Pipe ship connecting method suitable for deep sea mining

A deep-sea mining and pipe string technology, which is applied in the mining of minerals, special mining, pipes/pipe joints/fittings, etc., can solve the problems of excessive bending moment at the top of the hard pipe and damage to the hard pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

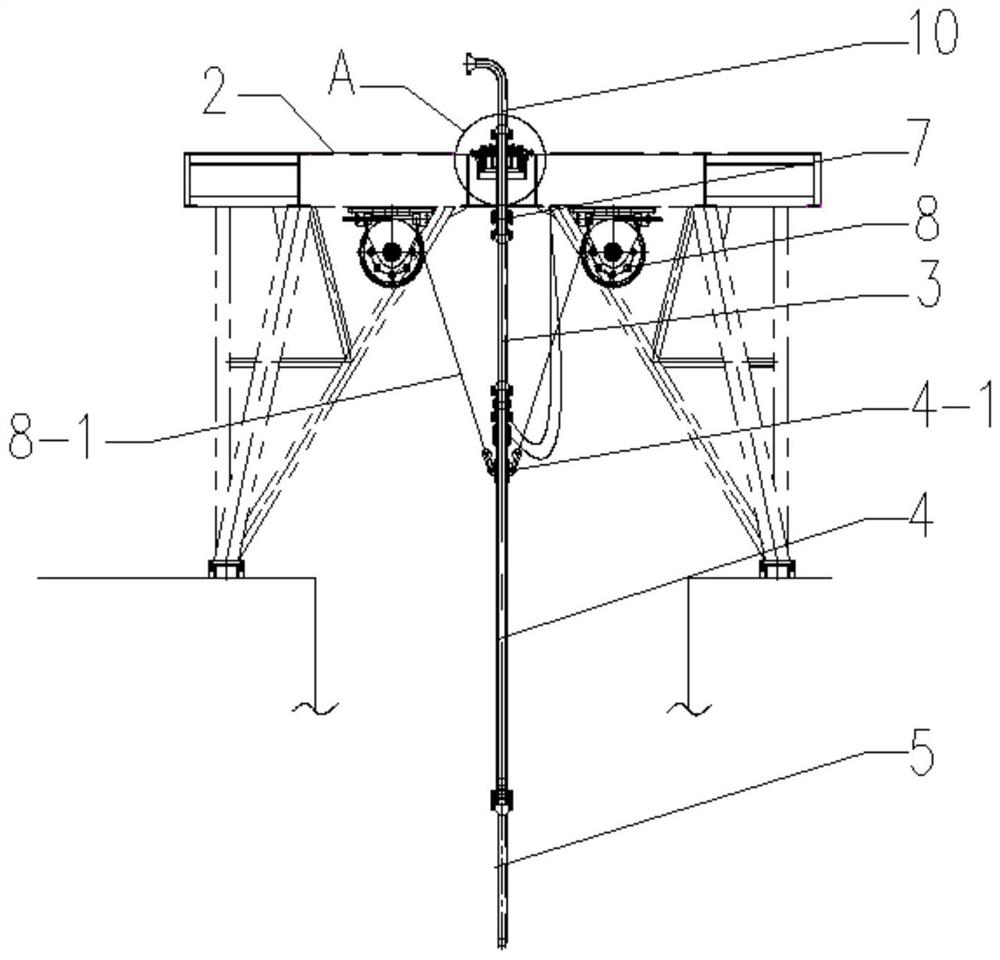

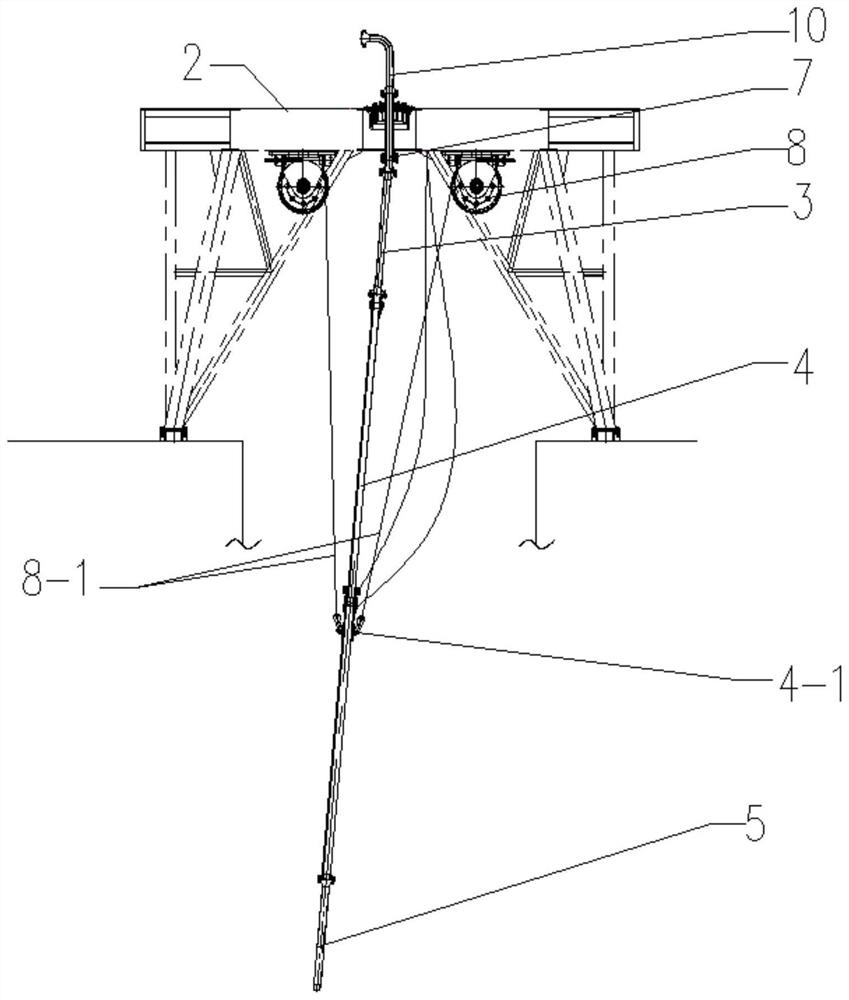

[0043] combine Figure 1 to Figure 3 As shown, a kind of pipe-ship coupling method suitable for deep-sea mining provided by the present invention comprises the following steps:

