Prefabricated building external wall panel production mold

An exterior wall panel, assembled technology, which is applied to molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of cumbersome installation and disassembly process, poor flexibility in injection molding, and inconvenient use, and achieves easy demoulding and quick disassembly. Solve the effect of convenient work and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

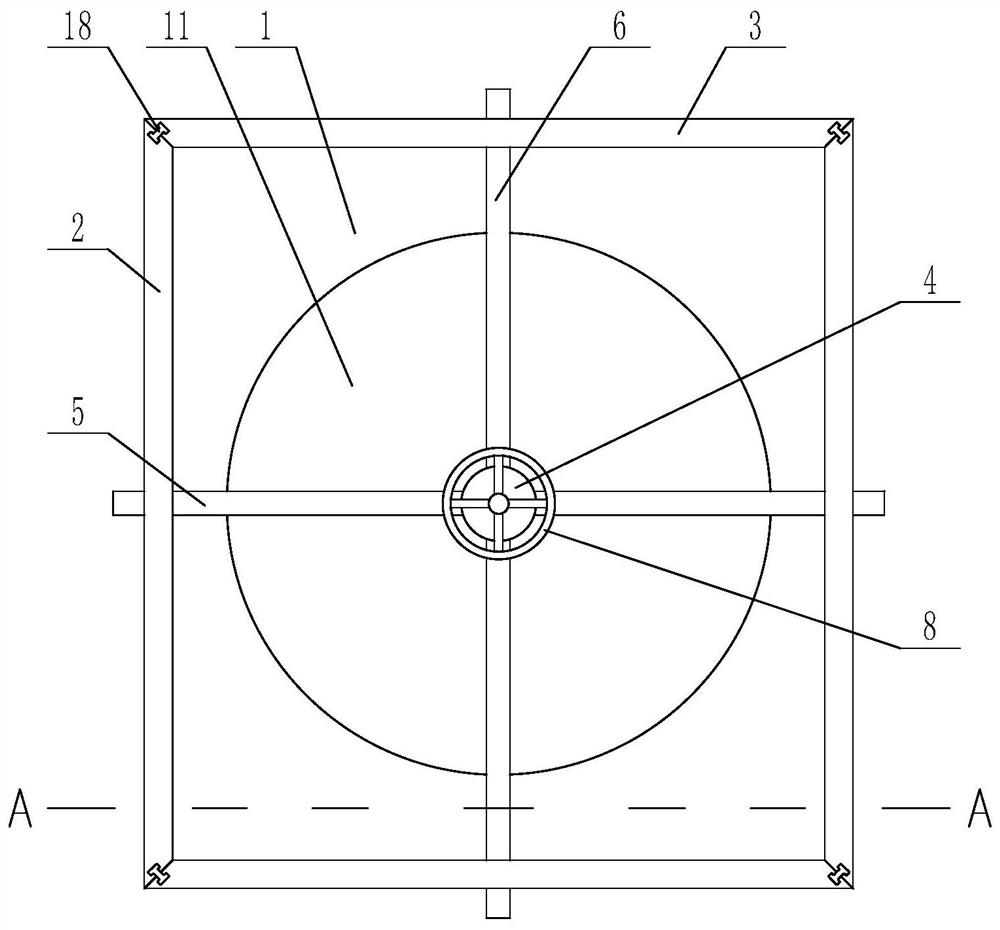

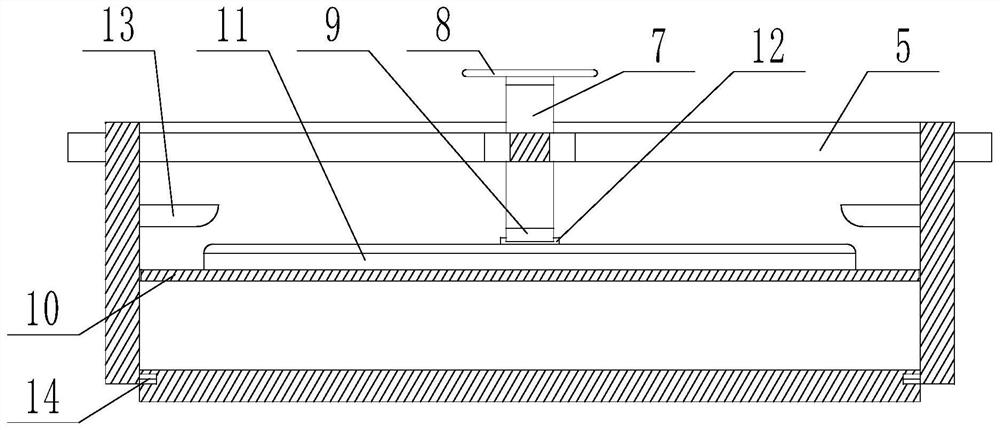

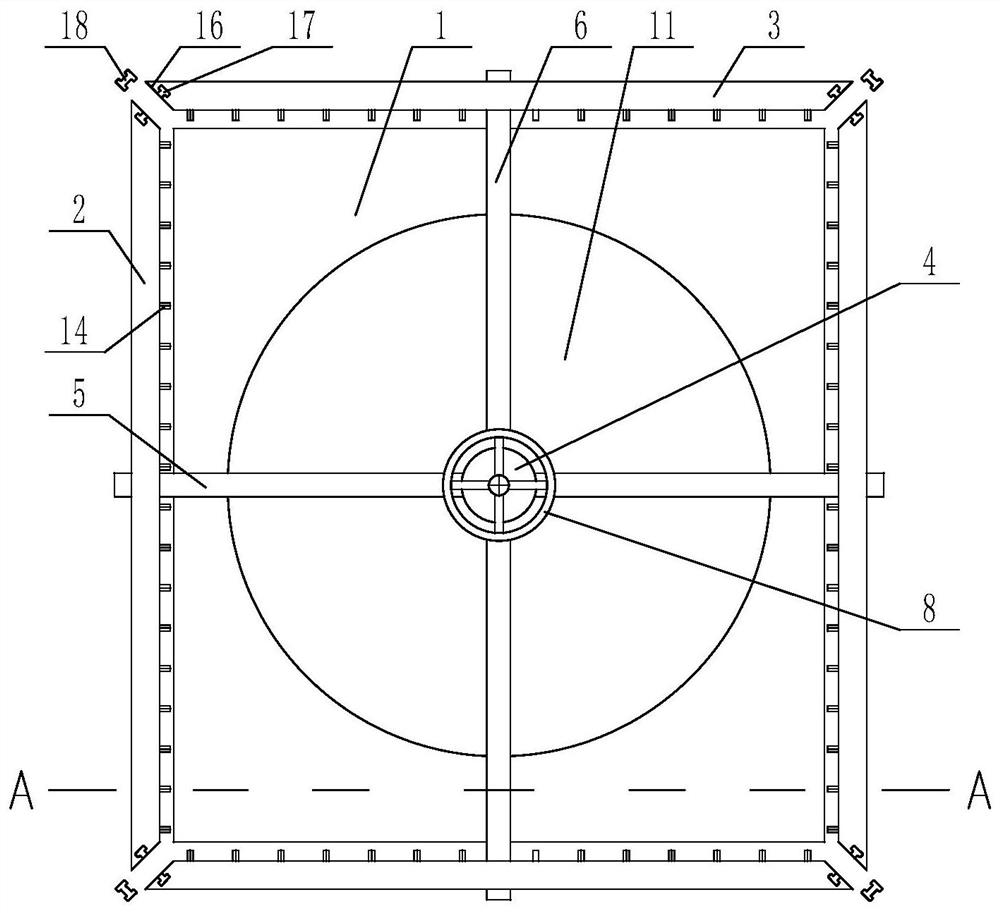

[0031] The inventive point of the present application is that a bearing plate 4 is provided above the base plate, and the left and right sides of the bearing plate are all movably connected with the guide rod one 5. The side plate one is vertical and runs through the side plate one on the left side of the top of the bottom plate, the guide rod one on the right side of the bearing plate is perpendicular to the side plate one on the right side of the top of the bottom plate and runs through the side plate one on the right side of the top of the bottom plate, the Both the front side and the rear side are movably connected to the guide rod 2 6, the guide rod 2 located at the front side of the load plate is perpendicular to the side plate 2 on the front side of the bottom plate top and runs through the side plate 2 on the front side of the bottom plate top, the guide rod located at the rear side of the load plate Two, perpendicular to the side plate two on the rear side of the top o...

Embodiment 2

[0040] The connecting body is in the shape of a truncated cone with a narrow top and a wide bottom. The distance between the other end of the driving rod and the side surface of the threaded rod is greater than the diameter of the upper surface of the connecting body and smaller than the diameter of the lower surface of the connecting body. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com