Straight condensing unit with phase change energy storage

A pure condensing unit, phase change energy storage technology, applied in mechanical equipment, steam engine devices, engine components, etc., can solve problems such as high peak pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

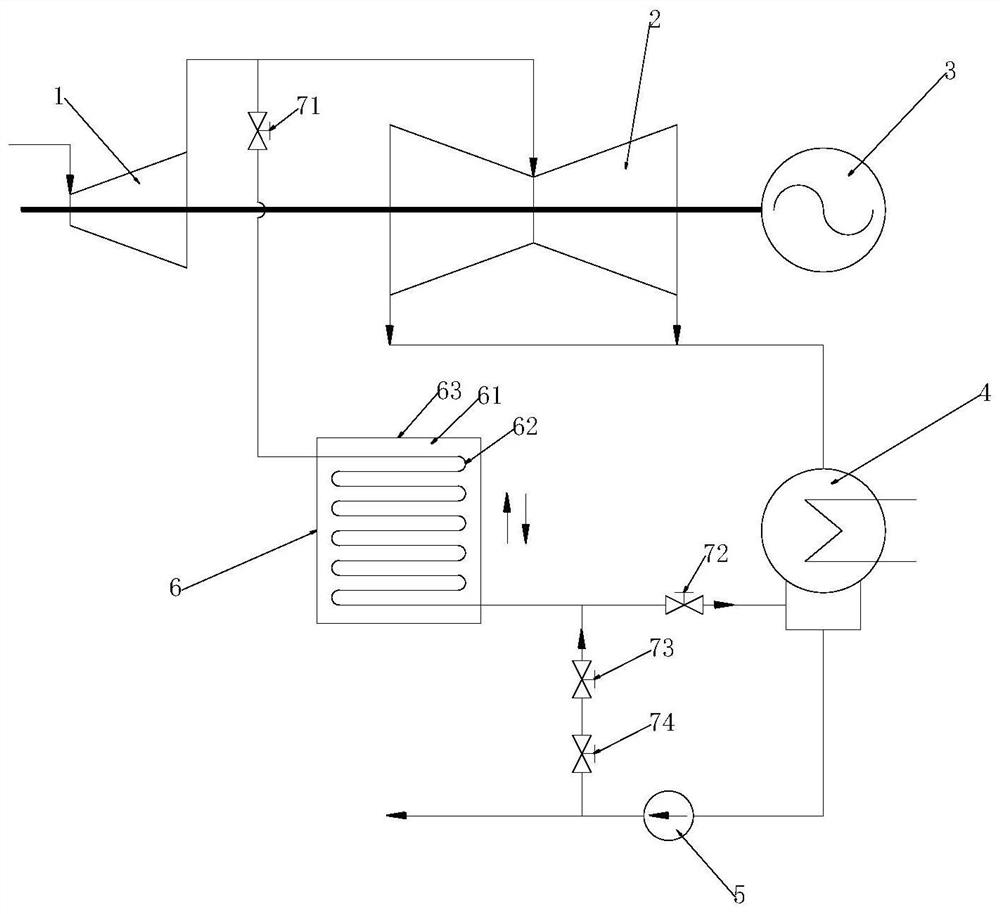

[0026] see figure 1 , figure 1 It is a schematic diagram of the piping structure of the pure condensing unit provided in Example 1 of the present invention.

[0027] In a specific embodiment, this embodiment provides a pure condensing unit with phase change energy storage, which may specifically be a deep peak regulation system of a pure condensing unit coupled with phase change energy storage, using coupled phase change energy storage The deep peak-shaving method of the pure condensing unit is used for peak-shaving work. Specifically, the pure condensing unit includes a steam turbine, a generator 3 , a condenser 4 , a phase change energy storage device 6 and a supply device 5 .

[0028] Among them, a rotary steam power device is installed inside the steam turbine. The high-temperature and high-pressure steam passes through the fixed nozzle to become an accelerated steam flow and is sprayed on the blades, so that the rotor equipped with blade rows rotates and at the same tim...

Embodiment 2

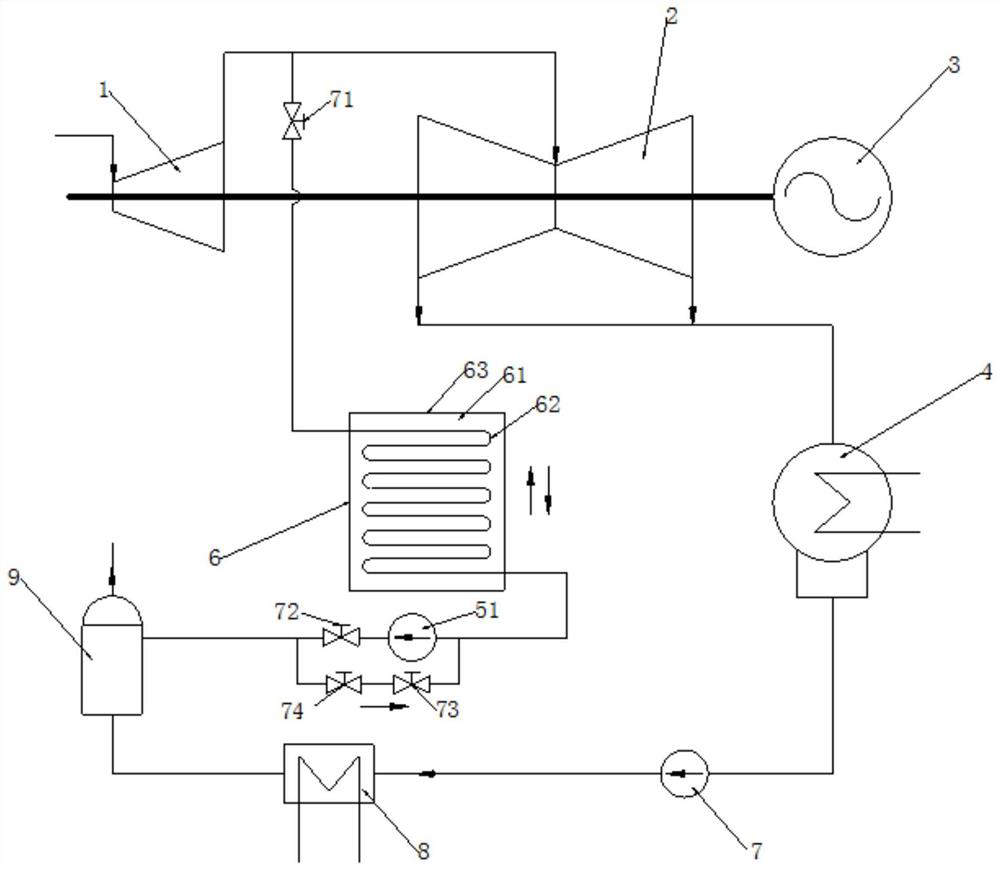

[0044] see figure 2 , figure 2 It is a schematic diagram of the piping structure of the pure condensing unit provided in Example 2 of the present invention.

[0045] Embodiment 2 is basically the same as the pure condensing unit in Embodiment 1. In this implementation, the connection mode of the high temperature port of the phase change energy storage device 6 and the internal structure of the phase change energy storage device 6 can refer to the above embodiment 1. How to supply liquid and how to discharge liquid to the low temperature port of the phase change energy storage device 6 in Embodiment 2 provides a new solution. Specifically, it is preferable that the supply device of the above-mentioned phase change energy storage device 6 is a deaerator 9, wherein the low temperature port communicates with the deaerator through an outflow channel and an inflow channel arranged in parallel with each other, so that the outflow channel can pass through, so that the low temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com