High boost multiple charge pump circuit for mems switch and manufacturing method thereof

A charge pump and circuit technology, which is applied in the direction of circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as circuit high-voltage breakdown, achieve high withstand voltage, low power consumption, and reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

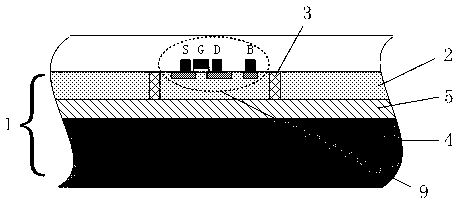

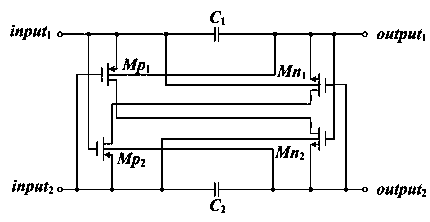

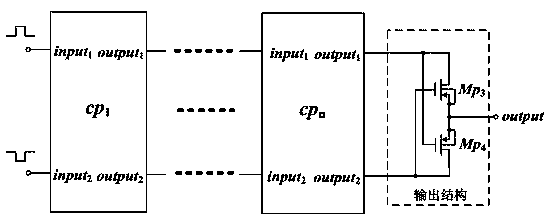

[0038] High boost multiple charge pump circuit for MEMS switches: its structure includes: SOI wafer 1, top layer silicon 2, Trench structure 3, high-resistance carrier 4, silicon dioxide layer 5, layout of the first Trench structure 6, second Trench Layout 7 of the structure, layout 8 of the third Trench structure, MOS tube 9, and MOS tube capacitor; wherein, the SOI wafer 1 is divided into the top layer silicon 2, the silicon dioxide layer 5, the high resistance carrier 4, and the SOI wafer 1 from top to bottom. Trench structure 3 is performed on the top layer of silicon 2 of wafer 1 to realize the electrical isolation of each MOS transistor 9 substrate. MOS transistor 9 and MOS transistor capacitor interconnection form a charge pump sub-circuit, and several stages of charge pump sub-circuits and output stages are cascaded to form a the entire charge pump circuit.

[0039] The overall layout of the charge pump circuit adopts a symmetrical structure up and down, the layout 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com