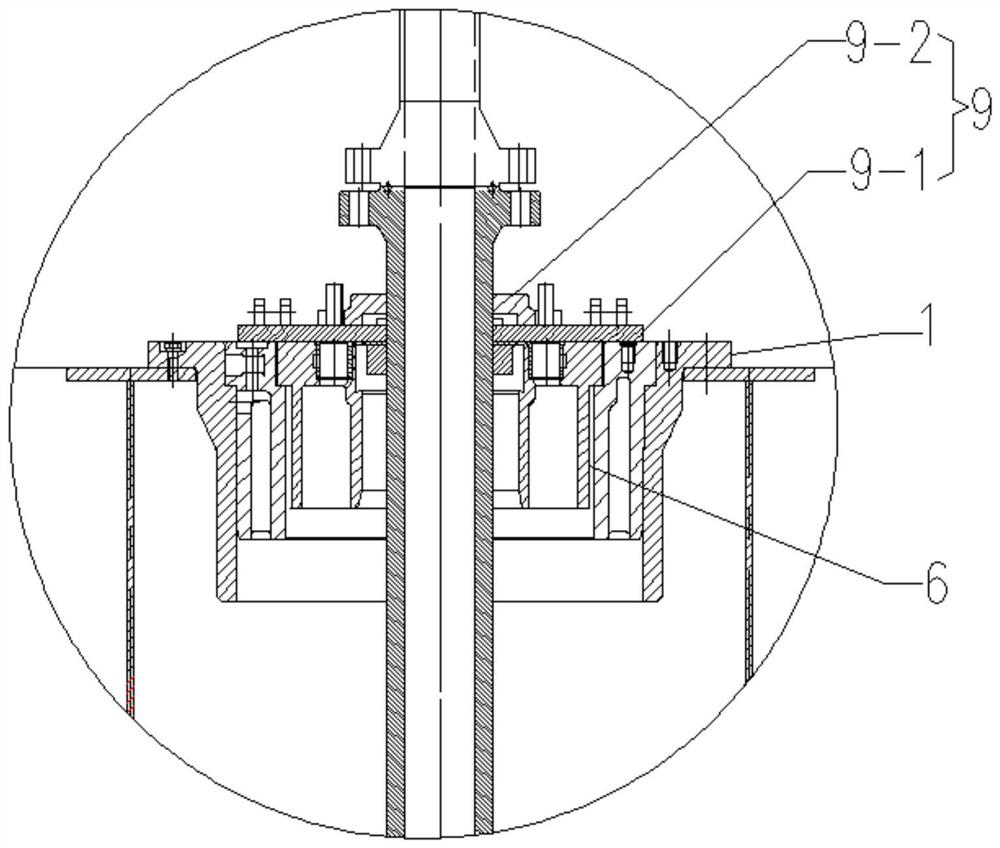

[0044] S1. After installing the support plate 1 on the mining platform 2, lower the adjusting nipple 3 and the telescopic device 4, connect the telescoping device 4 to the last hard pipe 5, and then lift the pipe composed of the adjusting nipple 3 and the telescoping device 4 string until the pup joint 3 is adjusted until the load-bearing shoulder is higher than the upper end surface of the support plate 1;

[0045] S2. Install the core bushing unit 6 in the support plate 1 to clamp and adjust the pup joint 3;

[0046] S3. After lowering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com