Anti-falling rubber shoe special for outdoor construction

An anti-shedding and outdoor technology, applied in the field of rubber shoes, can solve the problems of reducing the service life and waterproof protection of rubber shoes, reducing the flexibility and operability of rubber shoes, and increasing the inconvenience for staff to use, so as to increase the anti-shedding function and increase functionality. and wearing comfort, and the effect of preventing penetration into the inside of rubber shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

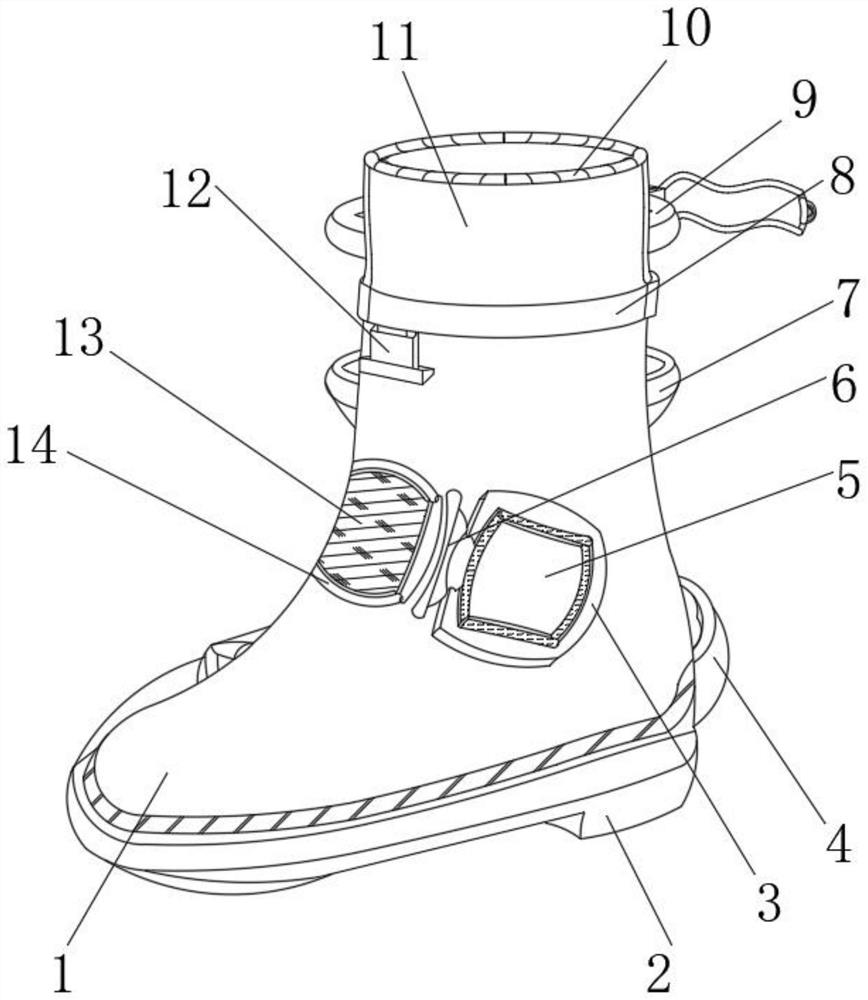

Embodiment 1

[0031] Example 1, such as image 3 As shown, when not working on a rainy construction site, the sealing block 5 can be opened to cancel the locking and fixing of the locking layer 14, so that the permeable layer 13 is in contact with the outside world, so that the breathable function of the shoe body 1 can be increased, and The canceled sealing block 5 can be stored in the storage slot 3, so that it can be used again for snapping and sealing, so as to increase the functionality of the device and enhance the comfort of the operator to wear.

