Asphalt concrete road reconstruction and extension roadbed construction process

A technology of asphalt concrete and construction technology, which can be used in infrastructure engineering, roads, roads, etc., and can solve the problems of insufficient connection strength of new and old roadbeds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

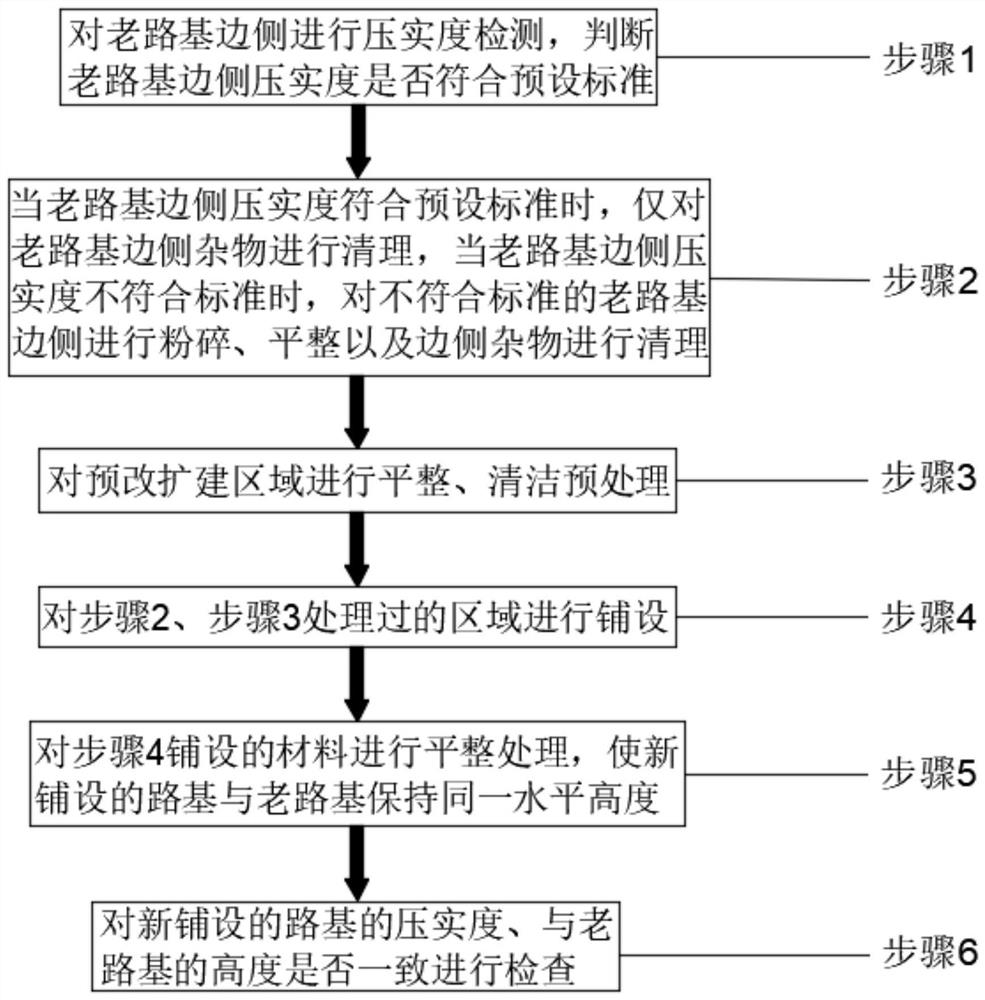

[0066] see Figure 1-2 , a kind of embodiment that the present invention provides: a kind of bituminous concrete highway rebuilds and expands subgrade construction technology, comprises the following steps:

[0067] Step 1: Check the compactness of the side of the old roadbed to determine whether the side compaction of the old roadbed meets the preset standard;

[0068] Step 2: When the side compaction of the old subgrade meets the preset standard, only clean up the debris on the side of the old subgrade, and when the side compaction of the old subgrade does not meet the standard, crush the side of the old subgrade that does not meet the standard , leveling and cleaning side debris;

[0069] Step 3: Level and clean the pre-renovation and expansion area;

[0070] Step 4: Pave the area treated in step 2 and step 3; for step 2, specifically, re-lay the side of the old roadbed when the side compaction degree of the old roadbed does not meet the standard;

[0071] Step 5: Leveli...

