Preparation process of concrete precast element

A technology of concrete prefabrication and prefabricated components, which is applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve the problems of large equipment occupation and waste of concrete raw materials, and achieve the advantages of reducing waste, reducing equipment occupation, and high connection strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

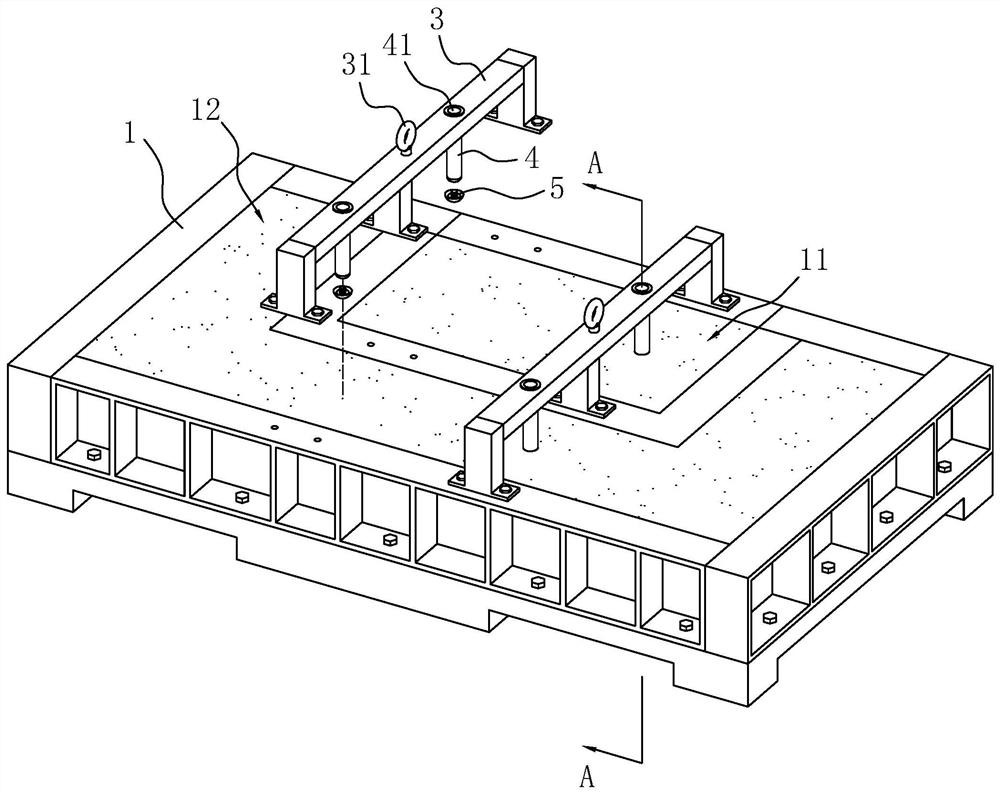

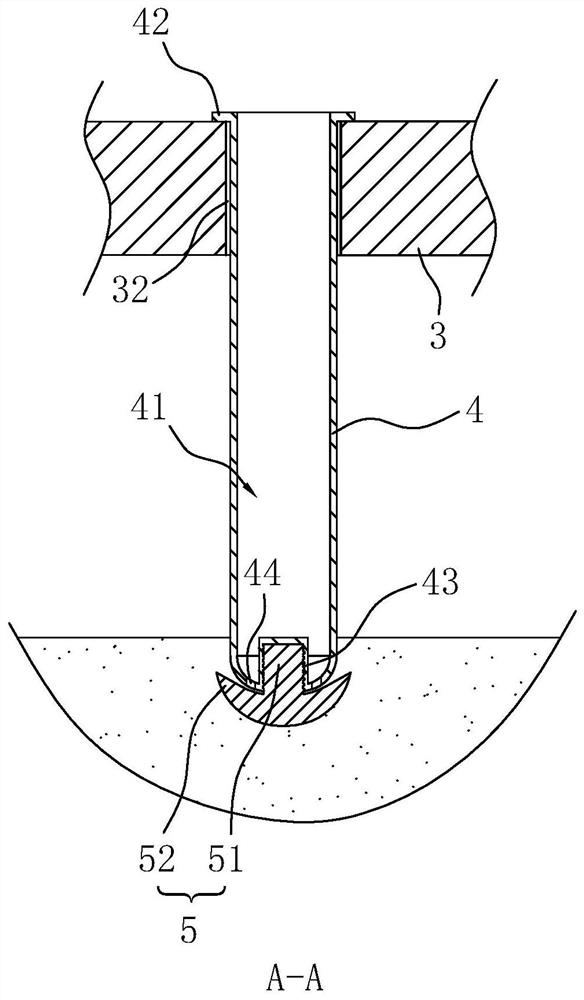

[0038] The following is attached Figure 1-5 The application is described in further detail.

