Insulator packaging device capable of preventing knocking damage

A technology of insulators and electric push rods, which is applied to the parts of bundling machinery, bundling materials, and the use of shock-absorbing media, etc., can solve the problems of bump damage to insulators, low manual work efficiency, and people are easily injured by iron wires. The effect of convenient bundling and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

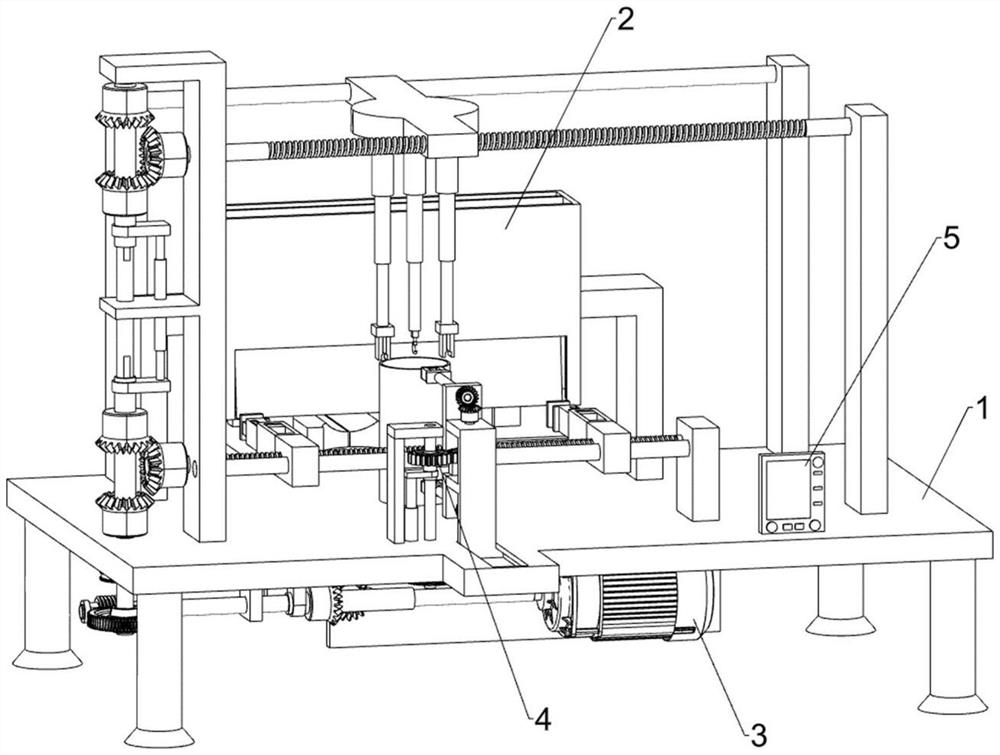

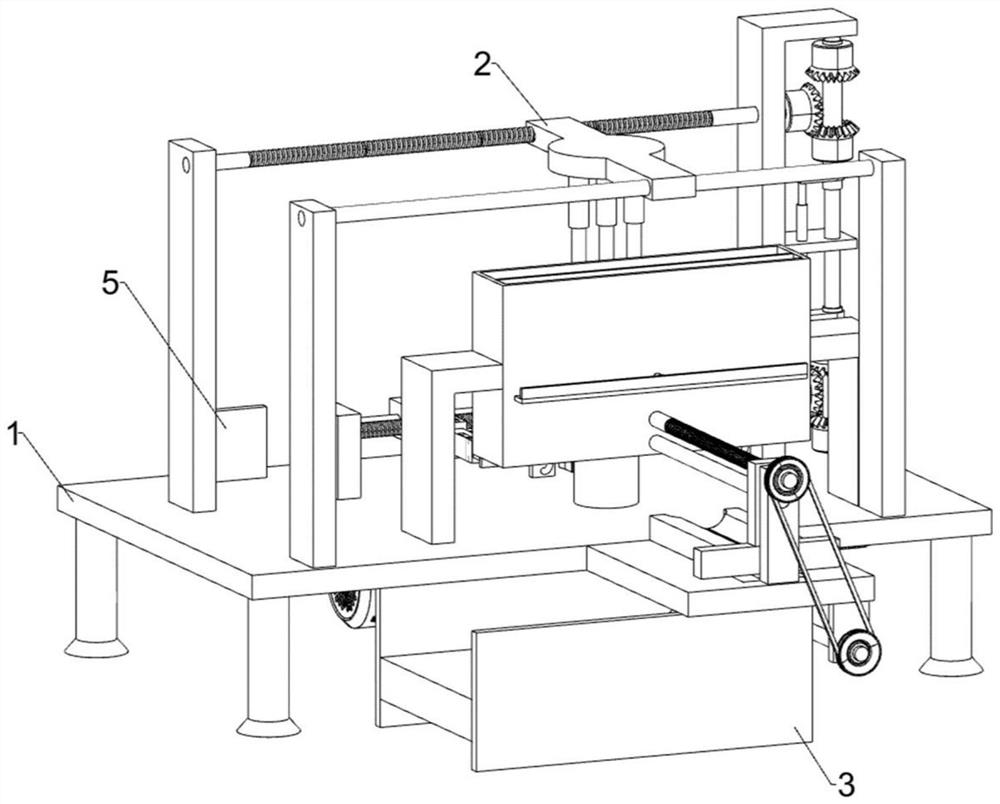

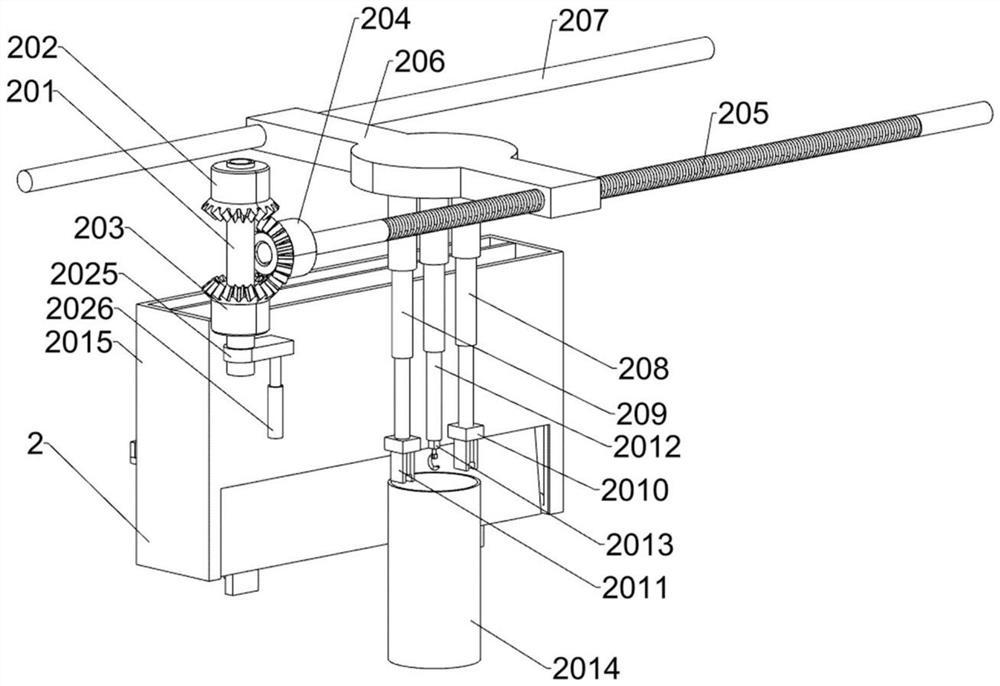

[0031]An insulator packaging device to prevent bumps, such asFigure 1-10As shown, the chassis 1, the upper unit 2, the bundling unit 3, the fastening unit 4, and the control screen 5 are included; the bottom frame 1 is connected to the upper unit 2; the chassis 1 is connected to the strapping unit 3; chassis 1 is connected to the fastening unit 4; the upper unit 2 is connected to the strapping unit 3; the bundling unit 3 is connected to the fastening unit 4.

[0032]When using the insulator packaging device that prevents the bumps from being placed to the position to be used, then the external power source is applied, and the device is activated by the control screen 5; using the upper unit 2 to realize the ordered material of the insulator and bamboo row, convenient to bundle the package. Next, the bamboo row is bundled in the periphery of the insulator using the bundling unit 3, and then the wire of the bamboo row is tightened by the fastening unit 4, and finally the insulator is col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com