Arc extinguishing structure of direct-current contactor

A DC contactor and arc extinguishing technology, which is applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., can solve problems that affect the electrical life of products, affect the purity of gas media, and are not resistant to arcs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

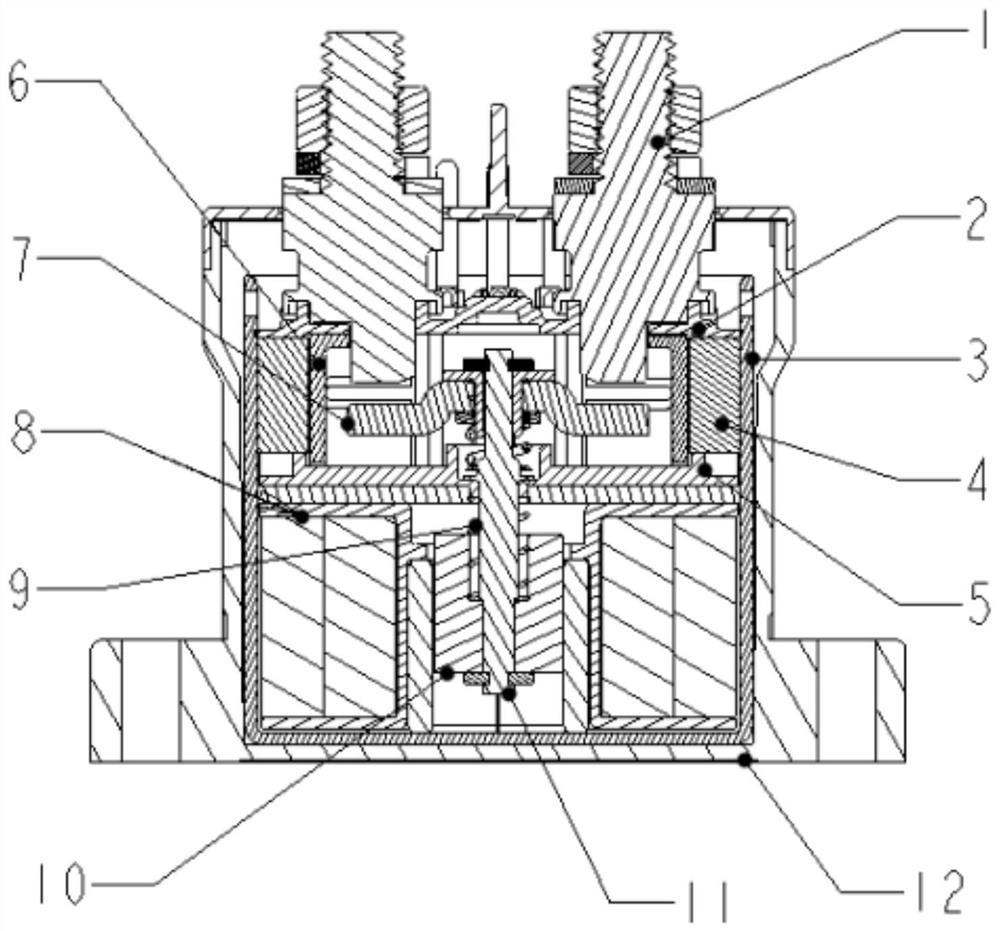

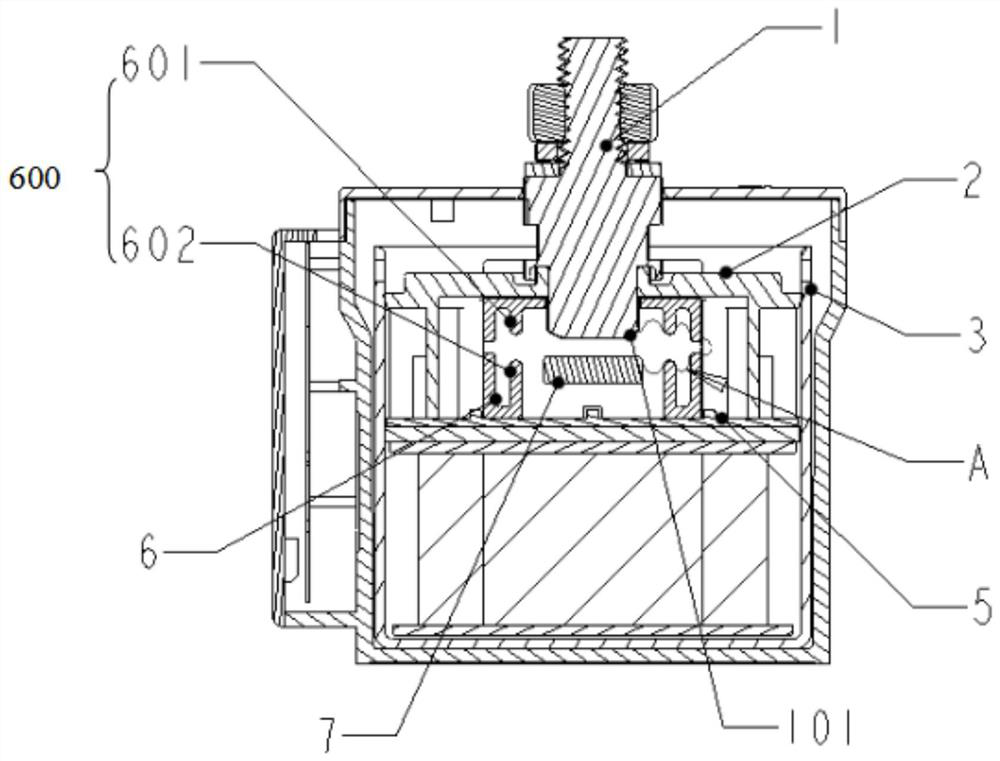

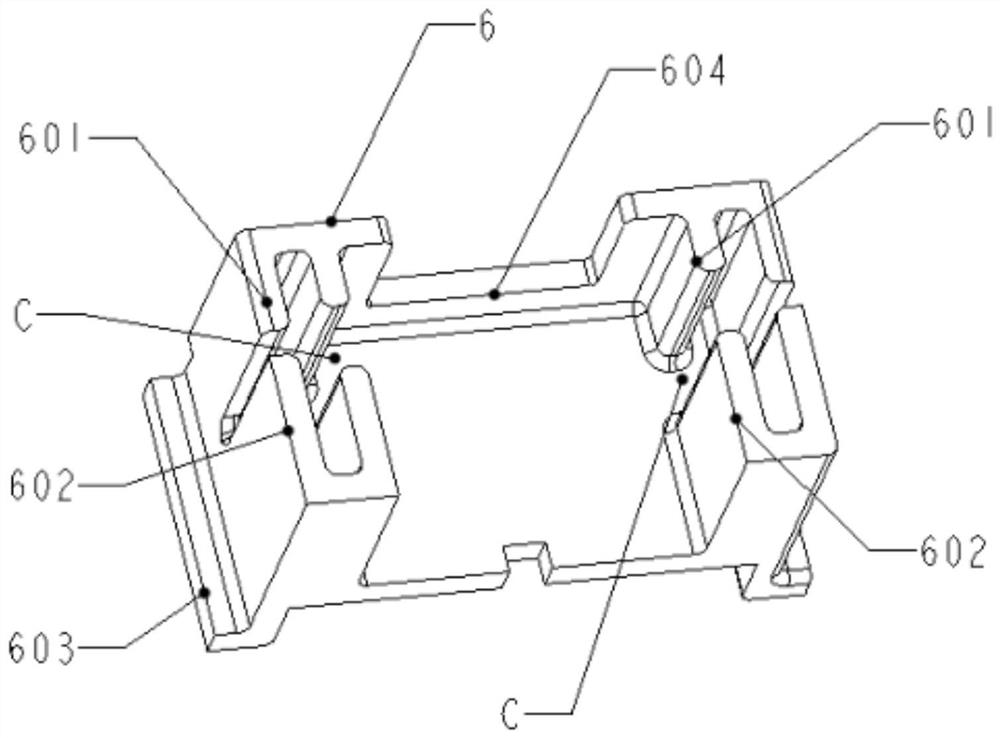

[0023] Such as Figure 1-Figure 4 As shown, the present invention discloses an arc extinguishing structure of a DC contactor, which includes an arc extinguishing cover 2, and a pair of static contacts 1 that pass through the arc extinguishing cover 2 and sit on it are provided with a static contact 1 Matching moving contact assembly 9. The static contact 1 is made of metal material and can be injection molded into one body or assembled together with the plastic-molded arc extinguishing cover 2 . The moving contact assembly 9 includes moving contacts 7, and each static contact 1 is in contact with or disconnected from a corresponding moving contact 7 to realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com