Patents

Literature

62 results about "Multi-link suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A multi-link suspension is a type of vehicle suspension design typically used in independent suspensions, using three or more lateral arms, and one or more longitudinal arms. A wider definition considers any independent suspensions having three control links or more multi-link suspensions. These arms do not have to be of equal length, and may be angled away from their "obvious" direction. It was first introduced in the late 1960s on the Mercedes-Benz C111 and later on their W201 and W124 series.

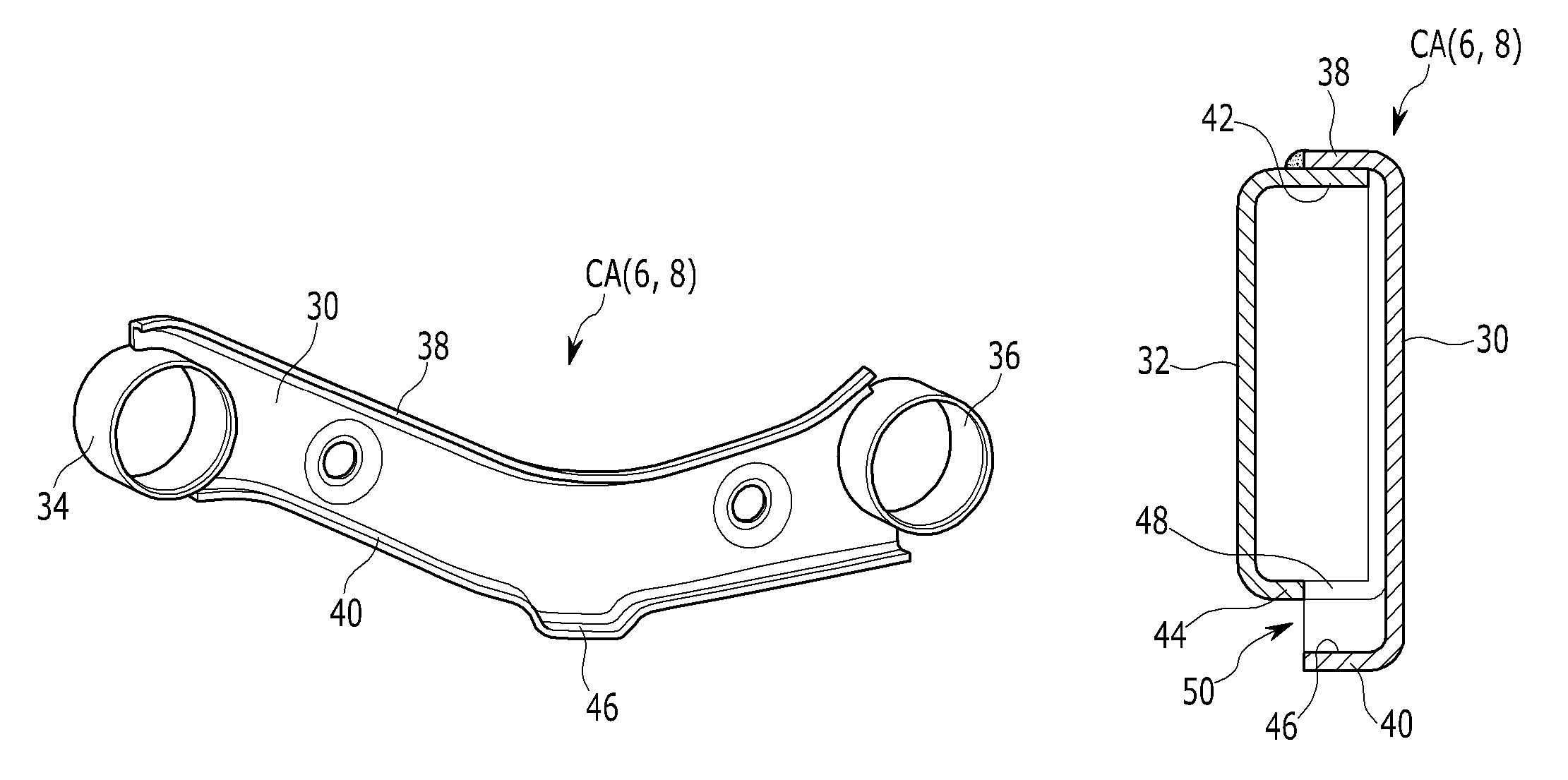

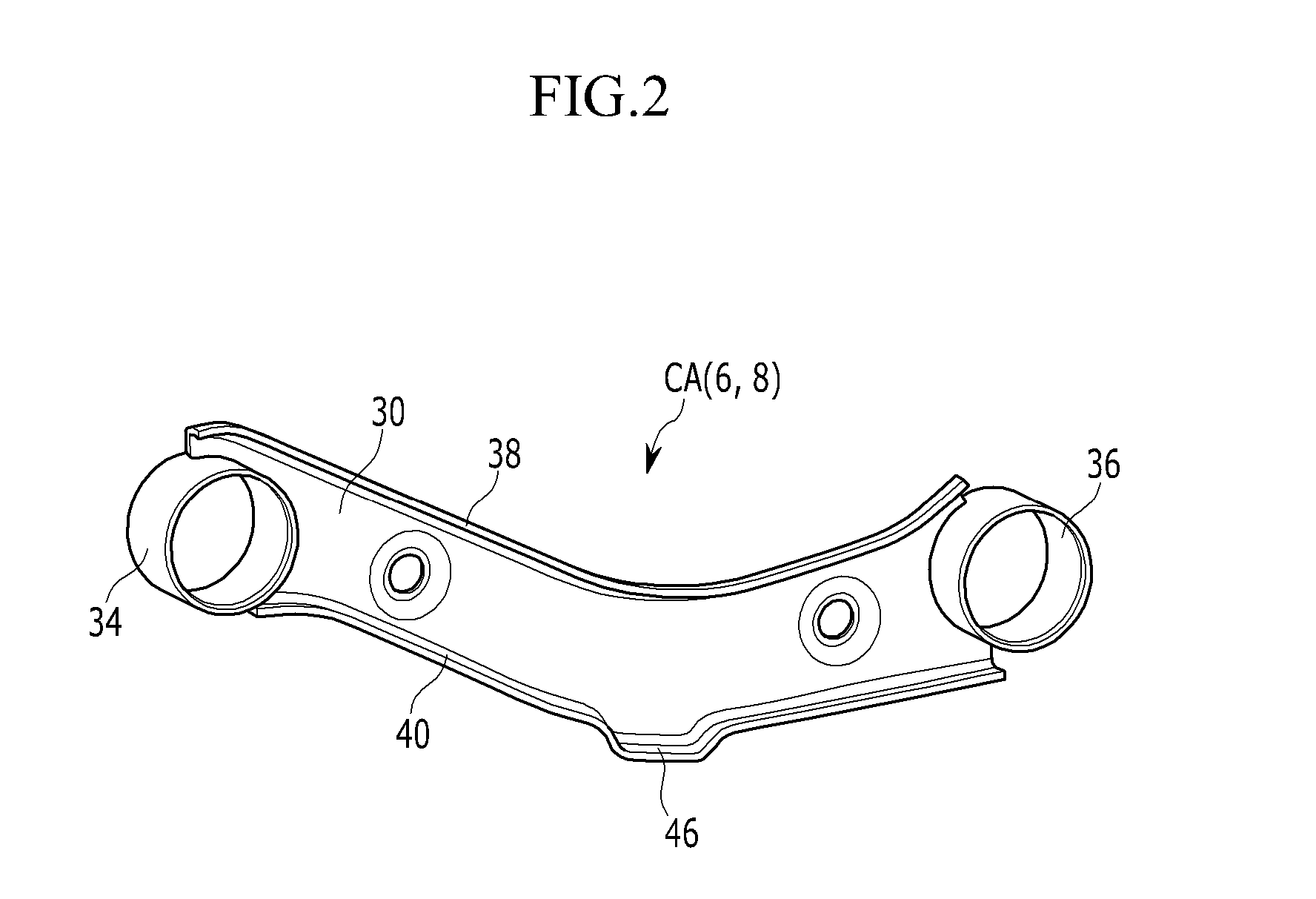

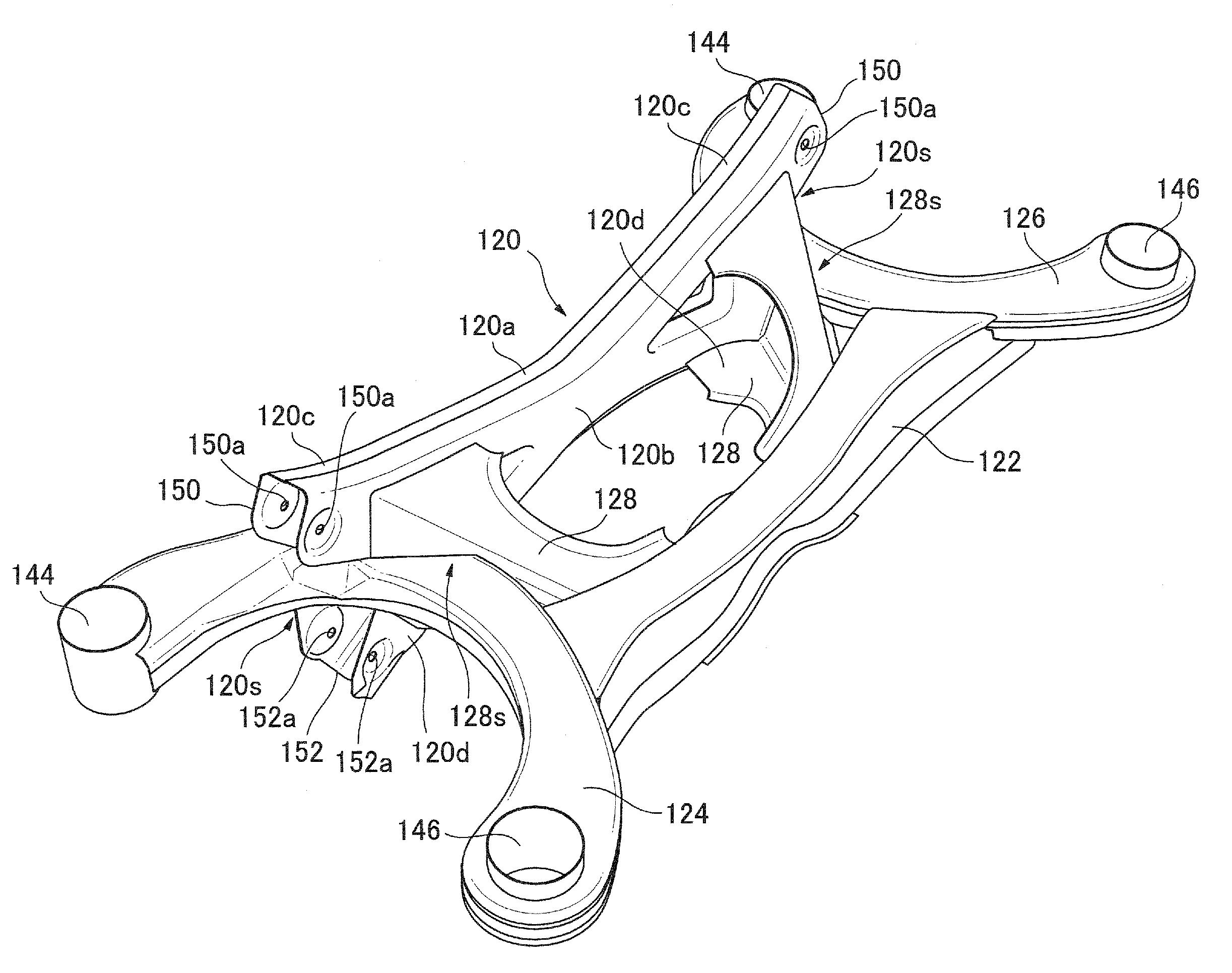

Control arm of multilink suspension system for vehicle

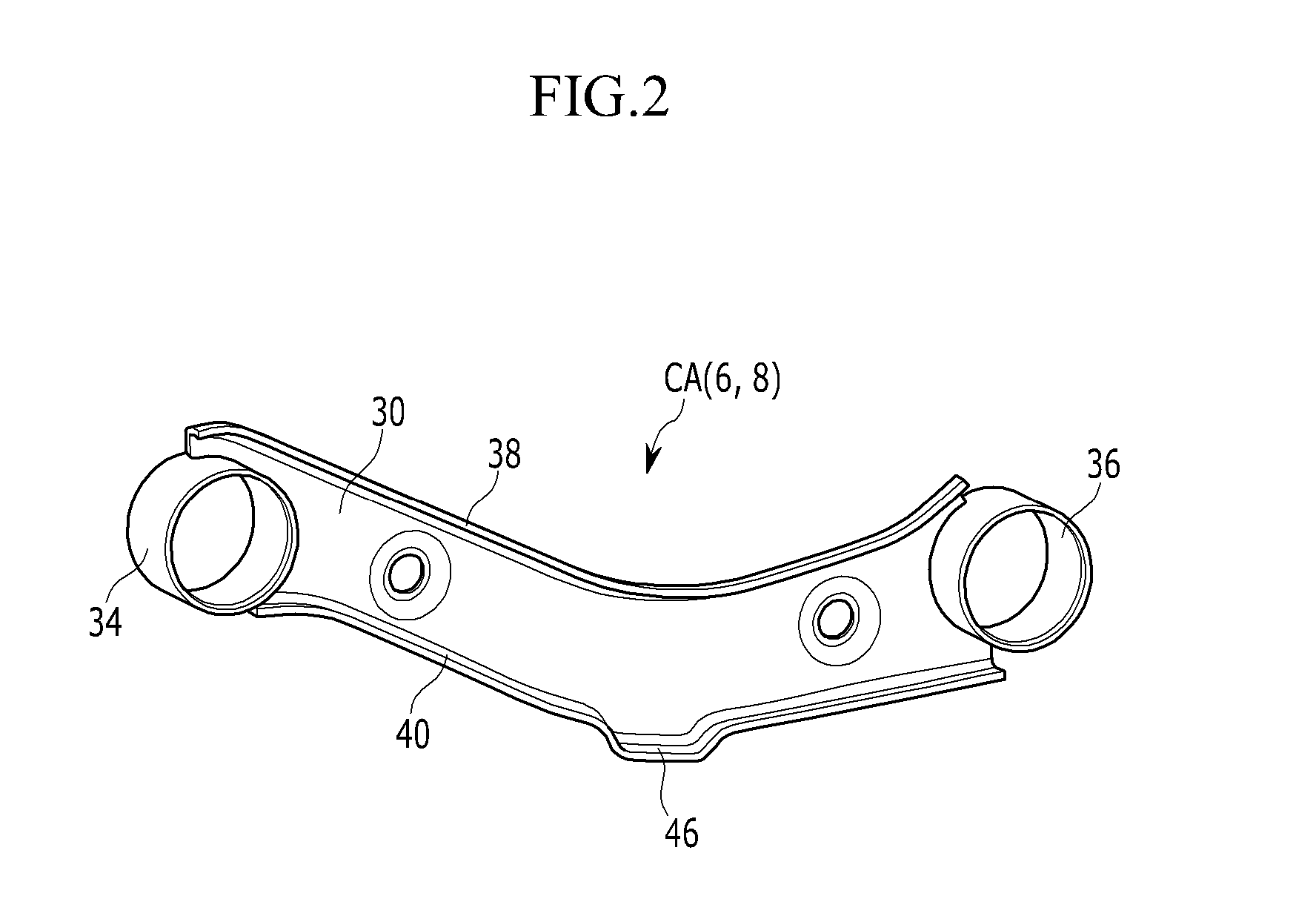

A control arm may be formed by assembling front and rear members respectively having upper and lower flanges so as to have a tubular cross-section, and a bending portion may be formed by bending the lower flange of the front member downwardly such that a drain hole is formed by the bending portion protruded downwardly when the front and rear members are assembled.

Owner:HYUNDAI MOTOR CO LTD +1

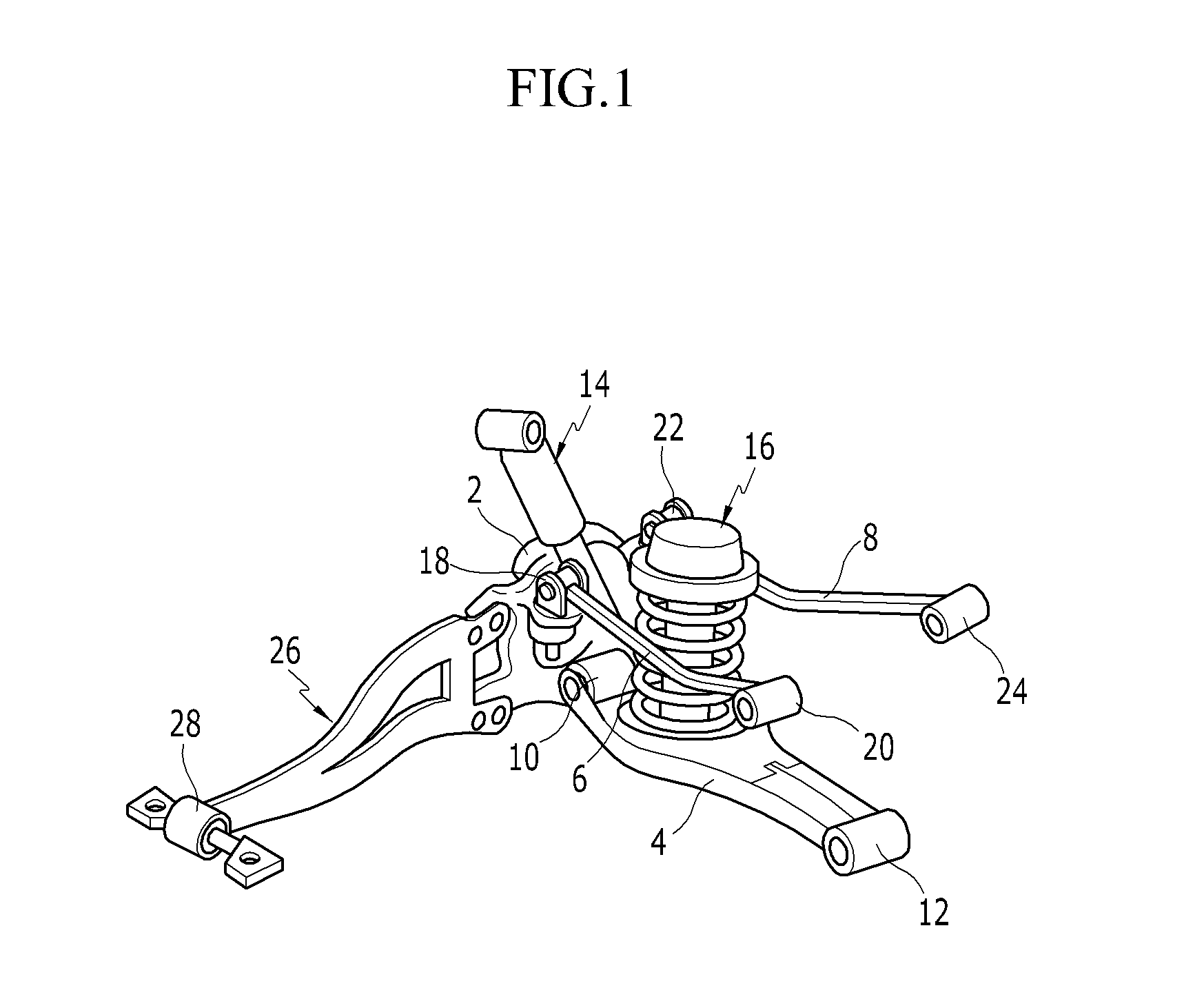

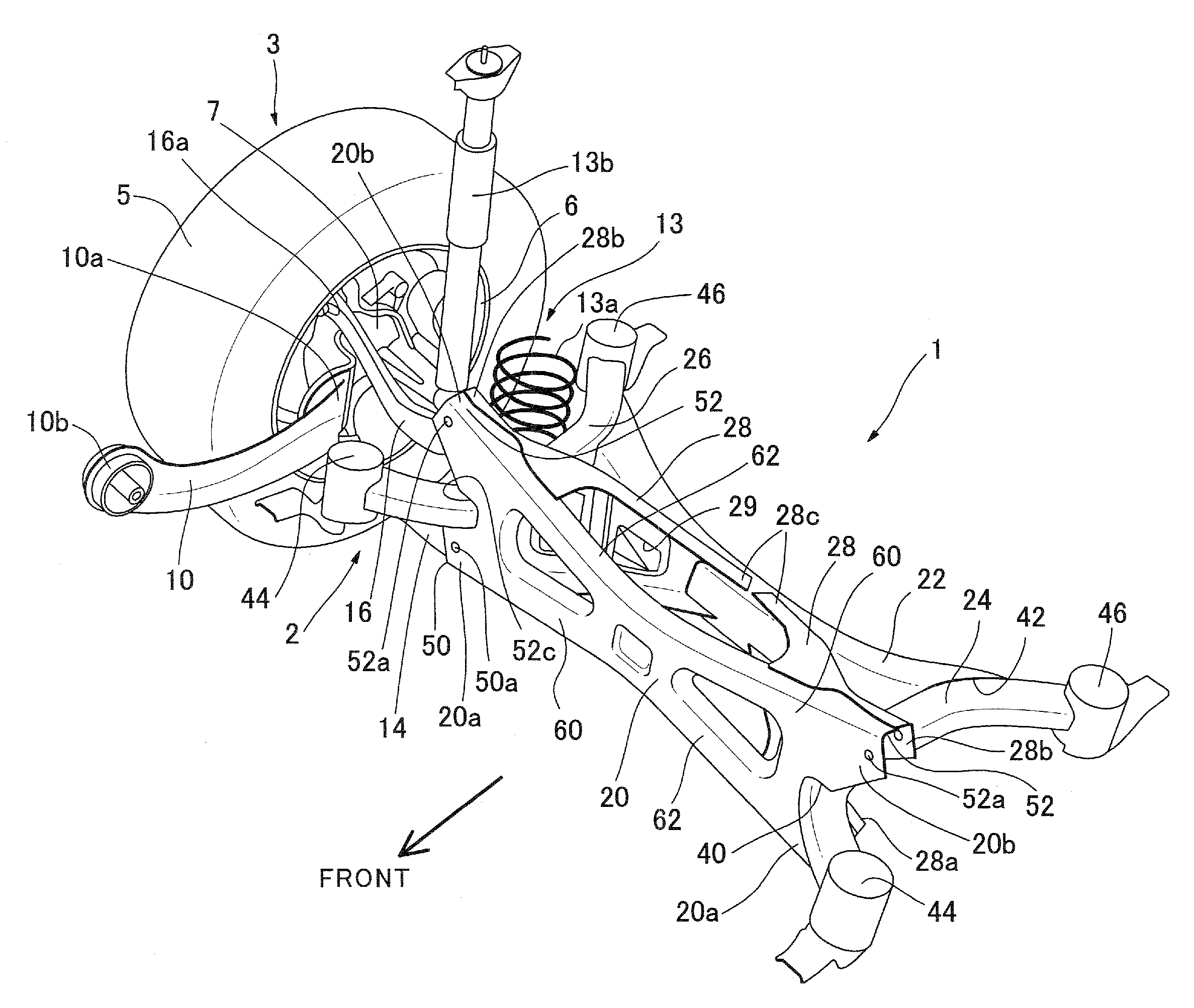

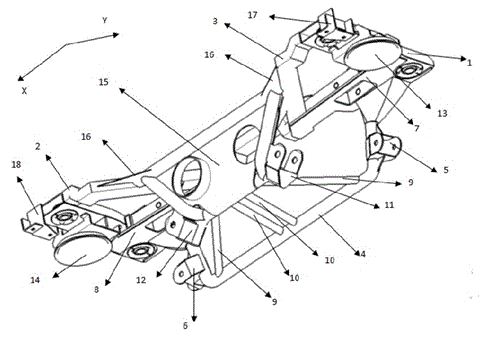

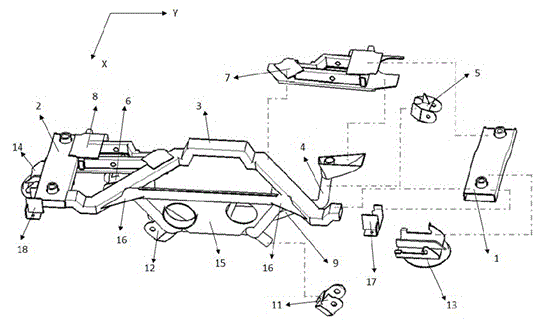

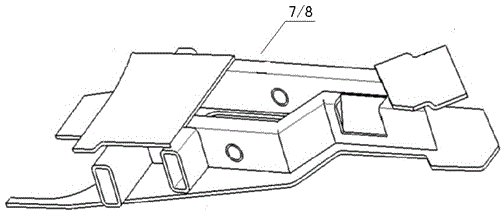

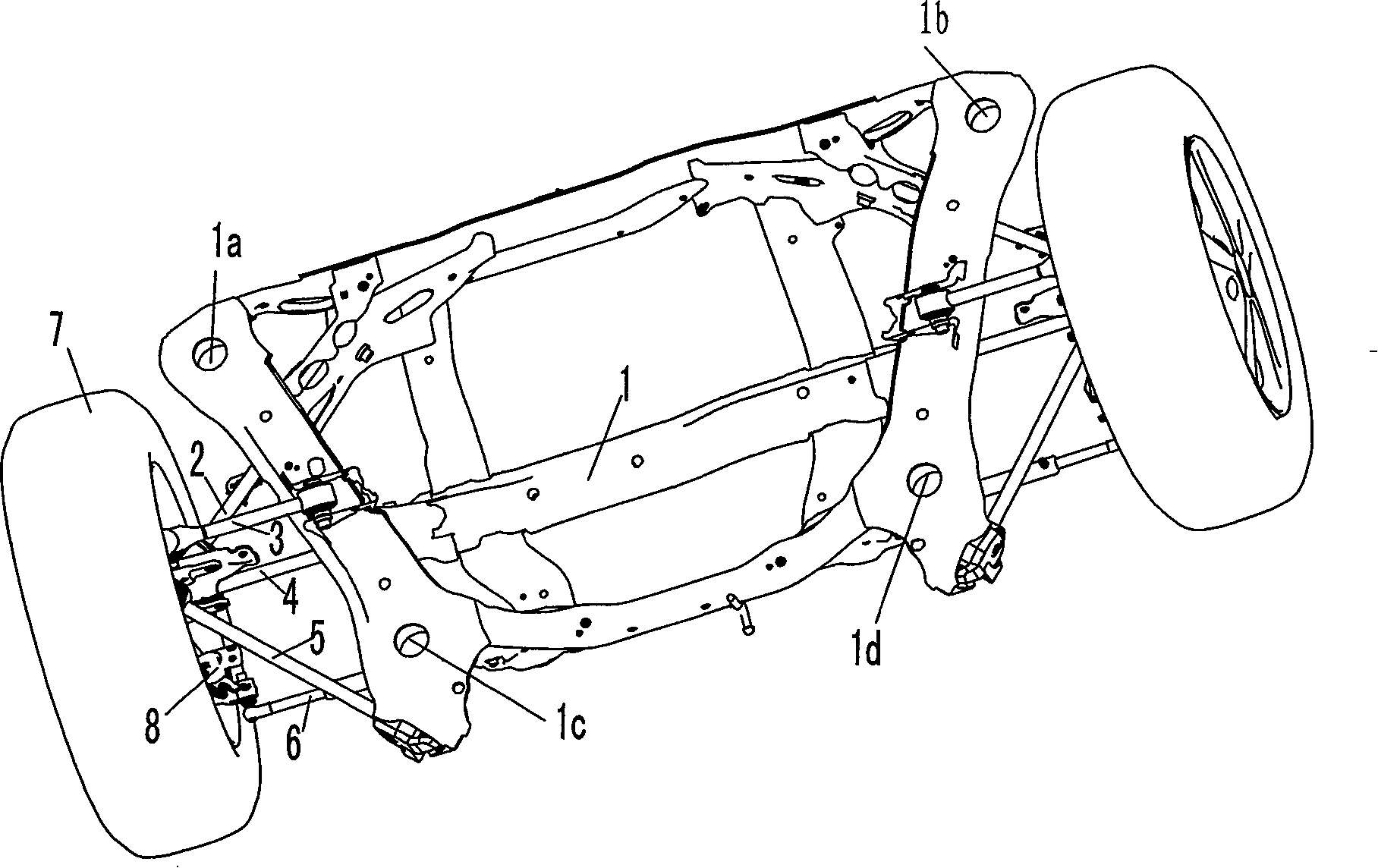

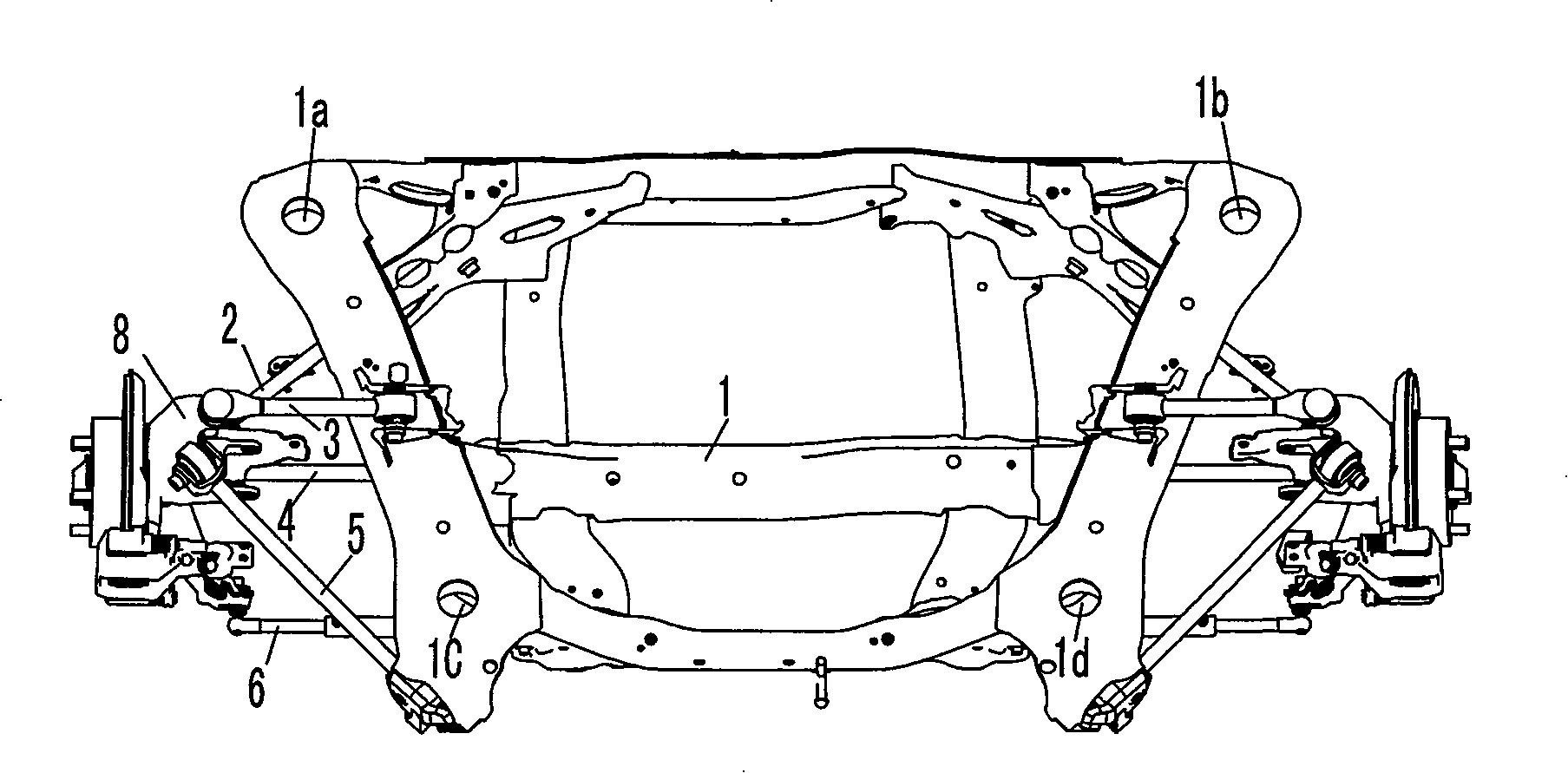

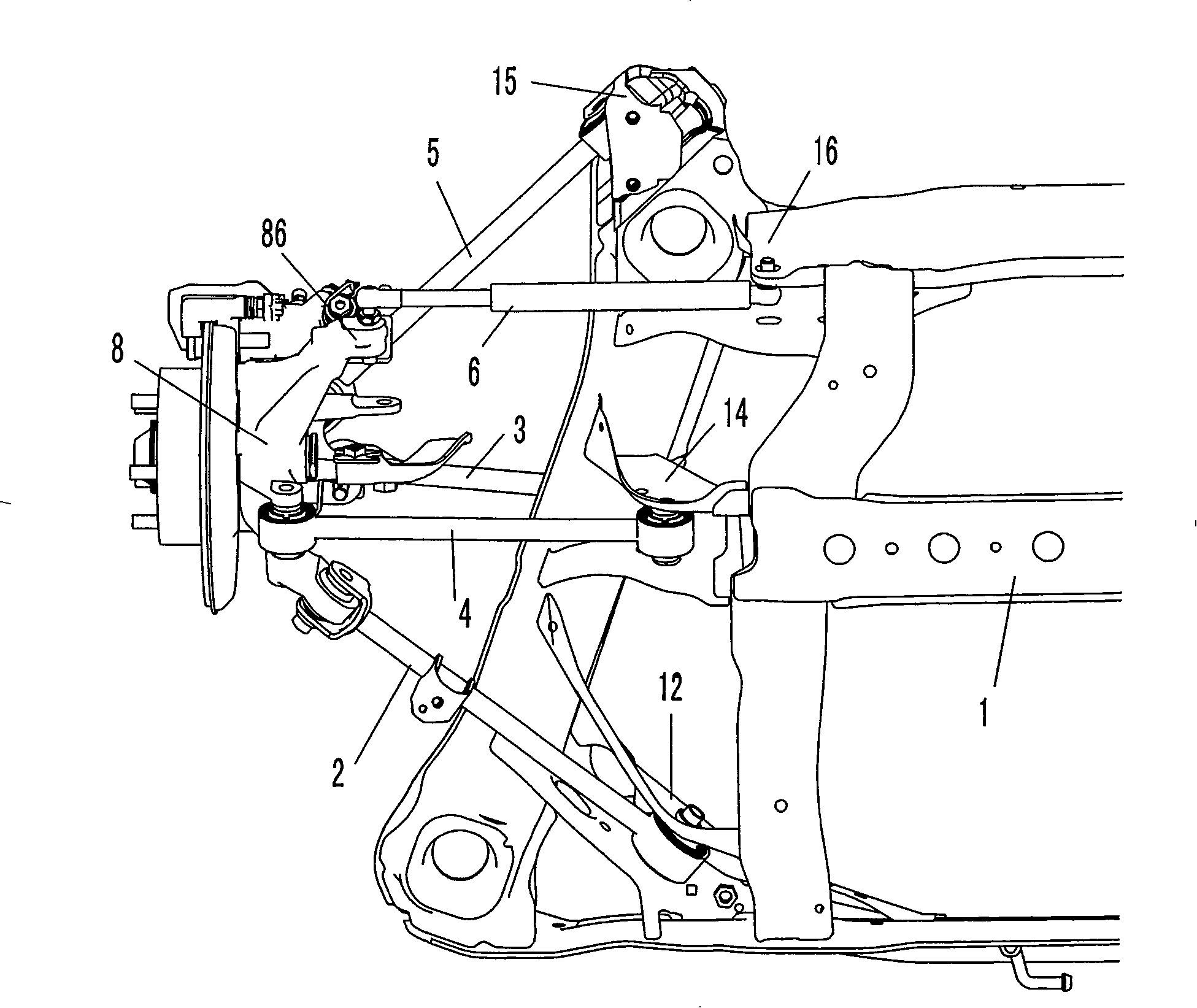

Suspension subframe structure of vehicle

ActiveUS20090243272A1Improve rigidityEfficient receptionVehicle body-frame connectionsUnderstructuresVehicle frameEngineering