[0039] The embodiment of the present application discloses a preparation process of a concrete prefabricated component, comprising the following steps:

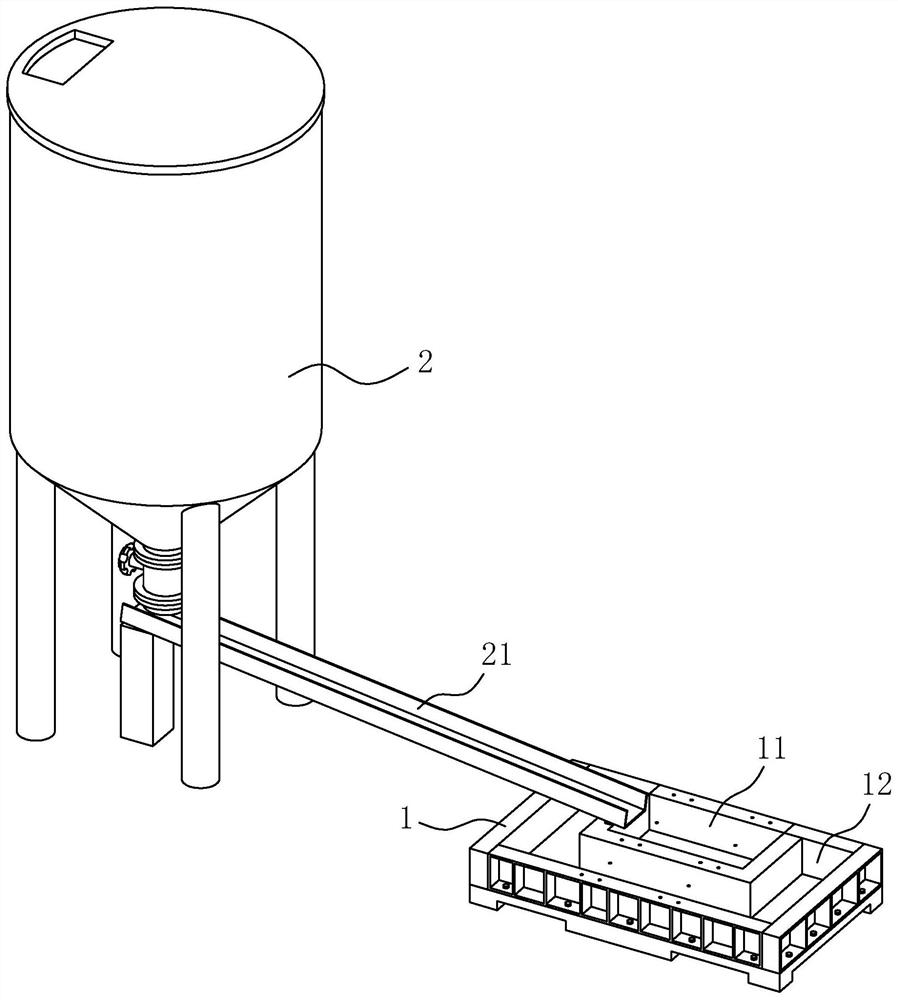

[0040] Step S1: Refer to figure 1 , the mold 1 is prepared in advance, and the concrete is prepared in the storage tank 2 . The mold 1 is provided with a mold cavity 11 and a mold cavity 12. The mold cavity 11 is located on one side of the horizontal direction of the mold cavity 12. The tops of the mold cavity 11 and the mold cavity 12 are all open, wherein the mold cavity 11 It is used for forming concrete prefabricated parts with relatively low moisture content, and the mold cavity 2 12 is used for forming concrete prefabricated parts with relatively high moisture content. The concrete in the storage tank 2 is consistent with the material of the prefabricated part to be formed in the first mold cavity 11, that is, the concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com