Connecting structure of GIS sleeve

A connection structure and bushing technology, applied in the direction of cable joints, electrical components, etc., can solve the problems of difficult standardization of assembly parts, different connection structures, and different installation positions, and achieve the effects of convenient installation, simplified structure, and improved standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

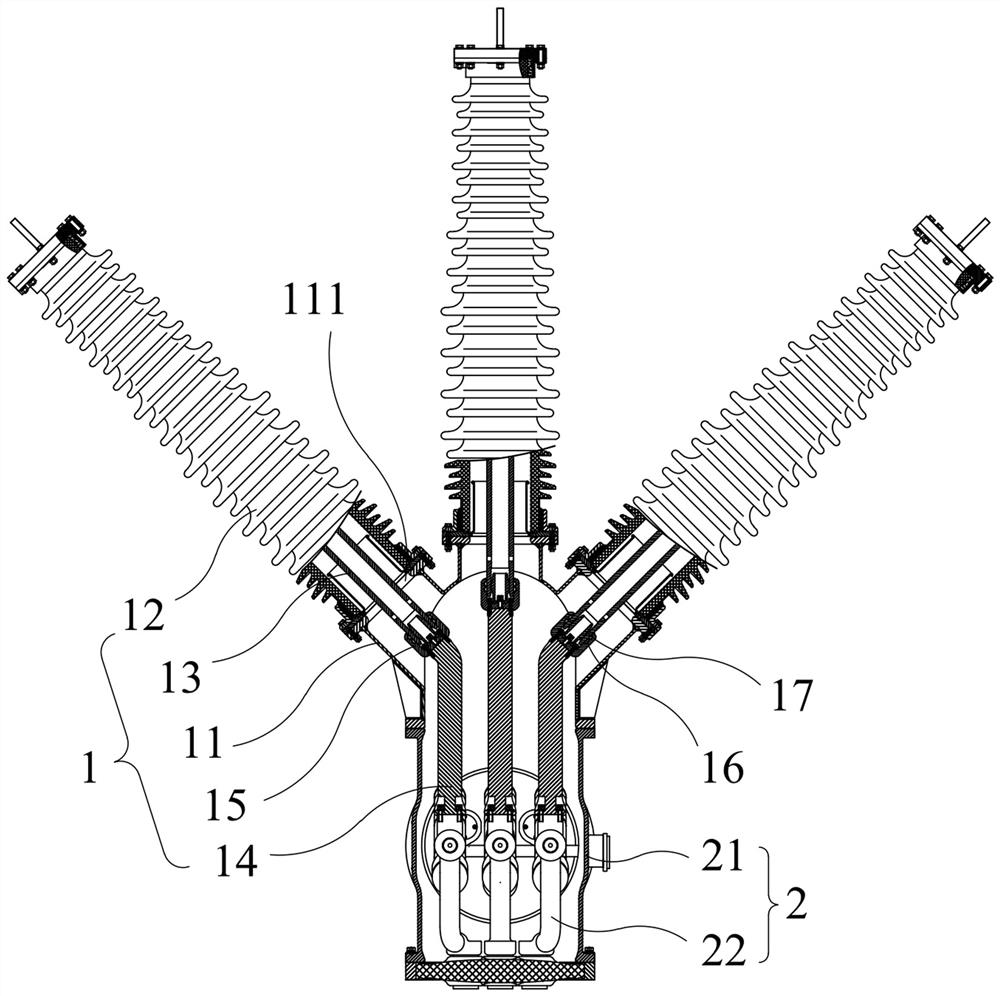

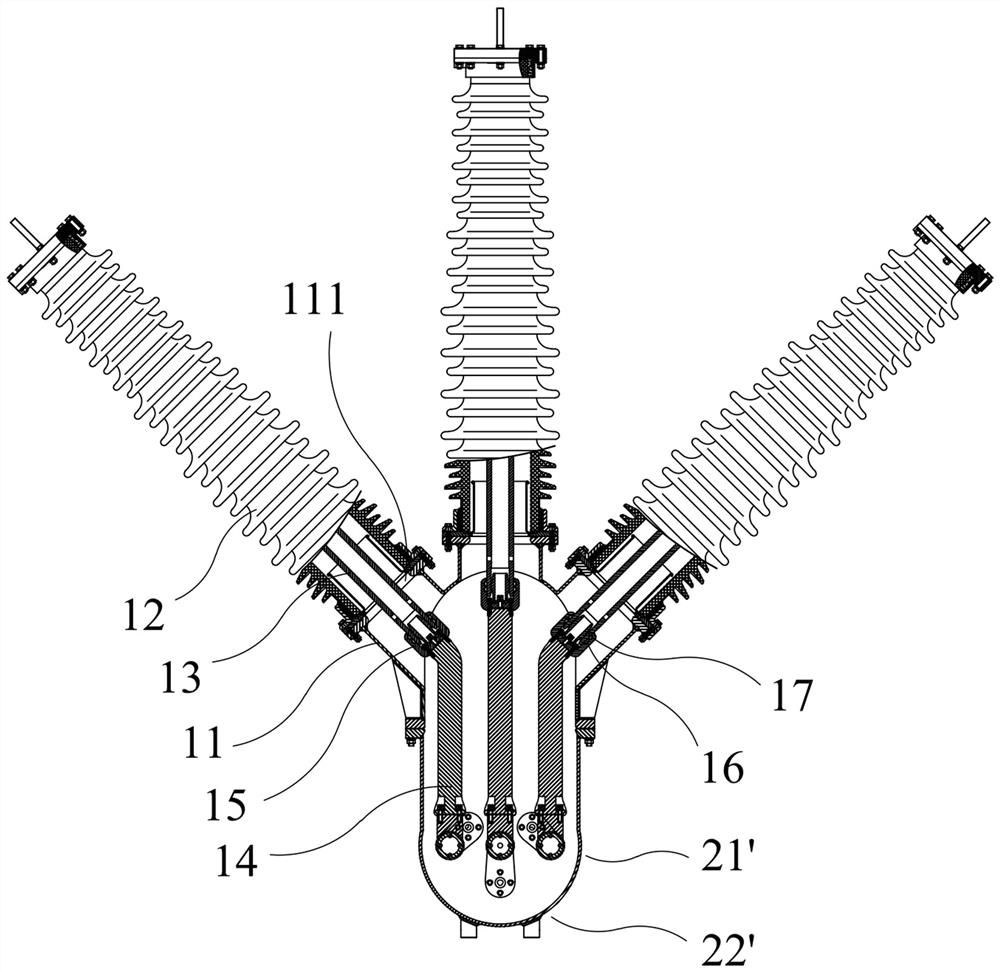

[0019] The invention relates to a connection structure of a GIS casing, which includes a casing module 1 and an assembly module 2 .

[0020] The bushing module 1 includes an outlet housing 11 and several sets of bushing assemblies. The bushing assembly includes a bushing 12, a conductive rod 13, an outgoing conductor 14, a conductive seat 15 and a spring contact finger 16; the bushing 12 is sealed and connected to the outlet housing. The upper end of 11; the conductive rod 13 is arranged inside the casing 12; the conductive seat 15 is connected to the upper end of the outgoing conductor 14, and is movably connected with the lower end of the conductive rod 13; the spring contact finger 16 is arranged between the conductive seat 15 and the conductive rod 13 ;

[0021] The assembly module 2 includes an assembly h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com