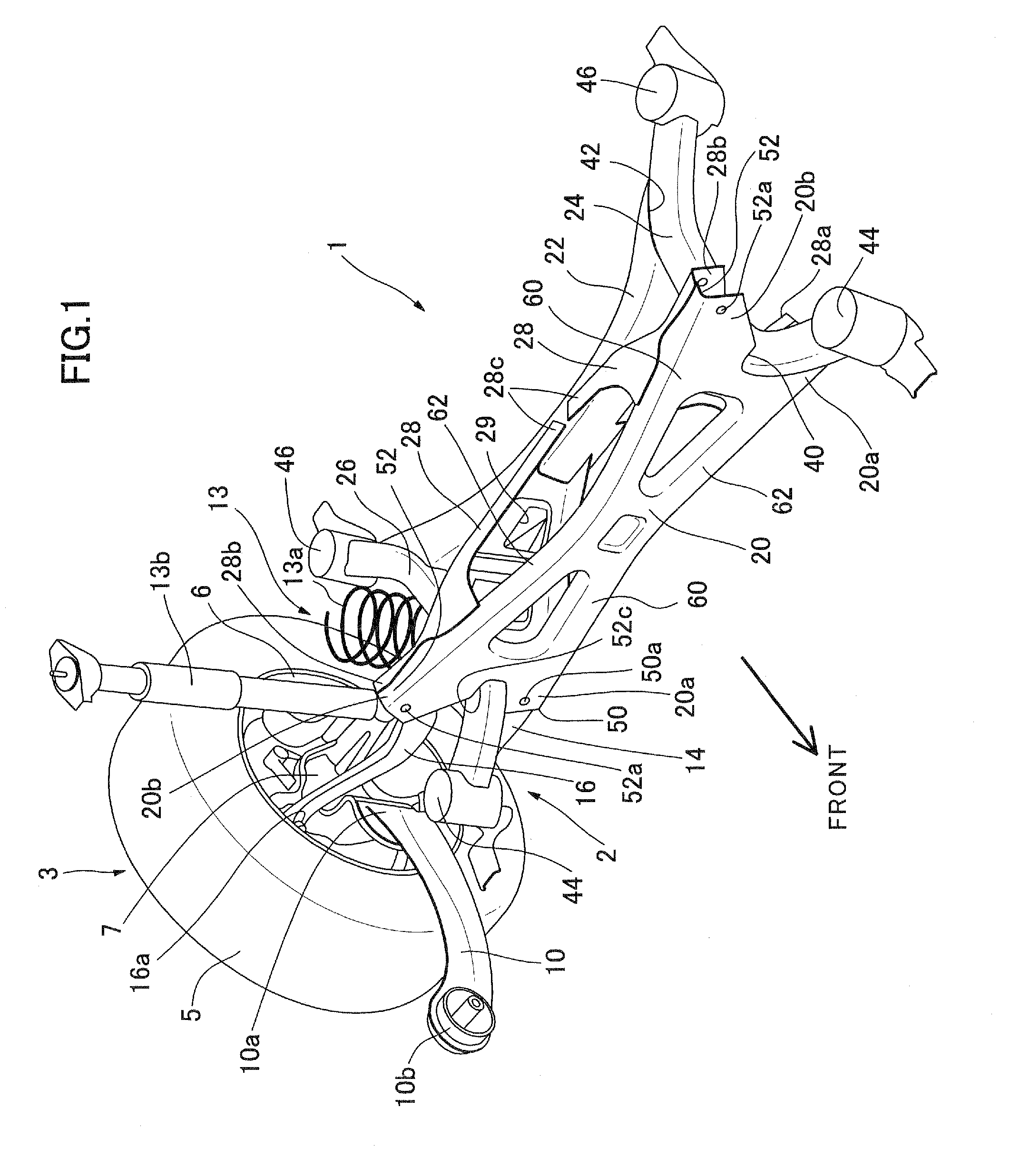

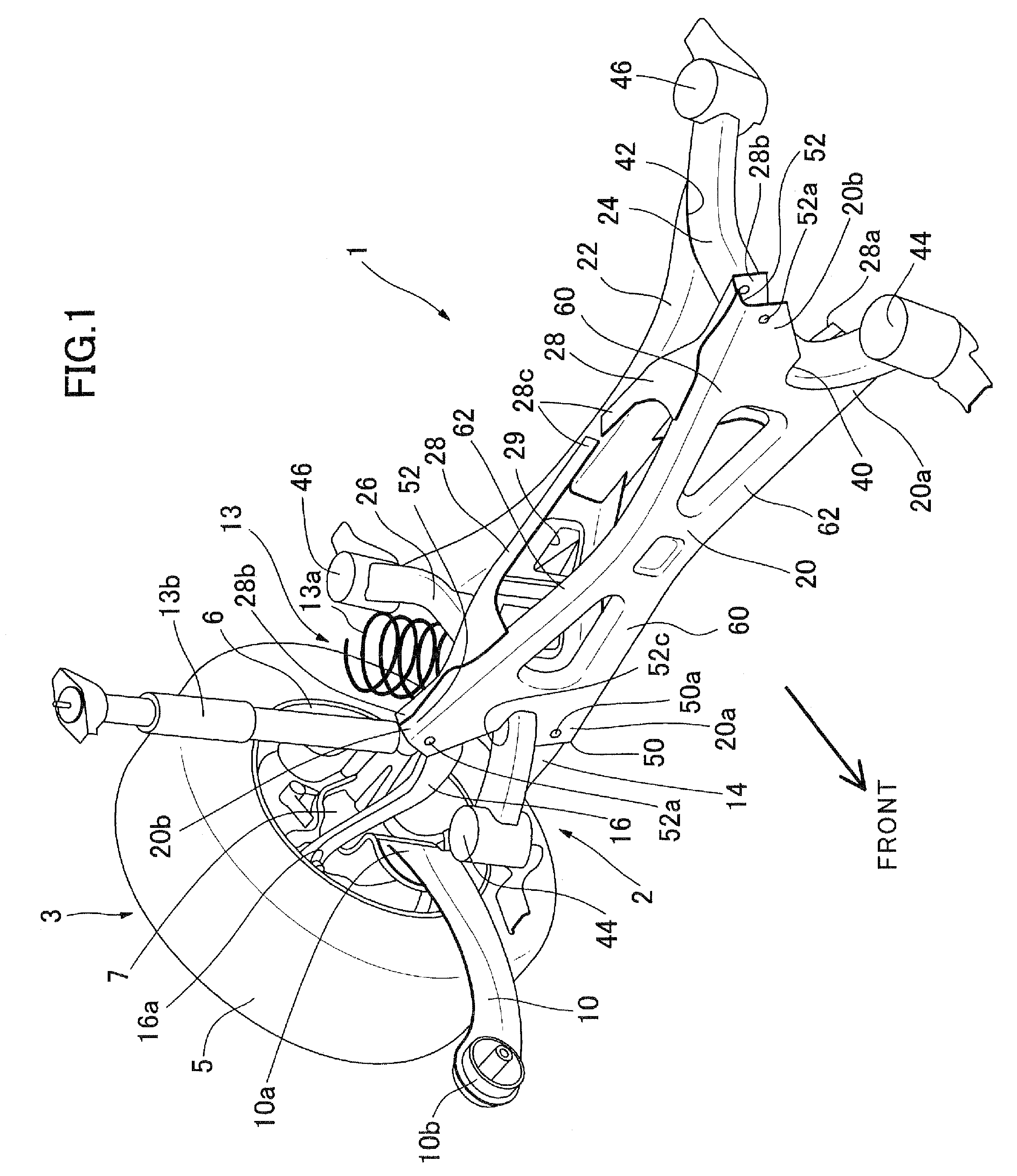

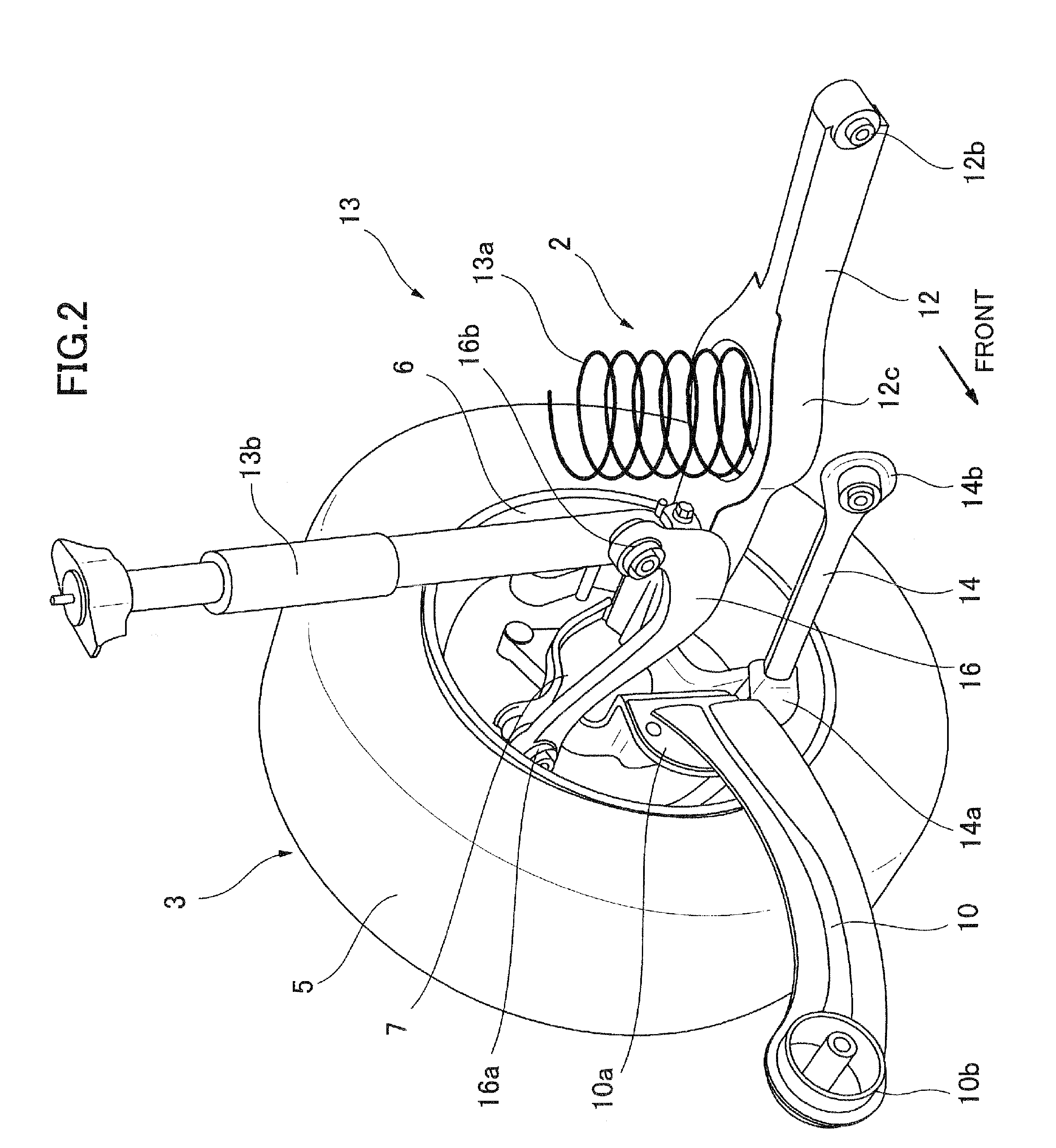

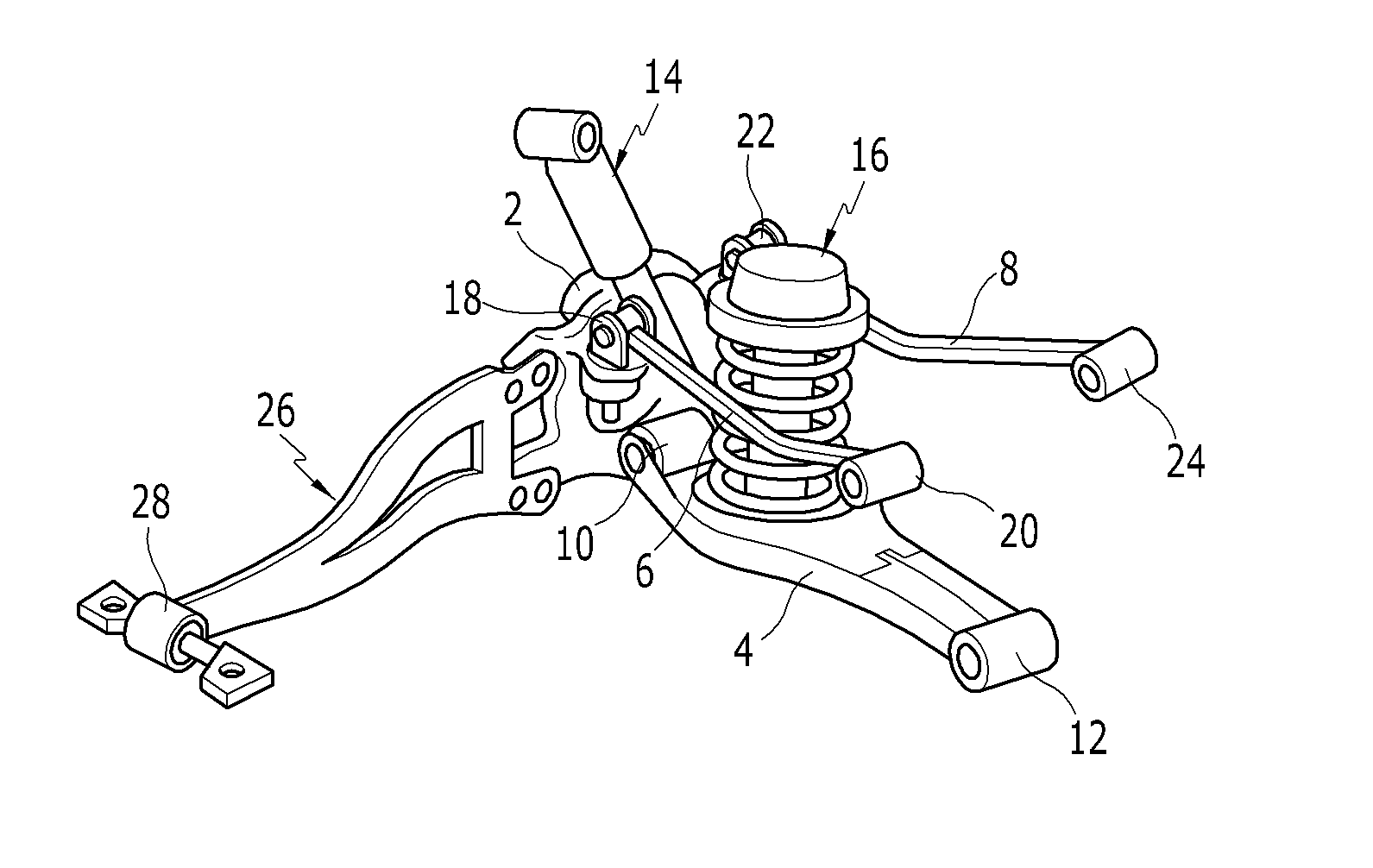

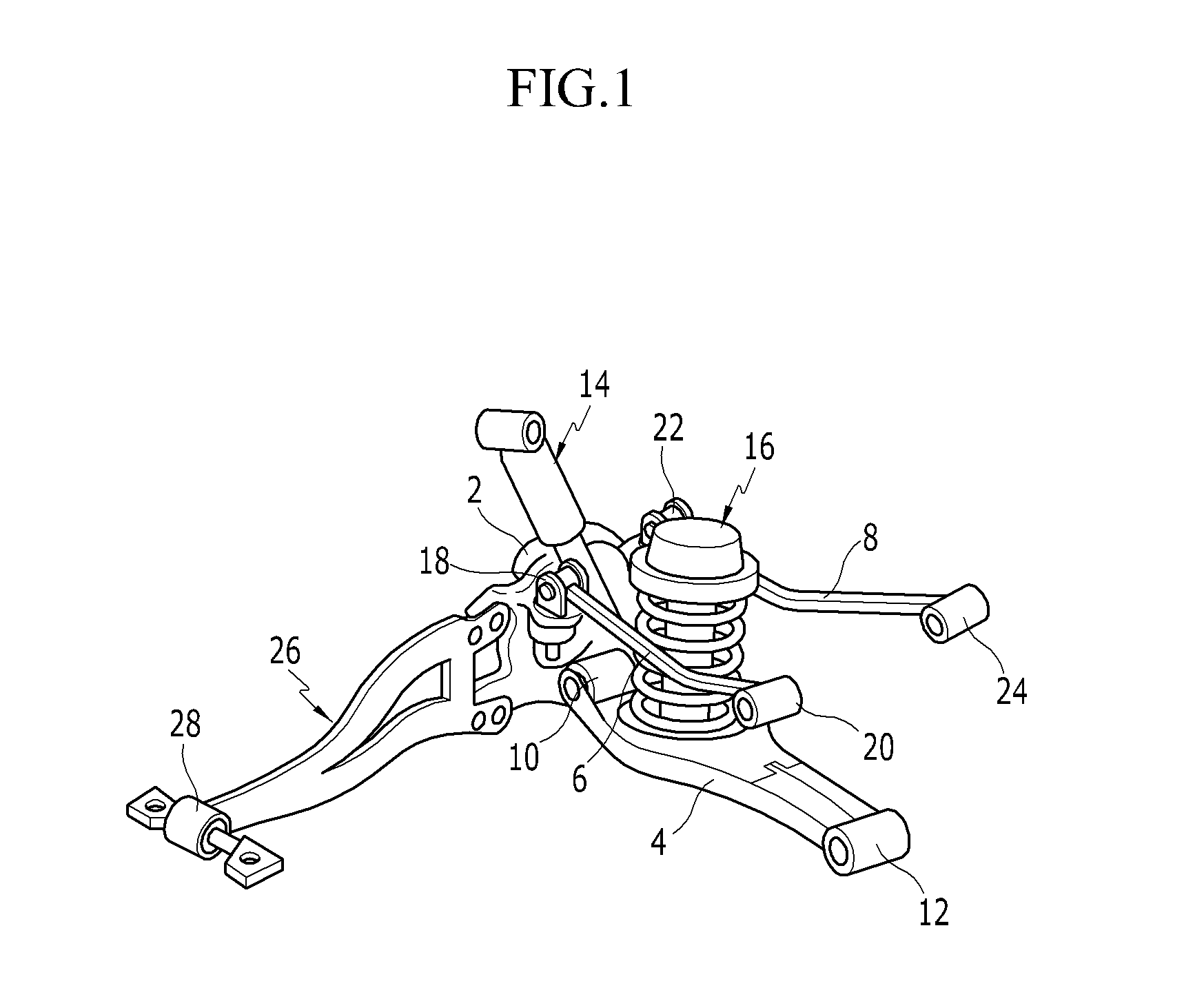

Disclosed is a suspension subframe structure of a vehicle, which is capable of improving the overall rigidity of a suspension subframe to effectively receive input loads from suspension arms, while reducing the overall weight of the suspension subframe. The suspension subframe structure for supporting a plurality of suspension arms 14, 16 of a multi-link suspension system comprises first and second lateral members 20, 22 each extending in a lateral direction of the vehicle body, a pair of longitudinal members each extending in a longitudinal direction of the vehicle body, and right and left inclined members 28 each having one end which is located on the side of a respective one of right and left ends of the first lateral member and provided with an upper-arm support portion and a lower-arm support portion, wherein each of the right and left inclined members extends obliquely relative to the lateral direction in top plan view to connect the upper-arm support portion and the lower-arm support portion with a laterally intermediate portion of the second lateral member.

