Bearing sealing performance detection device

A detection device and bearing sealing technology, which is applied in mechanical bearing testing, liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the detection result error, troublesome operation, and poor stability performance and other problems, to achieve accurate detection results, improve practical performance, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

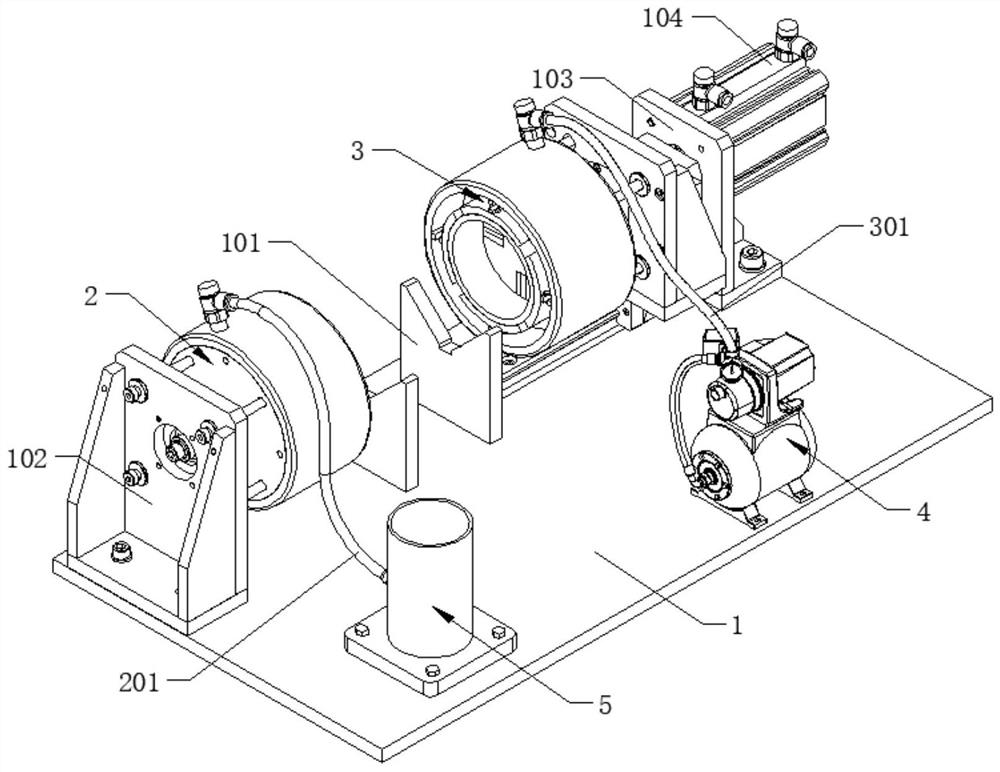

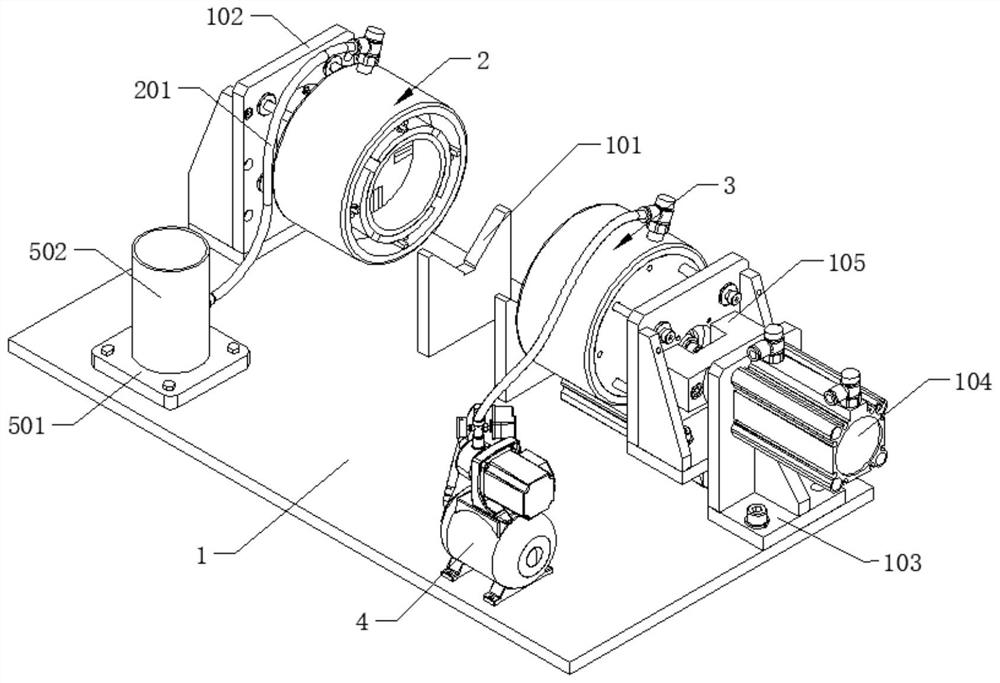

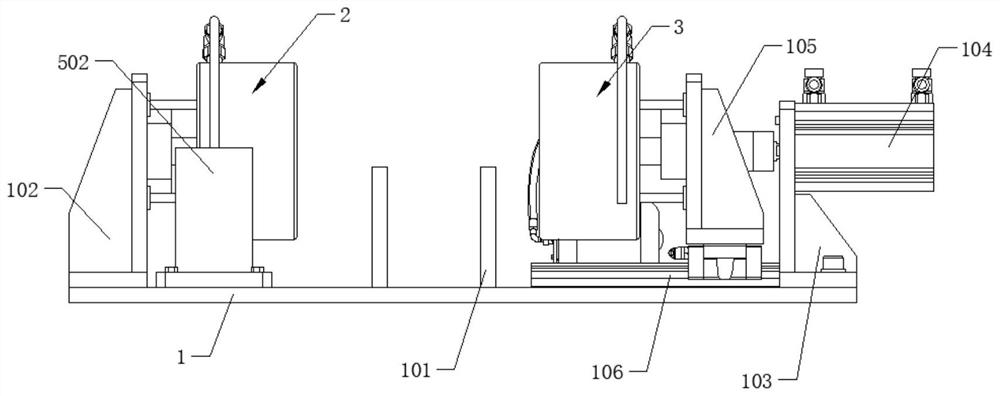

[0035] refer to Figure 1-4 , a bearing tightness detection device, including a bottom plate 1, a first fixed seat 102, a positioning block 101 and a second fixed seat 103 are connected to the top wall of the bottom plate 1 in sequence from left to right, and the first fixed seat 102 is fixedly connected to the bottom plate 1 on the top wall, the second fixed seat 103 is slidingly connected on the top wall of the bottom plate 1, the first fixed block assembly 2 is connected on the inner wall of the first fixed seat 102, and the cylinder 104 is connected on the outer wall of the second fixed seat 103, and the cylinder 104 The output end passes through the second fixed seat 103 and is connected with a connecting seat 105. The connecting seat 105 is slidably connected to the top wall of the bottom plate 1. The inner wall of the connecting seat 105 is connected with the second fixed blocking assembly 3, and the first fixed blocking assembly 2 Both the second fixed blocking assembl...

Embodiment 2

