Fabricated reinforced wall steering device and fabrication method

A steering device and assembled technology, which is applied in the direction of walls, building components, buildings, etc., can solve problems such as easy deviation, insufficient strength of steering walls, and influence on construction progress, and achieve the effect of insufficient steering strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

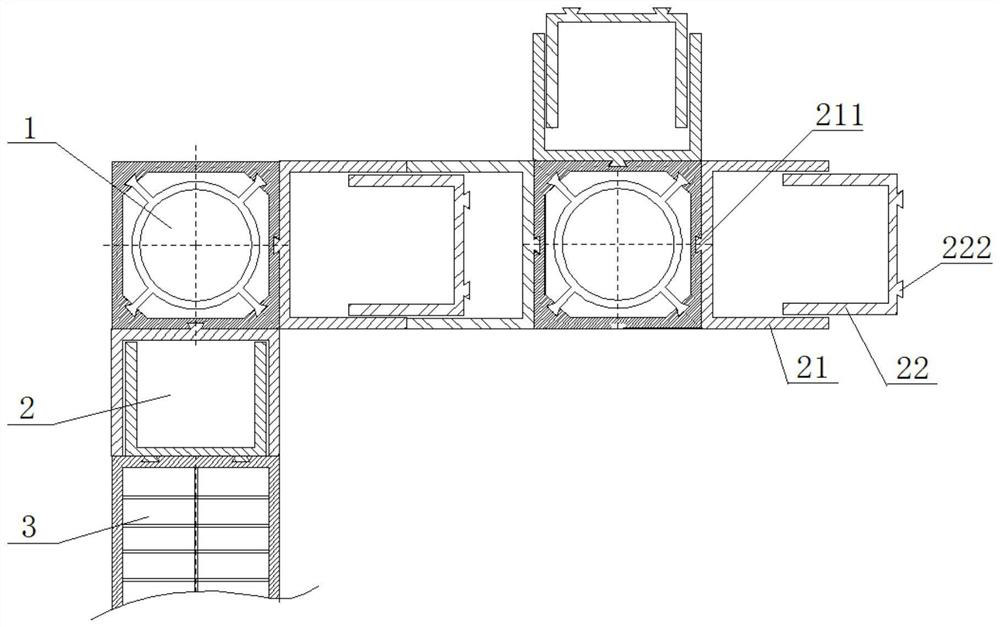

[0027] Such as figure 1 As shown, the assembled reinforced wall steering device of the present invention includes:

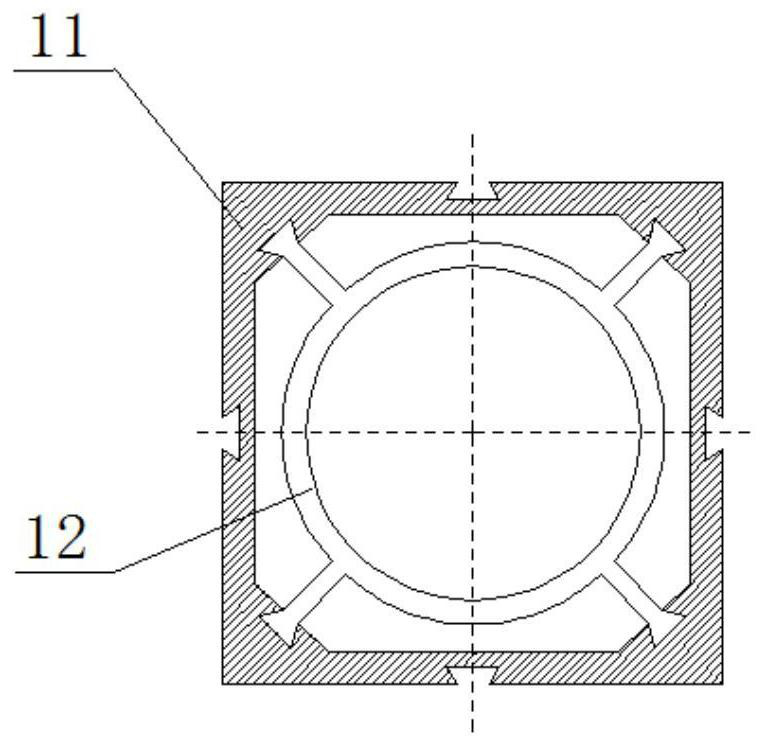

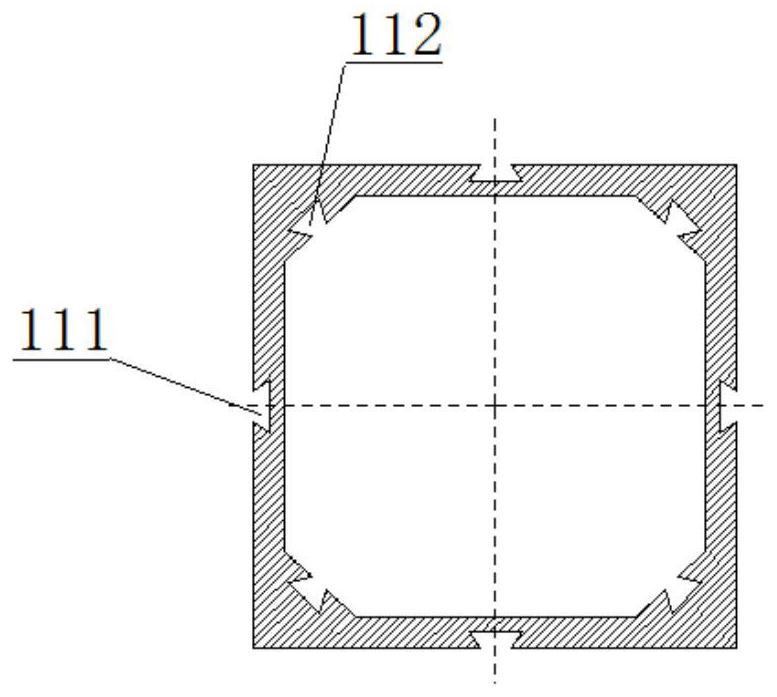

[0028] Turning to the wall 1, the turning wall 1 includes a square wall 11 and a turning rib 12 vertically inserted in the square wall 11. The four inner corners of the square wall 11 are provided with inner grooves 111 and the inner grooves 111 and the turning ribs 12 The four inner ribs 121 are mated and connected, and at least two outer grooves 112 are provided on the side of the square wall 11;

[0029] Nested wall body 2, nested wall body 2 comprises inner cover body 22 and outer cover body 21, and outer cover body 21 is provided with outer protrusion 211 along the other end of long side, and the outer protrusion 211 of outer cover body 21 and square wall 11 The outer groove 112 is matched and connected; the other end of the outer casing 21 along the long side is opposite to the adjacent outer casing 21 and spliced as a whole, and the inner casing 22 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com