Owner:MAZDA MOTOR CORP +1

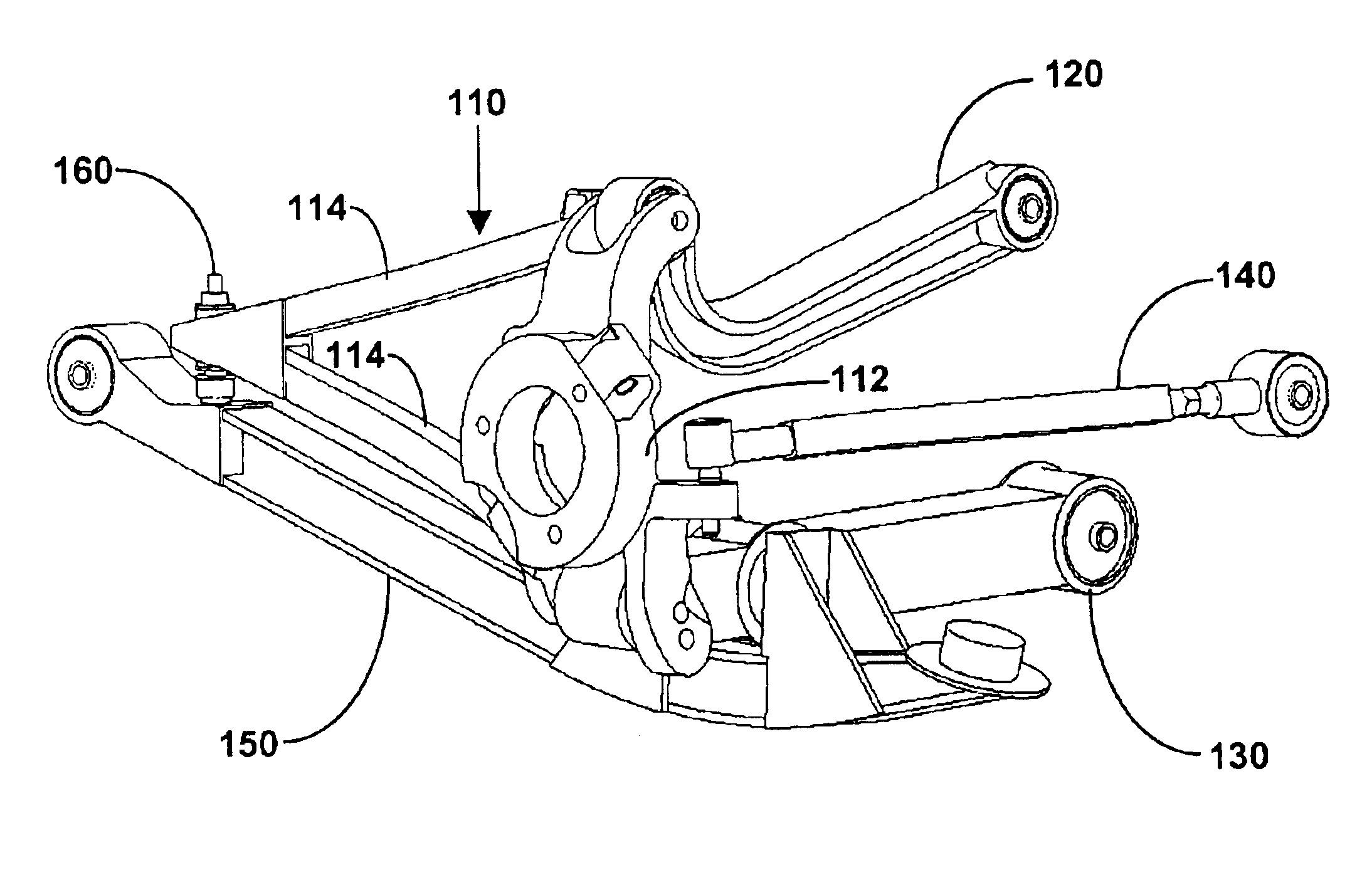

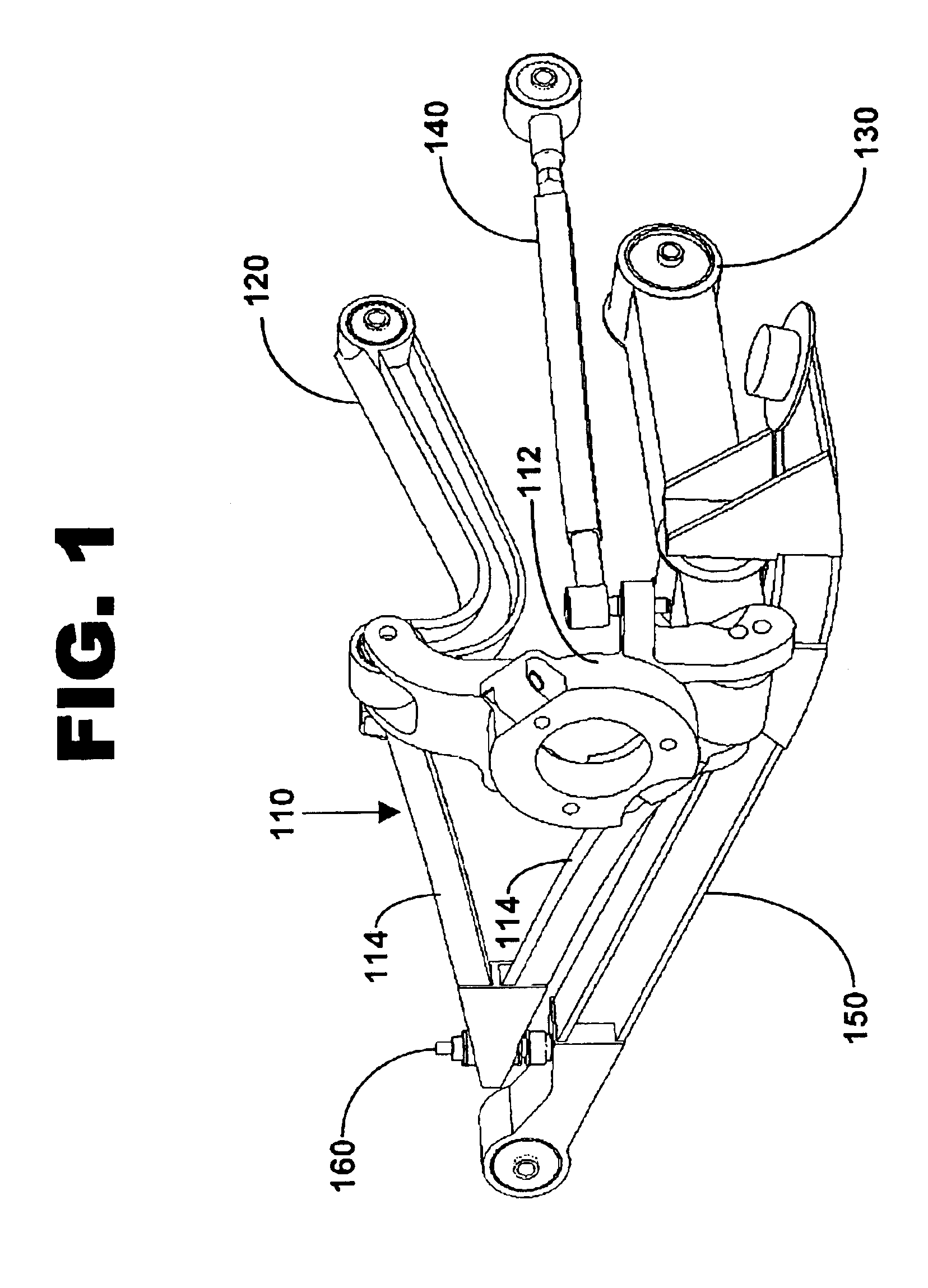

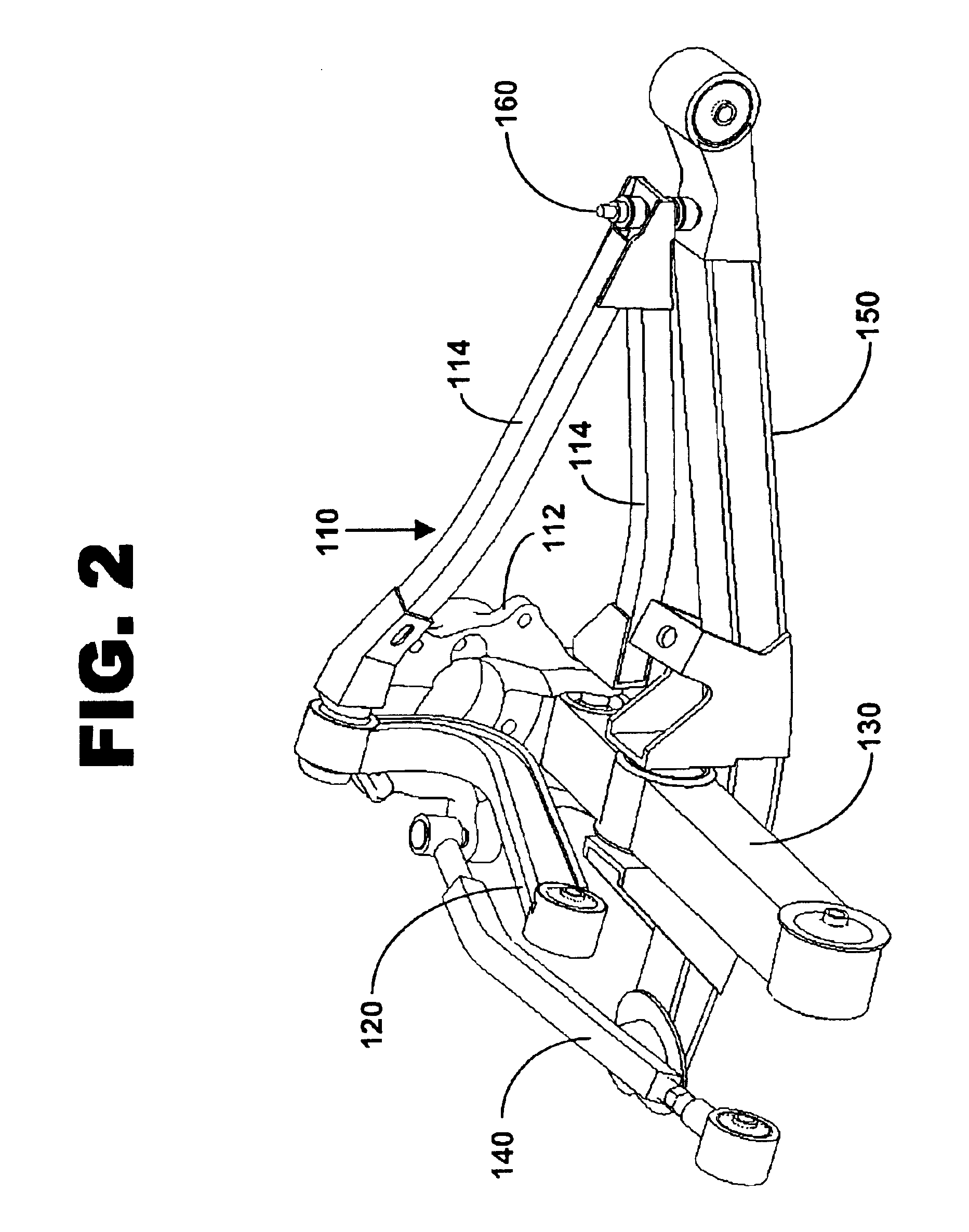

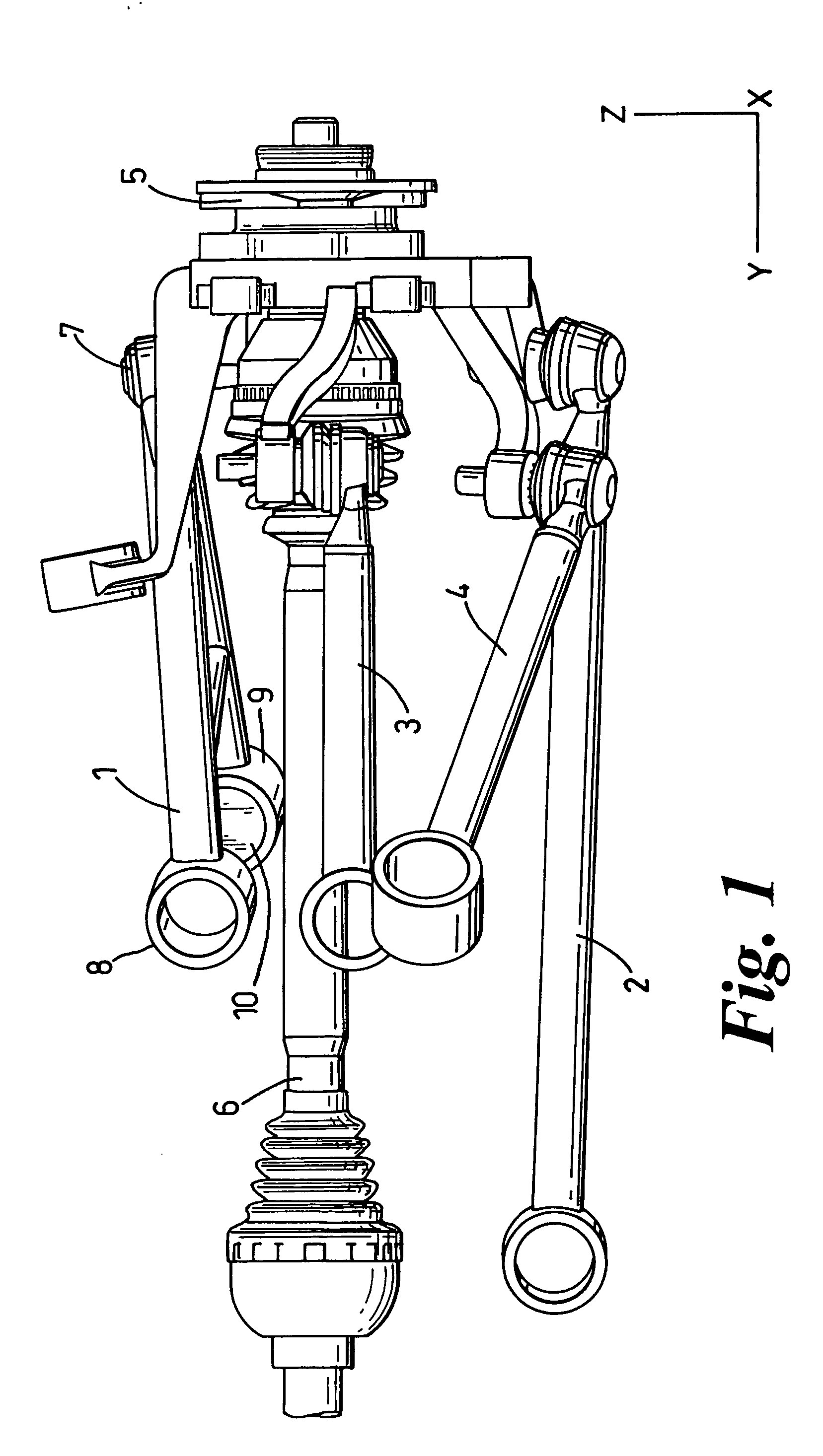

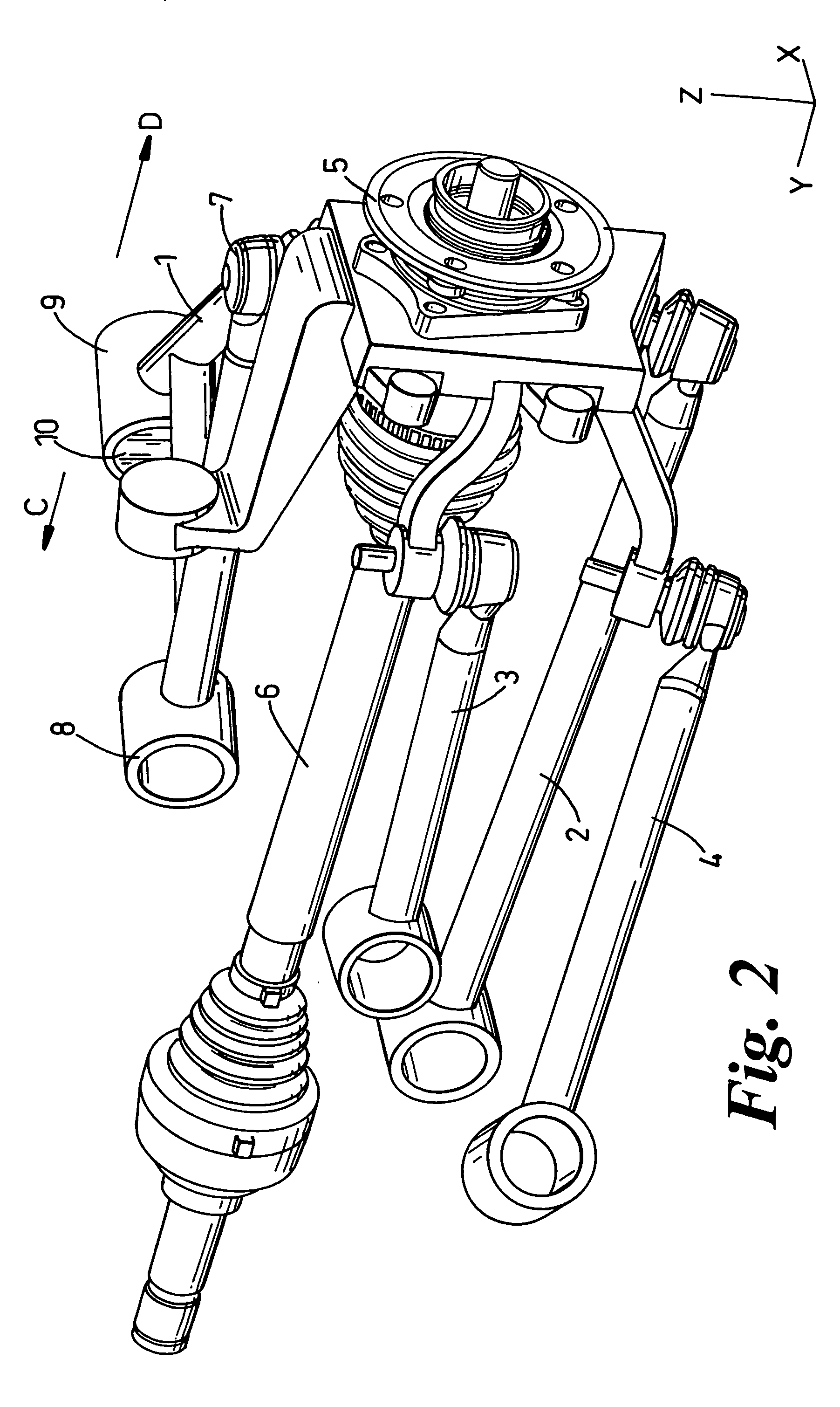

Multi-link independent rear suspension assembly

The invention provides a multi-link suspension assembly for a vehicle wheel, comprising a wheel carrier, an upper lateral link, a lower lateral link, a toe link, and a longitudinal link. The wheel carrier is oriented along a longitudinal axis of a vehicle body. The upper lateral link is oriented along a lateral axis of the vehicle body near the wheel center and is pivotally connected to the wheel carrier. The lower lateral link is oriented along a lateral axis of the vehicle body near the wheel center and is pivotally connected to the wheel carrier. The toe link is oriented along a lateral axis of the vehicle body behind the wheel center and is pivotally connected to the wheel carrier. The longitudinal link is oriented along the longitudinal axis of the vehicle body and is pivotally connected to the wheel carrier forward of the wheel center and pivotally connected to the lower lateral link near the wheel center.

Owner:BWI

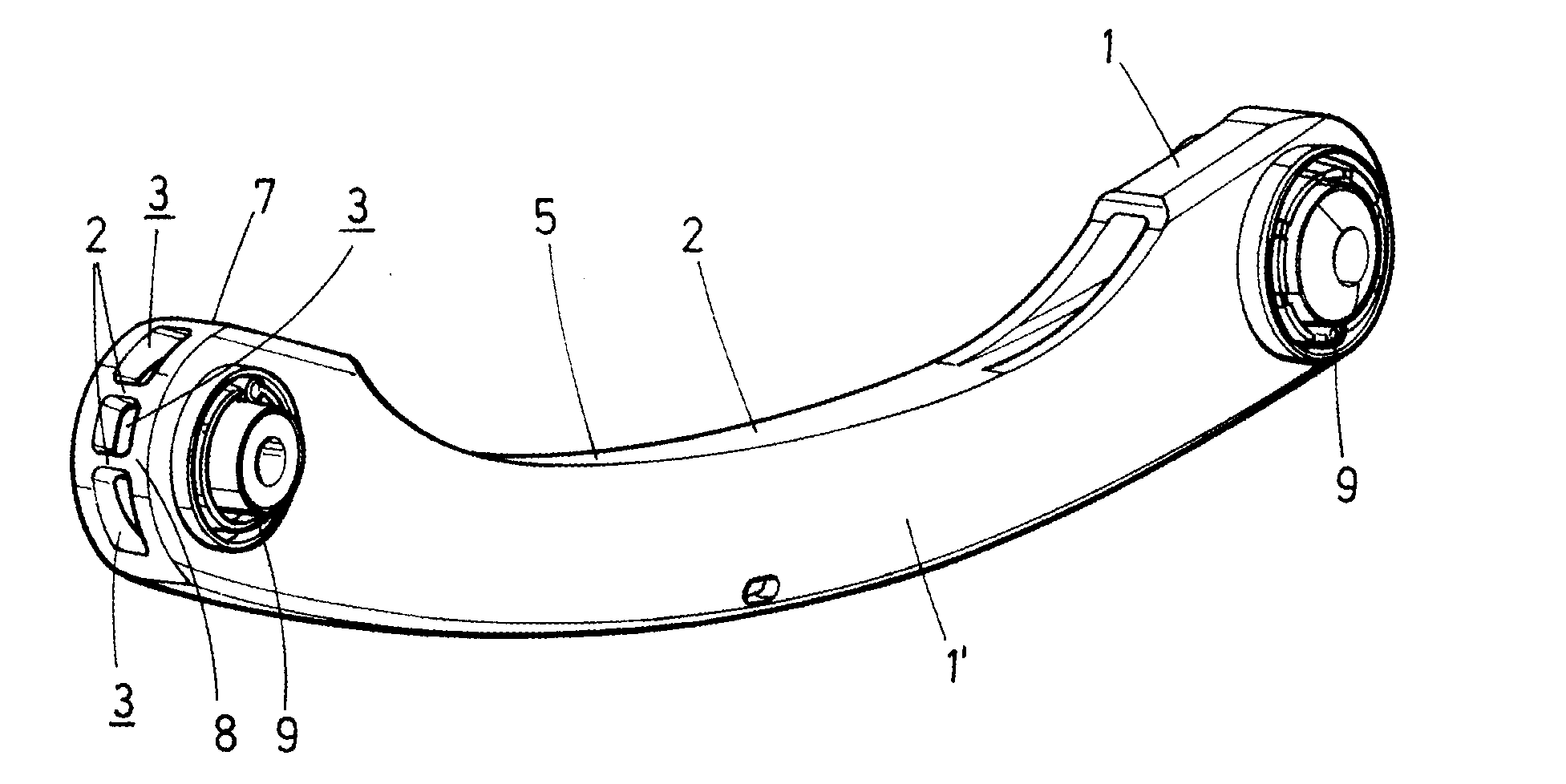

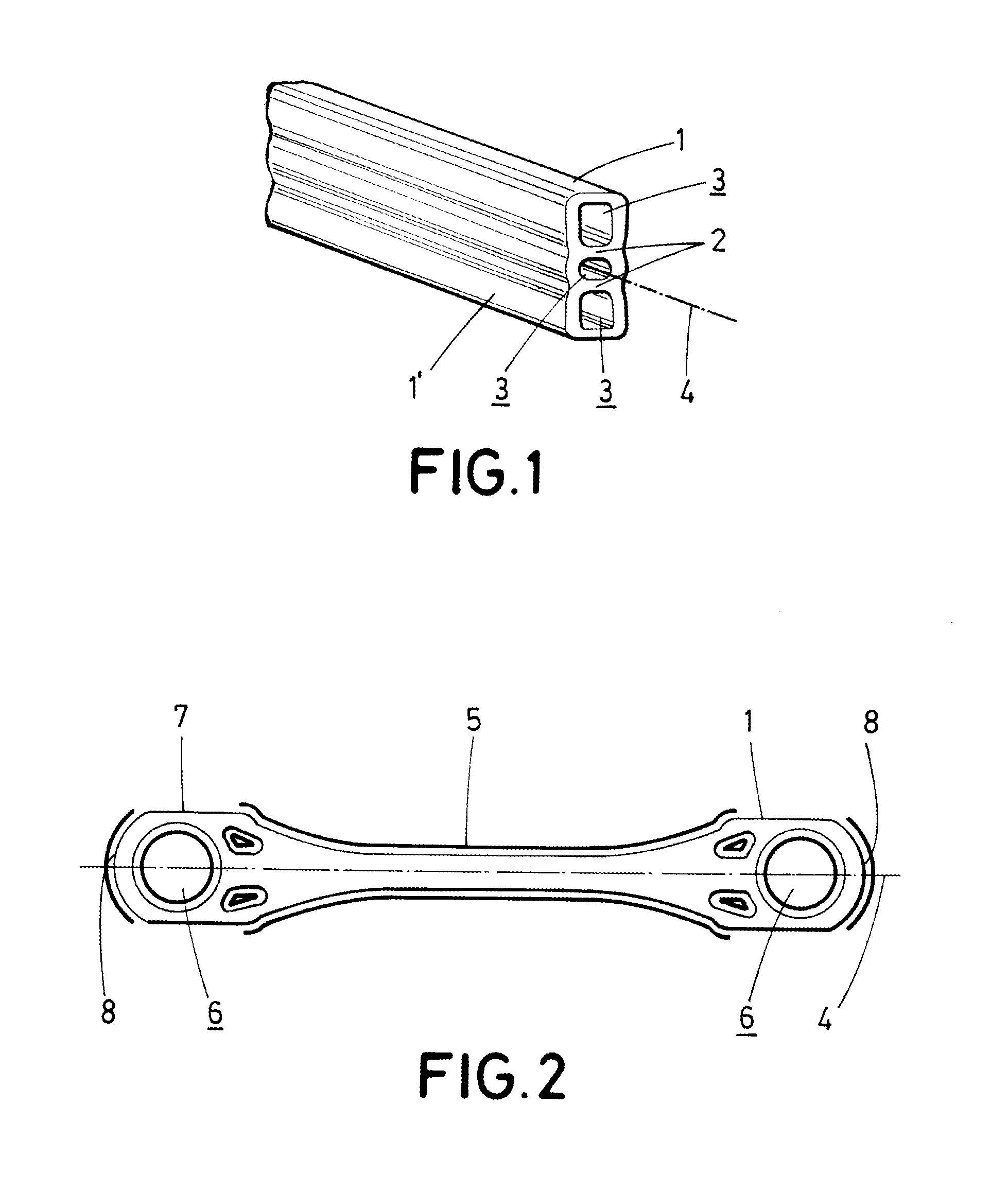

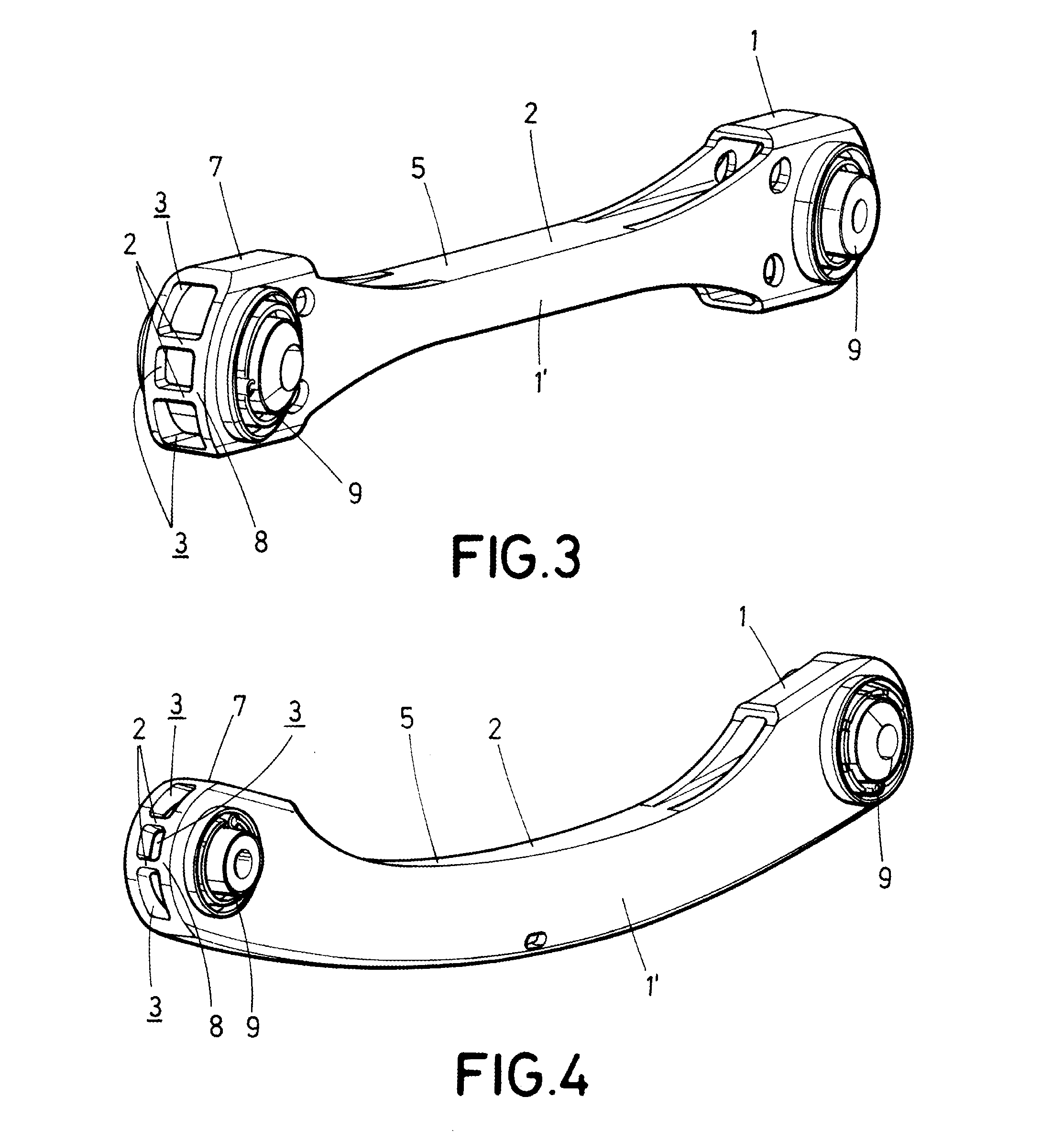

Method for obtaining an arm for multi-link suspensions of automotive vehicles and a suspension arm

InactiveUS20160075201A1Low costReduce the numberMetal-working apparatusResilient suspensionsMulti linkContour form

The present invention relates to a method for obtaining an arm for multi-link suspensions of automotive vehicles and a suspension arm, where the method comprises:e) extruding a hollow profile the cross-section of which has a closed outer contour formed by side walls (1, 1′) and comprising at least one inner partition (2) internally splitting the profile into at least two inner cavities (3),f) transversely cutting the extruded profile into sections corresponding with the length of the arm to be obtained, according to a longitudinal axis (4) of the arm,g) in a central section (5) of the arm, machining at least one side wall (1) having no inner partition (2) extending therefrom without the machining ever reaching said at least one inner partition (2), andh) in the side walls (1′) having said at least one inner partition (2) extending therefrom, making an end opening (6) in each end area (7) of the arm, between which the central section (5) is arranged.

Owner:ENG DEV FOR AUTOMOTIVE IND SL

Suspension subframe structure of vehicle

InactiveUS8025313B2Improve rigidityReduce weightVehicle body-frame connectionsUnderstructuresVehicle frameEngineering

Disclosed is a suspension subframe structure of a vehicle, which is capable of improving the overall rigidity of a suspension subframe to effectively receive input loads from suspension arms, while reducing the overall weight of the suspension subframe. The suspension subframe structure for supporting a plurality of suspension arms 14, 16 of a multi-link suspension system comprises first and second lateral members 20, 22 each extending in a lateral direction of the vehicle body, a pair of longitudinal members each extending in a longitudinal direction of the vehicle body, and right and left inclined members 28 each having one end which is located on the side of a respective one of right and left ends of the first lateral member and provided with an upper-arm support portion and a lower-arm support portion, wherein each of the right and left inclined members extends obliquely relative to the lateral direction in top plan view to connect the upper-arm support portion and the lower-arm support portion with a laterally intermediate portion of the second lateral member.

