Automobile interior injection molding part injection molding device

A technology for automotive interior and injection molding parts, which is applied in the field of injection molding equipment for automotive interior injection molding parts, which can solve problems such as difficulty, multiple processes, and long cooling and solidification cycles, so as to shorten the demoulding cycle, increase molding speed, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

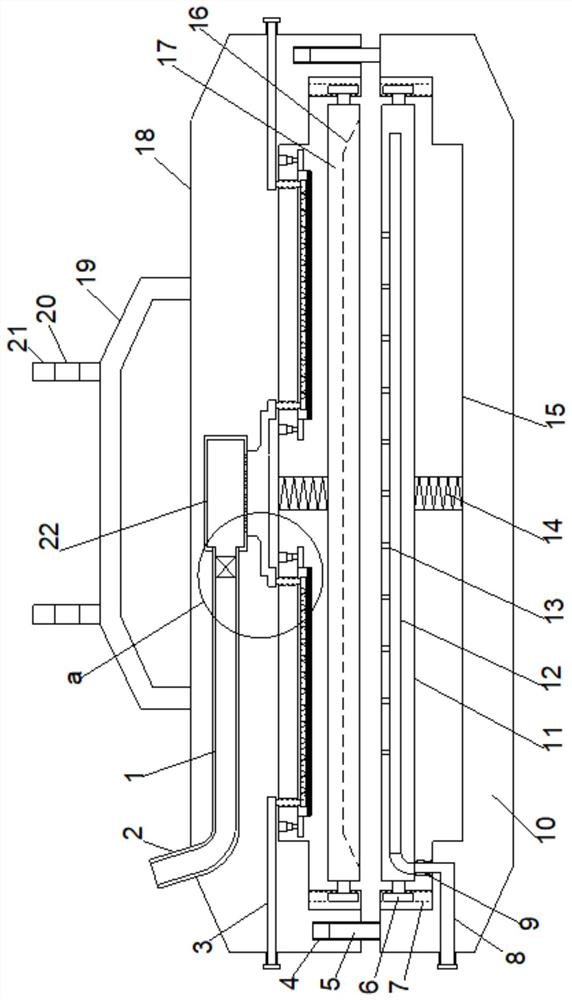

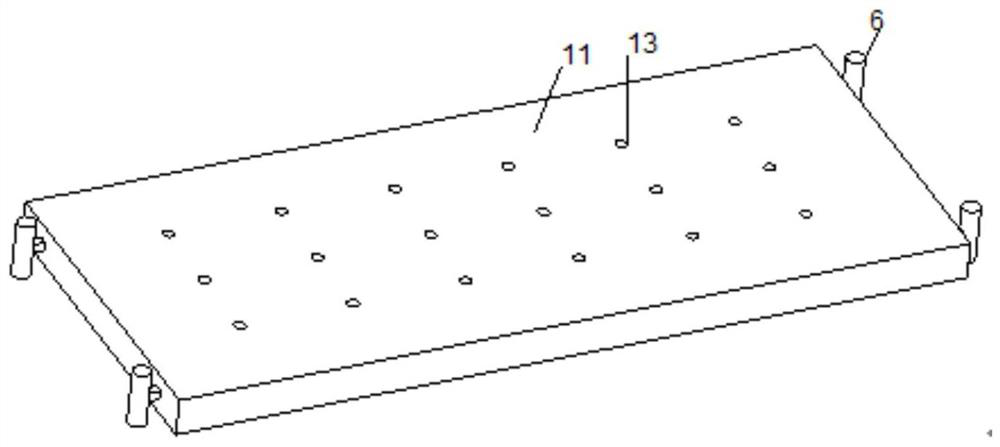

[0021] see Figure 1~3 , in an embodiment of the present invention, an injection molding device for injection molded automotive interior parts, comprising a support installation plate 10 arranged horizontally, an operation installation plate 18 is arranged horizontally directly above the support installation plate 10, and the middle position of the upper end of the operation installation plate 18 is vertical. Vertically be provided with lifting mounting frame 19, and the upper end of lifting mounting frame 19 is symmetrically provided with fixed mounting plate 21, and fixed mounting plate 21 is all provided with fixed mounting hole 20, and the middle of described supporting mounting plate 10 and operation mounting plate 18 directly opposites The areas are all concavely provided with operation installation grooves 15, and the two ends of the upper side of the support installation plate 10 are symmetrically and vertically provided with positioning installation columns 5, and the ...

