A fault self-detection module and method for a regenerative thermal oxidation device

A self-detection and thermal oxidation technology, which is applied in the direction of combustion methods, incinerators, lighting and heating equipment, etc., can solve problems such as exhaust gas emissions that cannot meet environmental protection requirements, regenerative thermal oxidation device explosion, etc., and achieve fault judgment Difficulty, reduce work cumbersomeness, and ensure safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

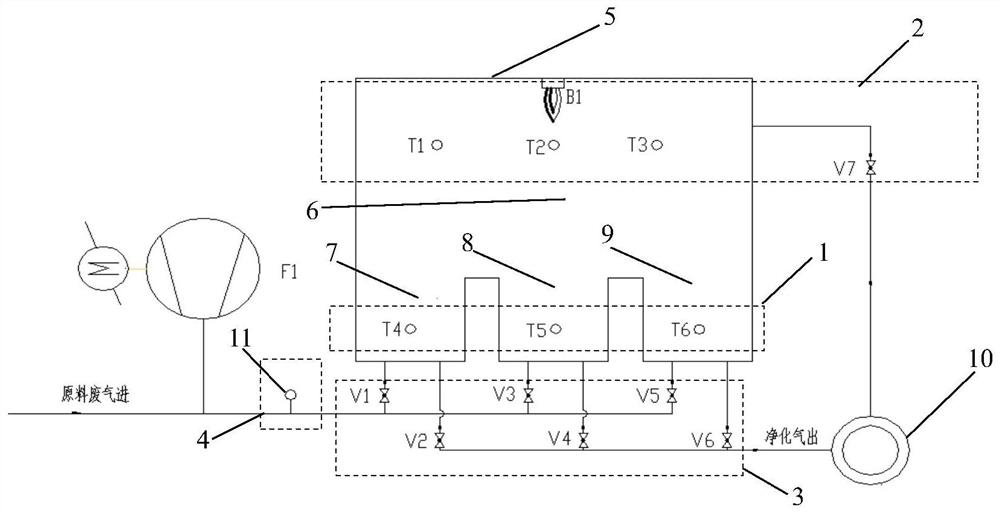

[0032] The first embodiment of the present application provides a method such as figure 2 The fault self-detection module of the regenerative thermal oxidation device shown, the RTO furnace 5 is provided with a combustion chamber 6, a regenerator 1 7, a regenerator two 8 and a regenerator three 9, and the fault self-detection module includes: exhaust gas. LEL value measurement module 4, regenerator temperature measurement module 1, combustion chamber temperature control module 2 and poppet valve switching control module 3; an alarm counting module is also provided to count the accumulated times of different faults; the regenerator temperature measurement module 1 is connected to the poppet valve switching control module 3, used to balance the temperature of each regenerator; the regenerator temperature measurement module 1 includes temperature detectors set in regenerator one 7, regenerator two 8, and regenerator three 9. Thermometer T4, Thermometer T5 and Thermometer T6 plac...

Embodiment 2

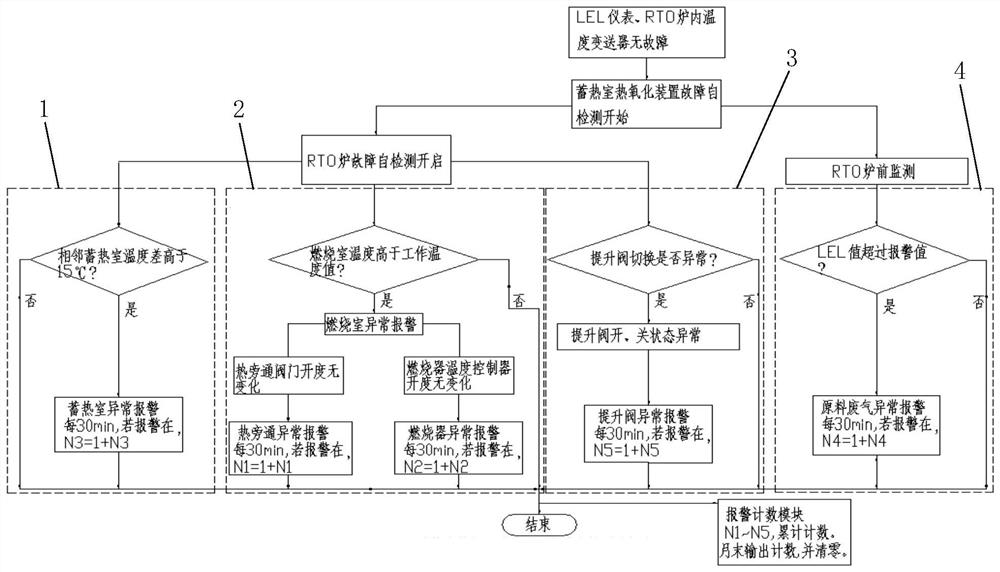

[0038] On the basis of Example 1, as figure 1 As shown, the second embodiment of the present application provides a self-detection method for the fault self-detection module of the regenerative thermal oxidation device in the first embodiment, specifically:

[0039] The combustion chamber temperature control module is connected with the burner control module and the heat bypass control module, and is used for controlling the normal temperature of the combustion chamber. When the measured temperature value exceeds the working temperature value within 25 to 35 minutes, the alarm counting module will prompt an abnormal alarm in the combustion chamber. In the case of an abnormality alarm in the combustion chamber, further, in the case of no change in the feedback of the opening of the hot bypass valve, the alarm counting module will prompt the abnormality alarm of the hot bypass valve, and every 30 minutes, if the abnormality alarm of the hot bypass valve still exists, then Alarm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com