Owner:MAZDA MOTOR CORP +1

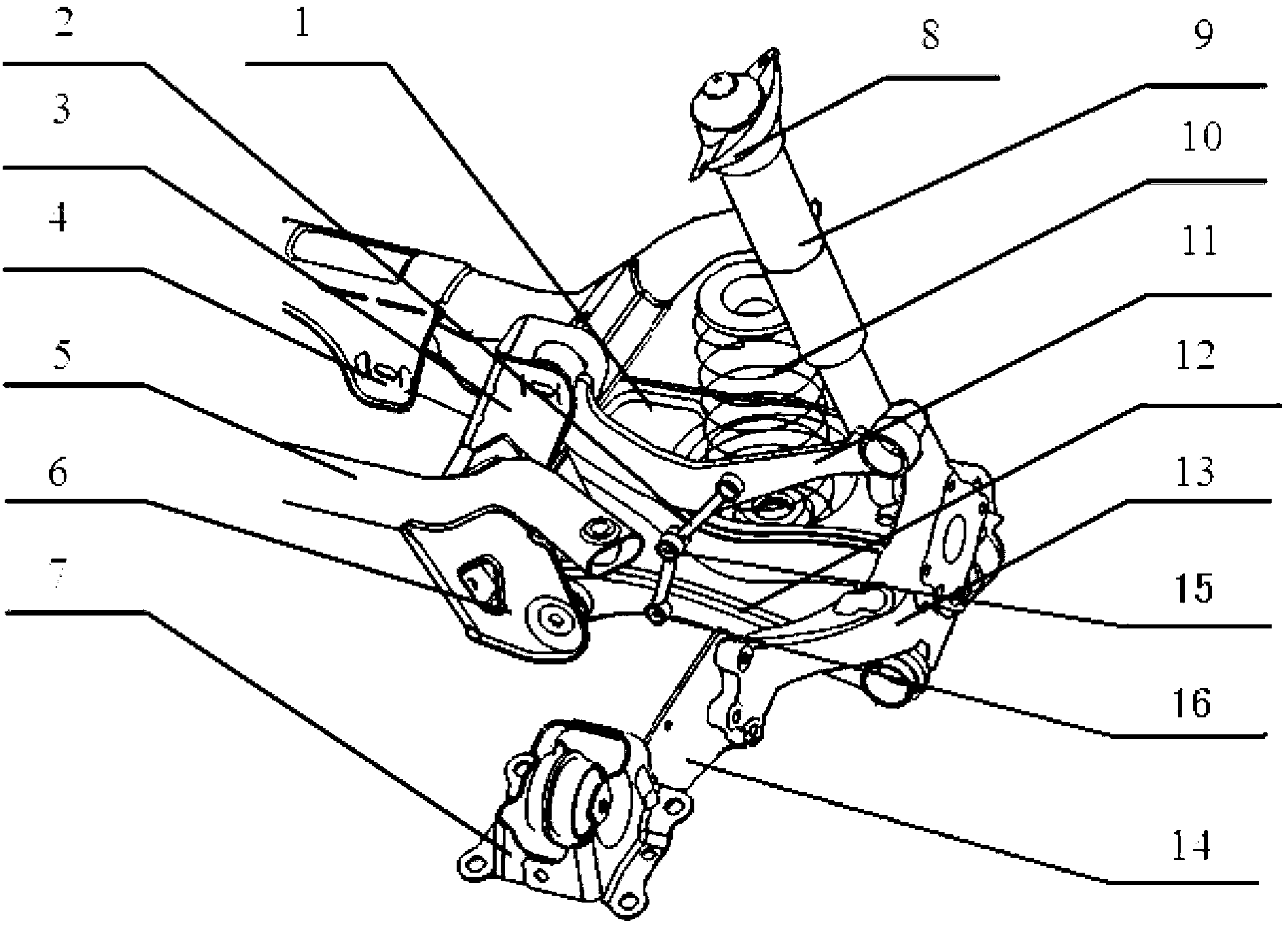

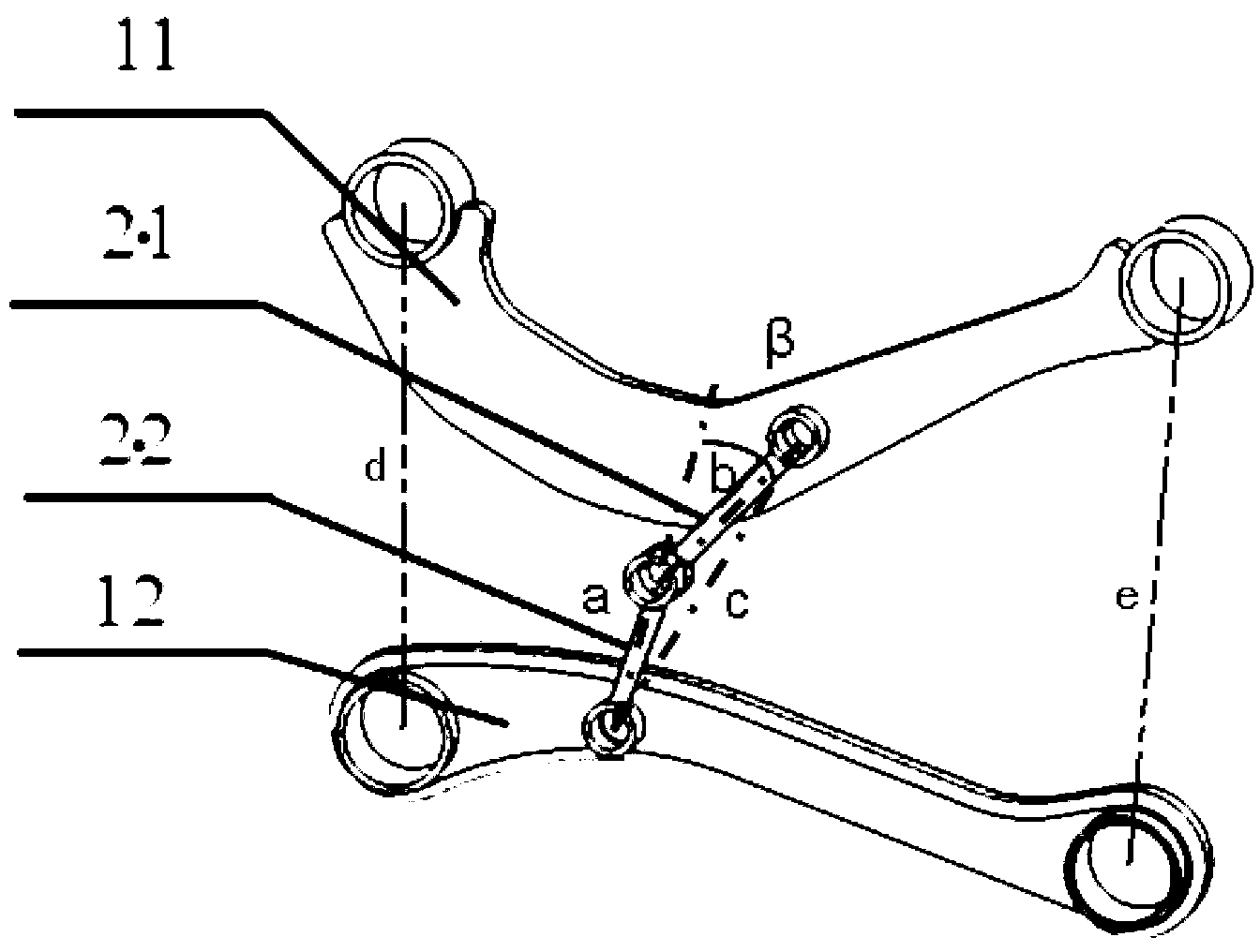

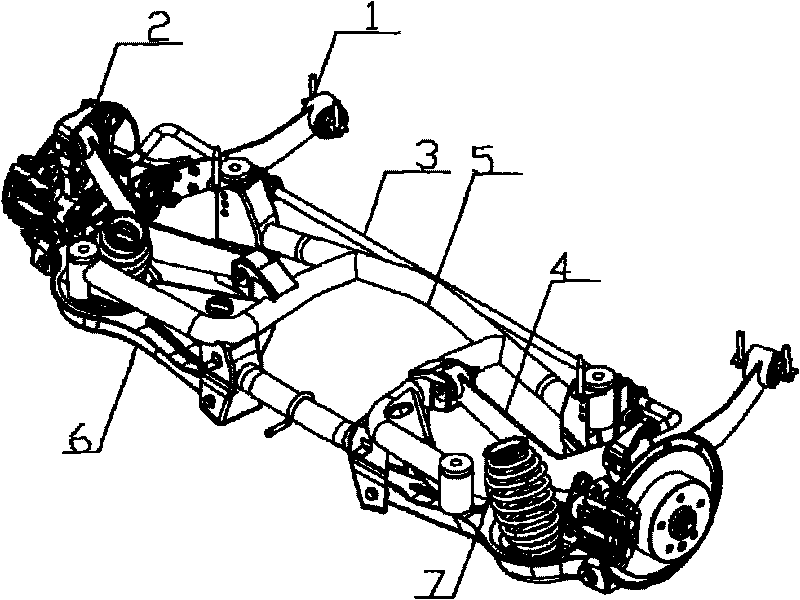

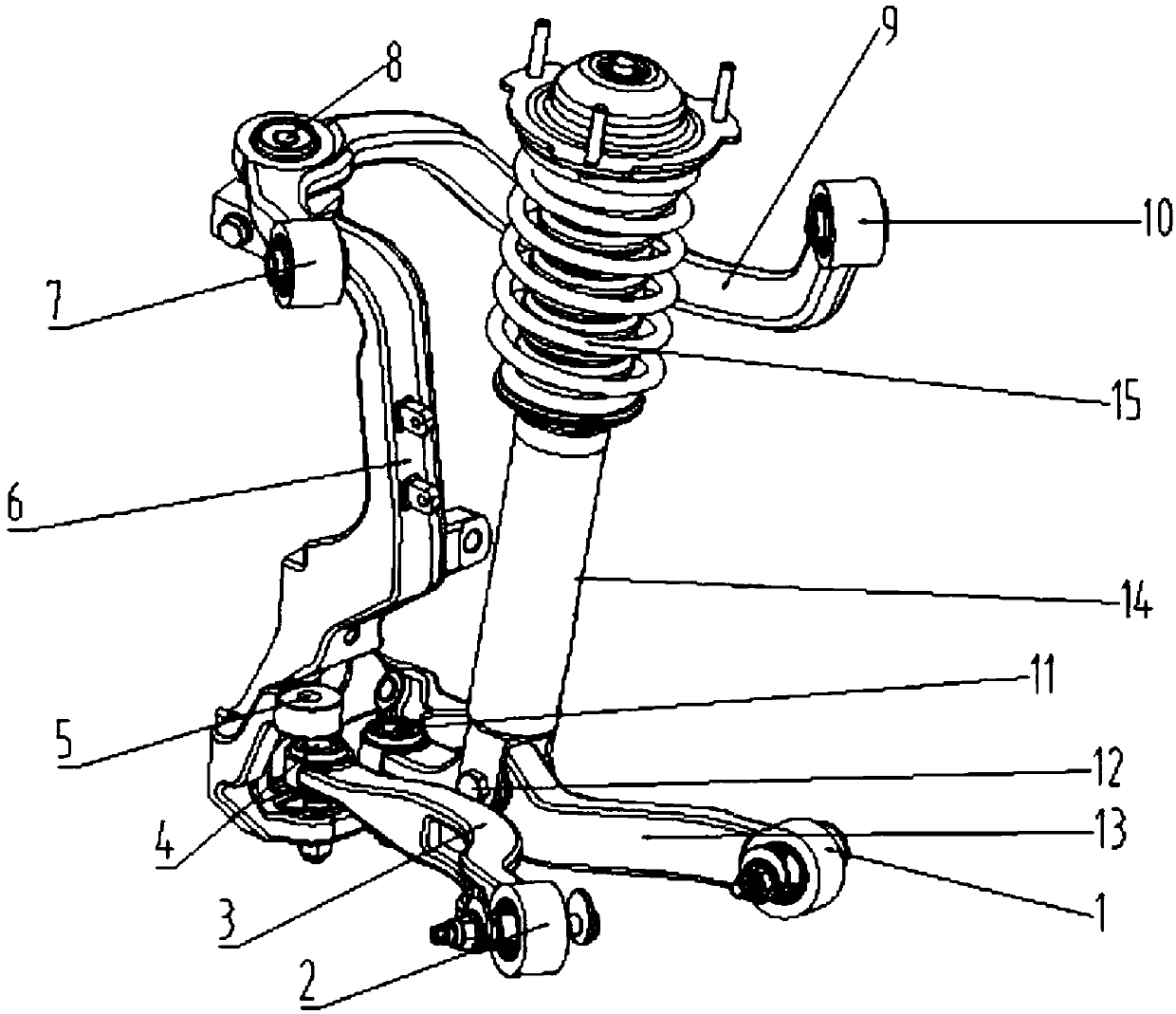

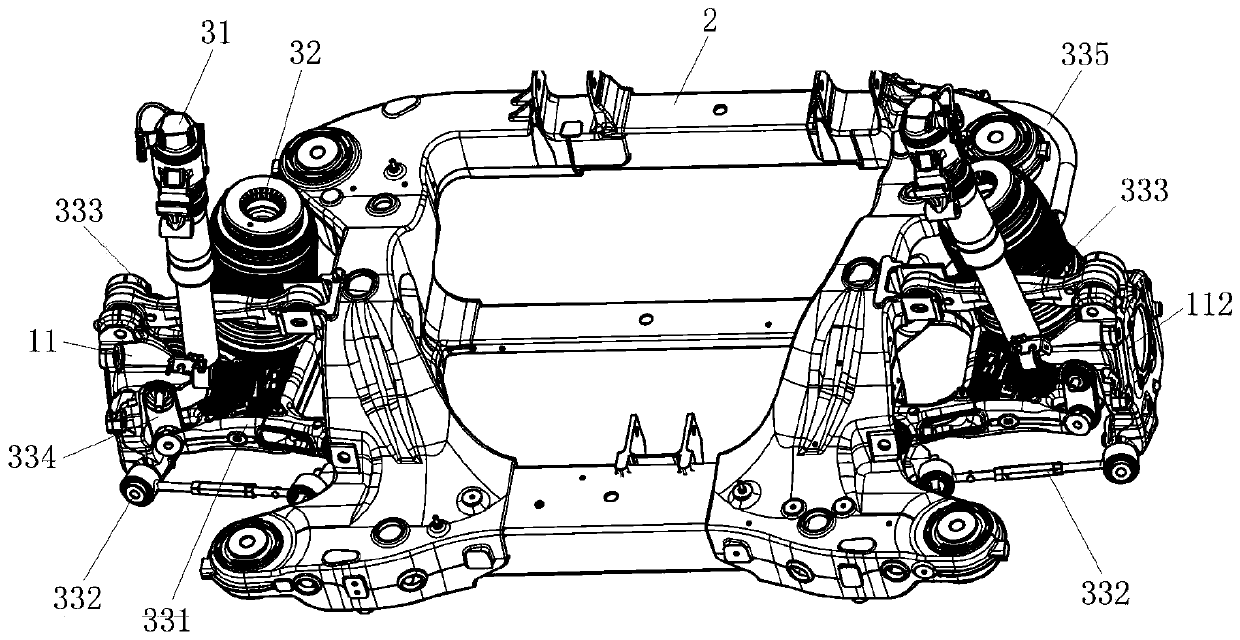

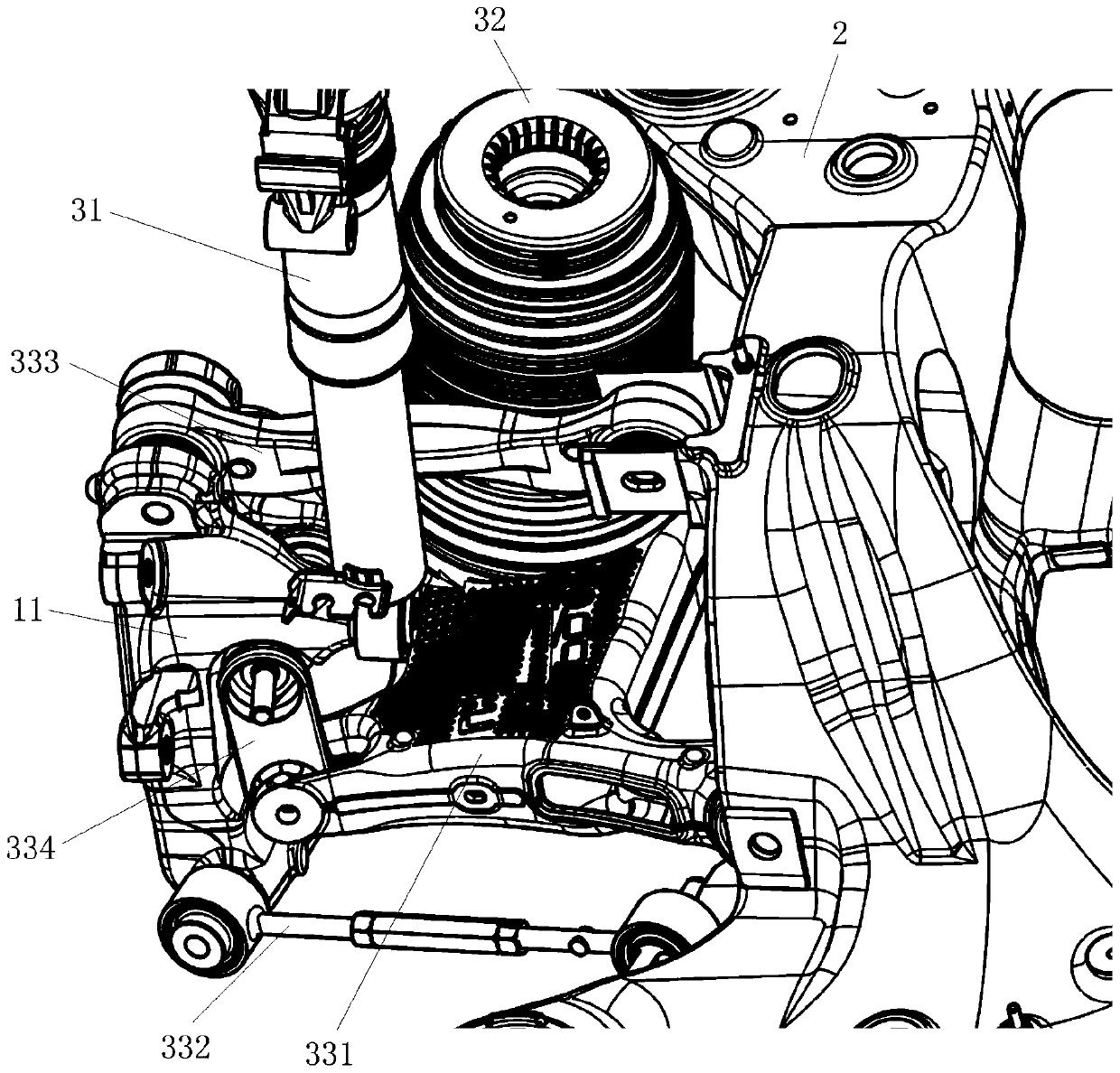

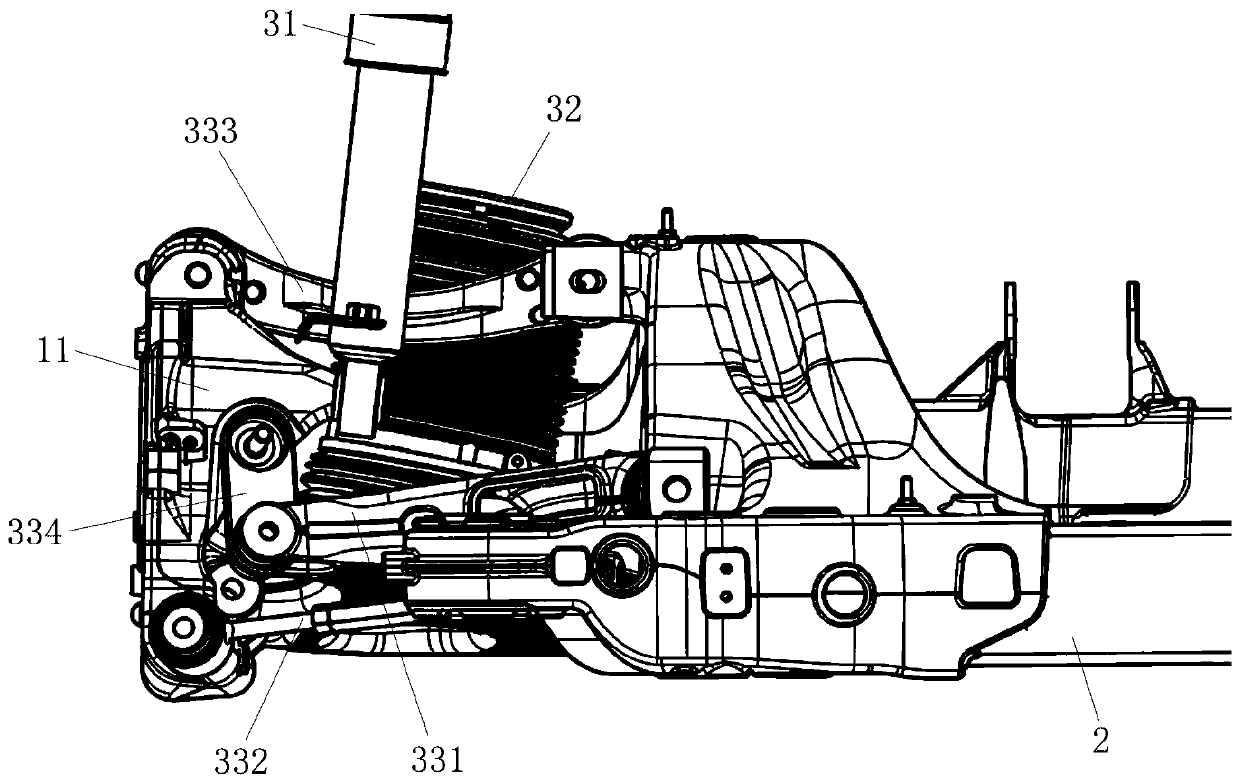

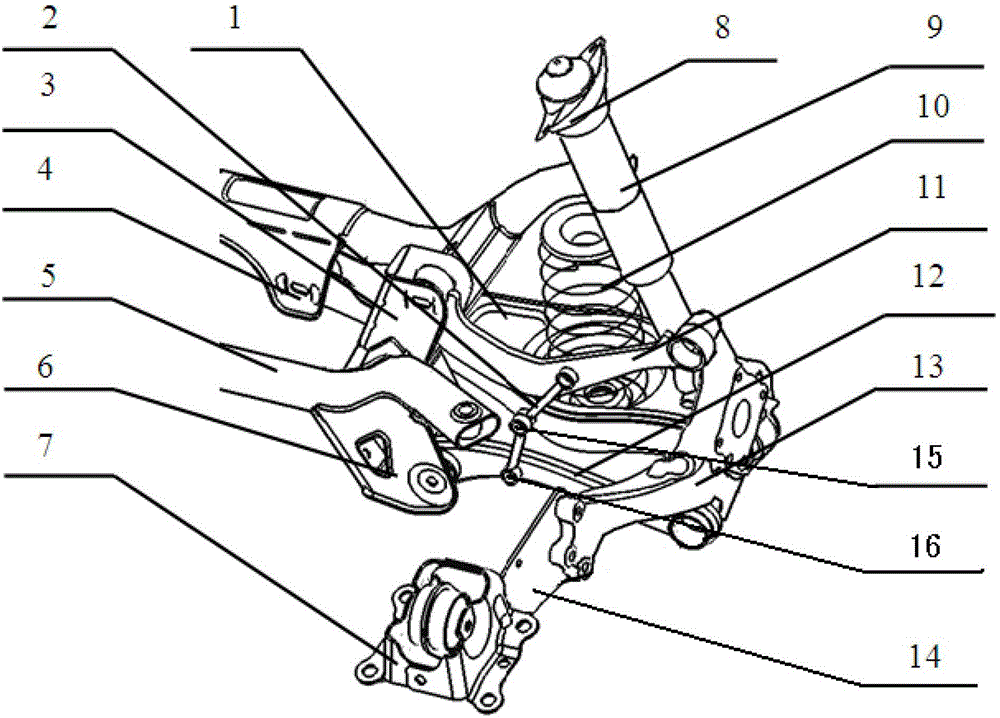

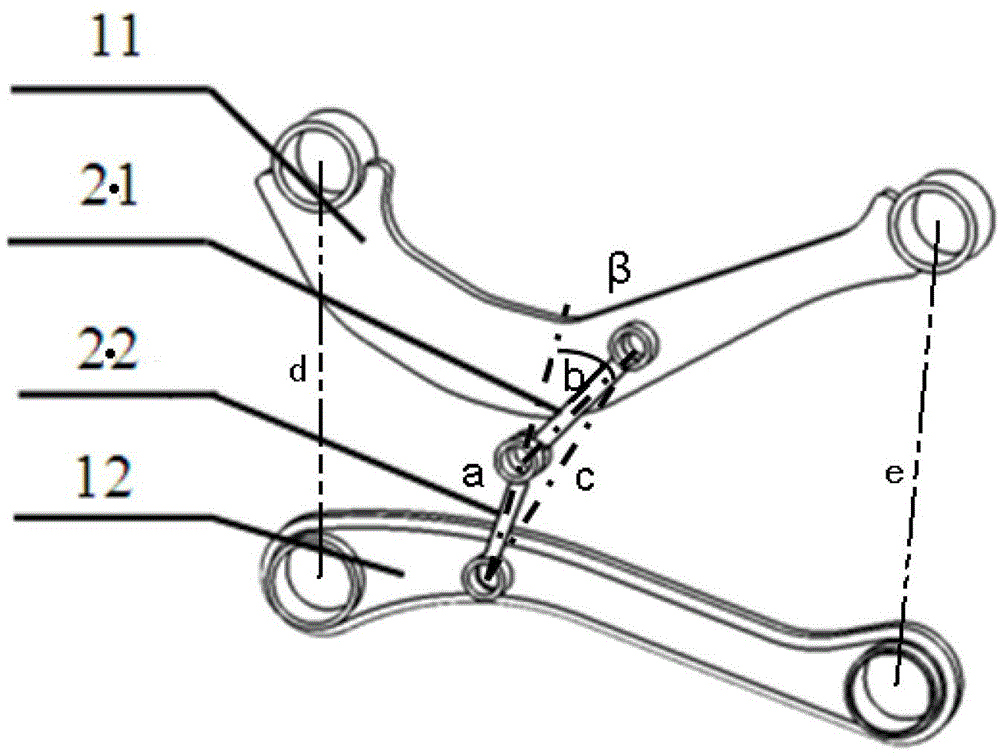

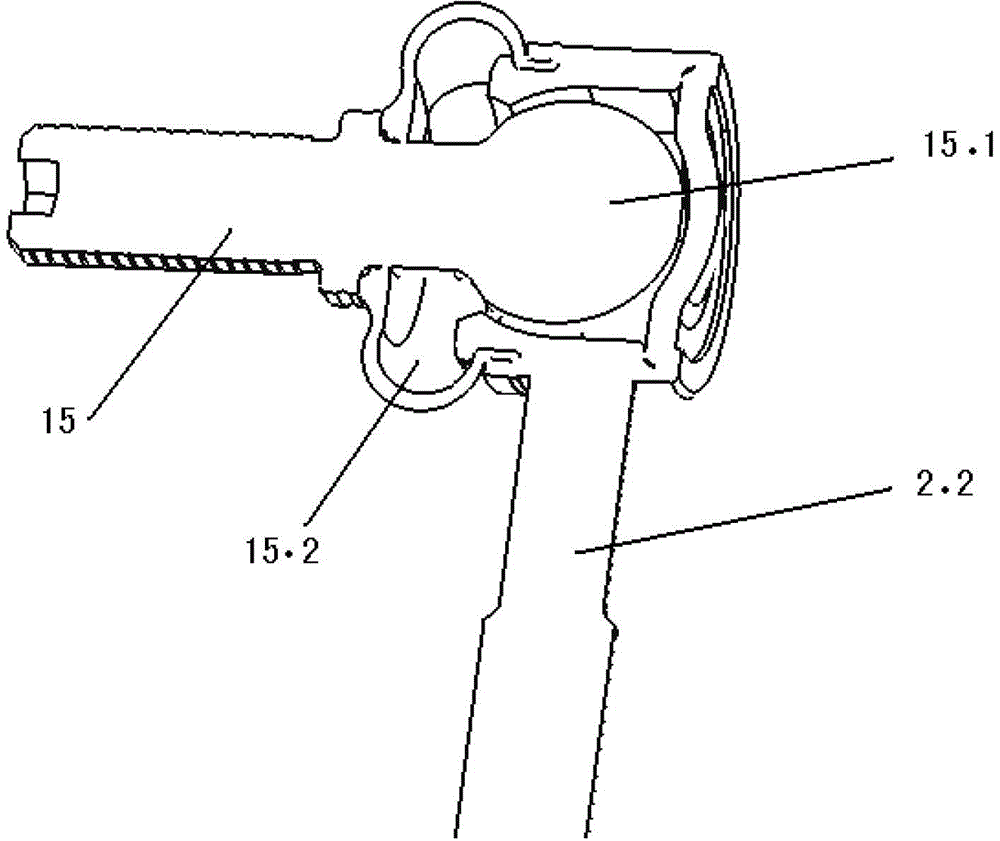

Multi-link suspension structure

ActiveCN103009951AEliminate large load shocksAvoid crackingResilient suspensionsPivoted suspension armsVehicle frameControl arm

The invention discloses a multi-link suspension structure, and belongs to the field of automobile suspension. The suspension structure comprises a down-back control arm, a limit rod assembly, an up control arm mounting bracket, a down-back drag arm mounting bracket, a sub-frame, a down-front control arm mounting bracket, a drag arm mounting bracket, an absorber mounting plate, an absorber assembly, a spring assembly, an up control arm, a down-front control arm, a knuckle, a drag arm, a spherical hinge assembly and a lining assembly, wherein the up control arm and the down-front control arm are connected with the limit rod assembly through the spherical hinge assembly and the absorber assembly; and the limit rod assembly is used for reducing the load born by a limit block in the absorber assembly when the load born by the wheels jumps to the limit position. According to the invention, heavy load impact on the mounting position of the absorber is eliminated for a multi-link suspension, the crack problem of metal plates in the positions for mounting absorbers on an automobile body is avoided, while the impact of the vertical load on the automobile body is avoided when the automobile wheels jump up, and the comfortableness of taking the automobile is improved.

Owner:CHERY AUTOMOBILE CO LTD

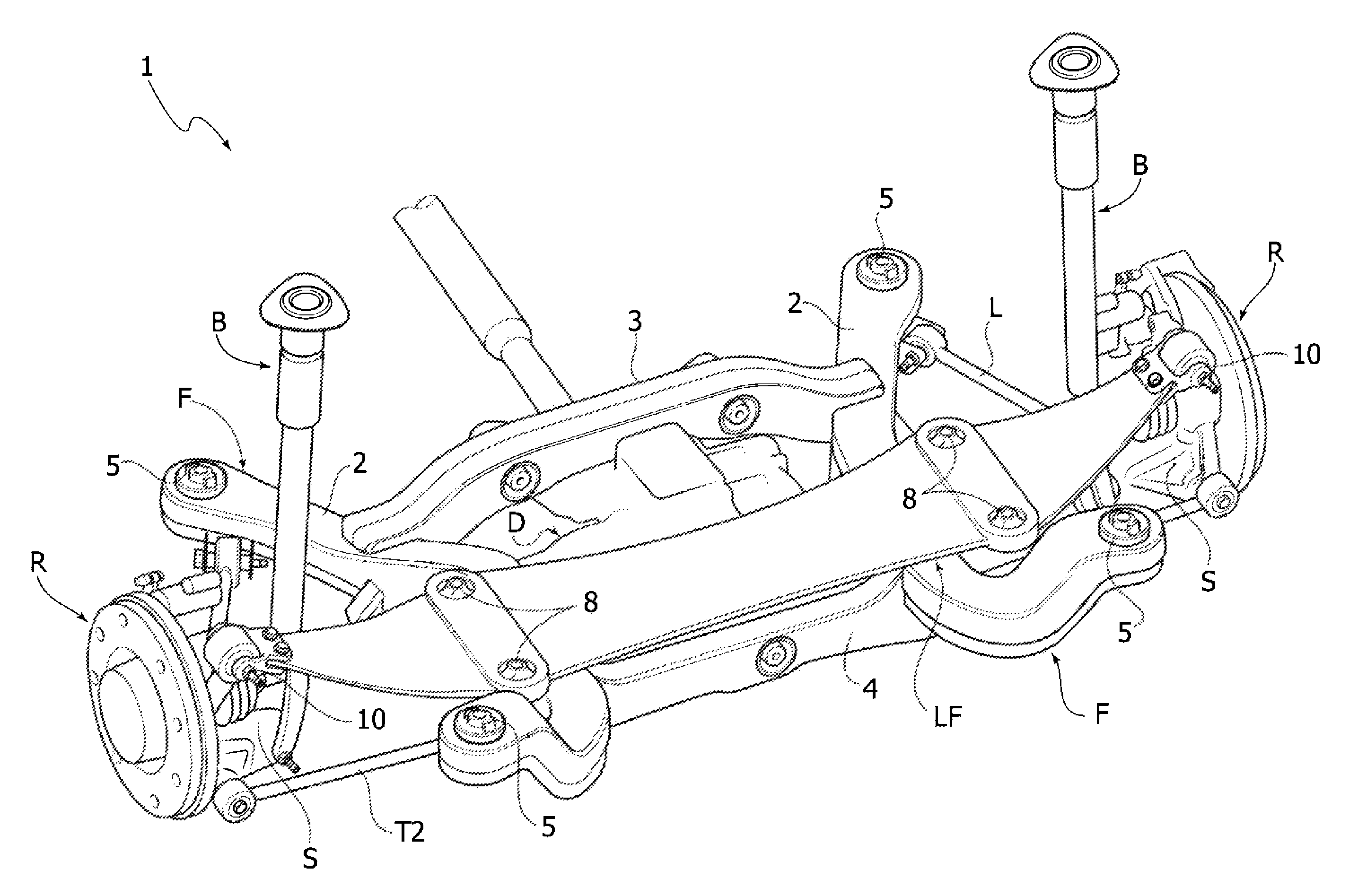

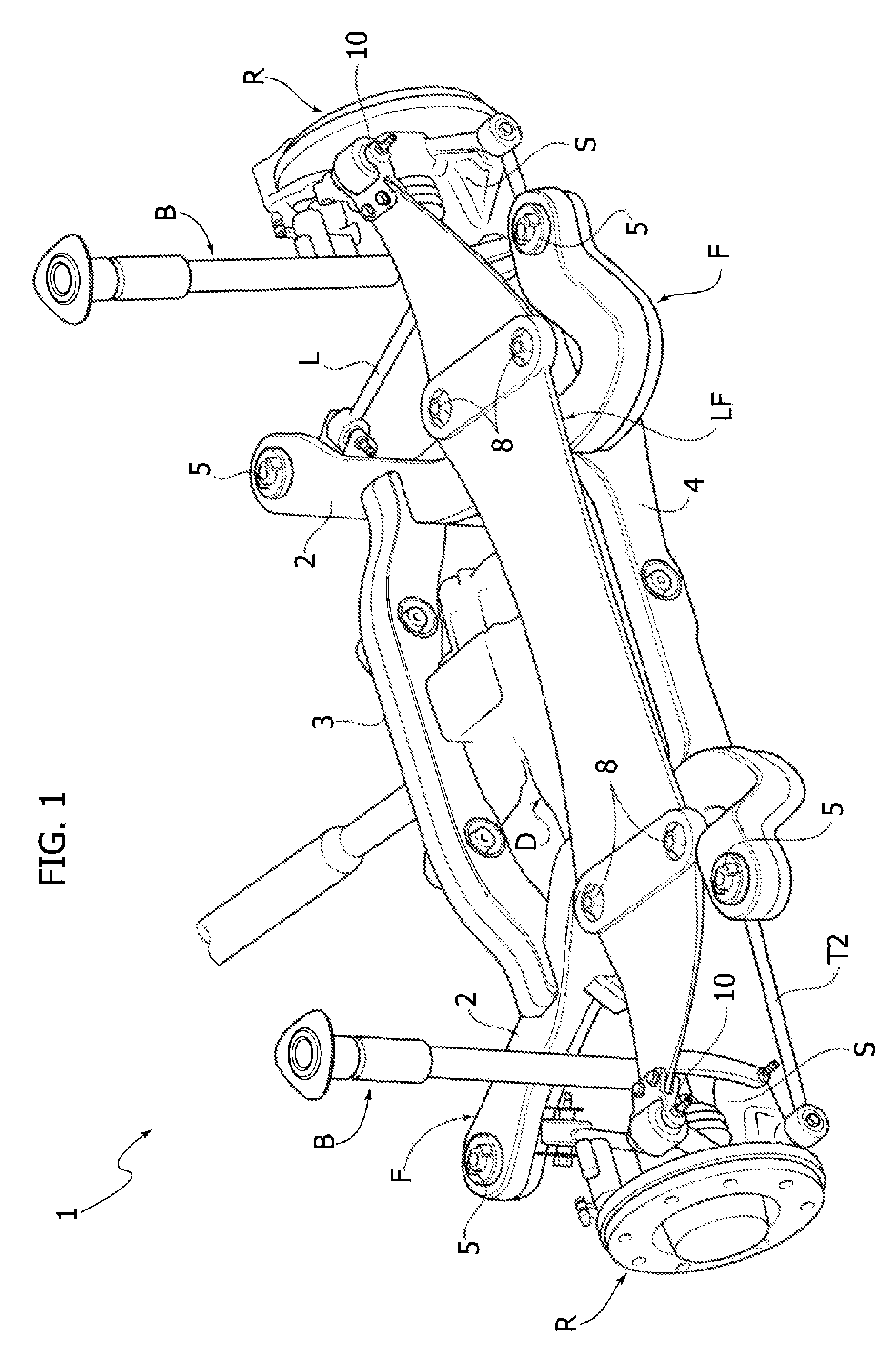

Motor vehicle multi-link suspension system including a transverse leaf spring

ActiveUS9073400B2Reduced dimensionReduce weightResilient suspensionsPivoted suspension armsEngineeringMotorized vehicle

A motor-vehicle multi-link suspension system includes, for each wheel, two lower transverse arms and a substantially longitudinal or inclined lower arm, each having one end pivotally connected to a respective wheel support and the opposite end pivotally connected to the motor-vehicle structure. A leaf spring is arranged transversally with respect to the longitudinal direction of the motor-vehicle. The leaf spring is supported by elastic supports arranged symmetrically at intermediate positions between the center of the leaf spring and the ends thereof. Ends of the leaf spring are pivotally connected to upper parts of the two wheel supports. Two jack-type shock absorbers have opposite ends swingably connected to the respective wheel support and the motor-vehicle structure. The end portions of the leaf spring also fulfill the function of triangular upper transverse arms of the multi-link suspension. Preferably the leaf spring is made of a composite material.

Owner:FIAT GRP AUTOMOBILES

Rear suspension for electric vehicle and vehicle body

ActiveCN105365543AIncrease stiffnessHigh strengthElectric propulsion mountingInterconnection systemsVehicle frameElectric vehicle

The invention discloses a rear suspension for an electric vehicle. By employing the rear suspension provided by the invention, space utilization ratio and crash safety can be improved. The rear suspension is a torsion beam type suspension and comprises two longitudinal supporting arms and a cross beam for connecting the two longitudinal supporting arms, wherein the front ends of the two longitudinal supporting arms are connected with a wheel bracket; and the back ends of the two longitudinal supporting arms are connected with a rear vehicle body through lining supports. The invention also provides a vehicle body. A battery box is additionally arranged at the vehicle bottom in front of the beam of the rear suspension. The vehicle body has the following beneficial effects that the conventional design is broken through, the longitudinal supporting arms are reversely arranged, a new space is made in a safety region in front of the cross beam of the rear suspension so as to place a battery, and about 35 percent regular space is added to place the battery, so that the endurance mileage of the electric vehicle is increased, and in addition, crash safety protection to the battery is added. The invention also discloses a reversely arranged multi-connecting-rod suspension. Longitudinal connecting rods of the multi-connecting-rod suspension are reversely arranged, the front ends of the longitudinal connecting rods are connected with wheels, and the back front ends of the longitudinal connecting rods are connected with an auxiliary vehicle frame after backward movement.