Embodiment 2

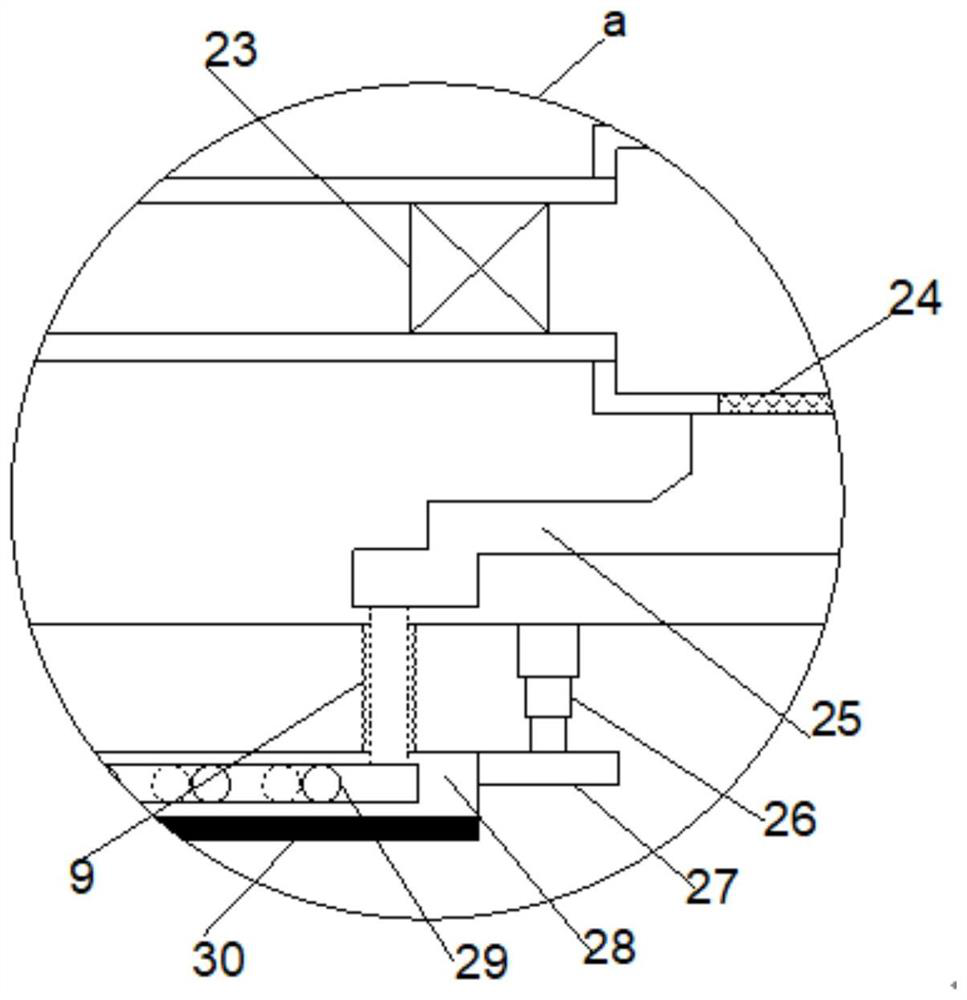

[0024] On the basis of Embodiment 1, the synchronous telescopic column 26 makes the heat conduction plate 30 contact with the displacement mounting plate 17 through the synchronous mounting plate 27, pours water into the slow flow chamber 22 through the liquid inlet pipe 1, and the water passes through the liquid delivery pipe 25 The S-shaped guide tube 29 is introduced and exported from the other end of the S-shaped guide tube 29 to realize rapid heat conduction of the displacement mounting plate 17, accelerate the shaping of injection molded parts, and significantly improve the production efficiency of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com