Cigarette stacking mechanism

A carton and stacking technology, which is applied in packaging and other directions, can solve the problems of easy cigarette jamming, low stability, and low efficiency, and achieve the effects of good linkage between structures, reduced production costs, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

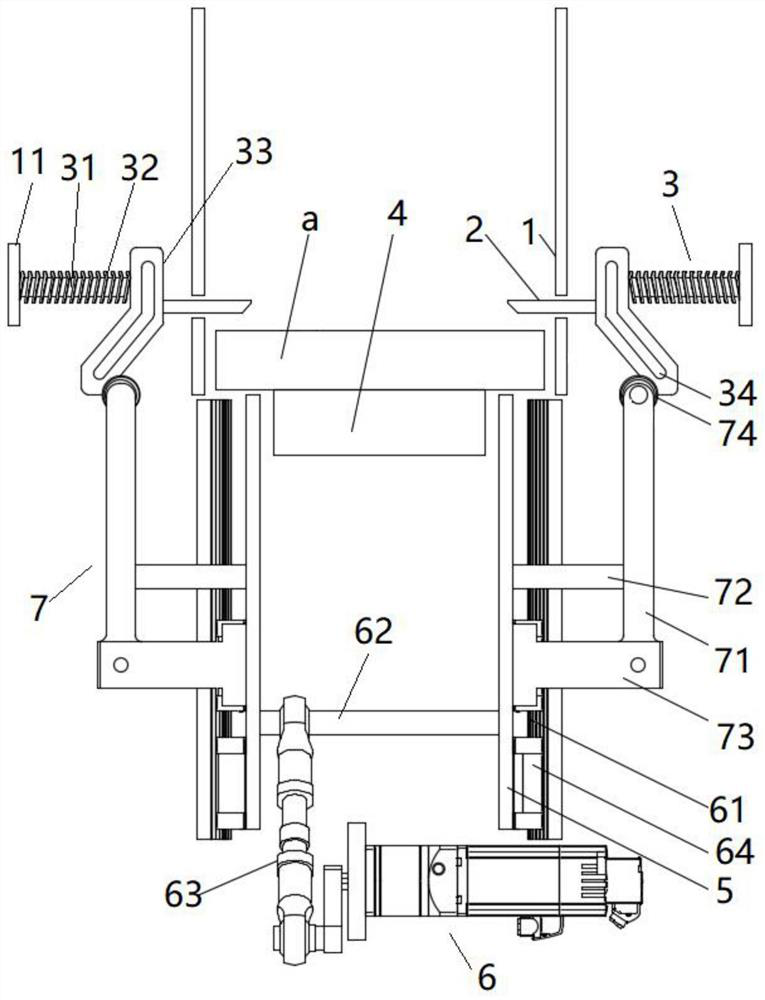

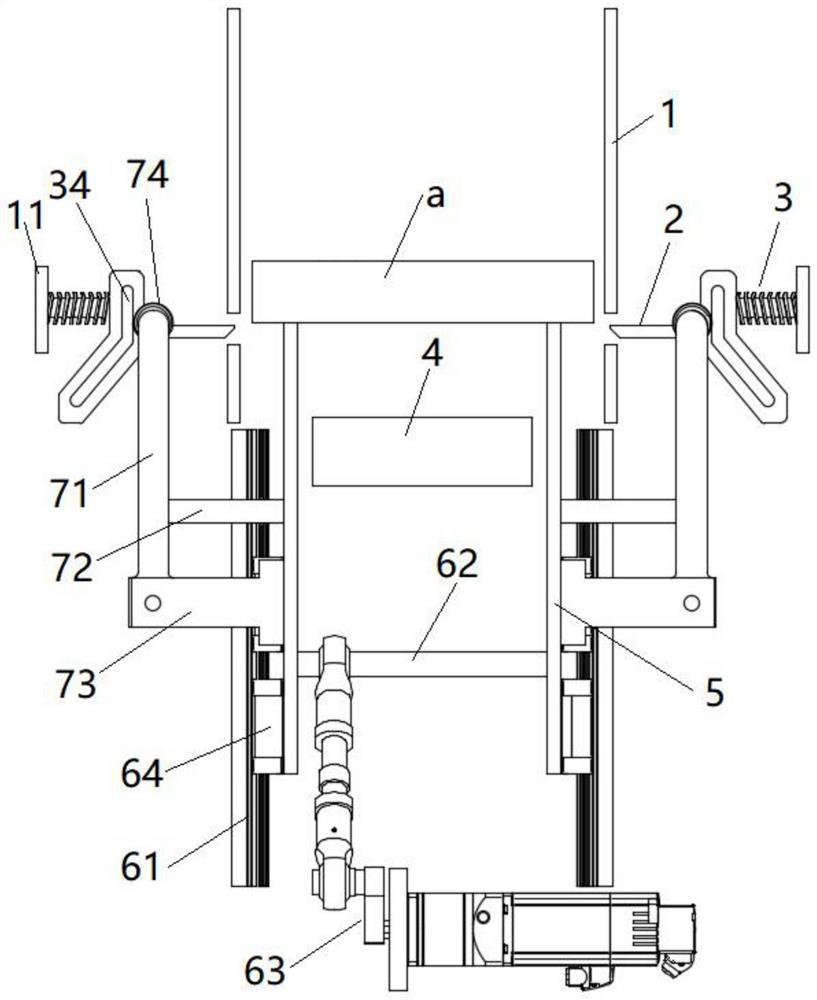

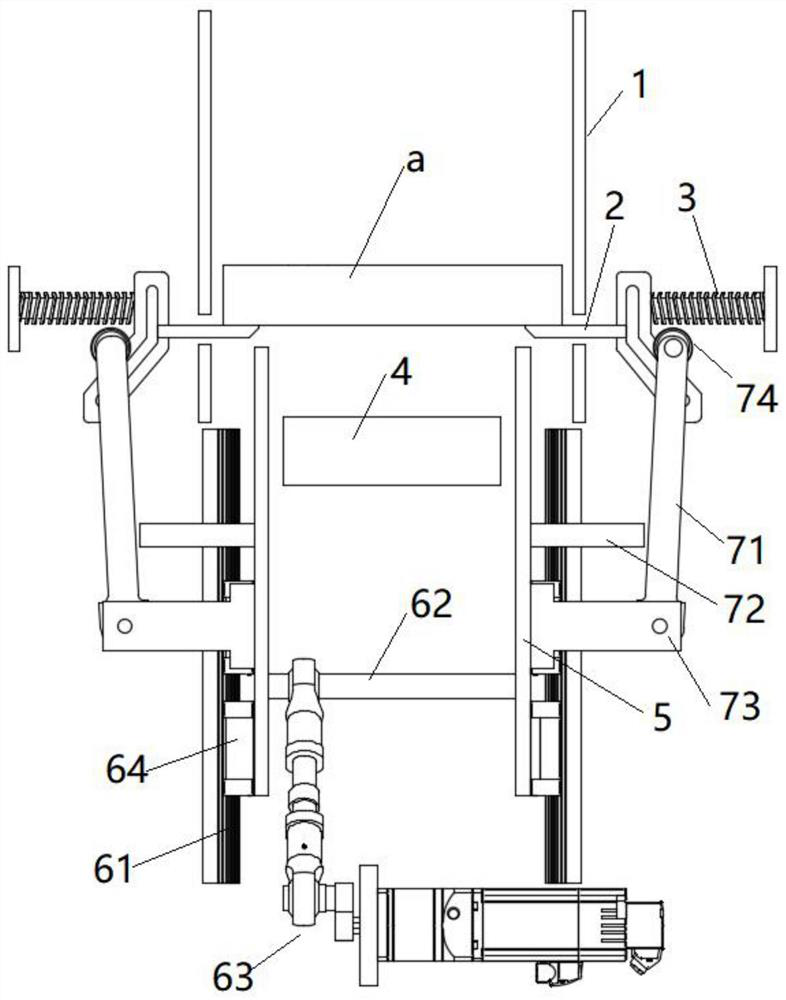

[0022] Example: such as Figures 1 to 3 As shown, the cigarette stacking mechanism of this embodiment includes a limiting plate 1, two of which are arranged vertically and parallel to each other, and the sides of the lower parts of the two limiting plates 1 are respectively There is an installation carrier 11; a cigarette holder 2, two of the above-mentioned cigarette holders 2 are provided, and they respectively horizontally pass through the perforations fitted at the same height at the lower part of the two above-mentioned limiting plates 1, and the two above-mentioned cigarette holders 2 are respectively Connect with the above-mentioned installation carrier 11 on the corresponding side through the elastic telescopic member 3; the conveying line 4, the discharge end of the above-mentioned conveying line 4 extends horizontally to the lower part between the two above-mentioned limit plates 1, and is located below the above-mentioned perforation; the top plate 5 The above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com