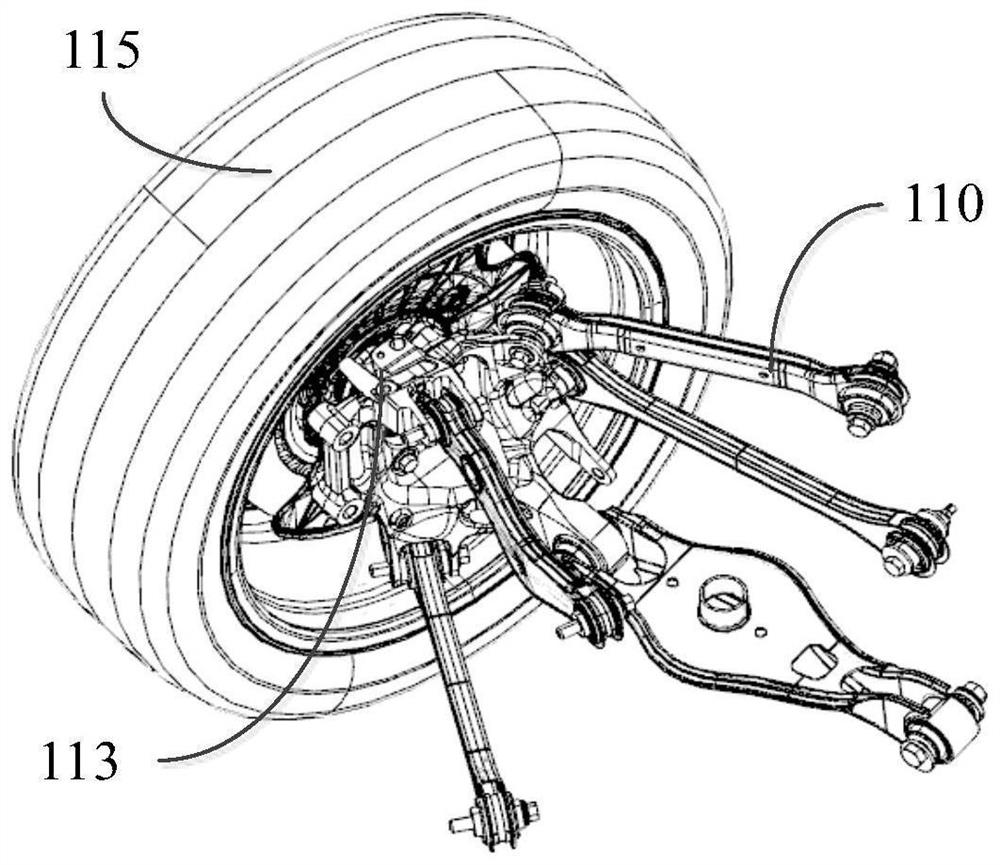

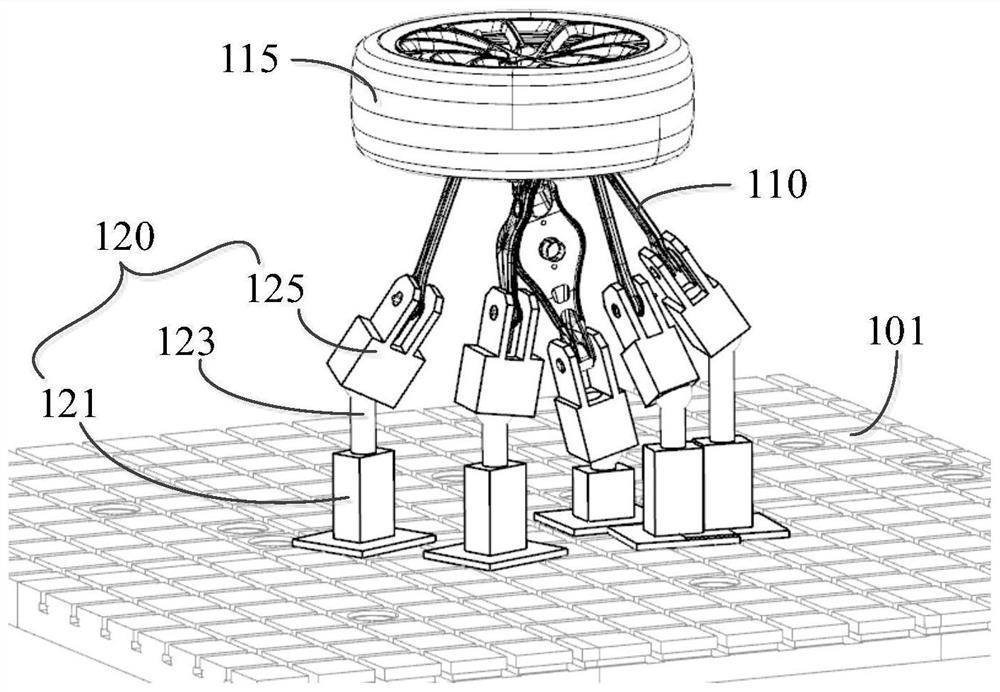

Multi-connecting-rod suspension strength test bed

A strength test, multi-link technology, used in vehicle suspension/shock absorber testing, vehicle testing, machine/structural component testing, etc. High cost, insufficient strength design and other problems, to achieve the effect of platformization, saving vehicle costs and related test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purposes, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the described embodiments It is a part of the embodiments of this application, not all of them. The components of the embodiments of the application generally described and illustrated in the figures herein may be arranged and designed in a variety of different configurations.

[0030] It should be noted that, in the case of no conflict, the features in the embodiments of the present application may be combined with each other.

[0031] During the design and development process of the parts on the vehicle, strength impact tests are required to pass the strength impact test to ensure that the parts will not crack, break and other strength failures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com