Turnover turnout for rail transit

A rail transit, flip technology, applied in the field of rail transit, can solve the problems of fatigue risk, prone to torsional vibration, large bending angle between beams, etc., to reduce fatigue risk, reduce torsional vibration, and simplify the mechanical system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

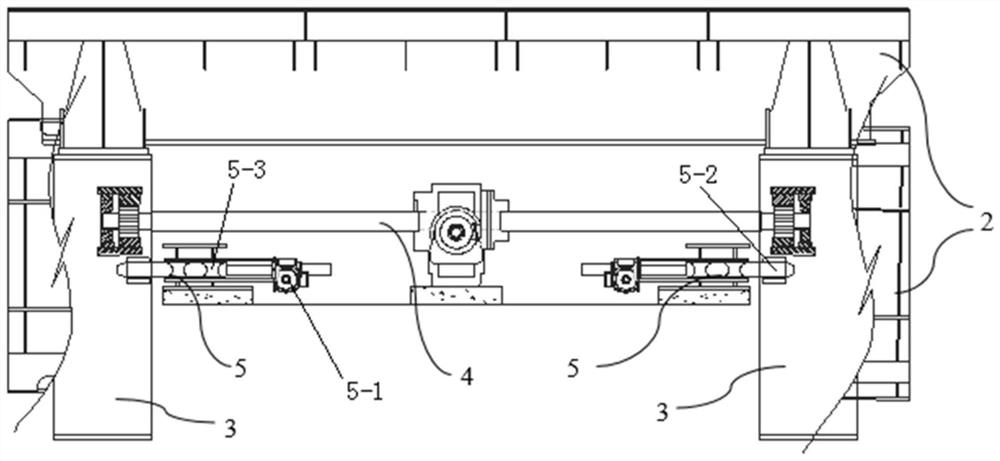

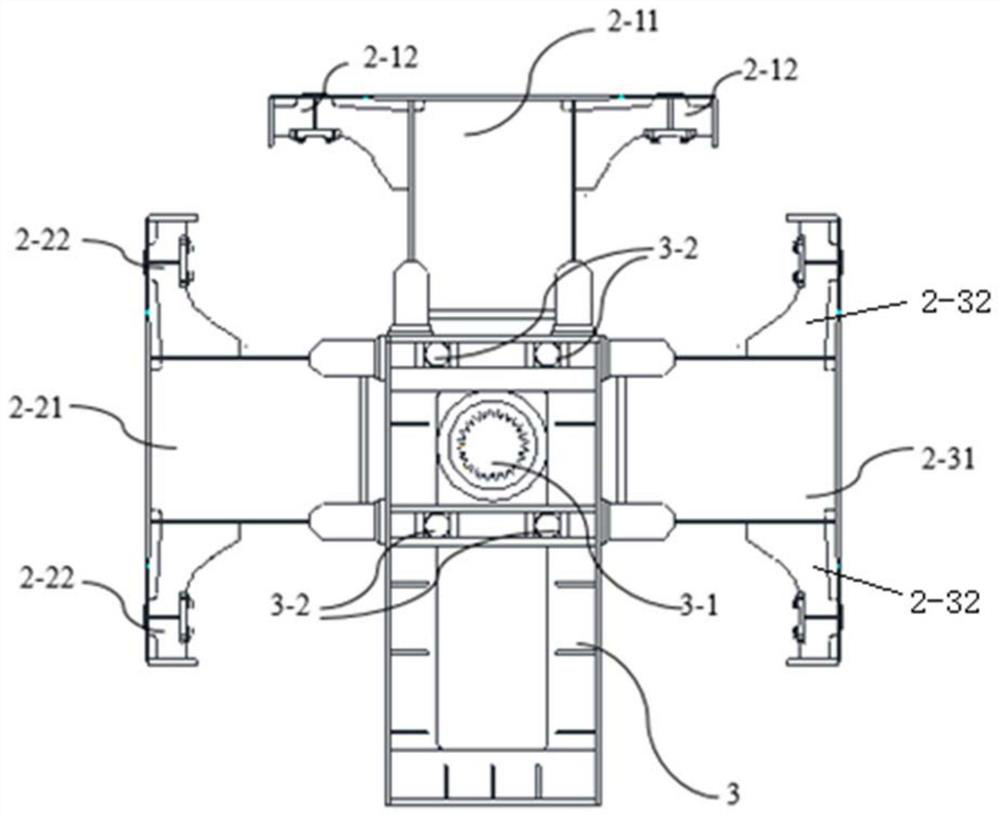

[0040] After the lock pin motor 5-1 and drive motor 4-1 of each turnout segment 1 receive the work order, the lock shaft 5-2 is retracted into the lock box 5-3 at the same time, and each drive motor 4-1 is started at the same time to drive the rotation shaft 4-2 and the drive gear 4-3 rotate, the drive gear 4-3 meshes with the internal gear 3-1 installed on the support beam 3, and the support beam 3 and track beam group 2 rotate around the center line of the drive gear 4-3, specifying After the track beam is overturned to the line plane, the locking shaft 5-2 extends out of the locking box 5-3 at the same time to lock and support the turnout segment 1, ensuring that the track beam group 2 is stably supported and locked at a designated position.

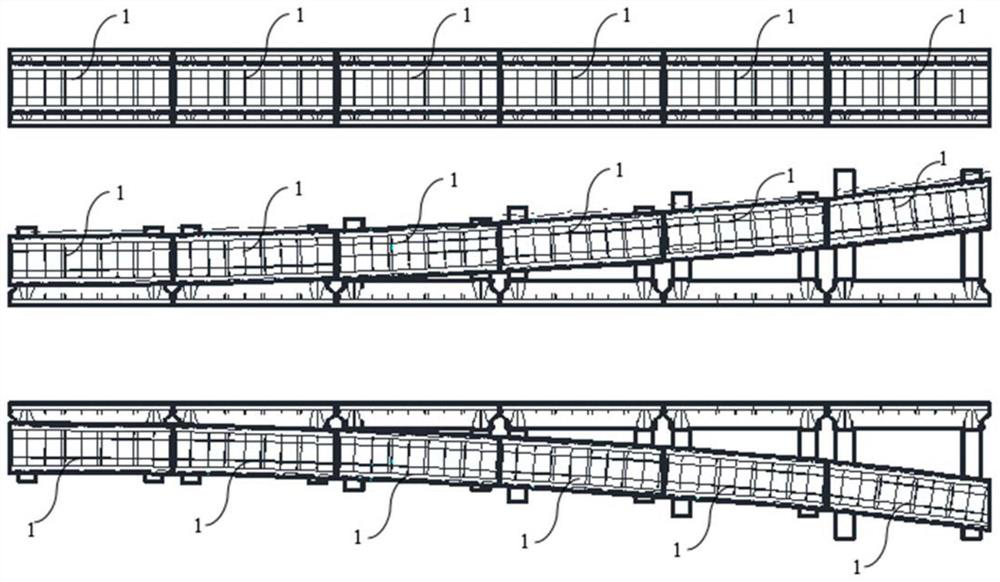

[0041] The turnout segment 1 can be configured with two or three track beams according to the line design requirements, and the number of the turnout segment 1 can be set according to the needs; the main beam of the turnout segment 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com