Owner:ENOVA TECH

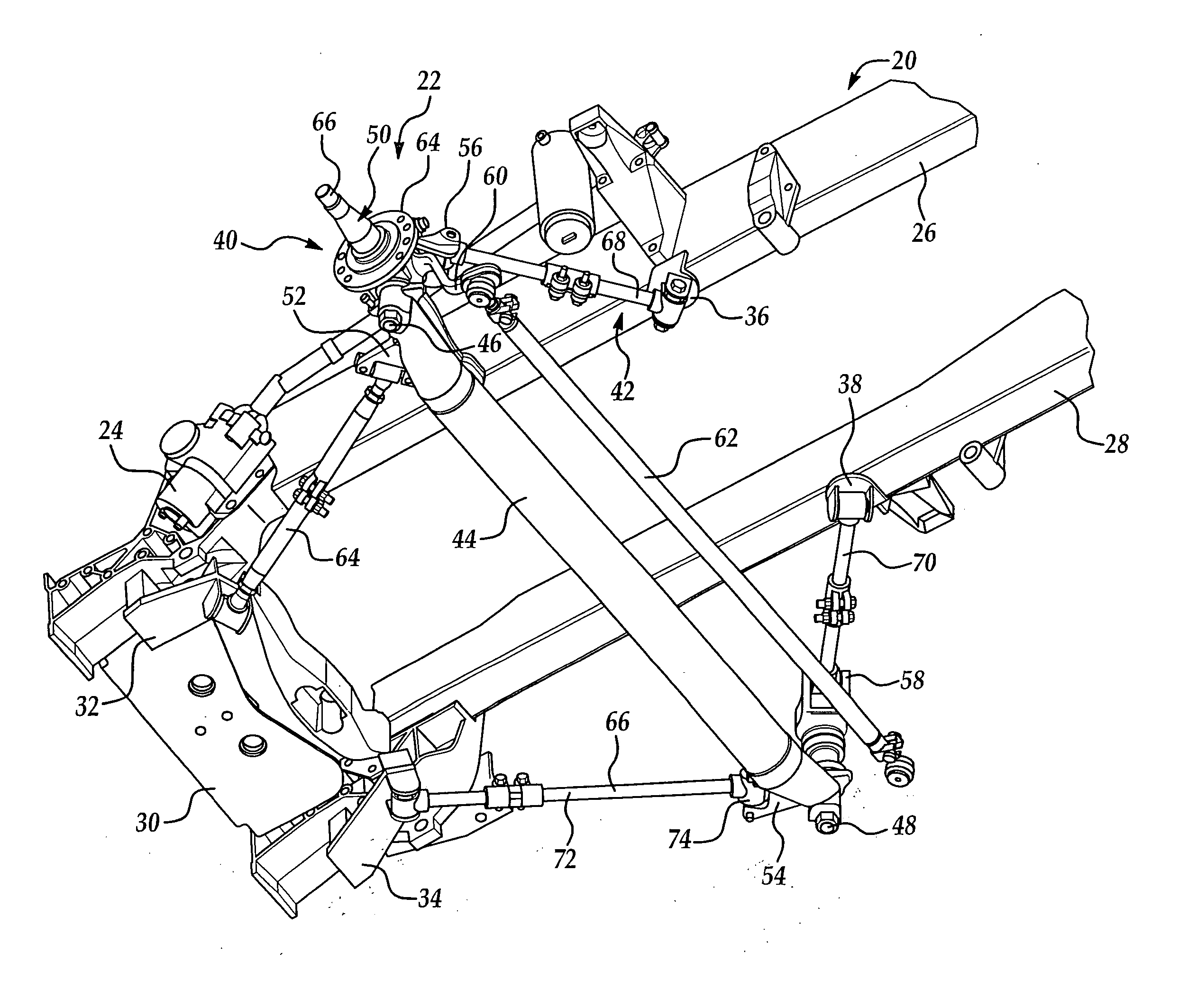

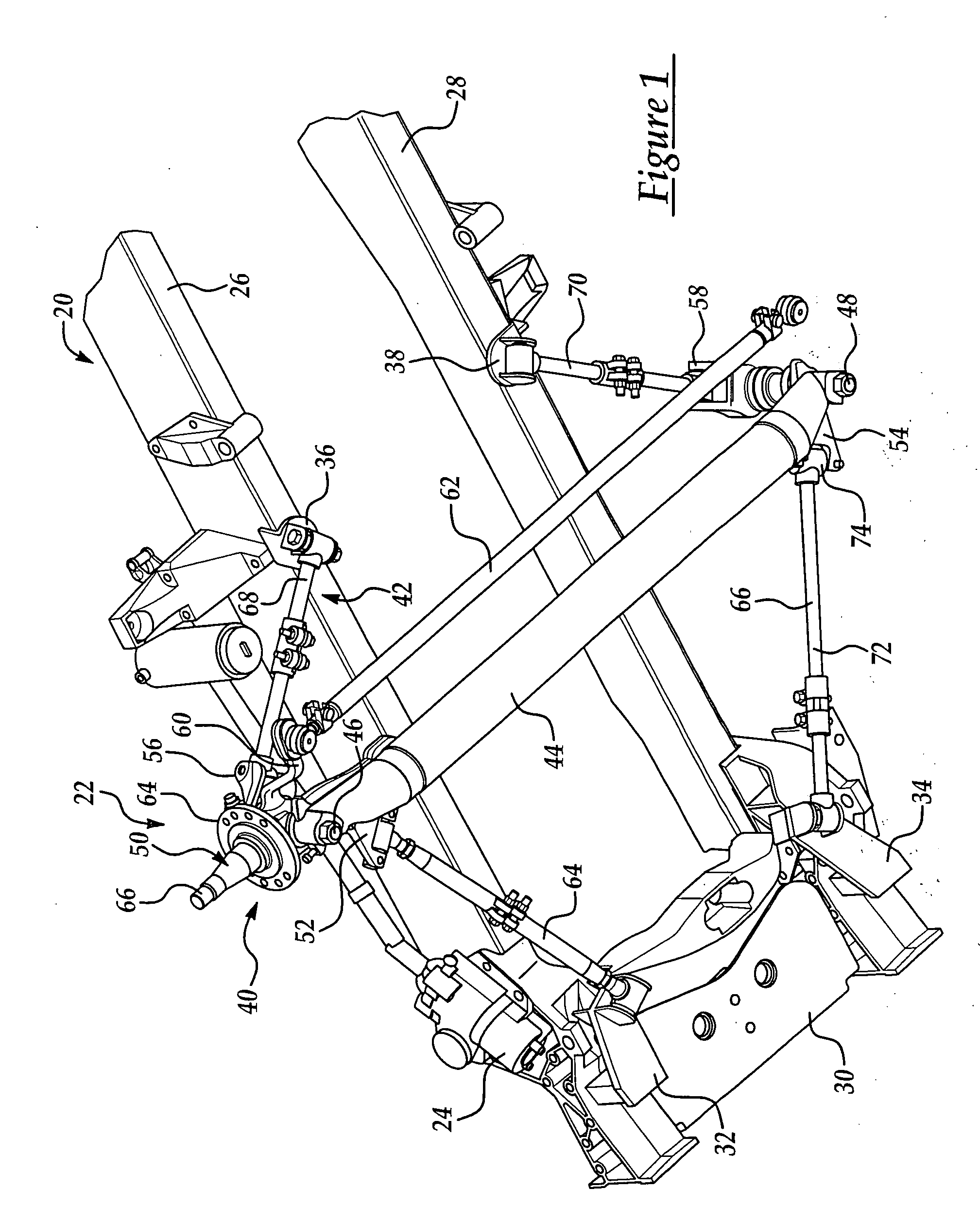

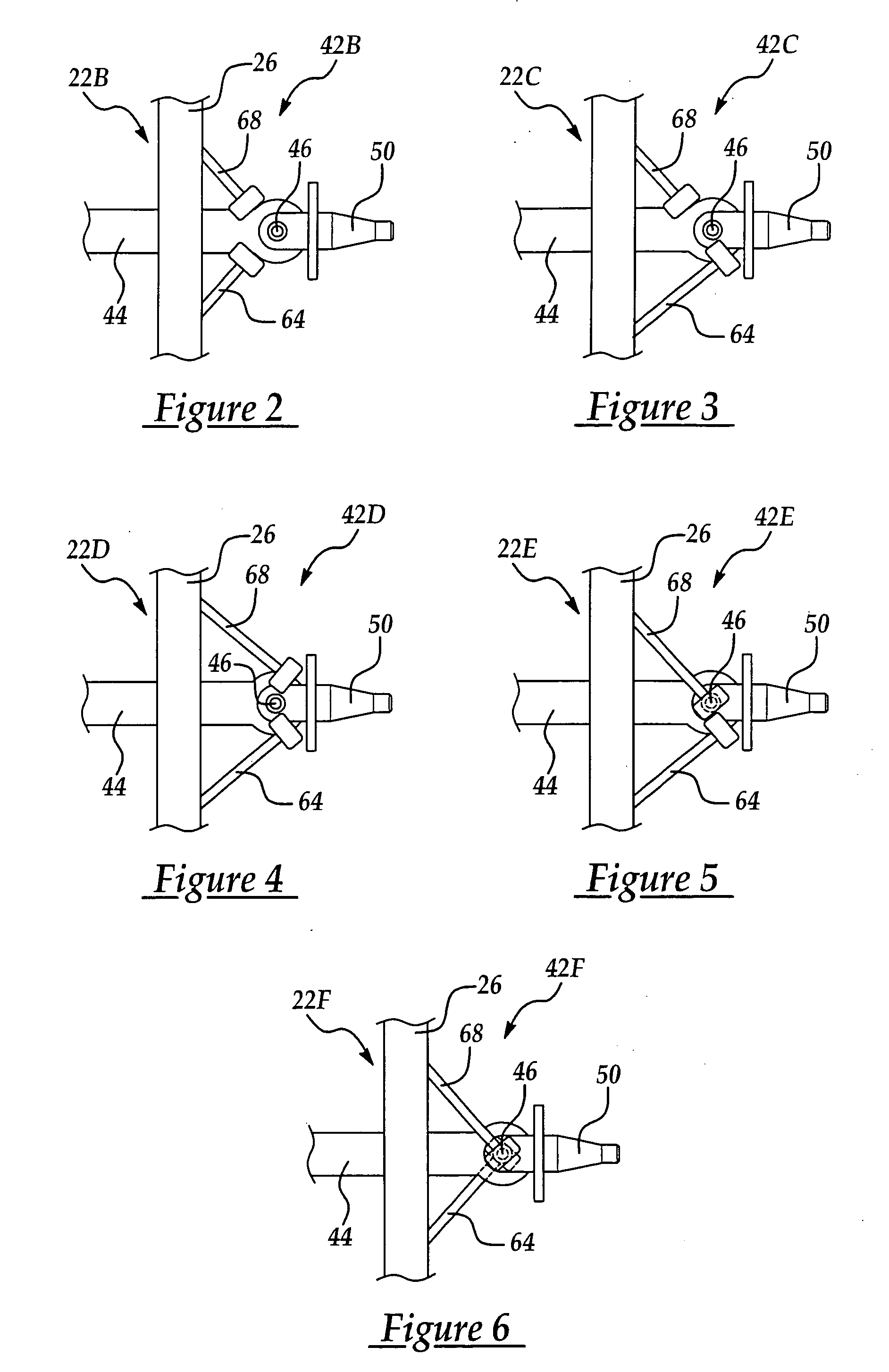

Beam axle suspension with diagonal link

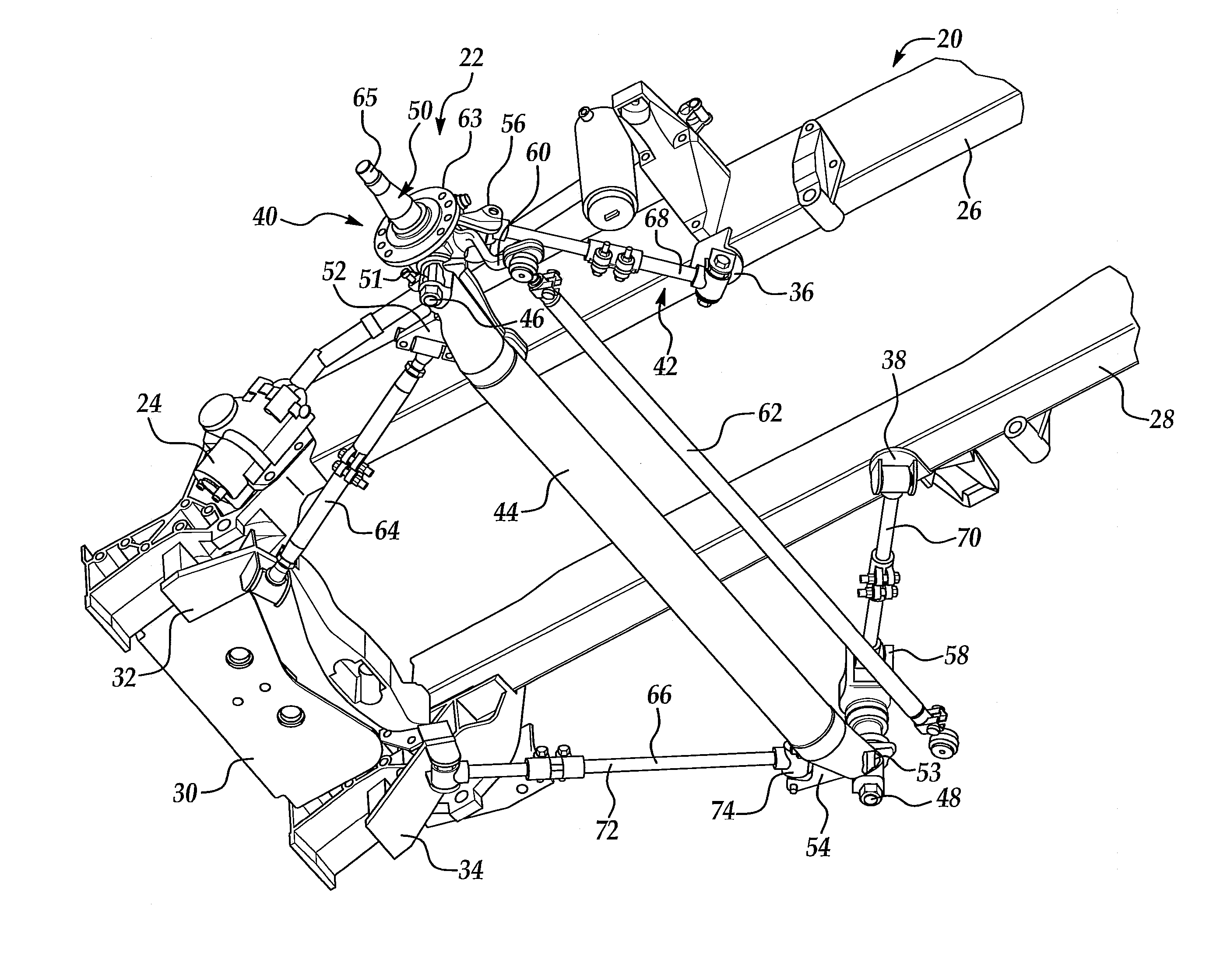

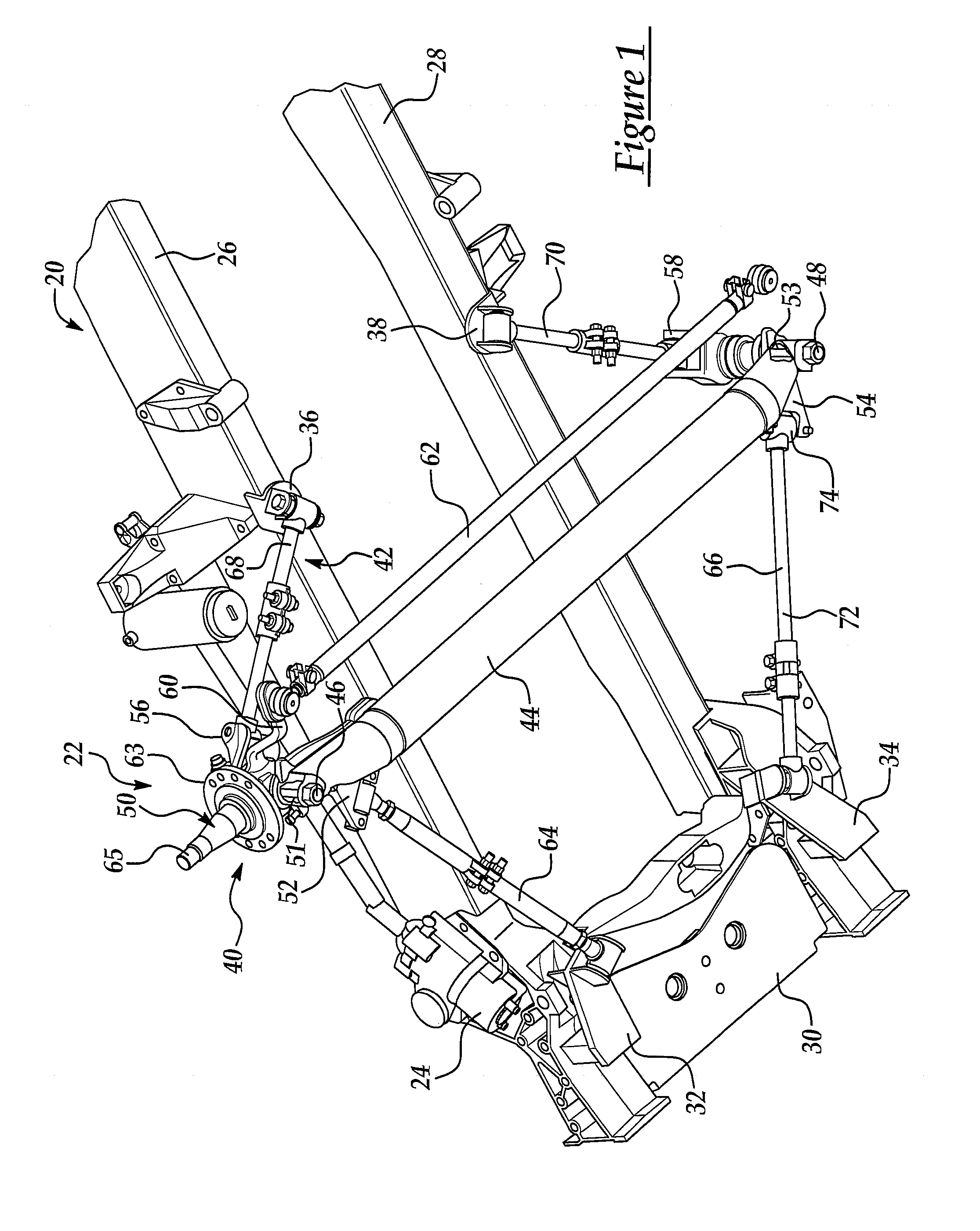

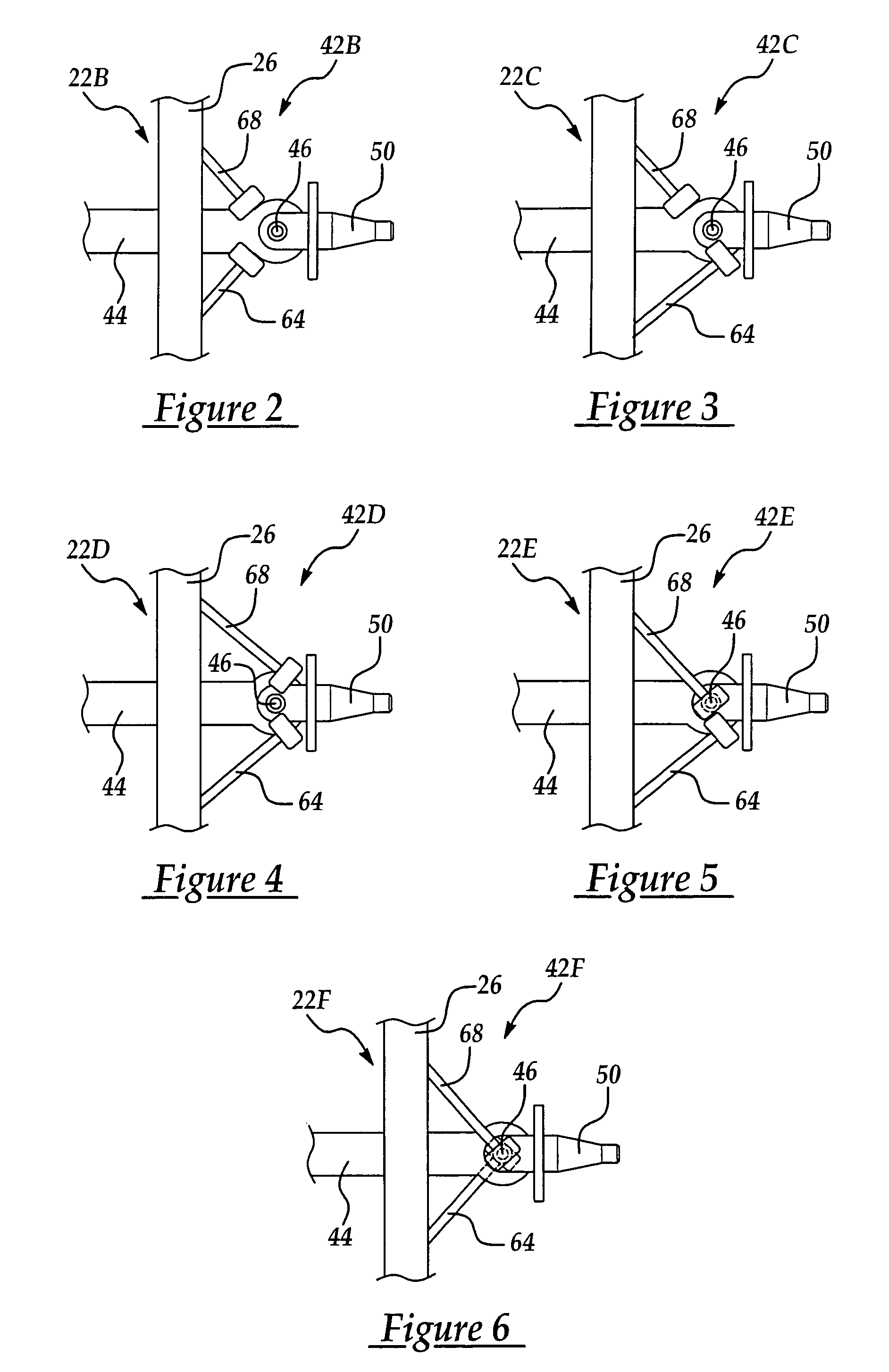

A steer axle and suspension assembly are provided that produce lateral stability in the vehicle without the use of a transverse rod and without generating undue loads on the steer axle beam. The assembly includes at least one suspension arm that is connected to the frame and to a component of the steer axle assembly such as the axle beam, kingpin, or steering knuckle. The suspension arm is connected to the steer axle assembly at a location outboard of the longitudinal frame rails of the vehicle and extends longitudinally at an angle to the frame rails. The suspension arm arrangement can be used with a variety of suspensions including leaf spring and multi-link suspensions.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

Four-link vehicle suspension system

InactiveUS20050046136A1Minimizing unwanted “ wind up ” movementReduce torqueRigid suspensionsResilient suspensionsVehicle suspension systemAutomotive engineering

Owner:FORD GLOBAL TECH LLC

Motor-vehicle multi-link suspension system including a transverse leaf spring

ActiveUS20140327219A1Reduced dimensionReduce weightUnderstructuresResilient suspensionsEngineeringMotorized vehicle

A motor-vehicle multi-link suspension system includes, for each wheel, two lower transverse arms and a substantially longitudinal or inclined lower arm, each having one end pivotally connected to a respective wheel support and the opposite end pivotally connected to the motor-vehicle structure. A leaf spring is arranged transversally with respect to the longitudinal direction of the motor-vehicle. The leaf spring is supported by elastic supports arranged symmetrically at intermediate positions between the center of the leaf spring and the ends thereof. Ends of the leaf spring are pivotally connected to upper parts of the two wheel supports. Two jack-type shock absorbers have opposite ends swingably connected to the respective wheel support and the motor-vehicle structure. The end portions of the leaf spring also fulfill the function of triangular upper transverse arms of the multi-link suspension. Preferably the leaf spring is made of a composite material.

Owner:FIAT GRP AUTOMOBILES

Control arm of multilink suspension system for vehicle

A control arm may be formed by assembling front and rear members respectively having upper and lower flanges so as to have a tubular cross-section, and a bending portion may be formed by bending the lower flange of the front member downwardly such that a drain hole is formed by the bending portion protruded downwardly when the front and rear members are assembled.

