Combined machining anti-static workbench

A mechanical processing and workbench technology, which is applied in workbenches, metal processing equipment, metal processing machinery parts, etc., can solve the problems of no workbench lifting adjustment, inconvenient storage of processed objects, etc., and achieves simple structure, convenient storage, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

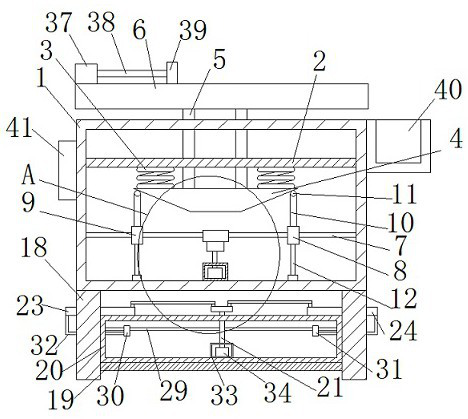

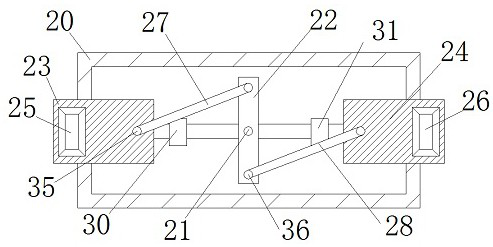

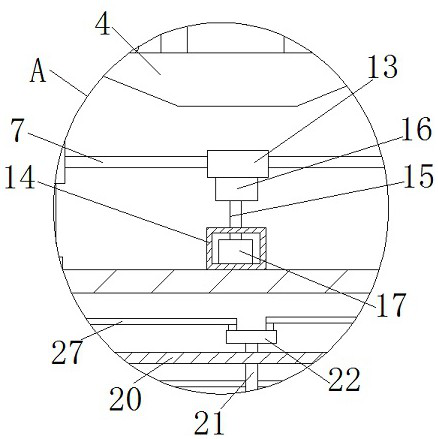

[0028] refer to Figure 1-5 , a combined anti-static workbench for mechanical processing, including an adjustment box 1, a support top plate 2 is fixedly installed in the adjustment box 1, two return springs 3 are fixedly connected to the bottom of the support top plate 2, and one end of the two return springs 3 is fixed The same inclined top plate 4 is connected, and two push rods 5 are fixedly installed on the inclined top plate 4. One end of the two push rods 5 extends through the support top plate 2 to the top of the adjustment box 1, and one end of the two push rods 5 is fixed. The same workbench body 6 is connected, and the adjustment box 1 is rotationally connected with a driving screw 7, the driving screw 7 is fixedly connected with a worm rod 13, and the driving screw 7 is threaded with a first threaded plate 8 and a second screw thread. Plate 9, the first threaded plate 8 and the second threaded plate 9 are all fixedly connected with a drag column 10, and one end of ...

Embodiment 2

[0039] refer to Figure 1-5 , a combined mechanical processing anti-static workbench, including an adjustment box 1, a support top plate 2 is welded and installed in the adjustment box 1, two return springs 3 are welded and connected to the bottom of the support top plate 2, and one end of the two return springs 3 is welded The same sloping top plate 4 is connected, and two push rods 5 are welded on the sloping top plate 4, and one end of the two push rods 5 extends through the support top plate 2 to the top of the adjustment box 1, and one end of the two push rods 5 is welded The same workbench body 6 is connected, and the adjustment box 1 is rotationally connected with a driving screw 7. The driving screw 7 is welded and connected with a worm rod 13, and the driving screw 7 is threaded with a first threaded plate 8 and a second screw thread. Plate 9, the first threaded plate 8 and the second threaded plate 9 are all welded with a drag column 10, and one end of the two drag c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com