Earth rammer for civil engineering

A technology of civil engineering and earth ramming machine, which is applied in basic structure engineering, soil protection, construction, etc. It can solve the problems of reducing the effect of ramming and leaving unrammed ground, so as to improve the effect of ramming and eliminate potential safety hazards , to avoid the effect of unstable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Here, this embodiment discloses a rammed earth machine for civil engineering.

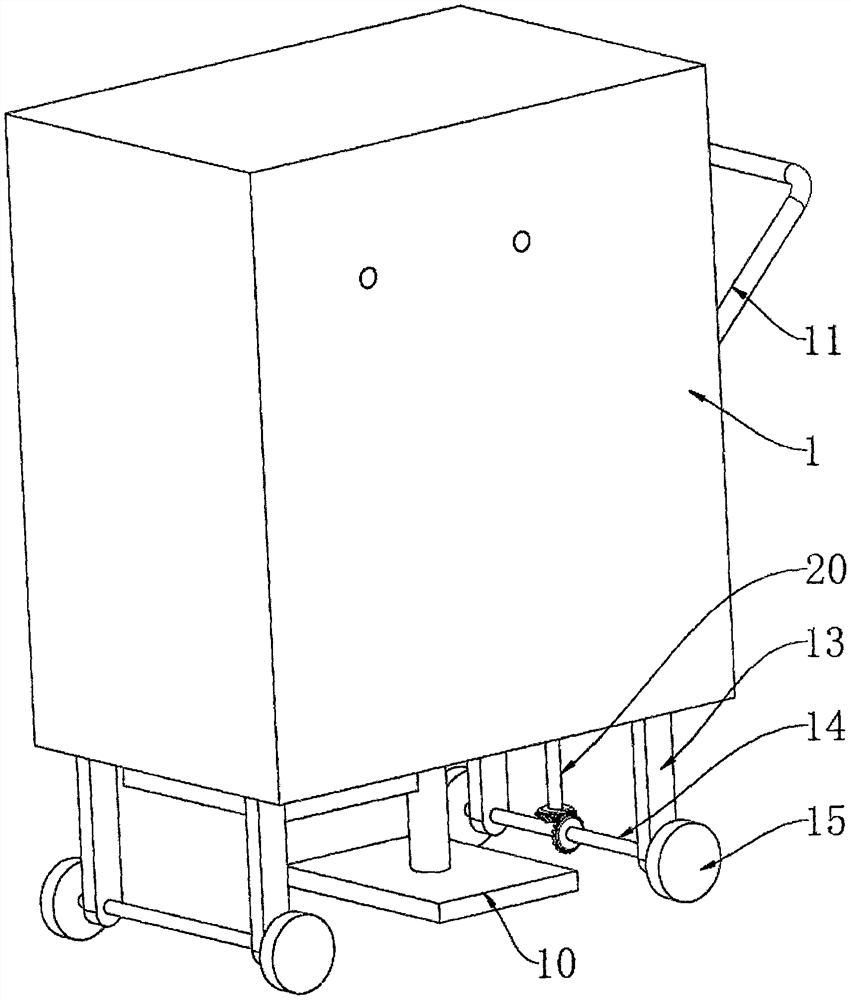

[0034] The invention comprises a protective housing 1 .

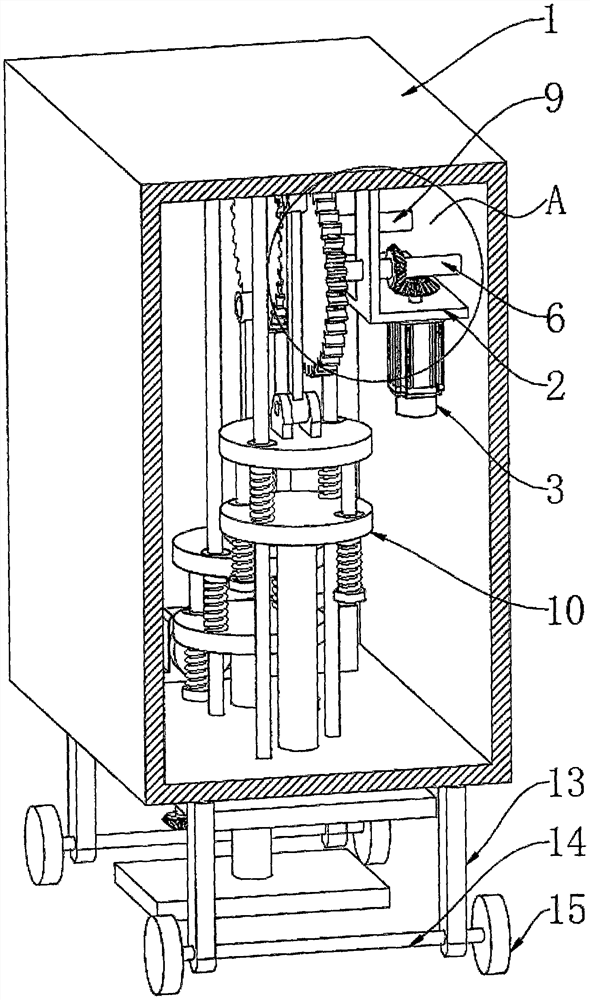

[0035] see Figure 3-4 Shown:

[0036] One side of the protective shell 1 is welded with an L-shaped fixed plate 2, and the bottom of the L-shaped fixed plate 2 is fixed with a rammed earth drive motor 3, and the output end of the rammed earth drive motor 3 is fixed with a first driving bevel gear 4. The top of the driving bevel gear 4 is meshed with the first driven bevel gear 5, and the inside of the first driven bevel gear 5 is welded with the driving central shaft 6, and the driving central shaft 6 is away from the side of the first driving bevel gear 4 The driving spur gear 7 is welded and connected, and one end of the driving spur gear 7 is meshed with the driven spur gear 8, and one side of the driven spur gear 8 is welded and connected with the driven central shaft 9, and the protective shell 1 and the driving central shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com