Owner:HYUNDAI MOTOR CO LTD +1

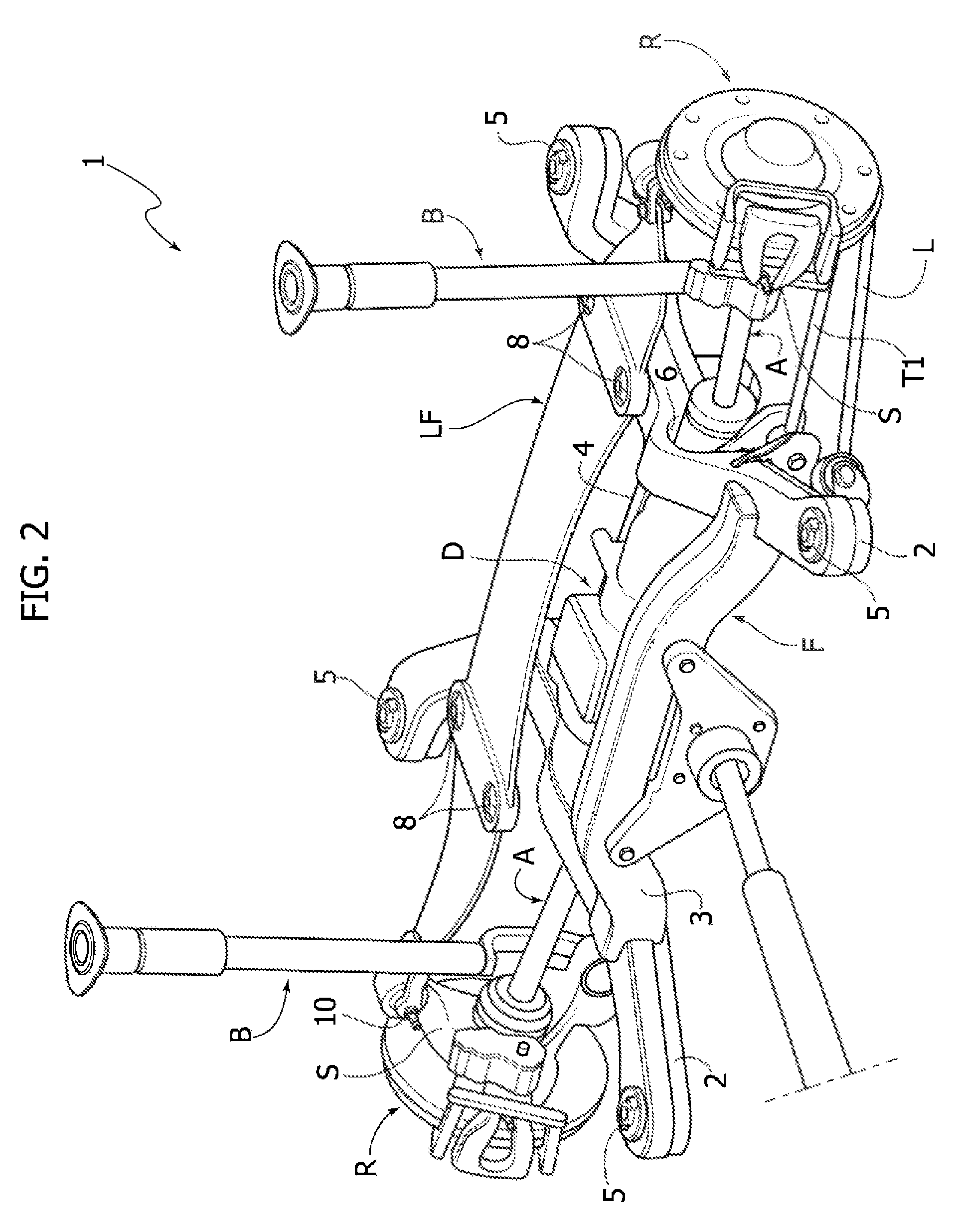

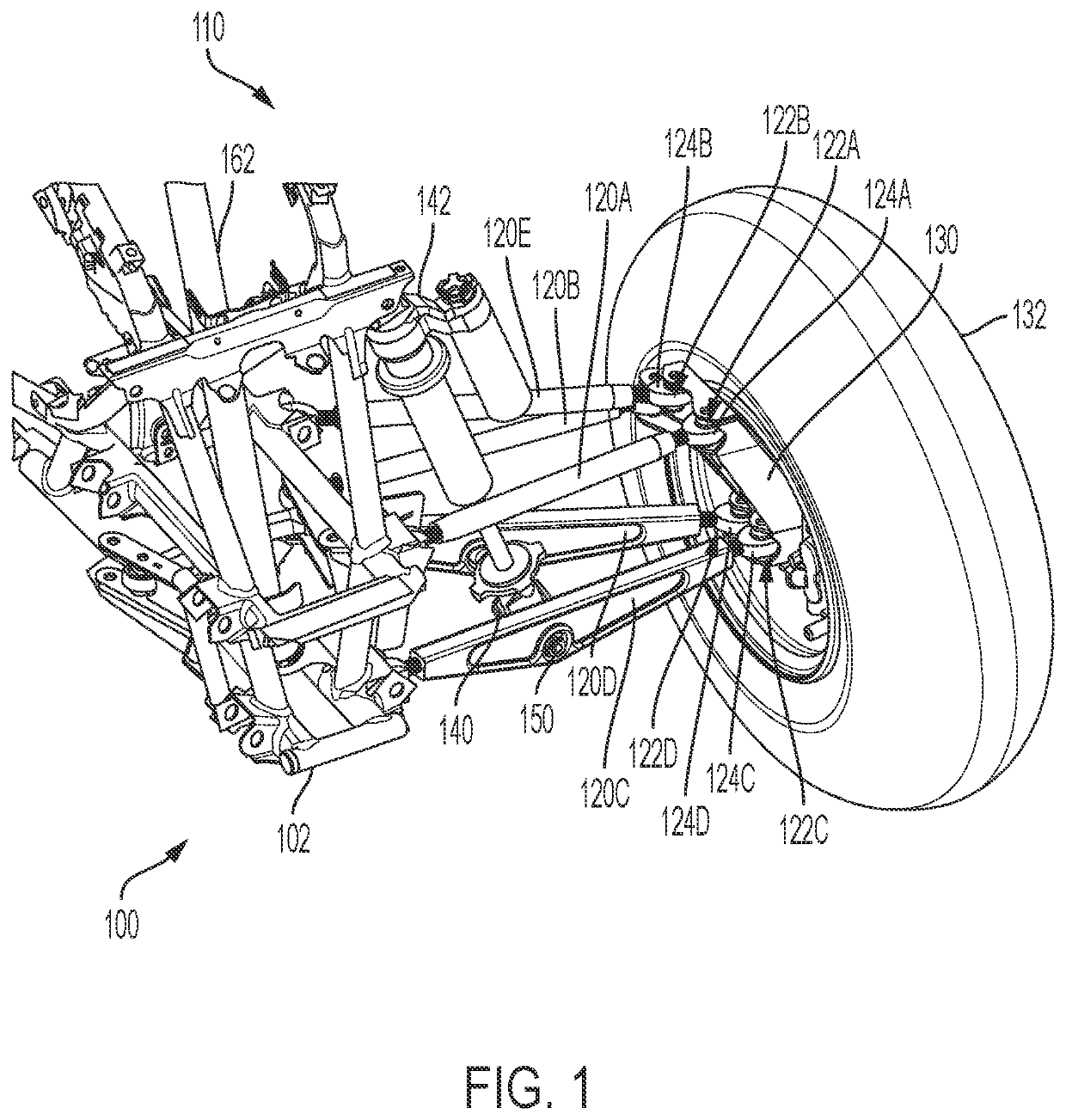

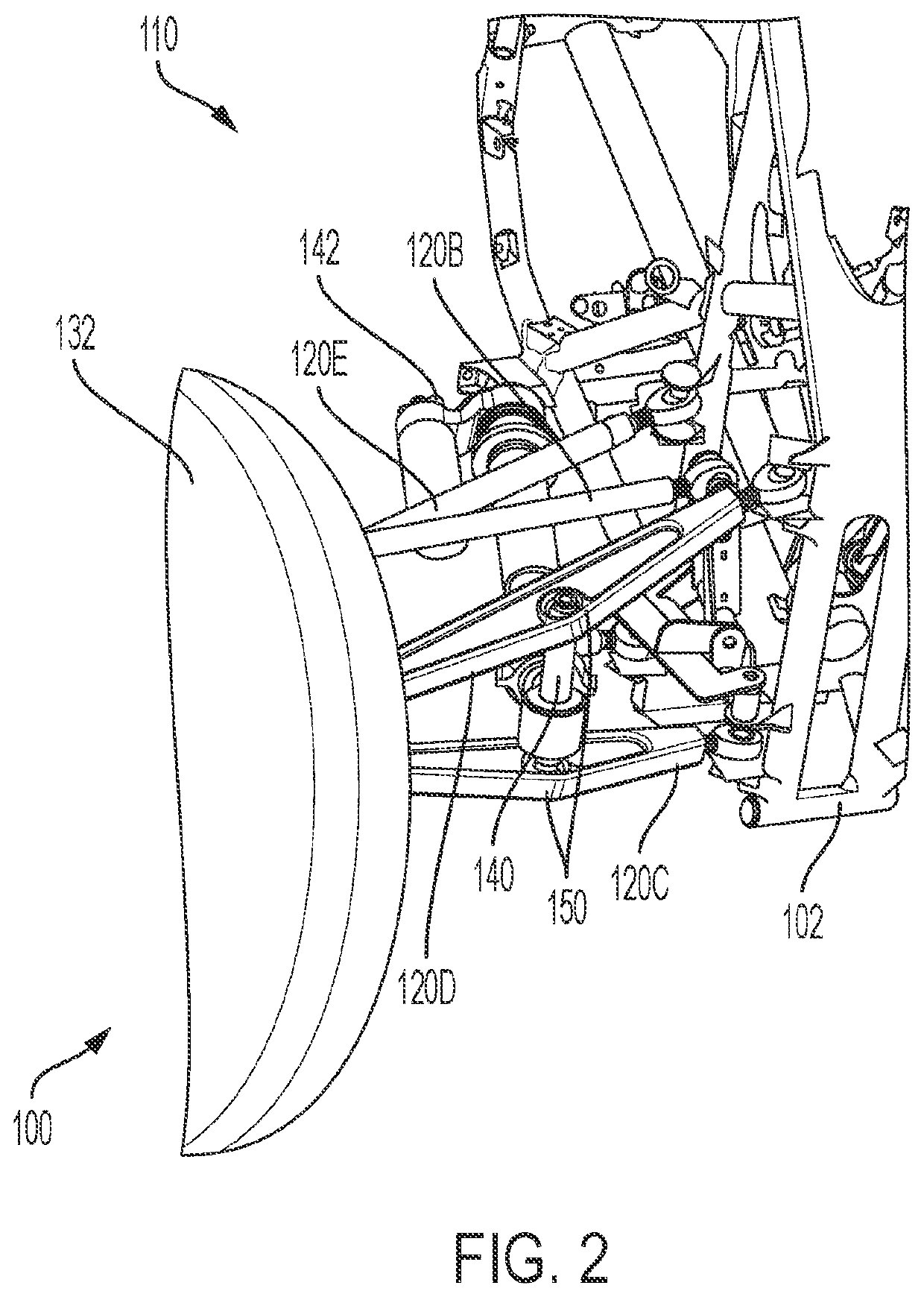

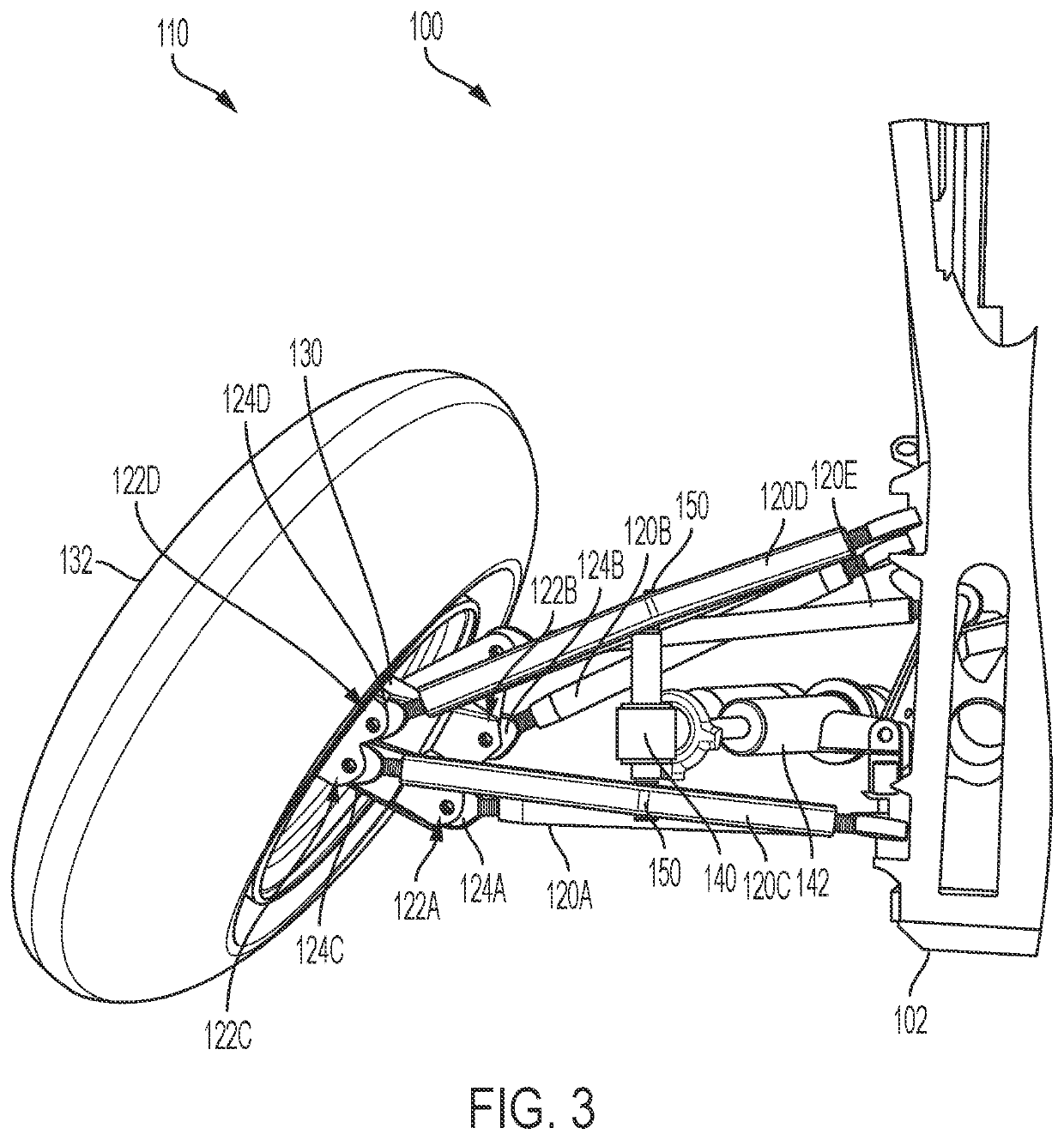

Suspension system

ActiveUS11192414B1Convenient angleRemove feedbackCyclesAxle suspensionsClassical mechanicsEngineering

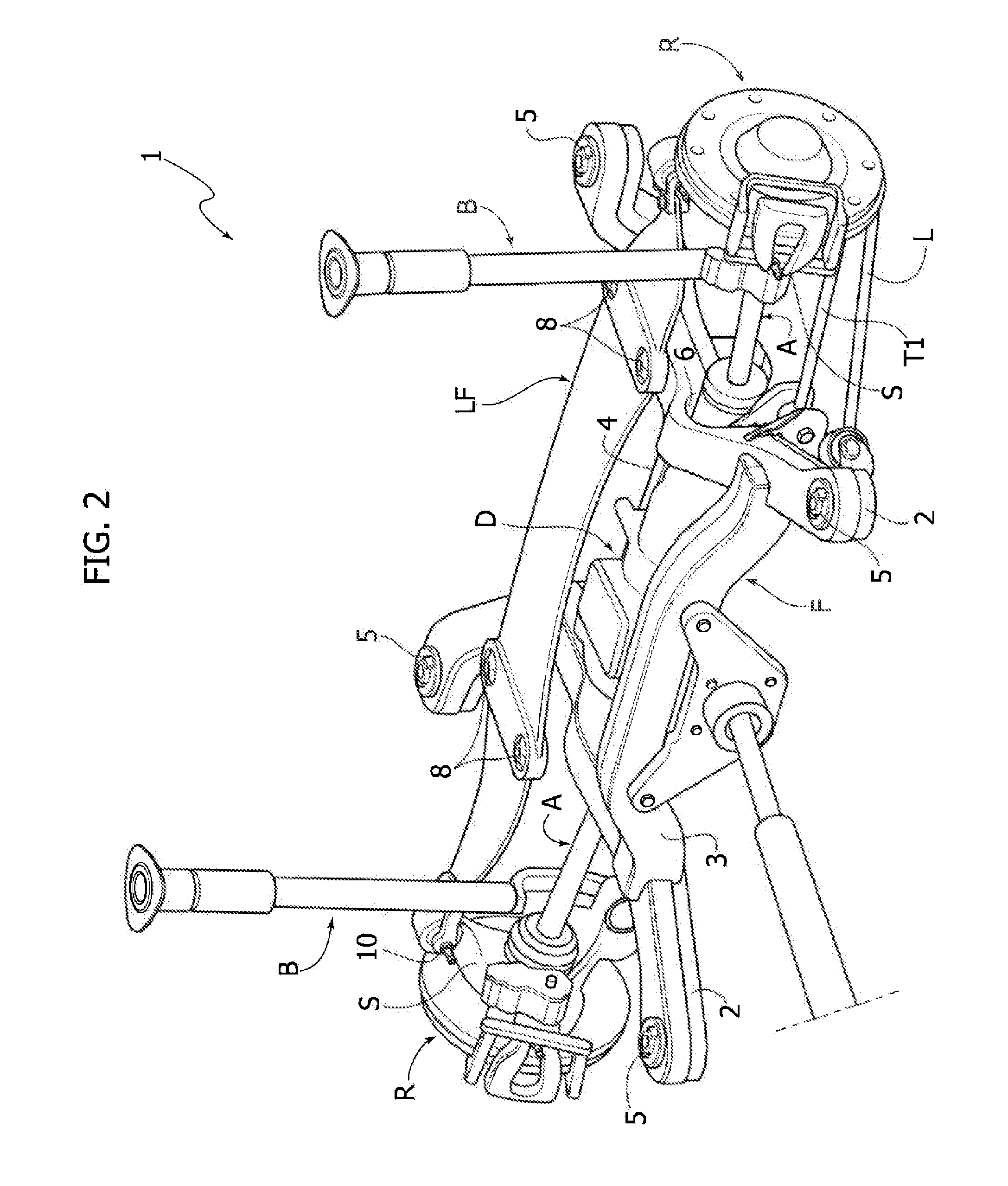

Multi-link suspension systems for vehicle are described having various linkage arms that connect to distinct points of a wheel mount. Each of the linkage arms are preferably coupled to the wheel mount via a spherical ball joint and mounted such that they can independently move with respect to the other linkage arms. A shock assembly is preferably mounted between two of the linkage arms on a separate links that is configured to vary its length based on movement of one or both of the two linkage arms.

Owner:XTRAVEL SUSPENSION LLC

Suspension systems, wheel spindle assemblies, and methods of retrofitting wheel spindles

A method of mounting to an A-arm suspension system a wheel spindle configured for use with a multi-link suspension system may involve the steps of: Removing at least one suspension link mount on the wheel spindle; mounting a ball joint bracket to the wheel spindle, the ball joint bracket being configured to mount to the A-arm suspension system, the removing and mounting steps producing a modified wheel spindle; and mounting the modified wheel spindle to the A-arm suspension system.

Owner:VANTAGE MOBILITY INT

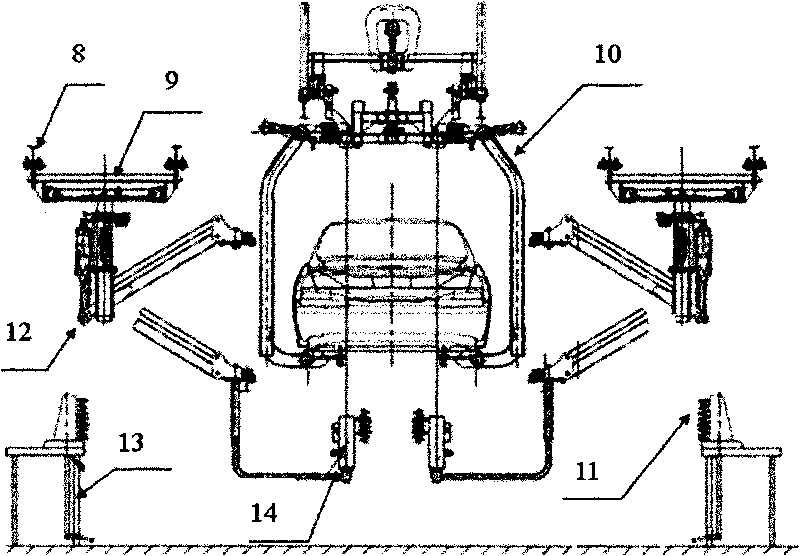

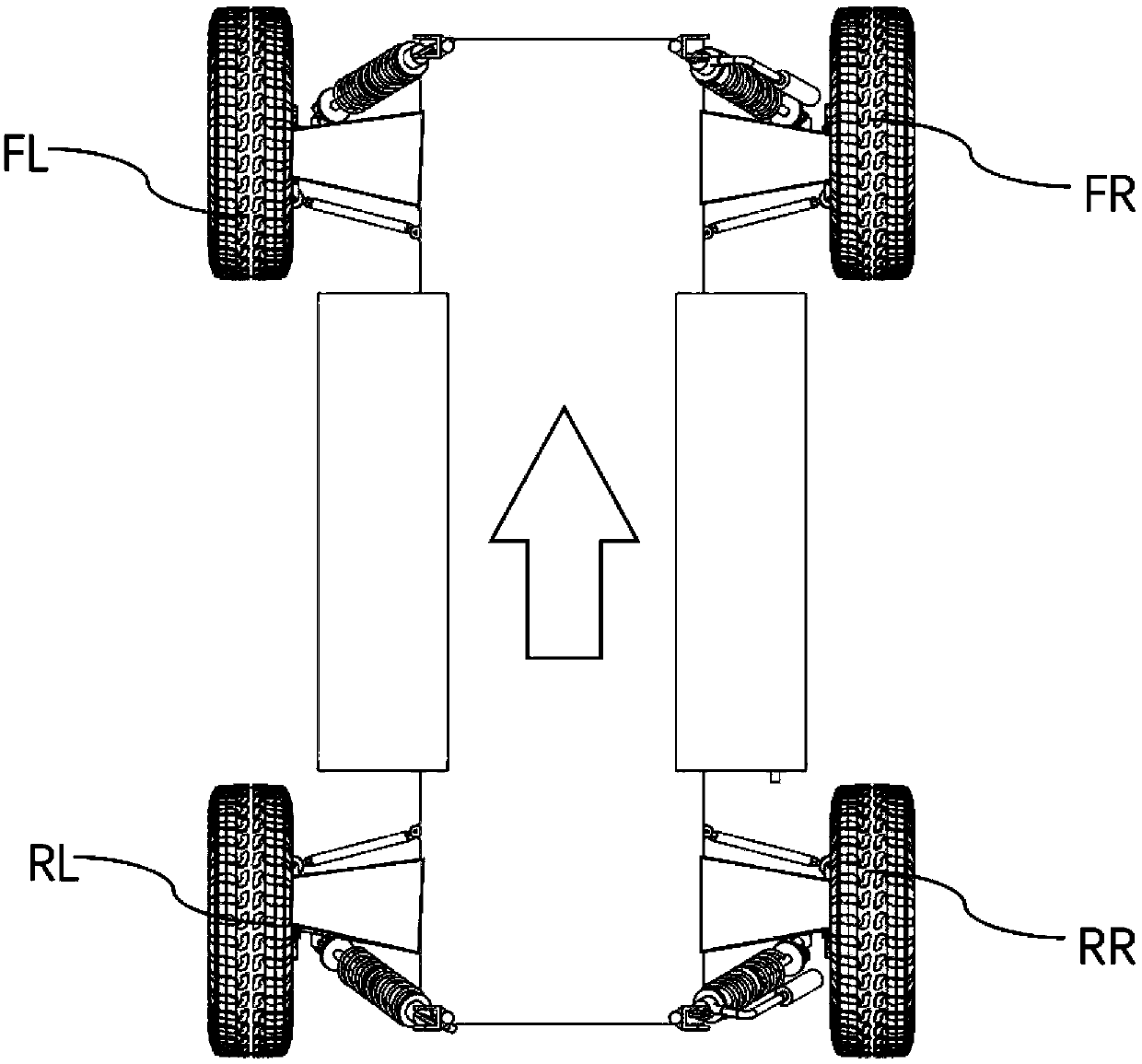

Method for assembling multi-link suspension

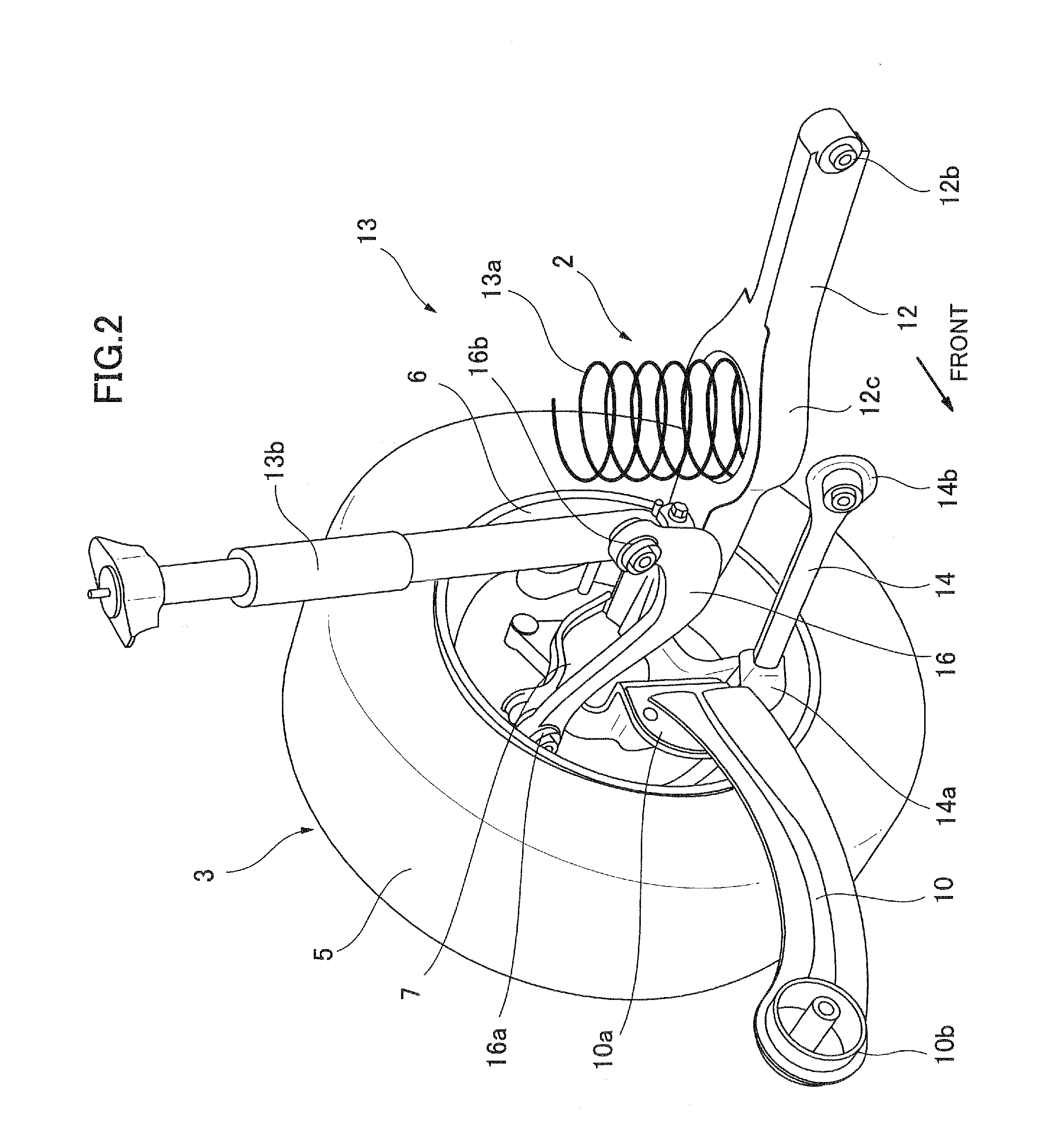

ActiveCN101698270AReduce assembly labor intensityShort time beatMetal working apparatusCoil springEngineering

The invention provides a method for assembling a multi-link suspension. The method comprises the following steps that: in parts and components of a rear suspension assembly, besides a spiral spring (7), other parts and components can be assembled into an assembly module below-the-line; then the assembly module is suspended onto a clamp of a jacking cart; besides the spiral spring (7), other parts are assembled with the body on the right positions; a manipulator is moved to an auxiliary workbench (13) to extend a spiral spring jaw (14) into the spiral spring (7), the spiral spring (7) is compressed to a certain height L; the spiral spring (7) is placed on a position of a lower swing arm (6) through the spiral spring jaw (14); and a compressing device of the spiral spring jaw (14) is released to complete assembly of the suspension. The operation method can be observed that compared with the prior assembling method, the method has low labor intensity of staff assembly, short time stamp, and can meet the assembling requirement under a condition that the self weight of the body cannot bear that elasticity of the spring and the axes of the spring have a certain inclination angle.

Owner:CHERY AUTOMOBILE CO LTD

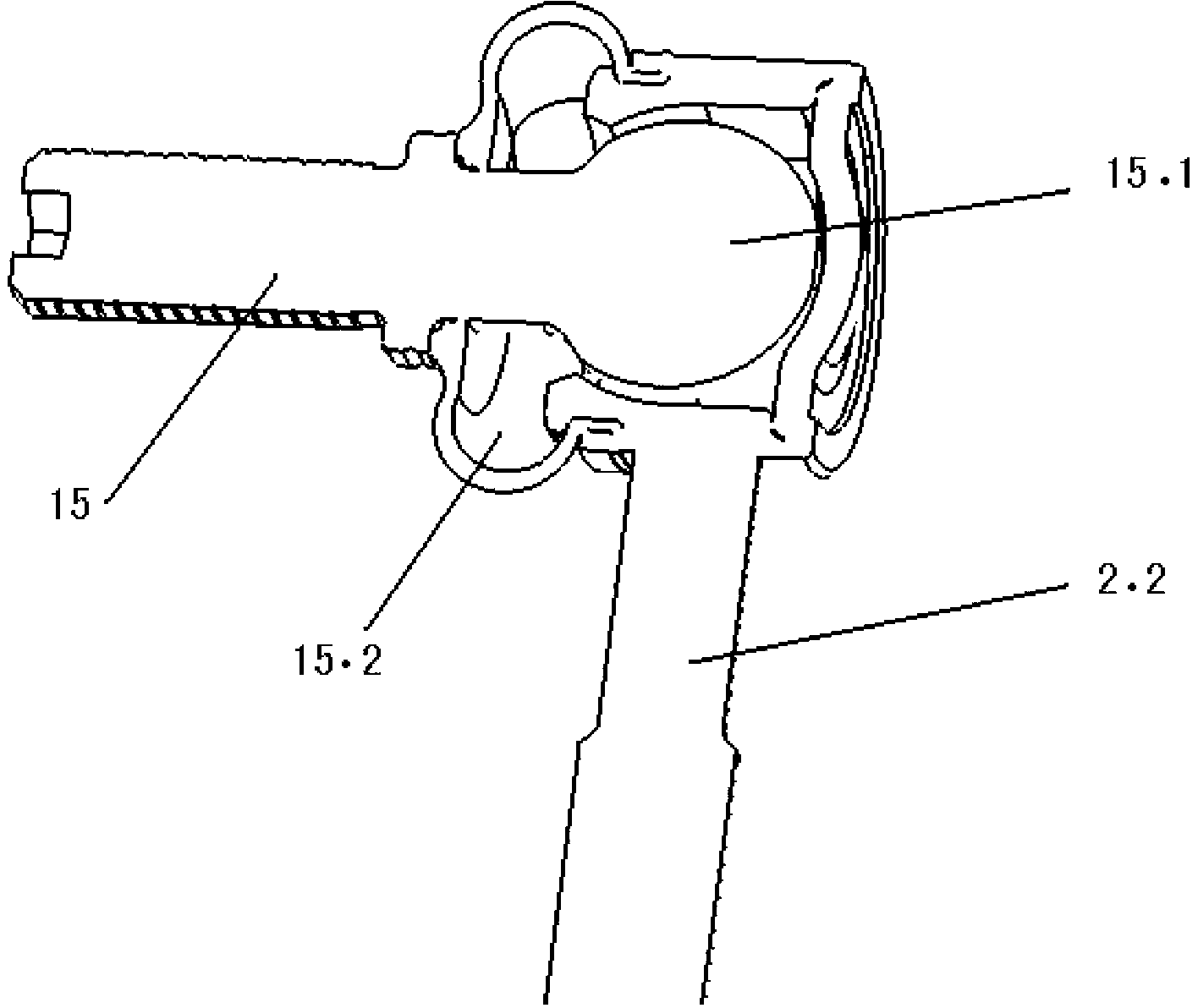

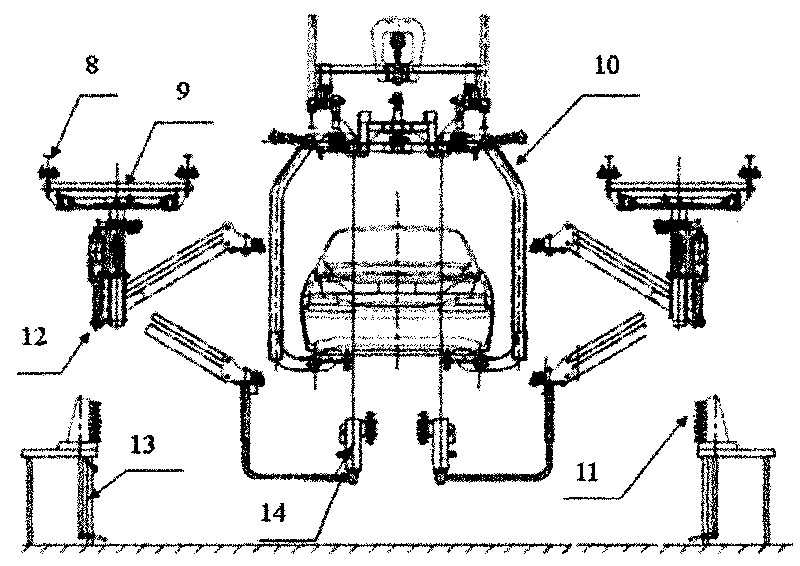

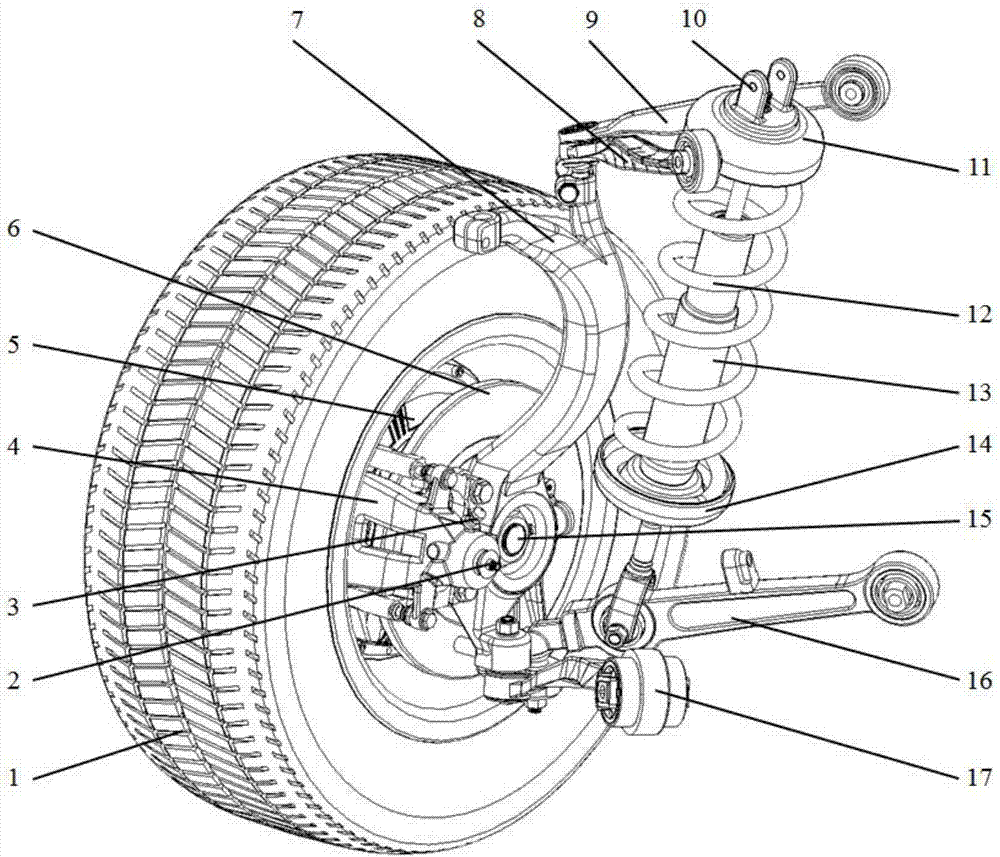

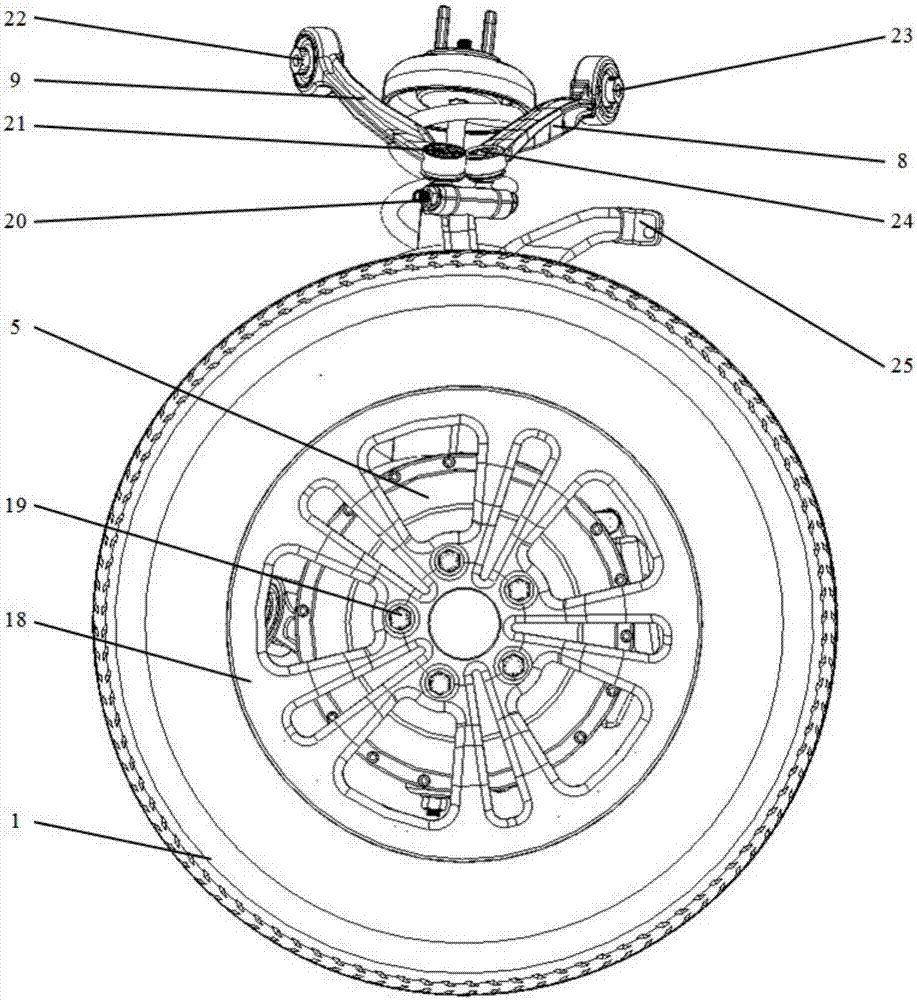

Multi-connecting-rod suspension mechanism for front and rear universal use in vehicle driven by wheel hub motor and

The invention discloses a multi-connecting-rod suspension mechanism for front and rear universal use in a vehicle driven by a wheel hub motor. The multi-connecting-rod suspension mechanism comprises asteering knuckle assembly, a lower front control connecting rod, a lower rear control connecting rod, an upper control arm assembly, a damper assembly and a spring, and the steering knuckle assemblyis hinged to the upper control arm assembly through an upper control arm outer ball hinge; the steering knuckle assembly is hinged to the lower front control connecting rod through a lower front control connecting rod outer ball hinge; the steering knuckle assembly is hinged to the lower rear control connecting rod through a lower rear control connecting rod outer ball hinge. The multi-connecting-rod suspension mechanism overcomes the limitations of insufficient space and large unsprung mass of a wheel hub motor suspension frame, the structure of the suspension frame is more compact, and the controllability and stability are better; a driving mechanism, a partial guiding mechanism and a braking device are all integrated into a wheel hub, so that the multi-connecting-rod suspension mechanism has the advantage of high integration degree, the general platform design of the whole vehicle is facilitated, the development cycle is greatly shortened, and the production line cost and the industrial chain scale can be greatly reduced; thus, the multi-connecting-rod suspension mechanism has good application prospects and high market value.

