Low-frequency shock-absorbing seismic super-glume structure

A kind of plate structure and ultra-bright technology, which is applied in the field of low-frequency shock absorption and earthquake ultra-bright plate structure, can solve the problems of uneconomical and low application type, and achieve the effects of material saving, consumption saving and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

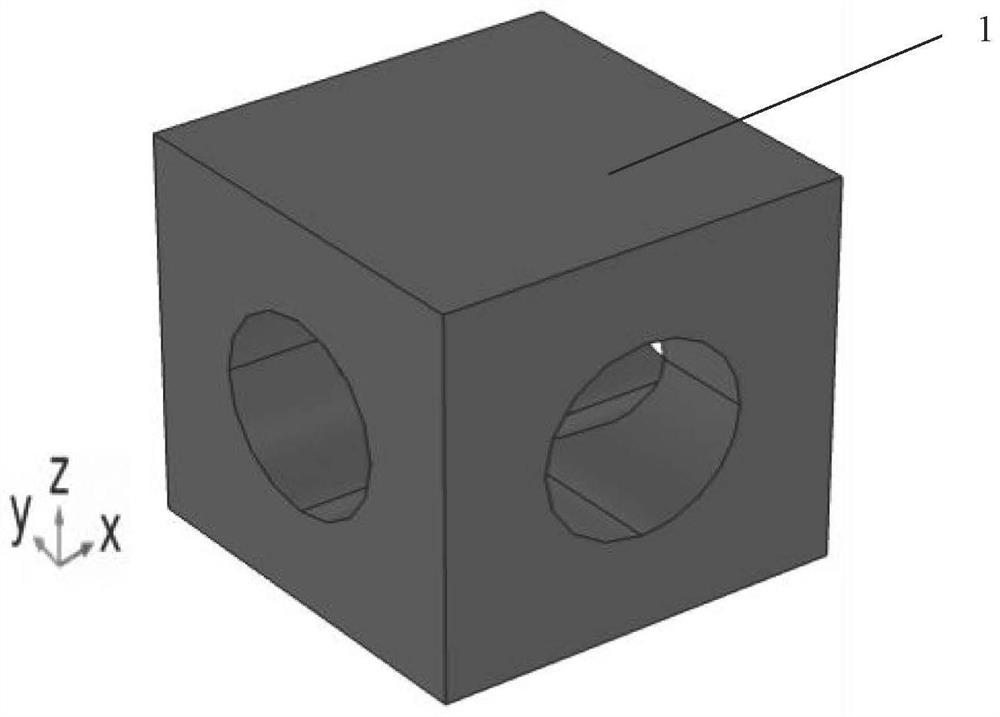

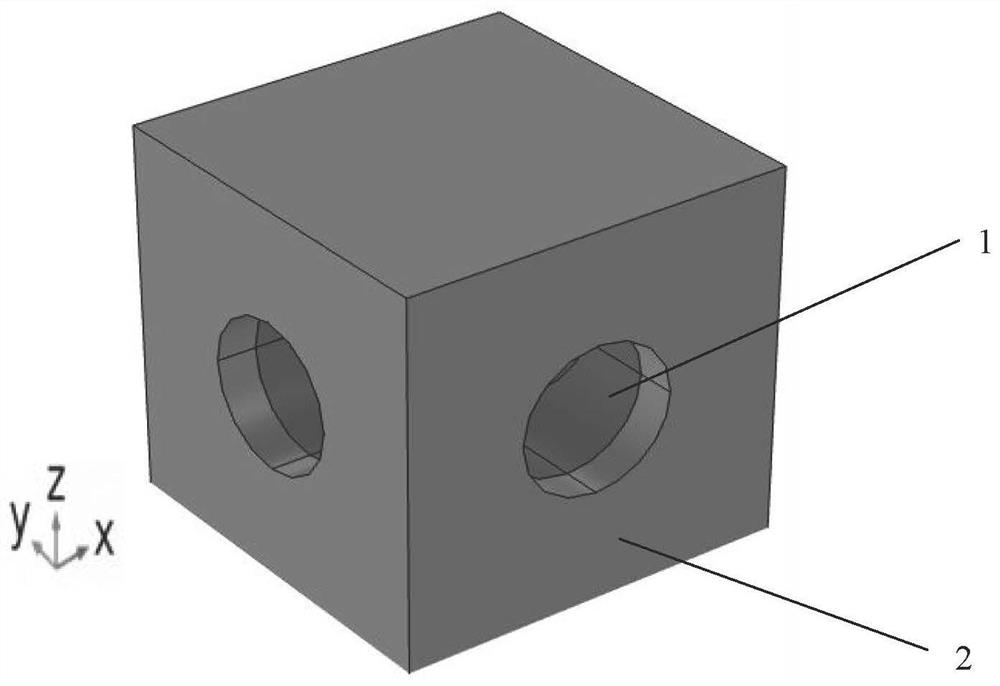

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings: the low-frequency shock-absorbing supergrain plate structure unit cell includes a steel core (1) with a cylindrical through hole and a rubber layer (2).

[0032] First, the steel block is arranged at the core position, and the steel block is a cube with a side length of 0.8m. Through technological means, two cylindrical through holes are respectively opened on the four vertical sides of the steel block.

[0033] Afterwards, a rubber layer (1) is coated on the outer side of the perforated steel core (1). The inside of the rubber layer (2) is in close contact with the outer surface of the steel core (1). The four vertical surfaces of the rubber layer (2) are opened along the side hole positions of the steel core (1).

[0034] The body centers of the steel core (1) with side holes and the rubber layer (2) coincide with each other.

[0035] see figure 2 and image 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com