upper side bracket 7 and lower side bracket 3, upper side bracket 7 is provided with upper side rolling body, lower side bracket 3 A lower rolling body is provided, and the upper rolling body includes an upper front rotating wheel 6 and an upper rear rotating wheel 10 that are rotatably matched with the upper bracket, and the upper rolling body also includes a front rotating wheel around the upper side and an upper rear rotating wheel The upper transmission belt on the outer circumference of the wheel is matched with the upper front rotating wheel and the lower rear rotating wheel, wherein the wheel shaft of the upper front rotating wheel 6 is connected with a power input shaft, and the power input shaft constitutes the power input end of the upper rolling body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com