Owner:KH AUTOMOTIVE TECH CHANGCHUN

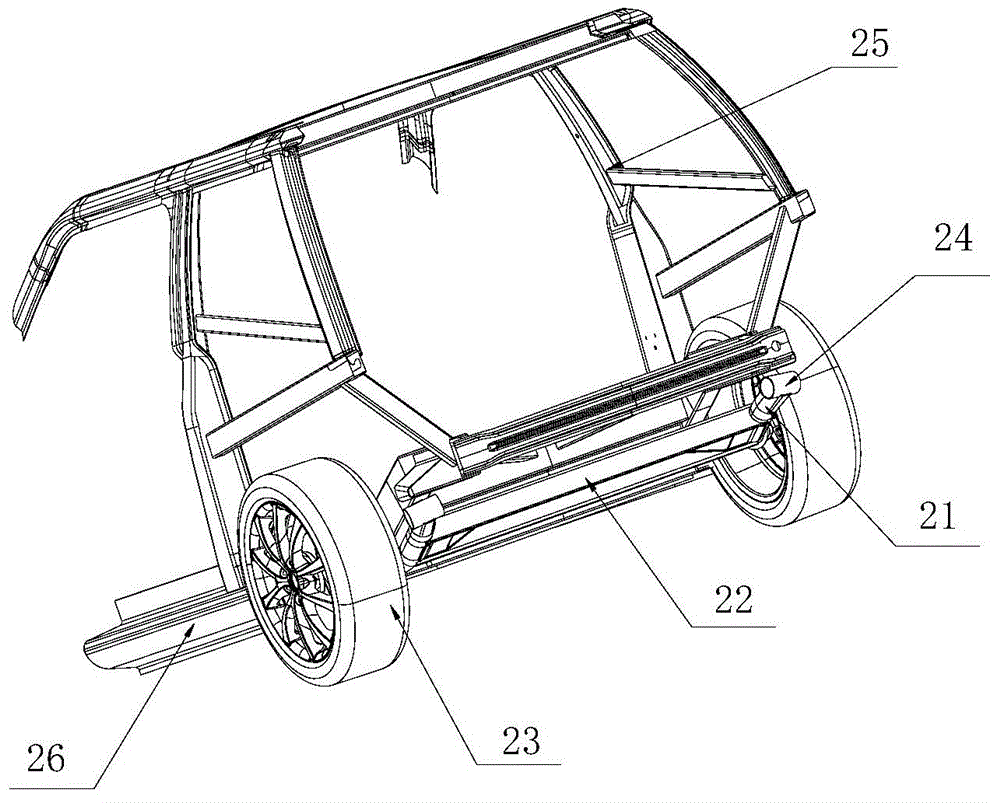

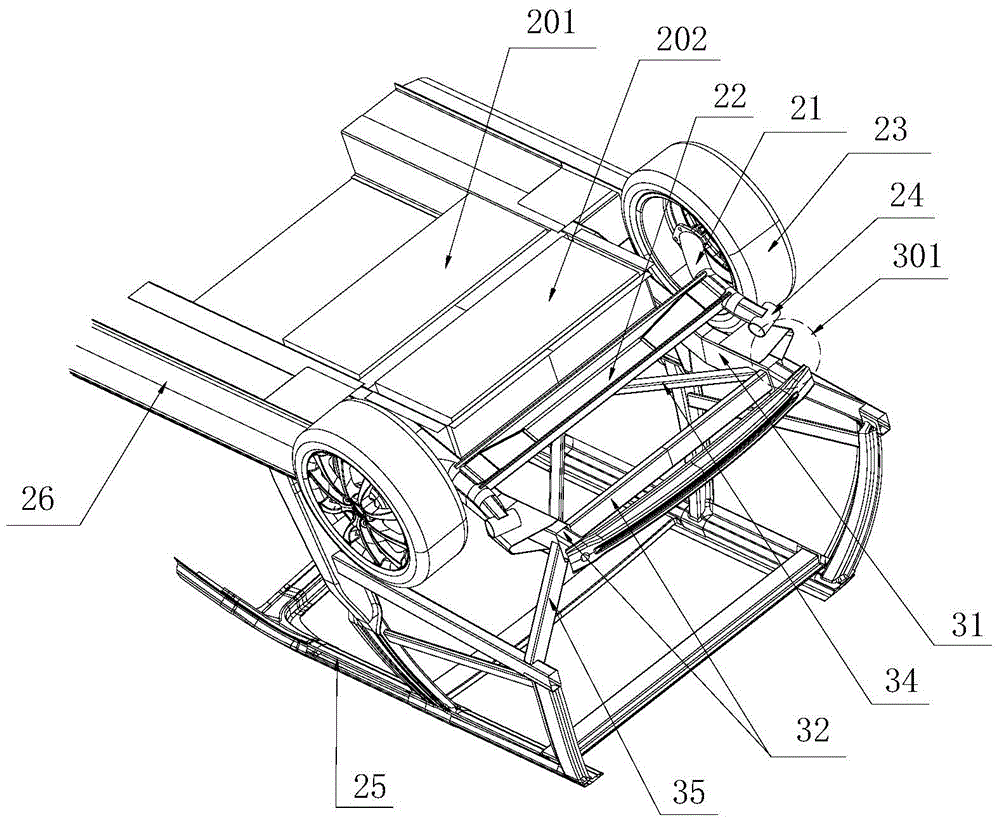

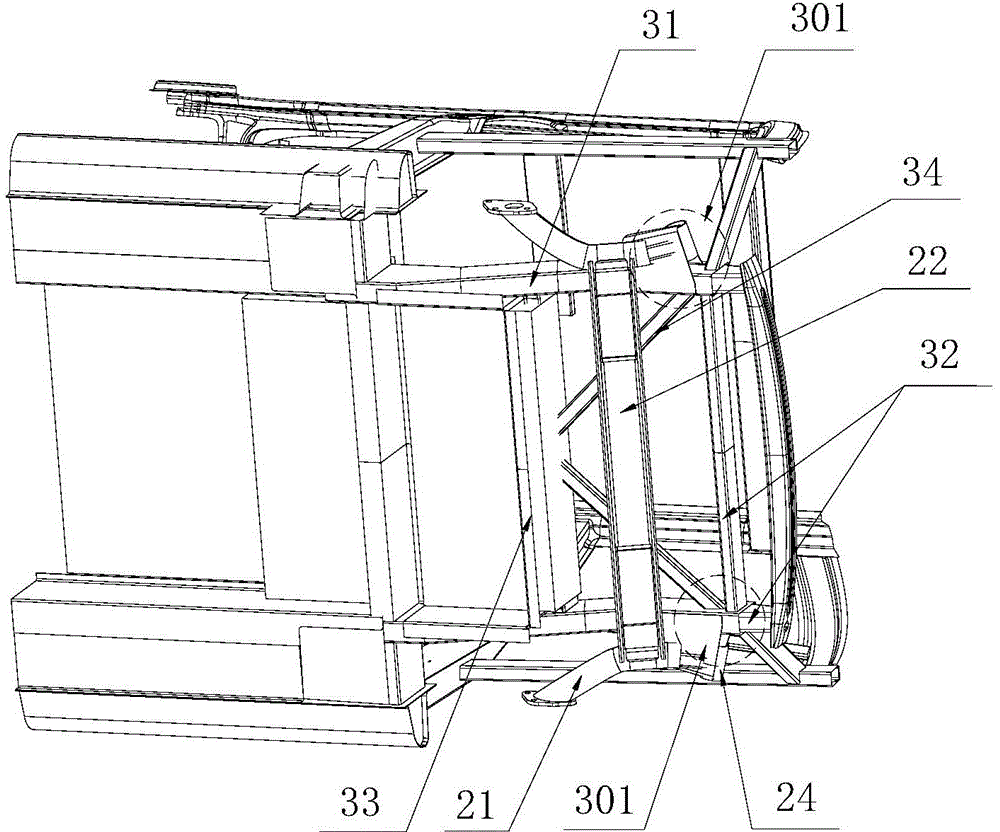

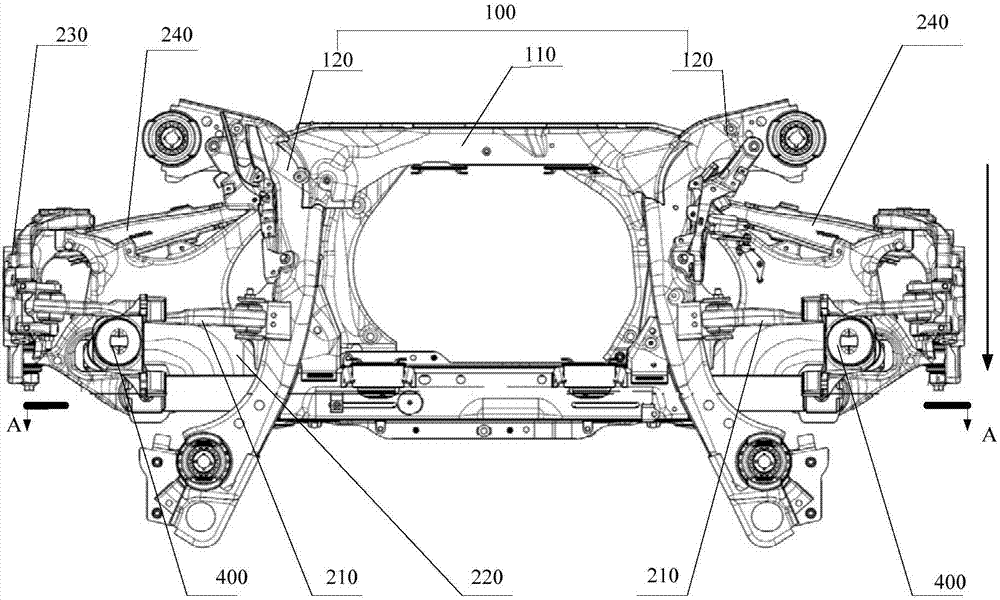

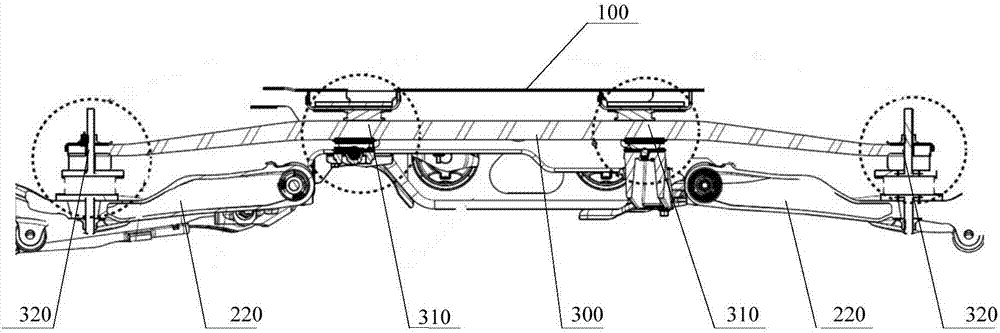

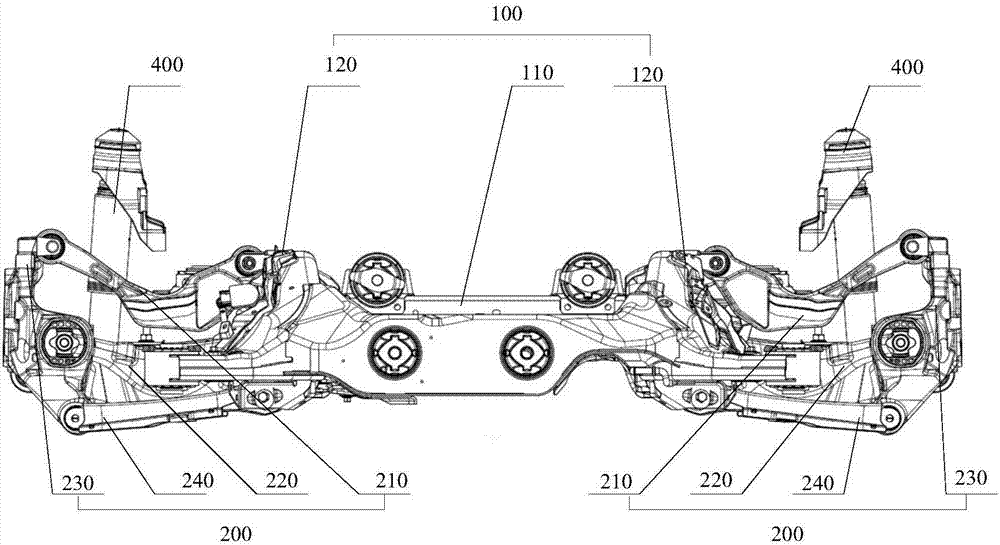

Multi-connecting-rod suspension frame and vehicle assembly thereof

PendingCN107499080ASmooth rideReduce weightResilient suspensionsVehicle springsVehicle frameEngineering

The invention relates to the technical field of chassis, in particular to a multi-connecting-rod suspension frame and a vehicle assembly thereof. The multi-connecting-rod suspension frame comprises a plate spring, a subsidiary vehicle frame and two sets of connecting rod components; the two sets of connecting rod components are arranged at the two sides of the subsidiary vehicle frame respectively; the subsidiary vehicle frame, the spring plate and the two sets of connecting rod components are arranged from top to bottom in sequence, and the plate spring is connected with the two sets of the connecting rod components. The multi-connecting-rod suspension frame solves the technical problem that too much space is occupied in the height direction when too many connecting rods exist.

Owner:ZHEJIANG YINGLUN AUTOMOBILE CO LTD +2

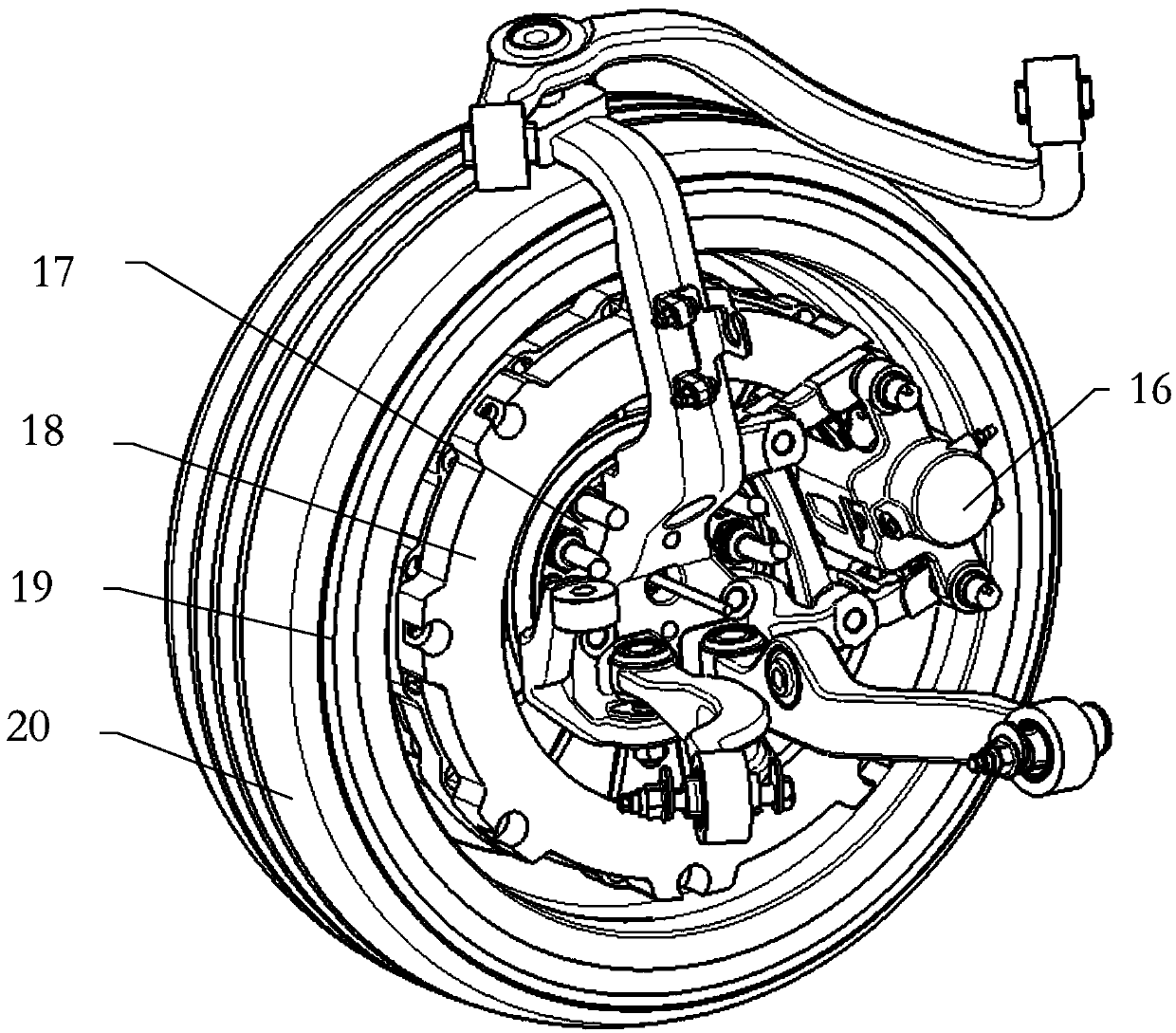

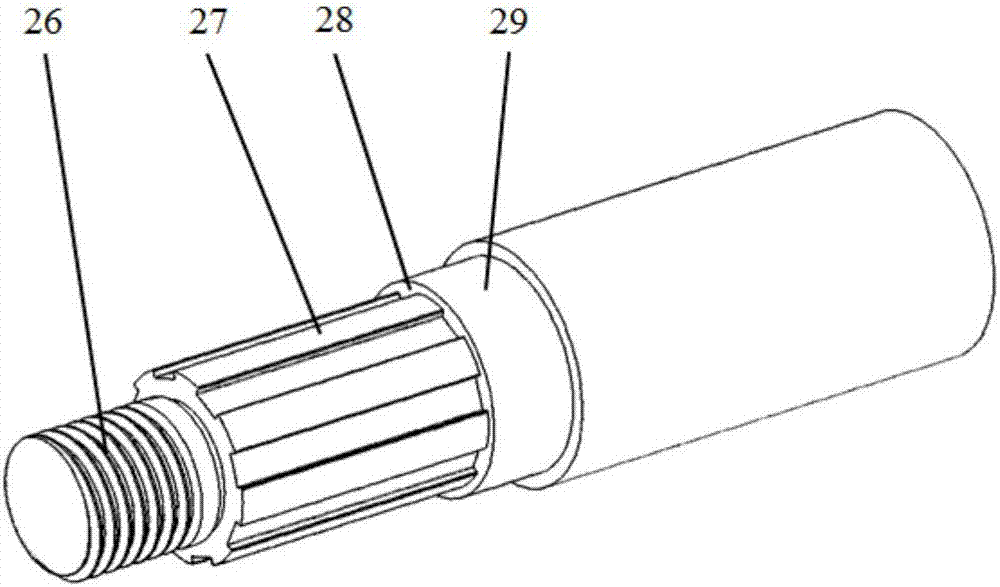

Multi-link suspension wheel rim drive system of wheel hub motor direct-drive electric vehicle

PendingCN106994875AImprove cooling effectImprove versatilitySteering linkagesMotor depositionVehicle frameControl arm

The invention discloses a multi-link suspension wheel rim drive system of a wheel hub motor direct-drive electric vehicle. The multi-link suspension wheel rim drive system comprises a tire, a wheel hub and a wheel hub motor, wherein the wheel hub motor is connected with the wheel hub through wheel hub bolts. A wheel hub motor shaft, a steering knuckle, an upper rear control arm, an upper front control arm, a lower front control arm, a lower rear control arm and a shock absorber are included, wherein the middle of the steering knuckle is connected with the wheel hub motor shaft through a shaft sleeve assembly; the top of the steering knuckle is connected with the upper front control arm and the upper rear control arm in a hinged mode; the bottom of the steering knuckle is connected with the upper rear control arm and the lower rear control arm in a hinged mode; the upper front control arm, the upper rear control arm, the lower front control arm and the lower rear control arm are connected with an auxiliary vehicle frame in a hinged mode; and the top end of the shock absorber is connected with the auxiliary vehicle frame in a hinged mode through an upper U-joint fork, and the bottom end of the shock absorber is connected with the lower front control arm in a hinged mode through a lower U-joint fork. The multi-link suspension wheel rim drive system not only can meet the power requirement of the electric vehicle, but also can reduce the weight of the whole vehicle and improve the power transmission efficiency, and has the effects of simple structure, good traveling stability and flexible controllabitity.

