Industrial robot track section transition method based on non-uniform B spline curve

An industrial robot, spline curve technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of not considering the connection of straight lines and arc trajectories, affecting efficiency, machine vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with specific embodiment:

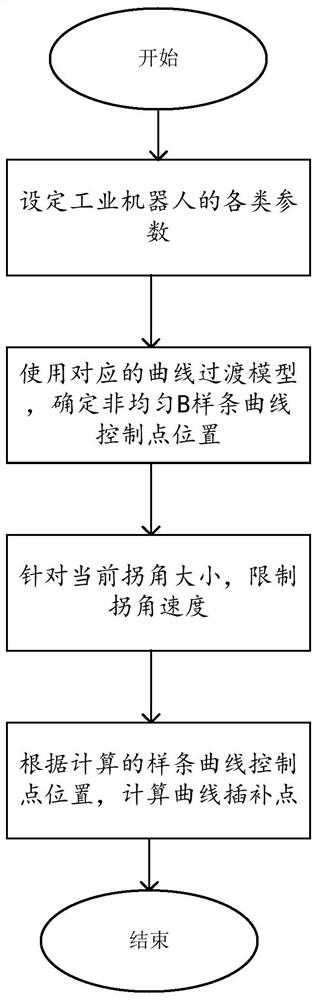

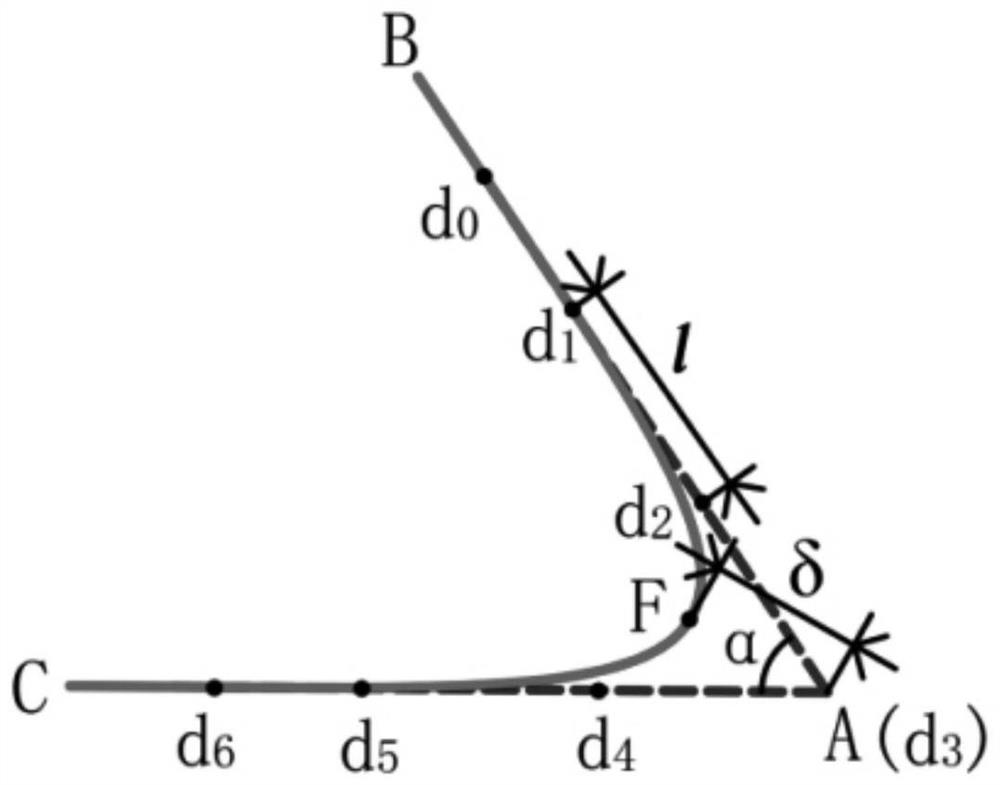

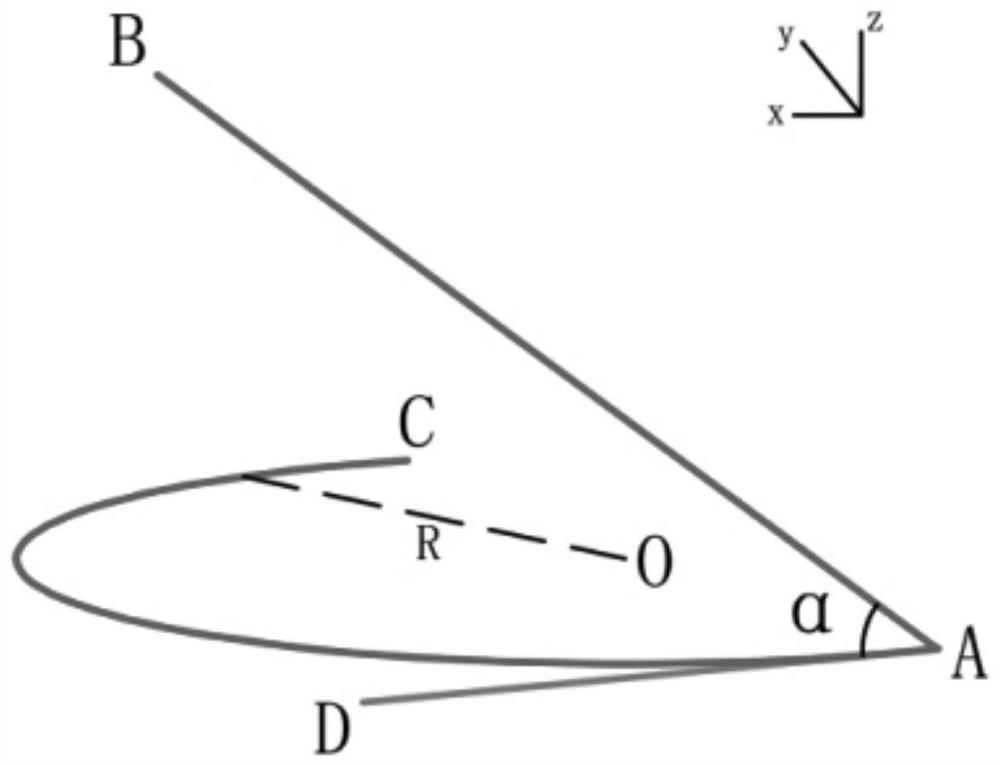

[0073] A trajectory segment transition method for an industrial robot based on a non-uniform B-spline curve described in the embodiment of the present invention uses a multi-track segment transition method to process the motion trajectory specified by the user: using the curve transition model to calculate the curve control point; using the velocity The constraint model is used to estimate the velocity of the trajectory transition area; the velocity planning curve is used to output the sequence of trajectory interpolation points in the Cartesian space of the robot to realize the high-speed smooth processing of the robot.

[0074] Such as figure 1 As shown, the specific process of the multi-segment trajectory transition method includes:

[0075] S1. Set various parameters of the six-degree-of-freedom industrial robot, including the performance parameters of the six joints of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com