Submarine optical cable and manufacturing method and splicing method thereof

A technology for a submarine optical cable and a manufacturing method, which is applied in the directions of optics, light guides, optical components, etc., can solve the problems of small transmission capacity and small number of cores of submarine optical cables, and achieve the effect of increasing the number of cores and improving the transmission capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

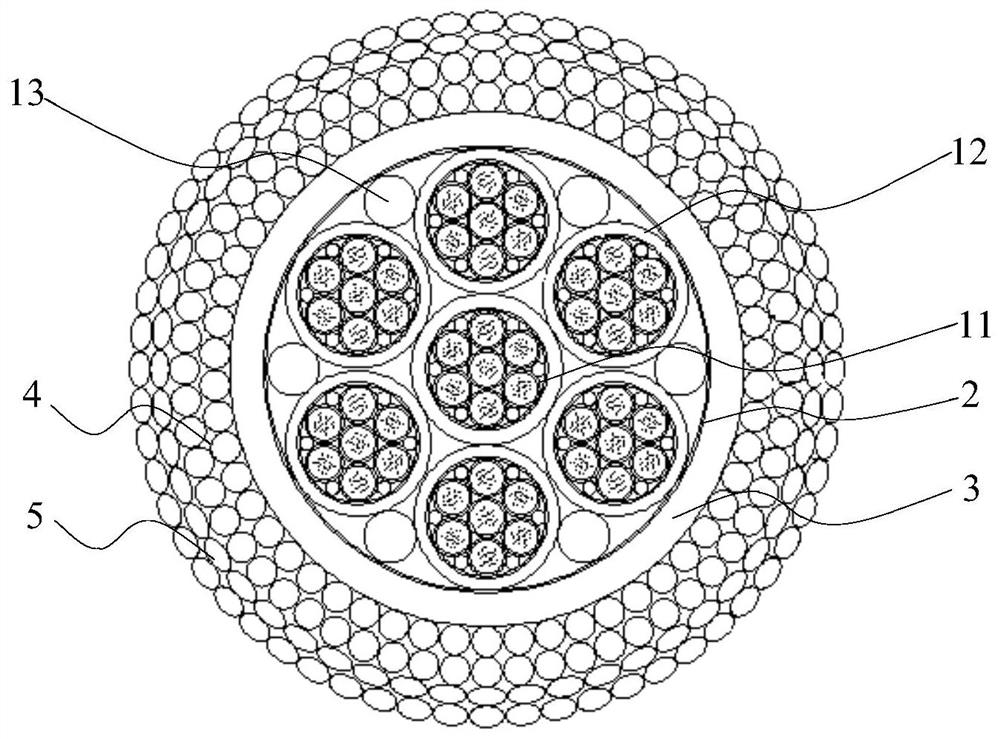

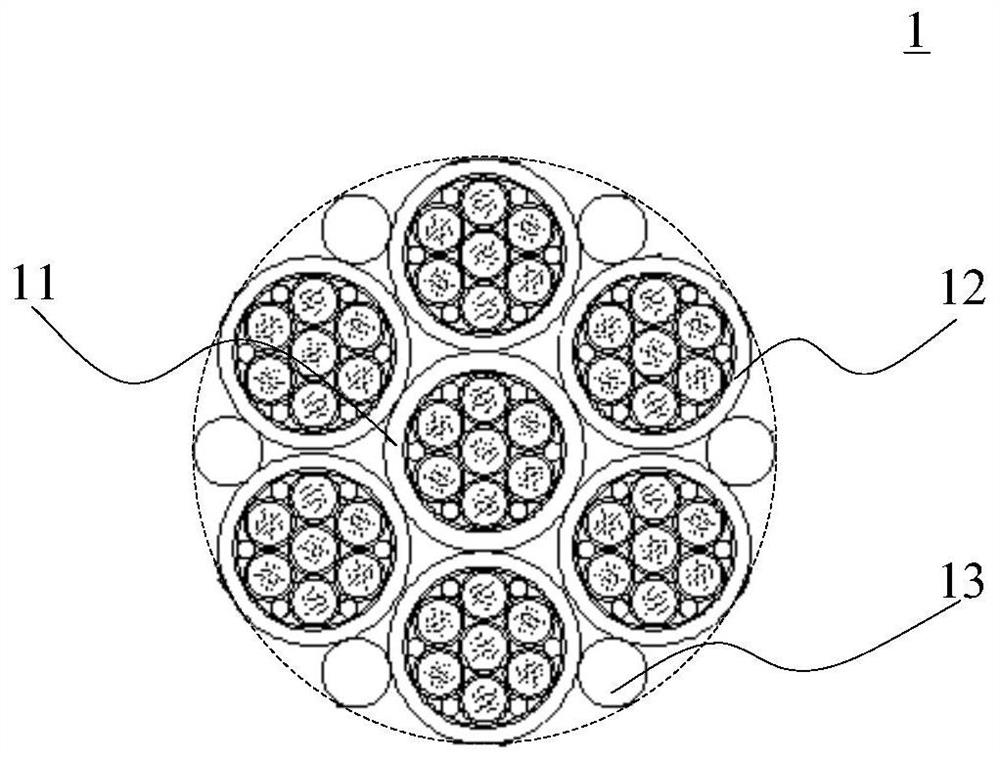

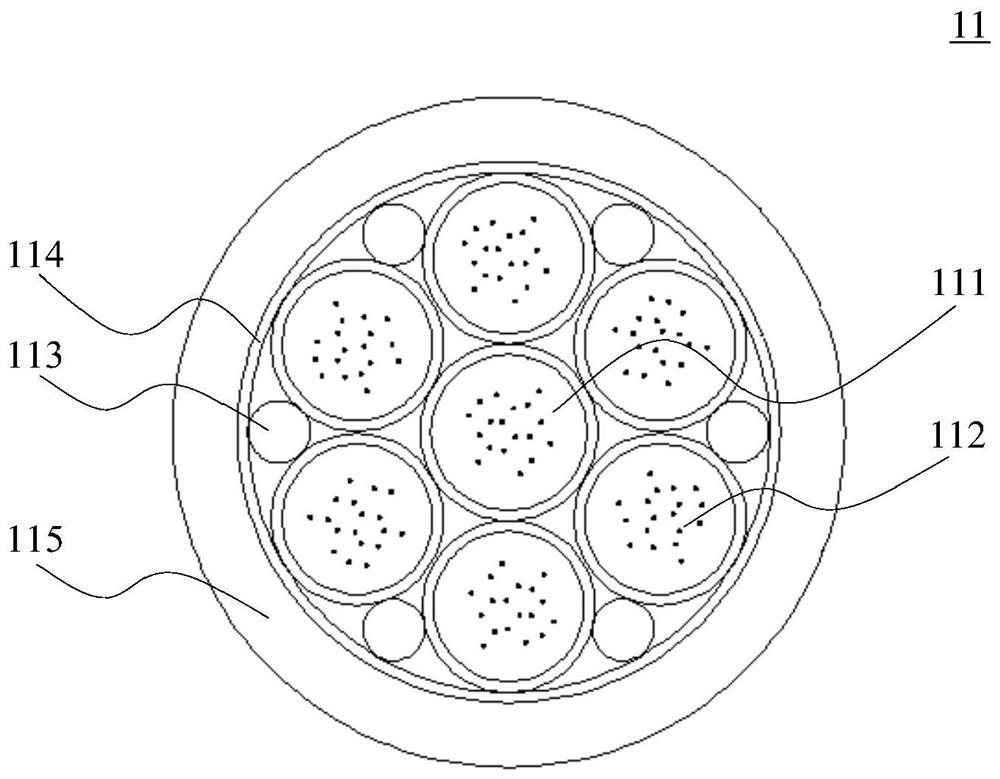

[0091] In the related art, a stranded submarine optical cable structure is usually used to increase the number of cores of the submarine optical cable. The layer-stranded submarine optical cable includes multiple optical fiber bundle tubes and a central strength member. Multiple optical fiber bundle tubes are stranded on the central core strength member in a twisted manner. By adjusting the number of optical fiber bundle tubes and the number of optical fibers in the fiber Combination, thereby increasing the number of cores of the submarine optical cable. However, the fiber bundle tubes of the stranded submarine cable generally do not exceed 6, and the number of optical fibers in each fiber bundle generally does not exceed 48, resulting in a small number of cores and a small transmission capacity of the stranded submarine cable.

[0092] In view of the above problems, the cable core of the submarine optical cable provided by the embodiment of the present invention includes a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com