[0039] refer to Figure 1-8 , a bearing tightness detection device, which is basically the same as Embodiment 1, and further, a bearing tightness detection device, comprising a bottom plate 1, the top wall of the bottom plate 1 is sequentially connected with a first fixing seat 102 from left to right , the positioning block 101 and the second fixed seat 103, the first fixed seat 102 is fixedly connected on the top wall of the bottom plate 1, the second fixed seat 103 is slidably connected on the top wall of the bottom plate 1, and the inner wall of the first fixed seat 102 is connected with the first Fixed block assembly 2, cylinder 104 is connected on the outer wall of the second fixed seat 103, the output end of cylinder 104 passes through the second fixed seat 103 and is connected with connecting seat 105, connecting seat 105 is slidably connected on the top wall of bottom plate 1, connecting seat The inner wall of 105 is connected with a second fixed blocking assembly 3, t...

Embodiment 3

[0049] refer to Figure 1-4 , a bearing tightness detection device, which is basically the same as that of Embodiment 1, furthermore, the air leakage detection assembly 5 includes a fixed plate 501 and a barrel body 502, the fixed plate 501 is connected to the top wall of the bottom plate 1, and the barrel body 502 is connected to On the top wall of the fixing plate 501, the first connecting hose 201 is connected to the bottom outer wall of the bucket body 502, and the inside of the bucket body 502 is filled with liquid.

[0050] There are two sets of positioning blocks 101, and the two sets of positioning blocks 101 are V-shaped structures.

[0051] Through the air leakage detection assembly 5 provided, when there is an air leakage in the bearing to be detected, the gas entering the second fixed sealing assembly 3 through the air pump 4 will pass through the bearing, the first fixed sealing assembly 2 and the The first connecting hose 201 enters the inside of the barrel body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com