Plastic stop valve

A cut-off valve, plastic technology, applied in the direction of lifting valves, valve devices, engine components, etc., can solve problems such as insufficient connection strength, affecting product quality and service life, and achieve the effect of solving insufficient connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

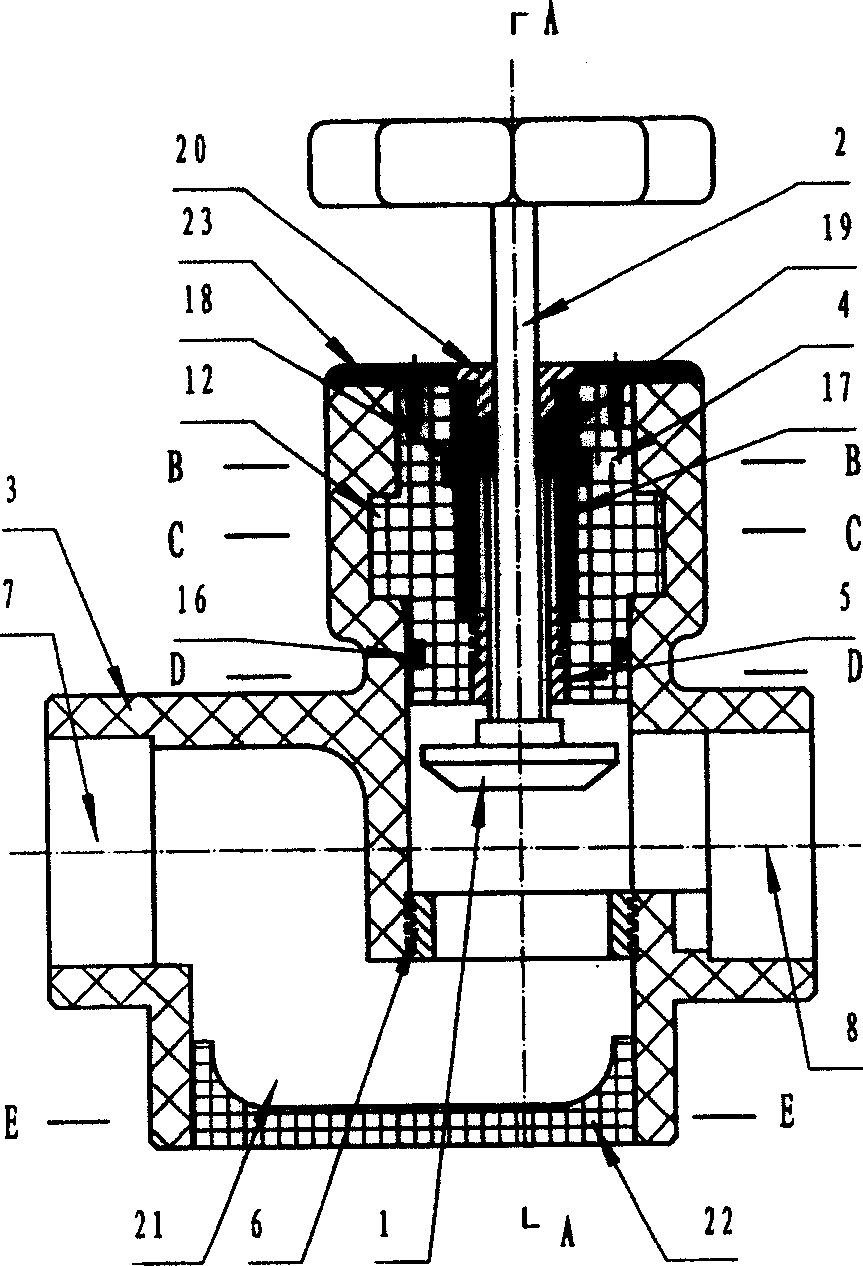

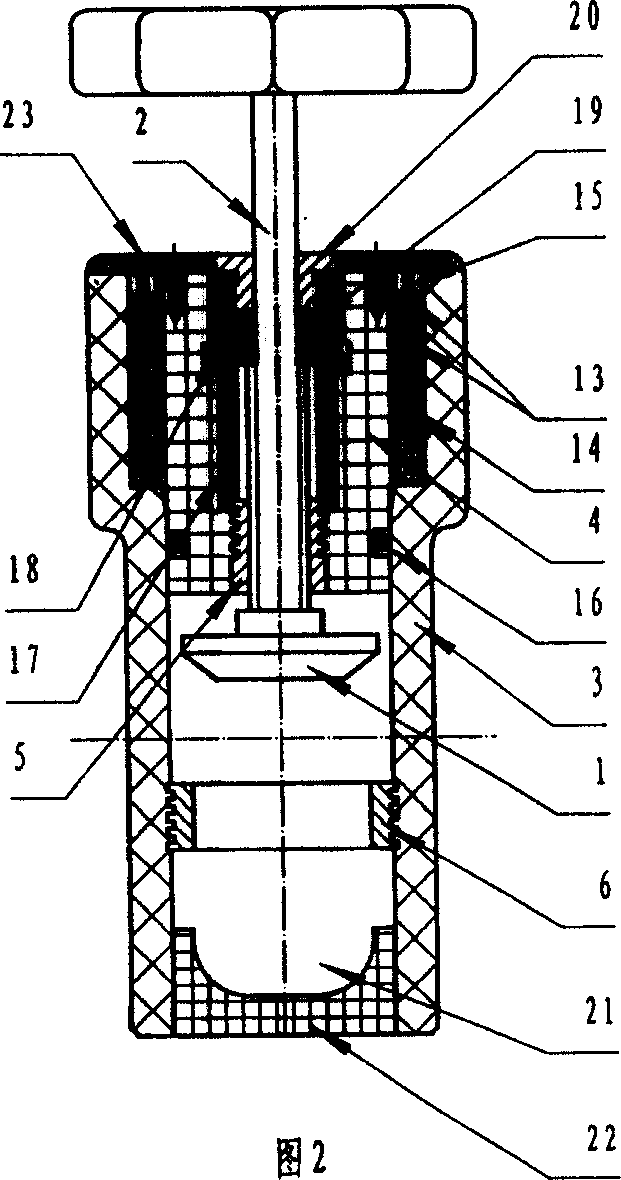

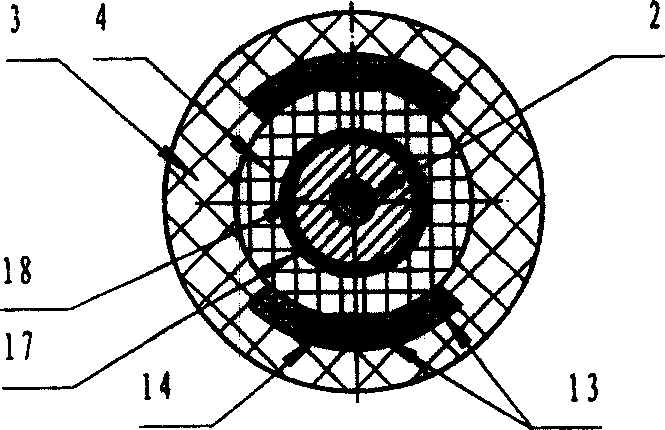

Embodiment 1

[0044] Embodiment 1: as Figure 1~1As shown in 3, the plastic globe valve in this embodiment has a valve cover, a valve disc 1, a valve stem 2 and a plastic valve body 3, and the plastic valve body 3 and the valve cover are connected through a valve cover connection structure. The bonnet is at least composed of a plastic bonnet base 4 and a valve stem nut insert 5 whose periphery is embedded and fixed on the plastic bonnet base. Screw holes are provided on the valve stem nut insert 5, and the valve stem 2 is sleeved on the In the screw hole, the external thread on the valve stem 2 cooperates with the internal thread of the screw hole to form a kinematic pair, and a valve seat 6 is arranged in the plastic valve body 3, and the valve seat 6 has a valve seat opening. The valve seat opening is opposite to the disc 1 located at the bottom of the valve stem, and the two ends of the plastic valve body 3 respectively have an inlet port 7 and an outlet port 8 communicating with the val...

Embodiment 2

[0053] Embodiment 2: as Figures 14-19 As shown, this embodiment is similar to Embodiment 1, the difference is that there are eight protrusions 12 on the side wall of the valve cover in this embodiment, and correspondingly, the above-mentioned grooves 11 leading to the recesses The number is also eight. At the same time, the valve seat 6 in this embodiment is no longer formed by a valve seat insert whose periphery is embedded in the plastic valve body, but is directly served by the plastic base material on the plastic valve body.

Embodiment 3

[0054] Embodiment 3: as Figure 20 As shown, the plastic shut-off valve in this embodiment is similar to that of Embodiment 2, the difference is that the inner walls of the hot-melt socket-type inlet 7 and the hot-melt socket-type outlet 8 in this embodiment are both A heating wire 24 is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com