Concrete excrement discharge groove manufacturing mold and concrete excrement discharge groove manufacturing method

A production method and concrete technology, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems that the concrete defecation tank cannot take into account the smoothness of the manure guiding surface and production efficiency, and the efficiency of the concrete defecation tank is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

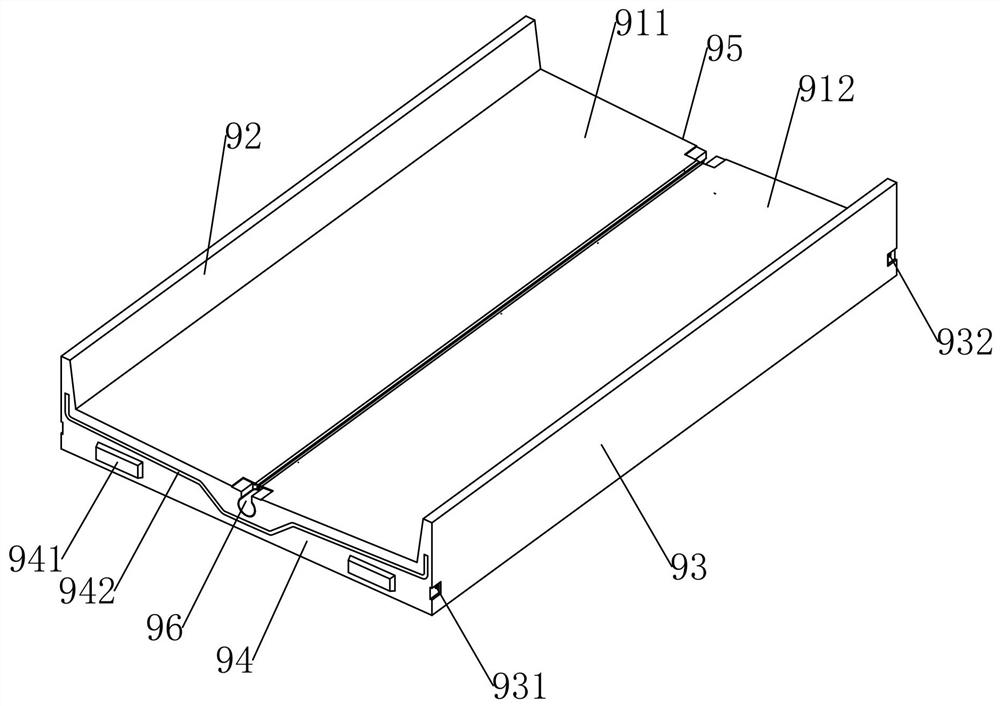

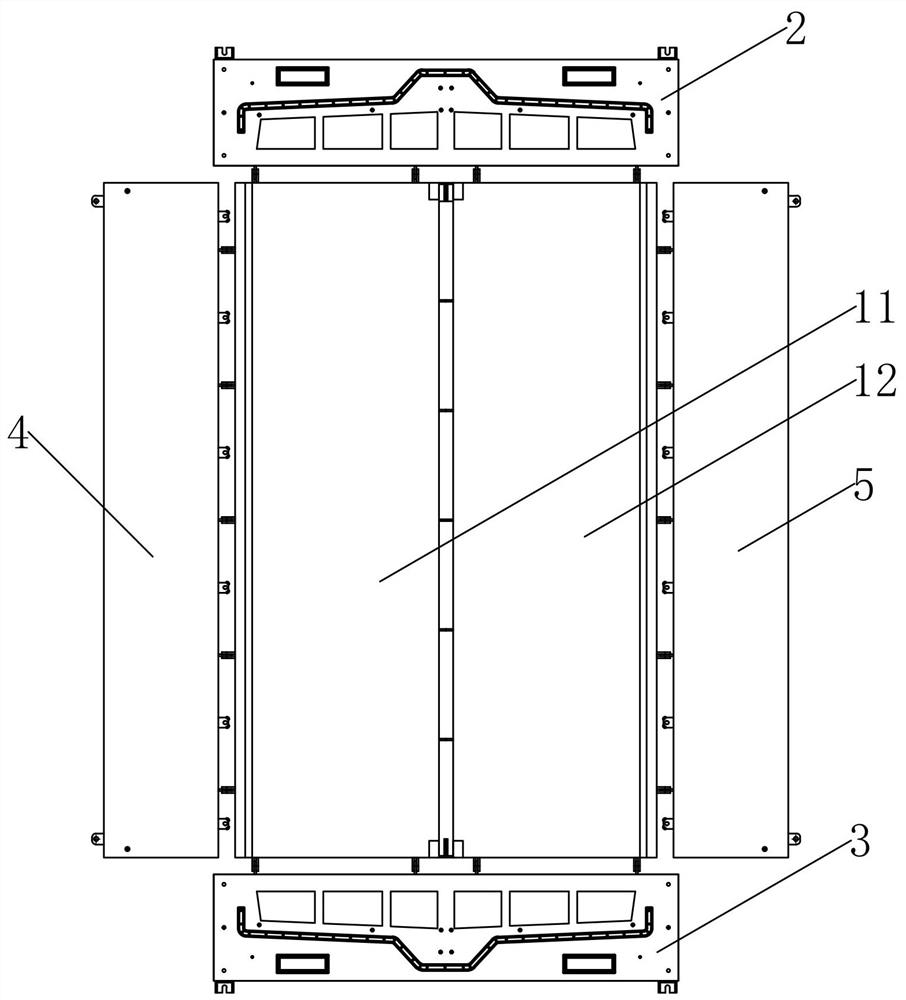

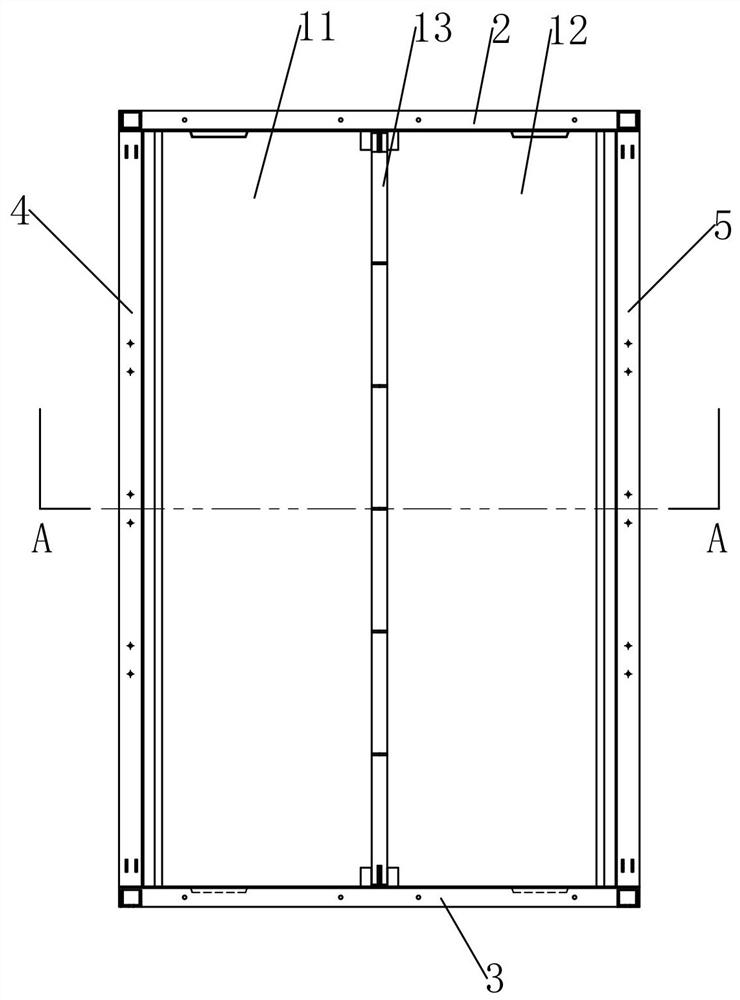

[0034] Embodiment 1: A mold for making a concrete defecation tank mainly consists of a first module, a second module, a third module, a fourth module, a fifth module and a sixth module. The first module is used to form the upper surface of the concrete defecation tank, and the manure-guiding surface of the concrete defecation tank is a part of the upper surface. The second mold part is used to form the first end face of the concrete manure trough. The third module is used to form the second end face of the concrete defecation tank. The fourth module is used to form the first side of the concrete manure tank. The fifth module is used to form the second side of the concrete manure tank. The sixth module is used to form the lower surface of the concrete excrement tank. The first module, the second module, the third module, the fourth module, the fifth module and the sixth module can be combined to form a concrete tank.

[0035] The molded surface of the first module is used t...

Embodiment 2

[0044] Embodiment 2: a kind of concrete defecation tank manufacture method, comprises the following steps:

[0045] The mold-closing step of making the mold for the concrete defecation tank, so that the mold joint of the defecating guide surface corresponding to the defecating guide surface is arranged on the bottom mold part of the concrete defecating tank making mold;

[0046] The step of making the concrete defecation tank prefabricated part is to make mold grouting to the concrete defecation tank, vibrate and solidify to form the concrete defecation tank prefabricated part;

[0047] demoulding step;

[0048] Steps to flip a concrete manure trough precast.

Embodiment 3

[0049] Embodiment 3: a kind of concrete defecation tank manufacture method, comprises the following steps:

[0050] (1) BIM intelligent processing and collision inspection, obtain the quantity, specification and size of the steel bars, and check whether the steel bars interfere; specifically, use BIM software to establish a three-dimensional model of the defecation tank, obtain the steel bar parameter table and conduct collision checks on the design drawings ;

[0051] (2) Rebar processing blanking, the steel bar table obtained through BIM intelligent processing is transmitted to the reinforcement processing background for blanking; specifically,

[0052] (3) Steel bar binding, the processed steel bars are bound manually, involving binding of several characters, binding of end stirrups, binding of board wall stirrups, etc.;

[0053] (4) Template cleaning and spraying of release agent, the cleaning part includes the cleaning of the side molds and bottom mold, so that there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com