Multipurpose cast ingot distribution device for aluminum ingot production

A dispensing device and ingot casting technology, which is applied in casting equipment, equipment for supplying molten metal, manufacturing tools, etc., can solve problems such as difficulty in meeting processing requirements, high requirements for aluminum ingot performance and matching processing, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

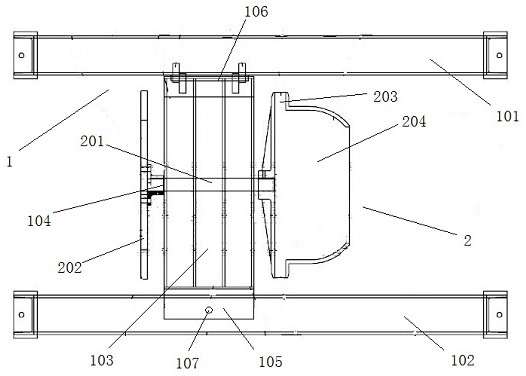

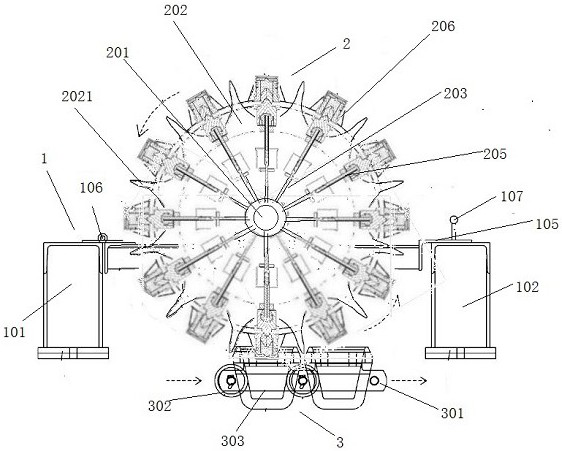

[0053] Start the mold part 3 to make it move horizontally or obliquely under the action of external power, and use the space between the parallel molds 303 to block the drive gear 2021, so that it drives the drive plate 202 to rotate, and the rotating shaft 201 rotates on the rotary bearing 104 at the same time. Drive the liquid distribution plate 203 to rotate, and the aluminum liquid in the liquid separation plate enters through the liquid storage chamber 204, and one end of the liquid storage chamber is open, and the aluminum liquid can be continuously filled into it.

[0054] When the liquid dispenser 205 moves to the top, the distance that the lower liquid dispensing rod 2054 is inserted into the upper liquid dispensing rod 2052 is the largest. The height of the liquid level of the aluminum liquid is such that when the liquid dispenser 205 moves downward to the point where the liquid dispenser tip 2057 is in full contact with the liquid dispenser head 2058 under the action...

Embodiment 2

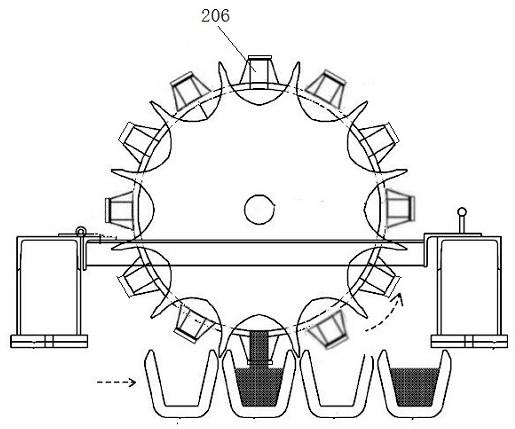

[0058] The other operation methods remain unchanged, by replacing the dispensing tip 2057 of different shapes, or replacing the dispensing bottom support 20583 of different thickness, so that the enclosed space surrounded by the dispensing tip 2057 and the dispensing head 2058 is different, and the corresponding different models are replaced. The mold 303 realizes simultaneous casting of aluminum alloy ingots of different shapes and or different weights in the same batch during the ingot casting operation, which ensures the distinction of subsequent processing and the requirements of different weights, and is more able to meet the requirements for the composition of different parts of the same equipment Complete consistency.

Embodiment 3

[0060] By replacing multiple different liquid-dispensing tips 2057 and / or liquid-dispensing heads 2058 and matching different molds 303 at the same time, a batch of aluminum alloy ingots with different weights and shapes can be cast at the same time, and the liquid-dispensing plate can be rotated for one rotation at most. The number of different aluminum alloy ingots that can be cast in the circle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com