Soft soil foundation explosive point cavitation and dynamic compaction method and complete device thereof

A technology of soft soil foundation and bursting point, which is applied in the field of construction engineering, can solve the problems of easy to produce rubber soil, increase drainage channels such as plastic drainage boards, and poor effect, so as to improve the effect of tamping, improve the depth of tamping and construction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, a kind of explosive cavitation dynamic compaction method of soft soil foundation

[0029] A kind of method for explosive cavitation dynamic compaction of soft ground, comprising the following steps,

[0030] A. Use small drilling rigs to drill blast holes in soft soil foundation. The drilling depth of the blast holes exceeds 1 meter according to the design to strengthen the stratum. Put multiple emulsion explosives, keep the distance between each emulsion explosive in the blast hole at 3 meters, and seal it with cement at a distance of 3 meters from the hole of the blast hole.

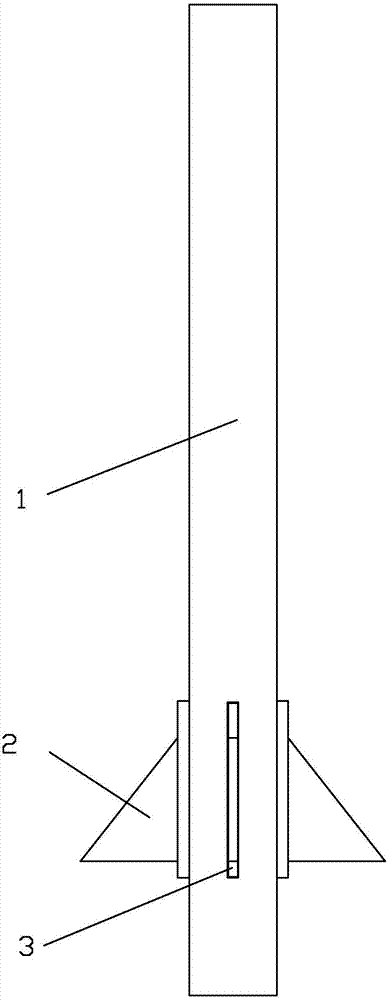

[0031] B. Install the protective tube 1, select the integral round steel protective tube (such as figure 1 shown), hoist the protective tube 1 to the position of the blast hole, make the center of the protective tube 1 align with the blast hole, and make it sink into the soil layer under the action of its own weight, and set four sliding grooves on the outer side of the protective...

Embodiment 2

[0036] Embodiment 2, a blasting dynamic tamping linkage device,

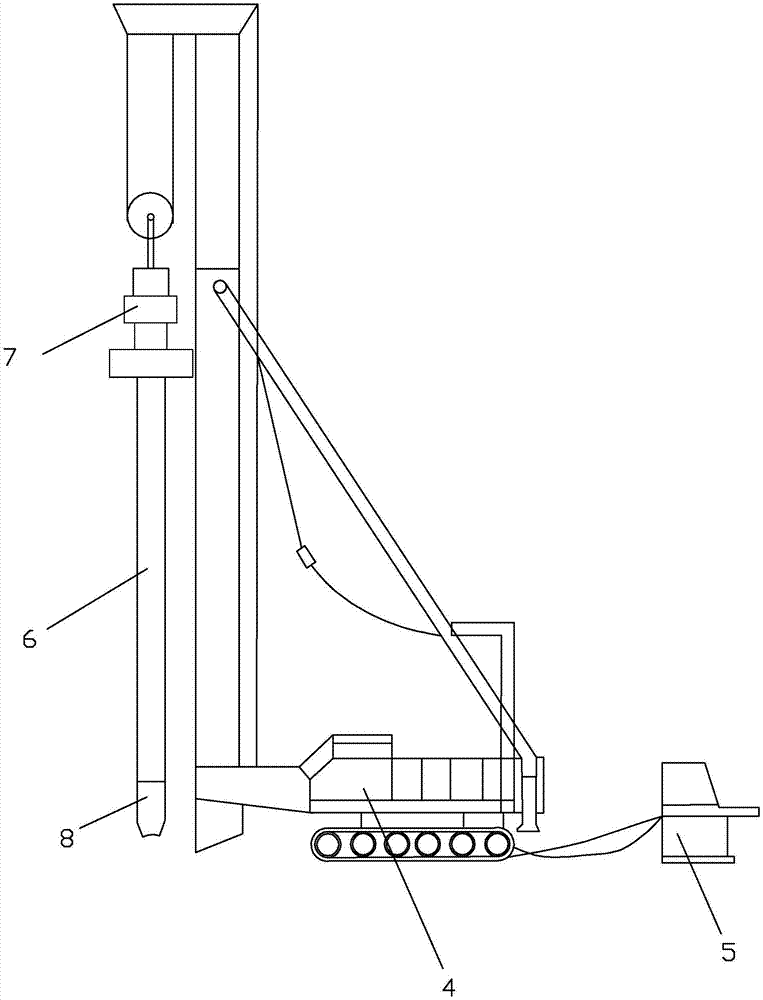

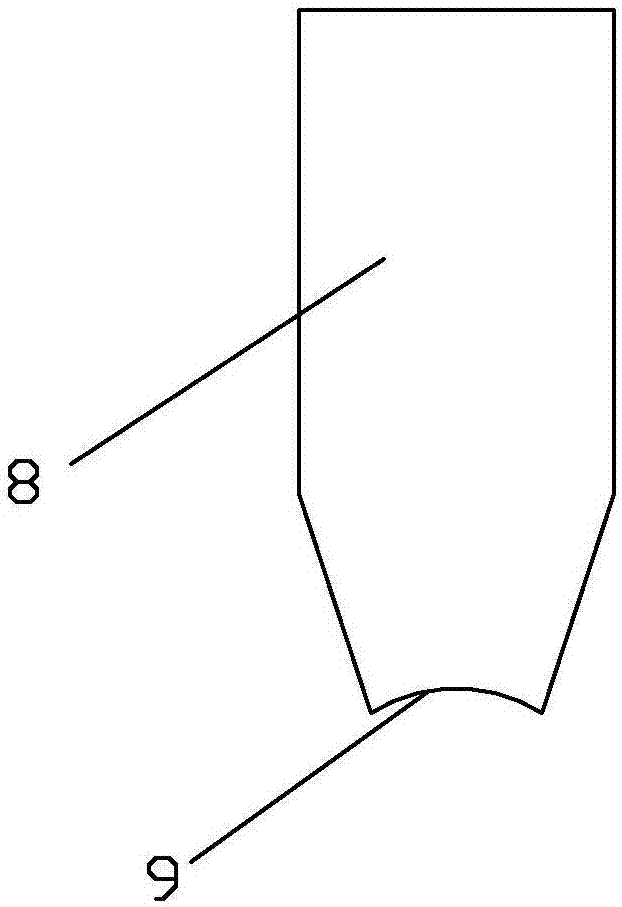

[0037] like Figure 1~3 As shown, a blasting dynamic tamping linkage device includes a crane 4, a decoupling device 7, a decoupling control device, a special-shaped weight 6 with a blunt head 8, a differential control detonator, and a controller, a controller, a differential control The detonators are all arranged in the console 5, and the controller controls the linkage between the decoupling control device and the differential control detonators. The controller automatically sets the delayed detonation time according to the lifting height of the special-shaped heavy hammer 6 through the program. The delayed detonation time is the free fall time from the special-shaped heavy hammer 6 from the lifting height to 1 meter above the ground. The special-shaped weight 6 with a blunt head 8 is connected to the hook of the crane 4 through a decoupling device 7, the decoupling device 7 is controlled by the decoupling co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com