Assembled house

A technology for houses and wall panels, applied in the field of assembled houses, can solve the problems of limited design form, difficult alignment and assembly, and inconvenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to achieve the above-mentioned purpose and effect, the technical means and structure adopted by the present invention, the features and functions of the preferred embodiments of the present invention will be described in detail as follows in order to facilitate a complete understanding.

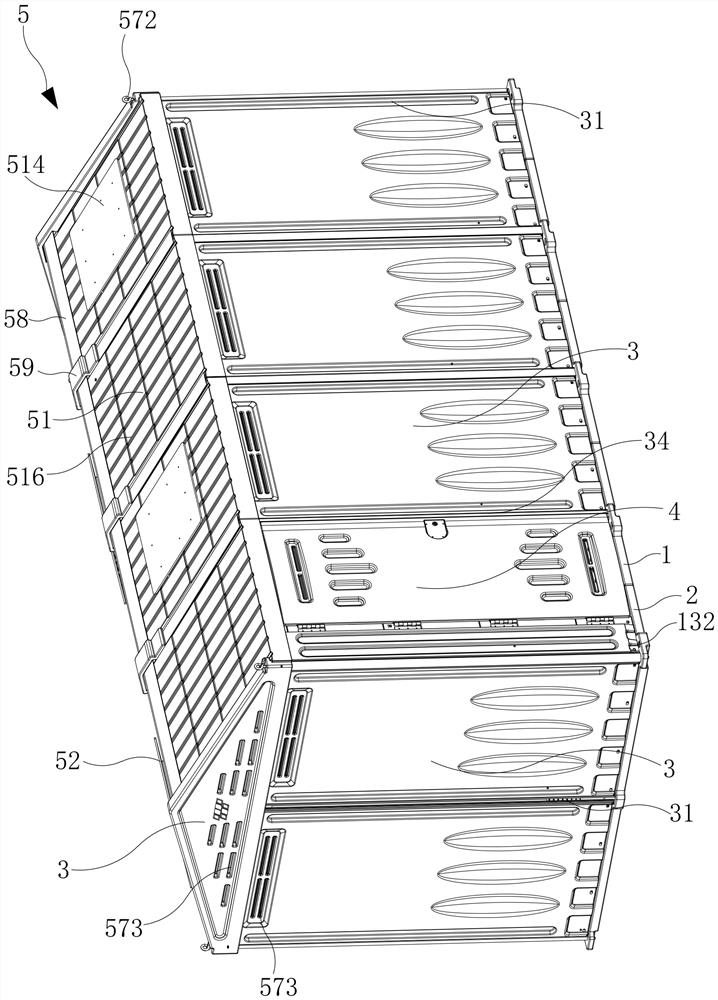

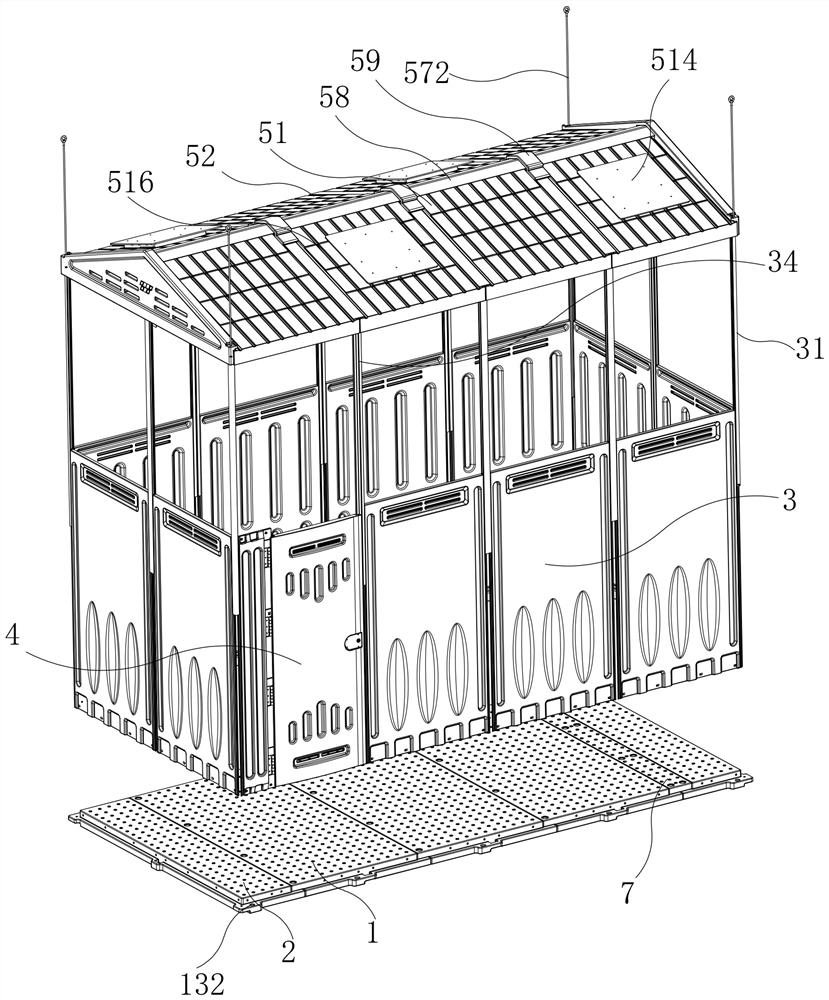

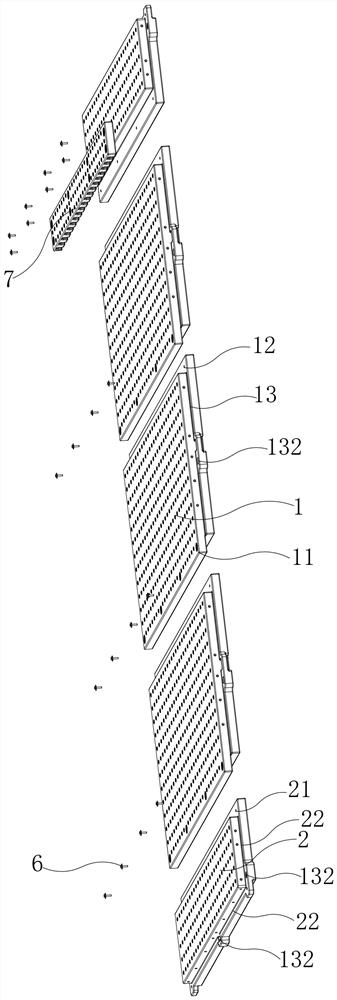

[0068] see Figure 1 to Figure 17 As shown, the present invention discloses an assembled house, comprising: a plurality of intermediate bases 1, two side bases 2, a plurality of wall panels 3, at least one door panel 4, and a top cover assembly 5, the intermediate base 1, the block The base, the wall panel 3, the door panel 4 and the top cover assembly 5 are all made of plastic, and one of the opposite sides of the middle base 1 forms an upper extension plate 11 and a lower extension plate 12 respectively, and the other opposite side of the middle base 1 Both sides are respectively extended to form a wall support plate 13, one side of the side base 2 forms a lower extension pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com