Embodiment 2

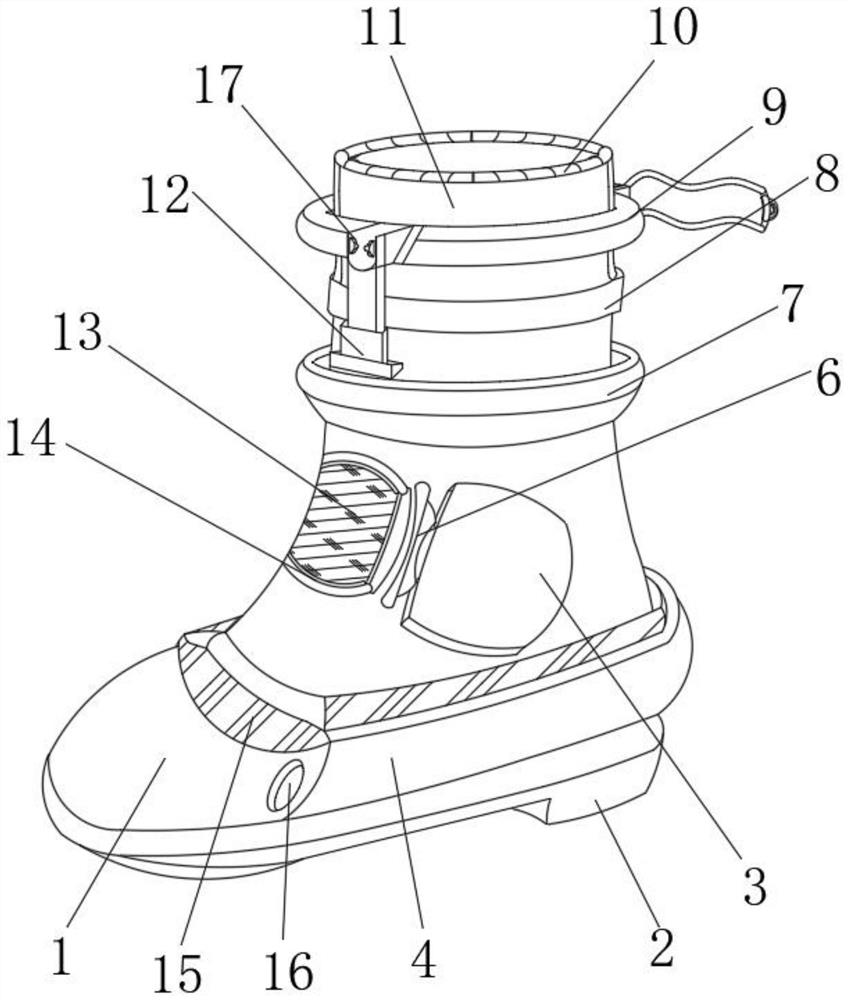

[0032] Example 2, such as Figure 5 As shown, when the water adhering to the outside of the shoe body 1 slips, the water liquid is received and guided through the sealing contact between the flow guide layer 15 and the shoe body 1, and the wrapping protection system formed by the protective layer 4 and the fixing buckle 16 is used. , greatly enhance the protection of the connection between the waterproof sole 2 and the shoe body 1, and prolong the service life and effectiveness of the rubber shoes.

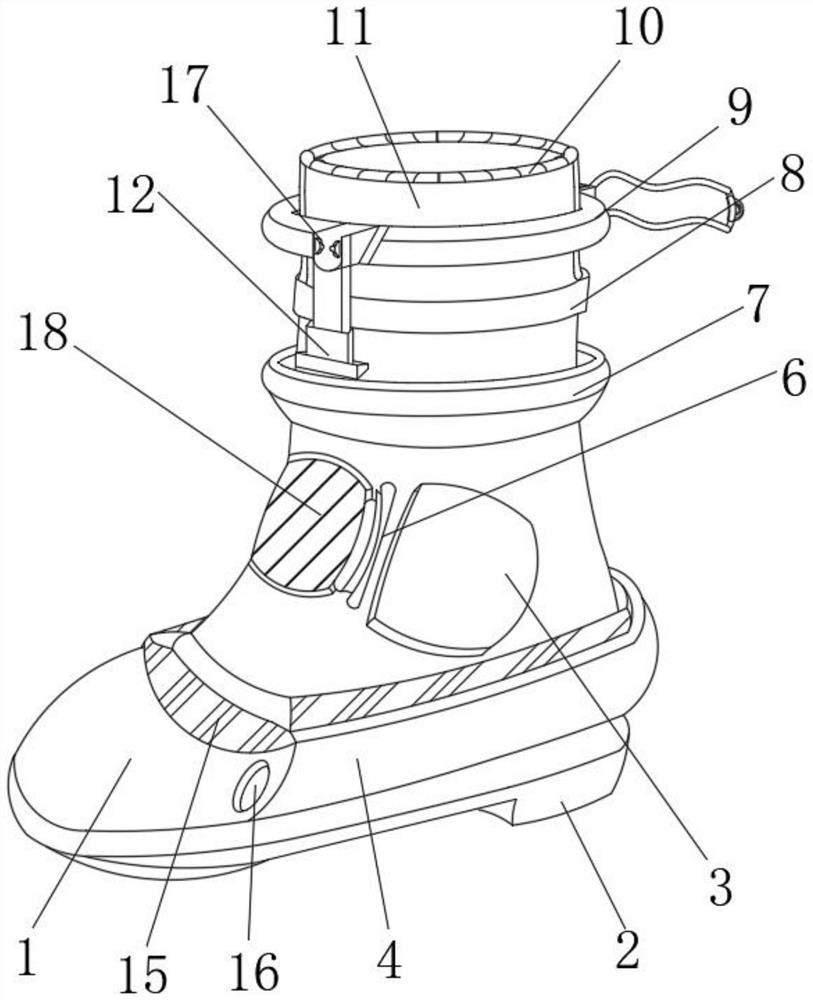

[0033]Working principle: when rubber shoes are used, the elastic ring 10, the waterproof cover 11 and the semi-arc clamp 9 can be expanded at the same time, so that the anklet can be more easily inserted into the shoe body 1, and the anklet can be completely integrated into the shoe body 1 , then adjust the bonding surface of the elastic ring 10 and the waterproof cover 11, pull the connecting plate 24 to drive the semi-arc clamp 9 to fit, so that the semi-arc clamp 9 is in the at...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap