Portable and detachable high-voltage cable butt joint box grounding wire and using method thereof

A technology of high-voltage cables and docking boxes, which is applied in the direction of electrical connection sockets, connecting device connection/disconnection, and connecting contact materials, etc., which can solve the problem of expanding the scope of power outages, grounding wires cannot be connected with cables, and increasing the workload of operators, etc. problems, to achieve the effect of improving safety performance, avoiding the expansion of power outage range, and facilitating maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

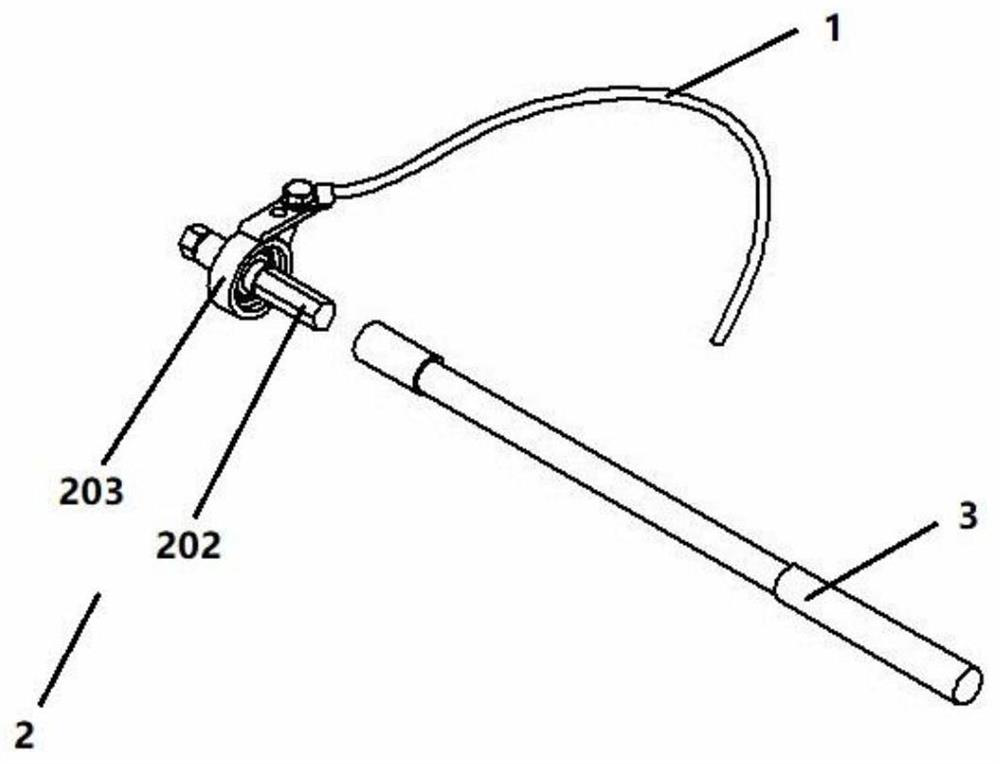

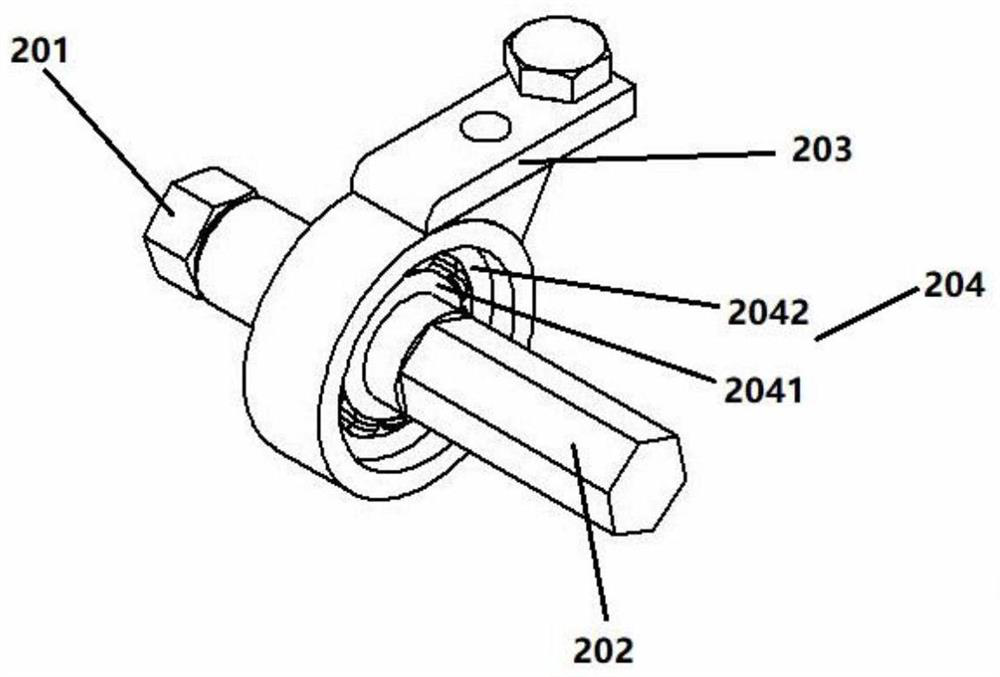

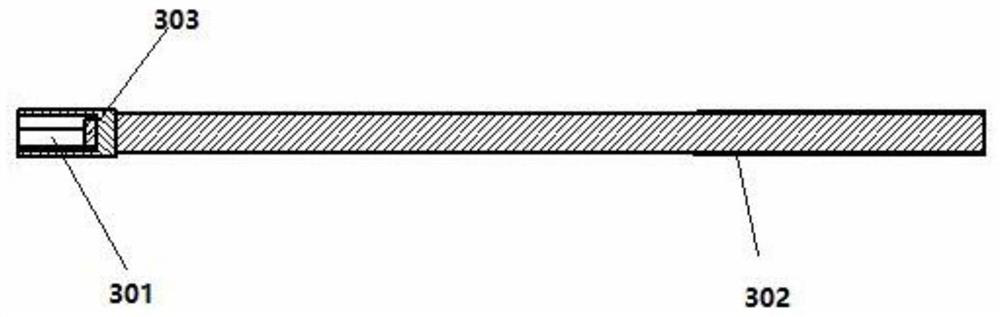

[0030] Implementation: Reference Figure 1 to Figure 3 , a portable and detachable high-voltage cable docking box grounding wire, including a cable 1, one end of the cable 1 is connected with a connecting piece 2, the connecting piece 2 is provided with a connecting nut 201, the connecting nut 201 and the docking box The screws on the cable match, and the cable 1 and the connector 2 are in electrical communication; the connector 2 also includes a rotating rod 202, a cable connecting member 203 and a rotating member 204, and the rotating rod 202 is connected to the cable through the rotating member 204. The connecting pieces 203 are connected together, and the rotating rod 202 and the rotating piece 204 are in electrical communication with the cable connecting piece 203, the cable 1 is connected to the cable connecting piece 203, and the connecting nut 201 is connected to one end of the rotating rod 202; it also includes an operating rod 3. One end of the operating rod 3 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com