Embodiment 2

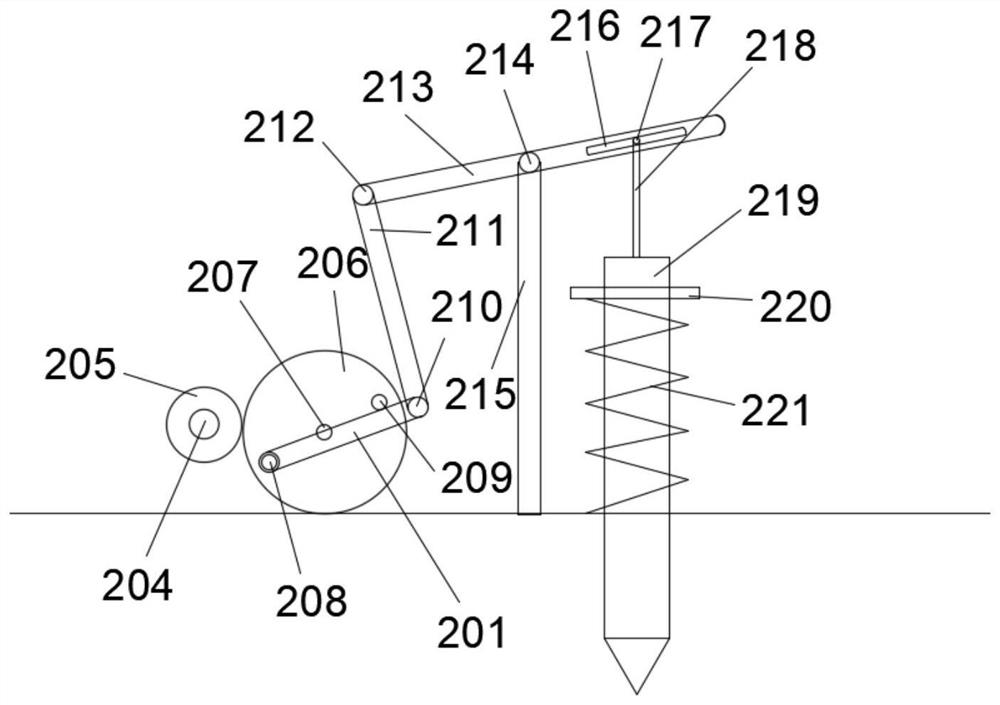

[0079] refer to Figure 2-5 , on the basis of the above-mentioned embodiment 1, the pulverizing device includes:

[0080] The first connecting rod 201, the second driving pulley 202, the second belt 203, the second driven pulley 204, the first gear 205, the second gear 206, the rotating shaft 207, the first joint 208, the block 209, the first Two joints 210, second connecting rod 211, third joint 212, third connecting rod 213, fourth joint 214, support rod 215, chute 216, slider 217, fourth connecting rod 218, crushing drill bit 219 , the first limit block 220, the tension spring 221;

[0081] The second driving pulley 202 is fixed on the transmission shaft 11, the second driving pulley 202 is connected with the second driven pulley 204 through the second belt 203, and the second driven pulley The pulley 204 is fixed to the first gear 205, and the first gear 205 meshes with the second gear 206;

[0082] The second gear 206 is connected to the inner wall of the housing 1 thr...

Embodiment 3

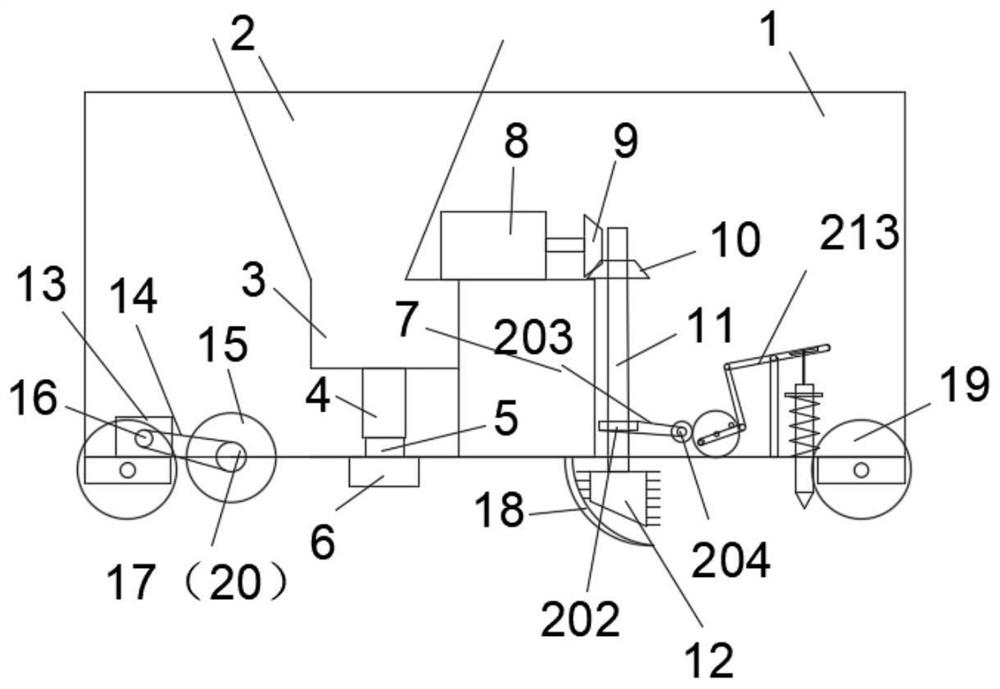

[0088] refer to figure 2 , on the basis of the above-mentioned embodiment 1, the blanking device includes a blanking chute 2, a feed box 3, a connecting pipe 4, a blanking switch 5, and a blanking port 6;

[0089]The lower chute 2 is fixed to the housing 1, the upper opening of the lower chute 2 is located outside the upper surface of the housing 1, the lower opening of the lower chute 2 is connected to the material box 3, the The lower part of the material box 3 is connected to the switch 5 through the communication pipe 4 , and the switch 5 is connected to the discharge opening 6 located outside the casing 1 and fixed to the casing 1 .

[0090] The working principle and beneficial effects of the above-mentioned technical scheme are as follows: the unloading device uses the unloading trough 2 to receive foreign materials, the material box 3 stores the material, and the unloading operation is performed through the connecting pipe 4 and the unloading port 6, and the unloading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com