Owner:SANJIANG UNIVERSITY

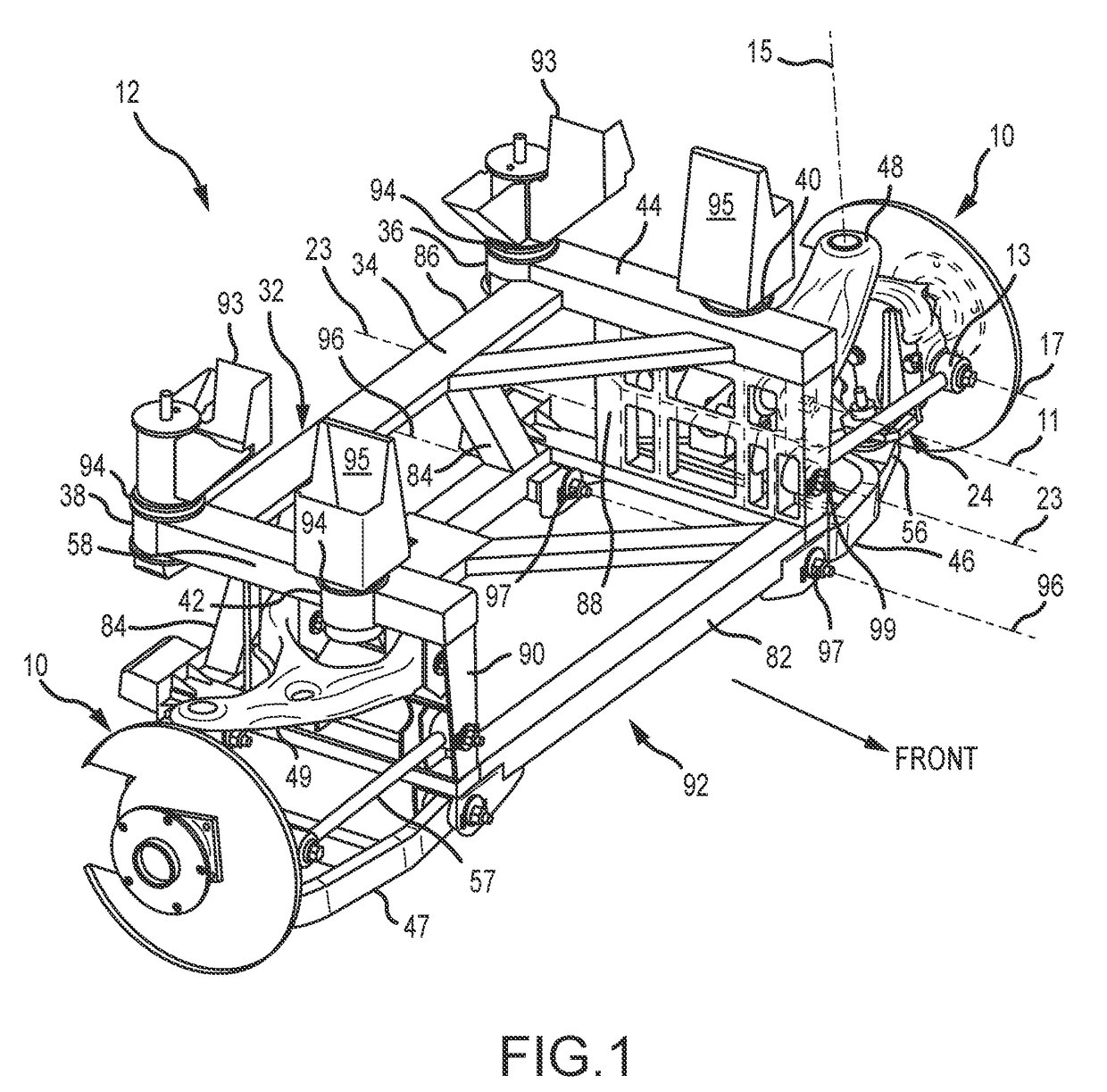

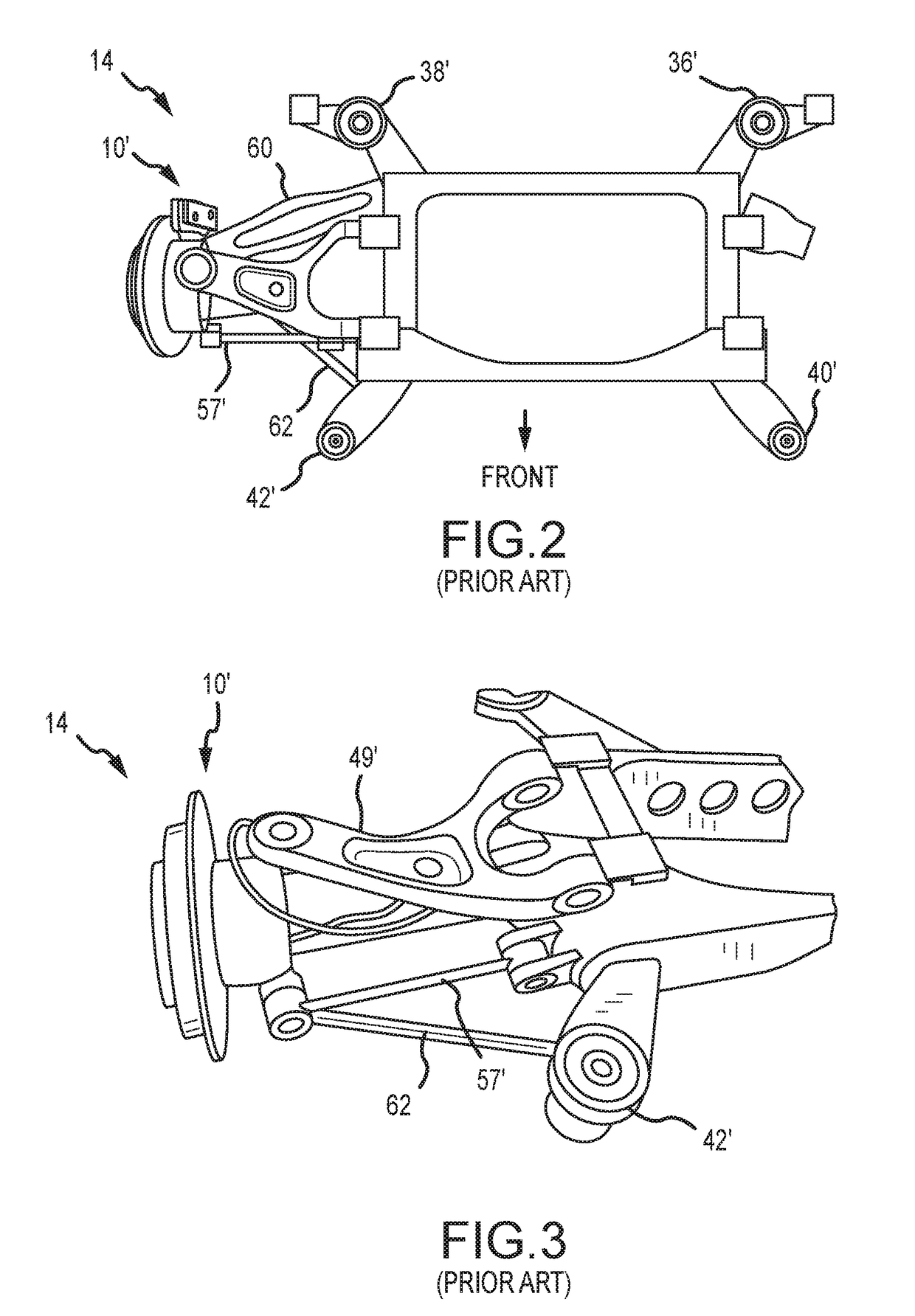

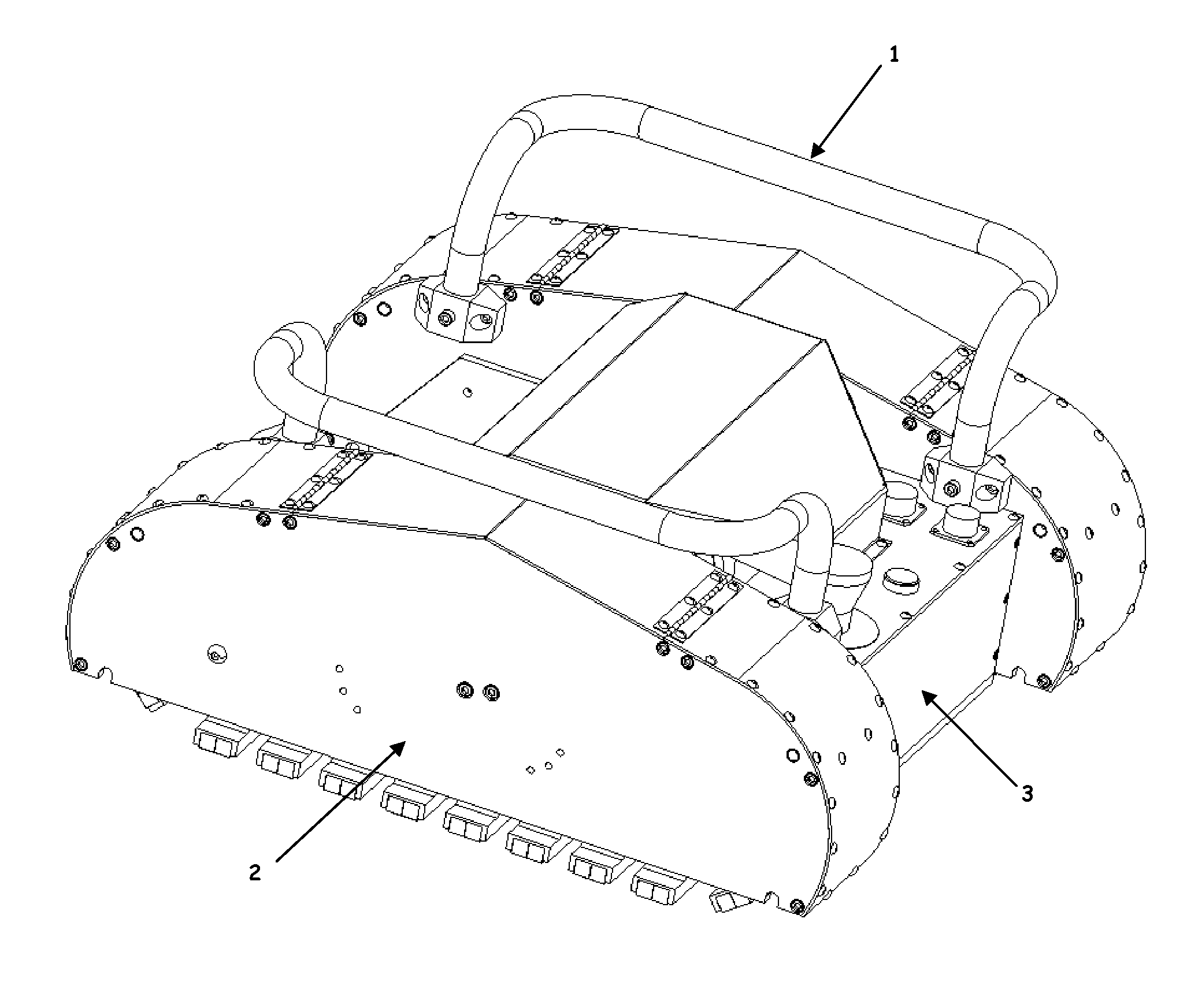

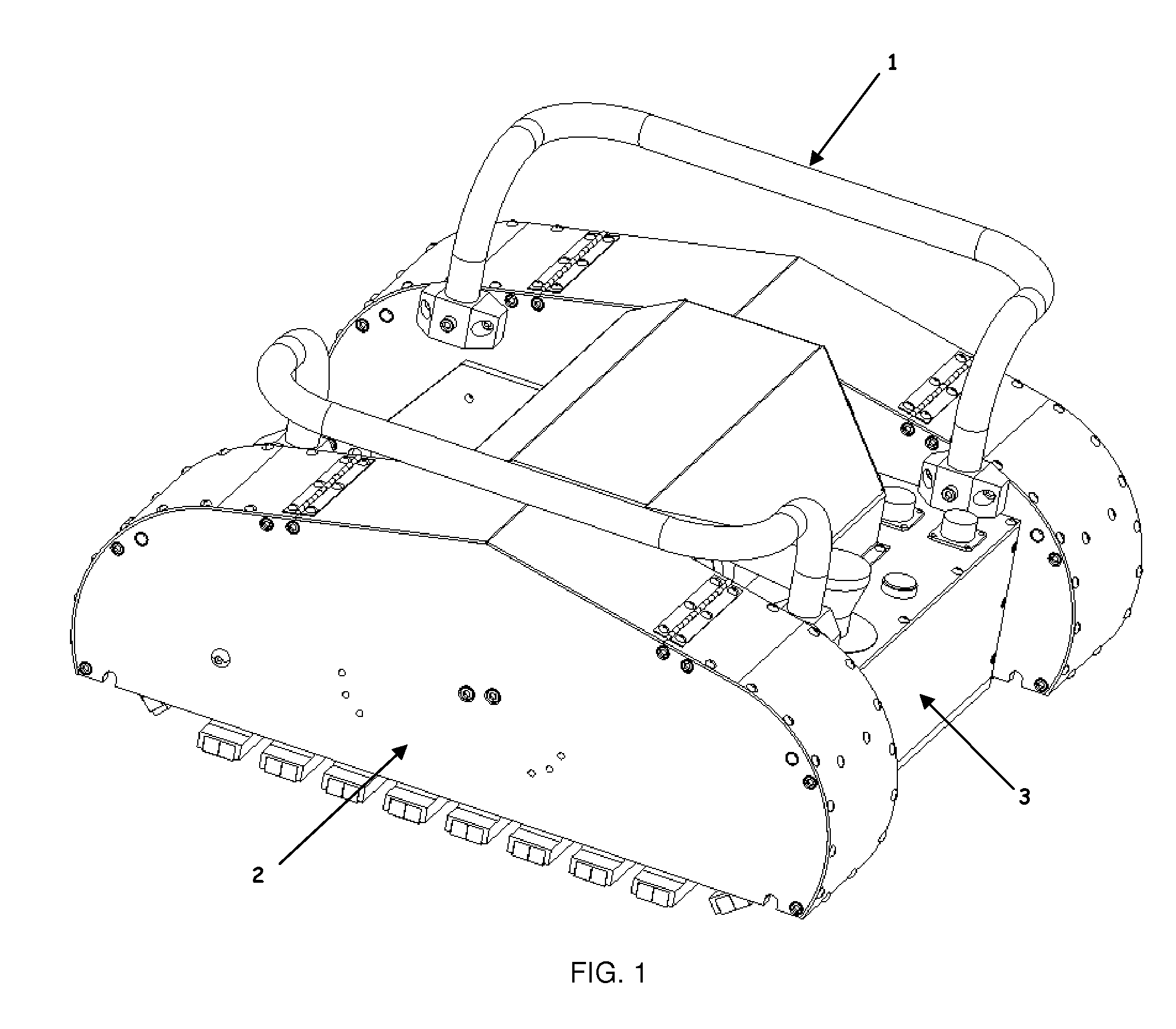

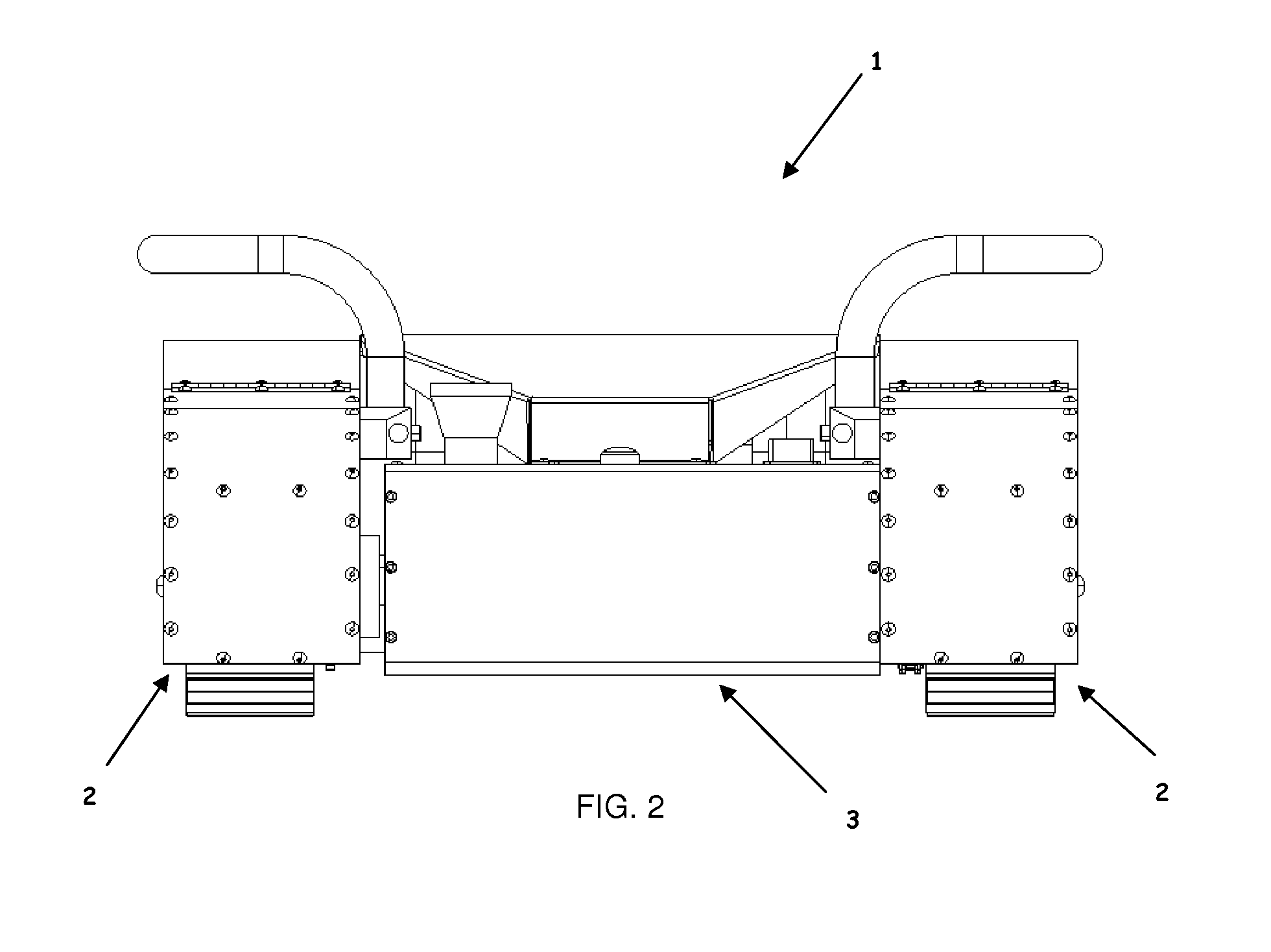

Suspension for an endless track climbing machine

An endless-track type climbing vehicle containing a multi-link suspension apparatus to uniformly distribute the forces on the on the adhering members while traversing irregular climbing surfaces. The multi-links suspension apparatus is able to conform to large range of surface irregularities while providing push and pulling forces on the adhering members to uniformly distribute the climbing loads on the adhering members. The result is a climbing machine that can accommodate large surface irregularities while maximizing the climbing payload with a minimum number and size of adhering members.

Owner:BEARD JAMES WALTER +2

Multi-link rear suspension, vehicle axle assembly and vehicle

ActiveCN110001343AReduce structural complexitySmall footprintInterconnection systemsResilient suspensionsVehicle frameMulti link

The invention relates to the technical field of automobiles, in particular to a multi-link rear suspension, a vehicle axle assembly and a vehicle. The multi-link rear suspension, the vehicle axle assembly and the vehicle aim to solve the problems of complex structure and large occupied chassis space of existing multi-link suspensions. To solve the problems, the multi-link rear suspension comprisesa damping mechanism, an elastic mechanism and a link assembly, wherein the link assembly comprises a first control arm, the two ends of the first control arm are connected with a steering knuckle andan auxiliary frame separately, the two ends of the damping mechanism are separately connected with the steering knuckle and a vehicle body, and the two ends of the elastic mechanism are separately connected with the first control arm and the vehicle body. A shaft hole allowing a wheel shaft of wheels to penetrate through is formed in the steering knuckle, the damping mechanism is located on one side of the shaft hole in the length direction of the vehicle, and the elastic mechanism is located on the other side of the shaft hole in the length direction. According to the multi-link rear suspension, the structure complexity of the multi-link rear suspension is greatly reduced, and the occupied space of the multi-link rear suspension is reduced.

Owner:NIO ANHUI HLDG CO LTD

Beam axle suspension with diagonal link

InactiveUS20050218621A1Provide lateral stabilityLateral stabilitySteering linkagesResilient suspensionsVehicle frameMulti link

A steer axle and suspension assembly are provided that produce lateral stability in the vehicle without the use of a transverse rod and without generating undue loads on the steer axle beam. The assembly includes at least one suspension arm that is connected to the frame and to a component of the steer axle assembly such as the axle beam, kingpin, or steering knuckle. The suspension arm is connected to the steer axle assembly at a location outboard of the longitudinal frame rails of the vehicle and extends longitudinally at an angle to the frame rails. The suspension arm arrangement can be used with a variety of suspensions including leaf spring and multi-link suspensions.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

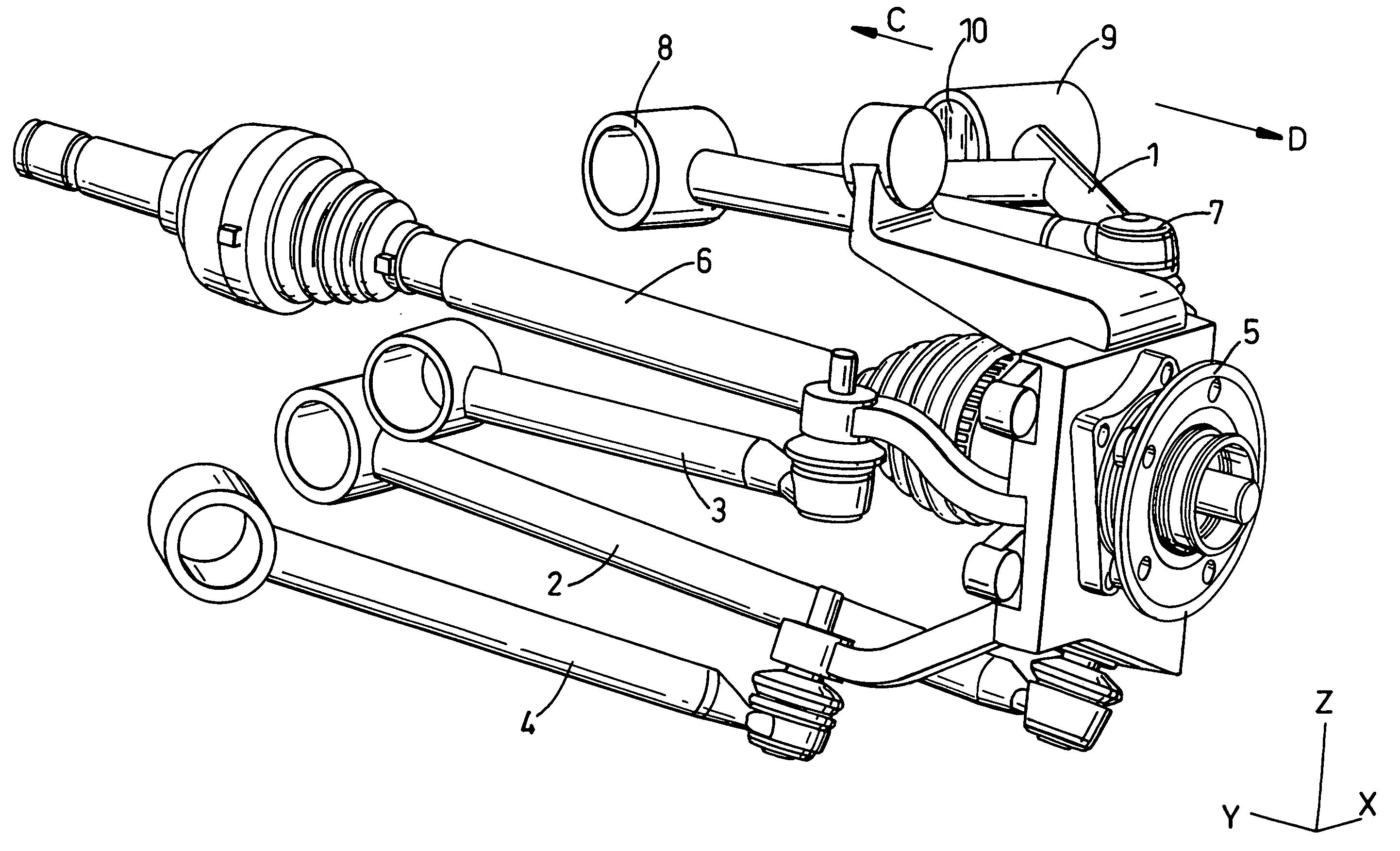

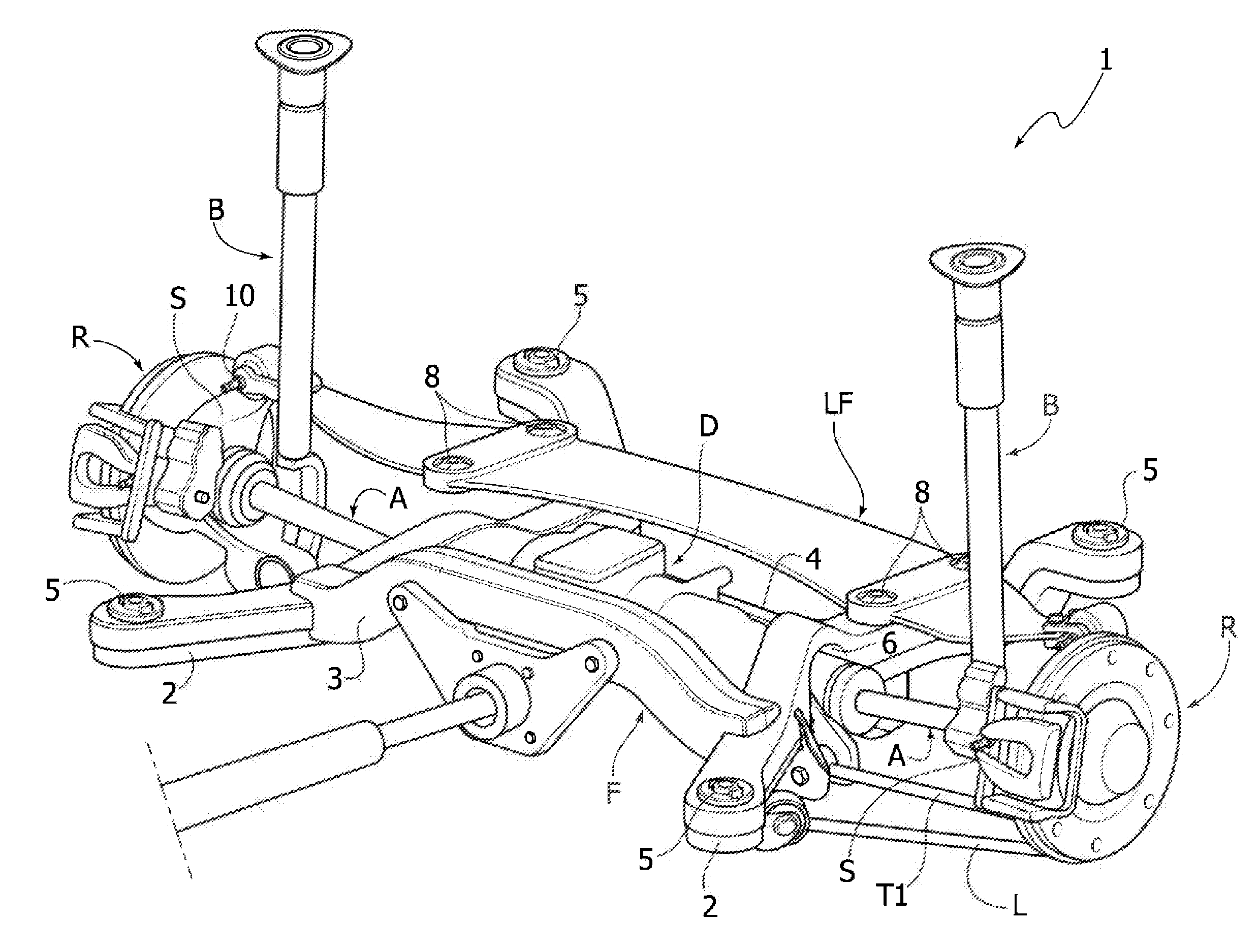

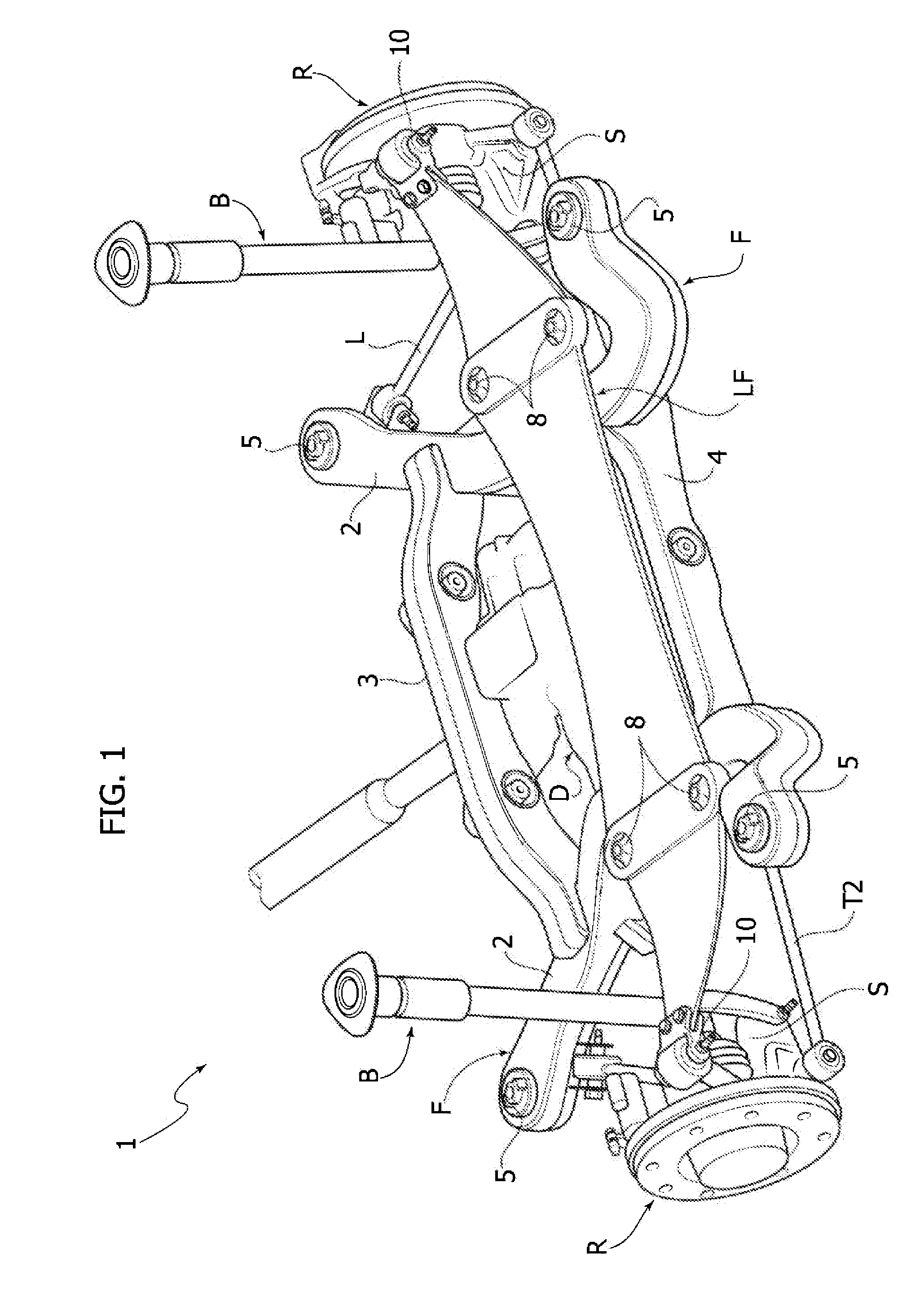

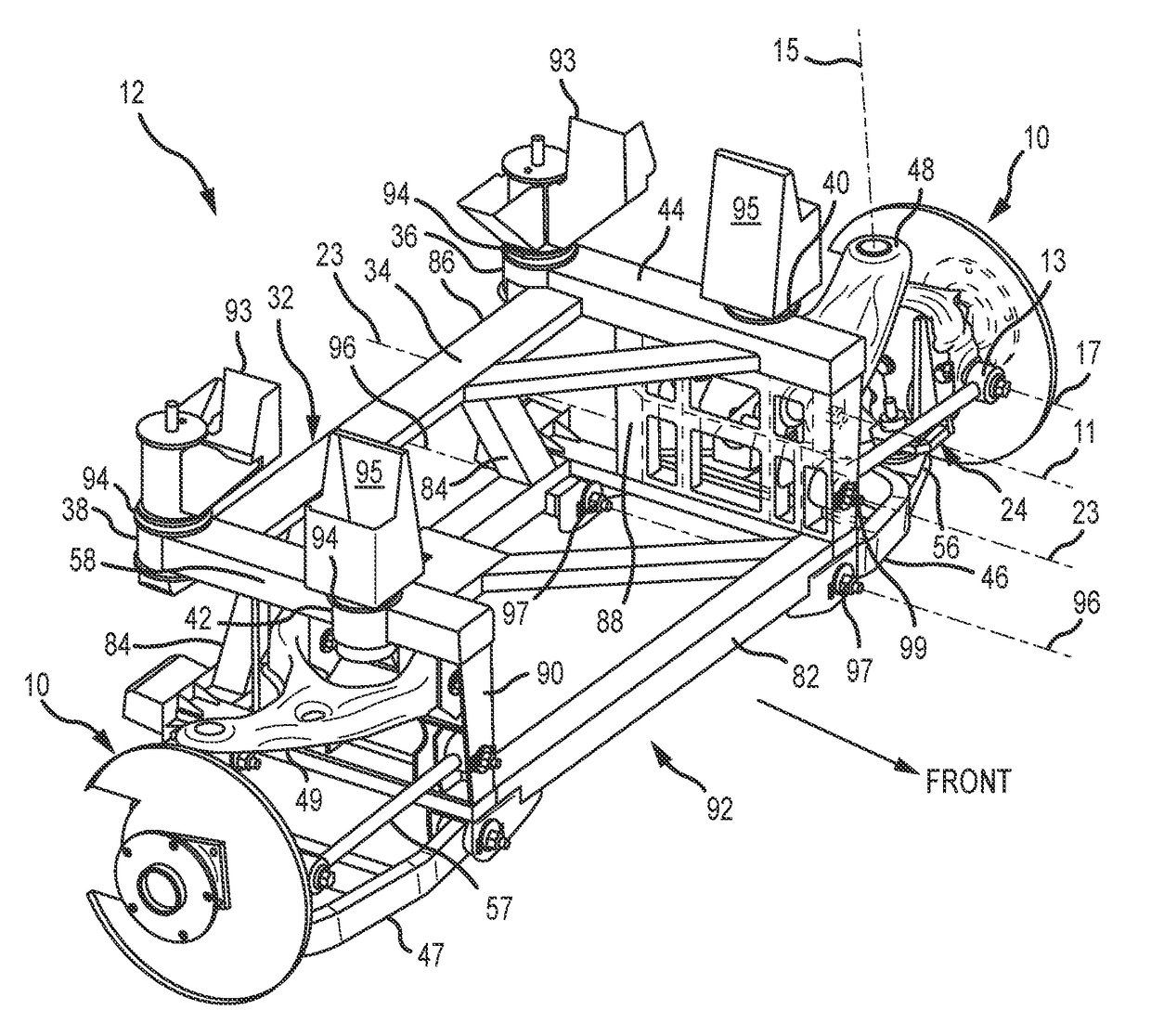

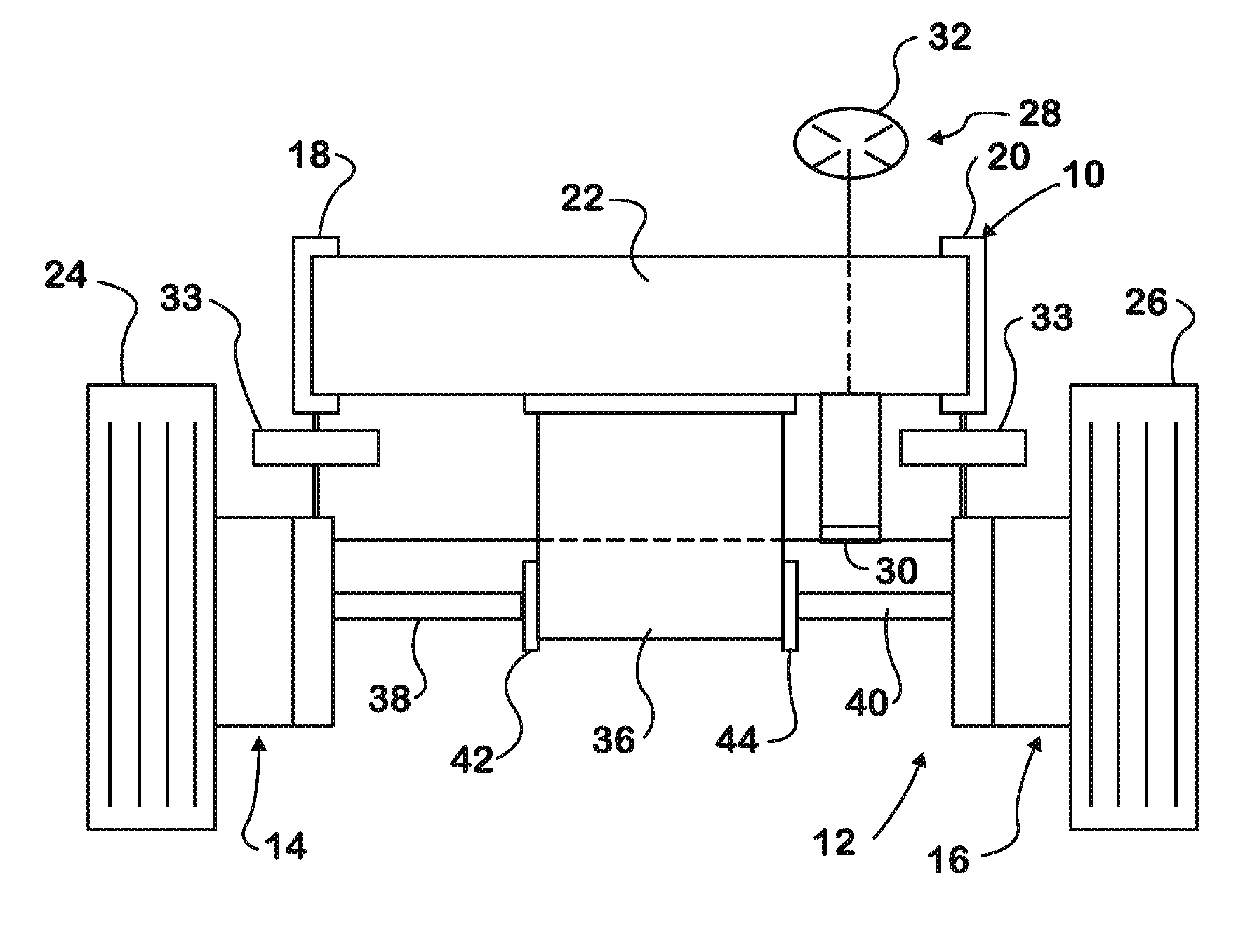

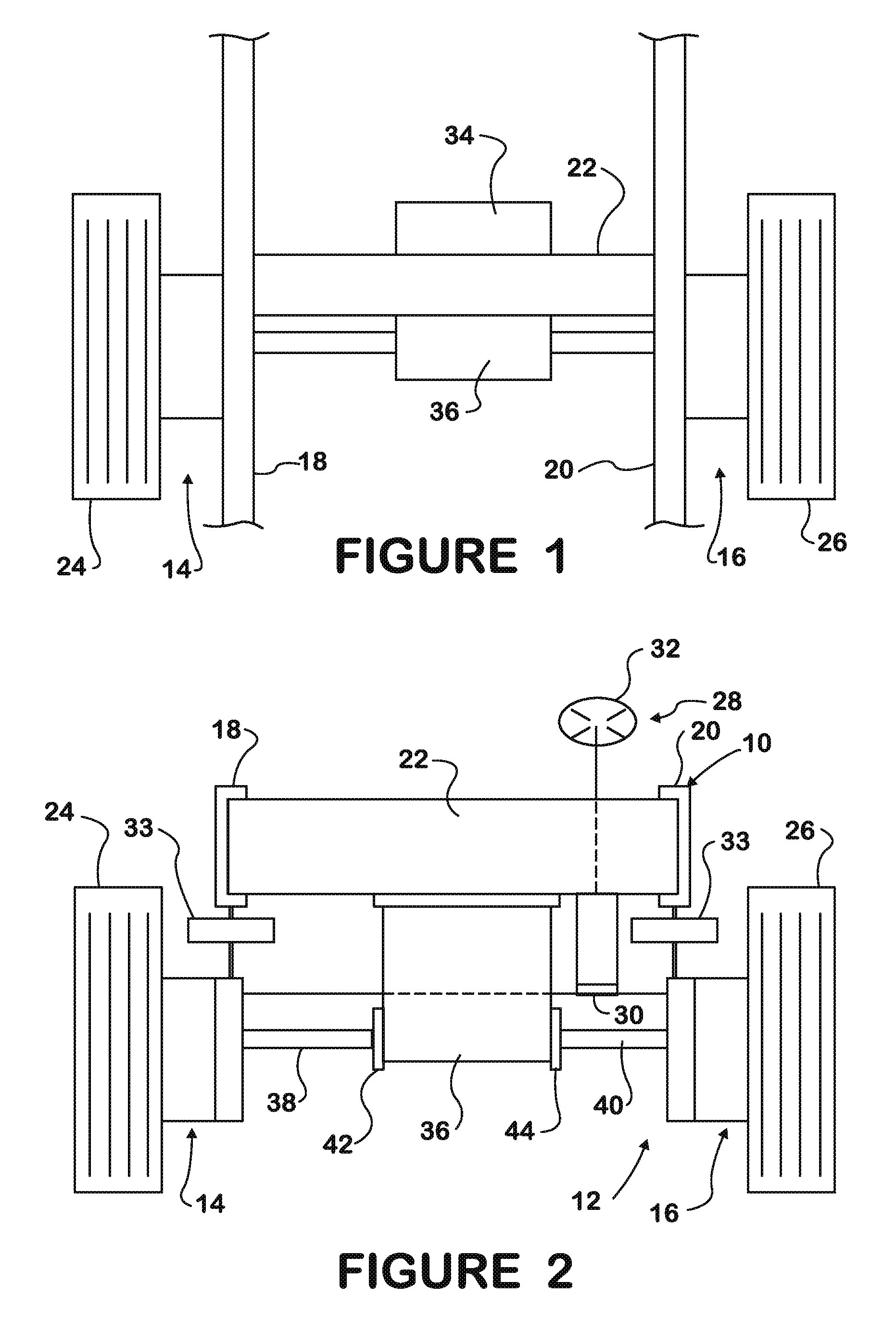

Chassis mounted electric, independent, steering axle of a vehicle

InactiveUS7980350B2Reduce rateImprove drivabilityBraking element arrangementsSteering linkagesVehicle frameDrive shaft

A chassis frame (10) has a cross member (22) that bridges right and left side rails (18, 20). Right and left wheel units (14, 16) comprising respective right and left steered road wheels (24, 26) are suspended from the frame by respective multi-link suspensions (33). A steering system (28) steers the wheels. An electric motor (34) and gear box (36) mounted on the cross member is coupled to the right and left wheels by respective drive shafts (38, 40). The weight of a brake system (42, 44) for the wheels is supported by the frame.

Owner:NAVISTAR CANADA

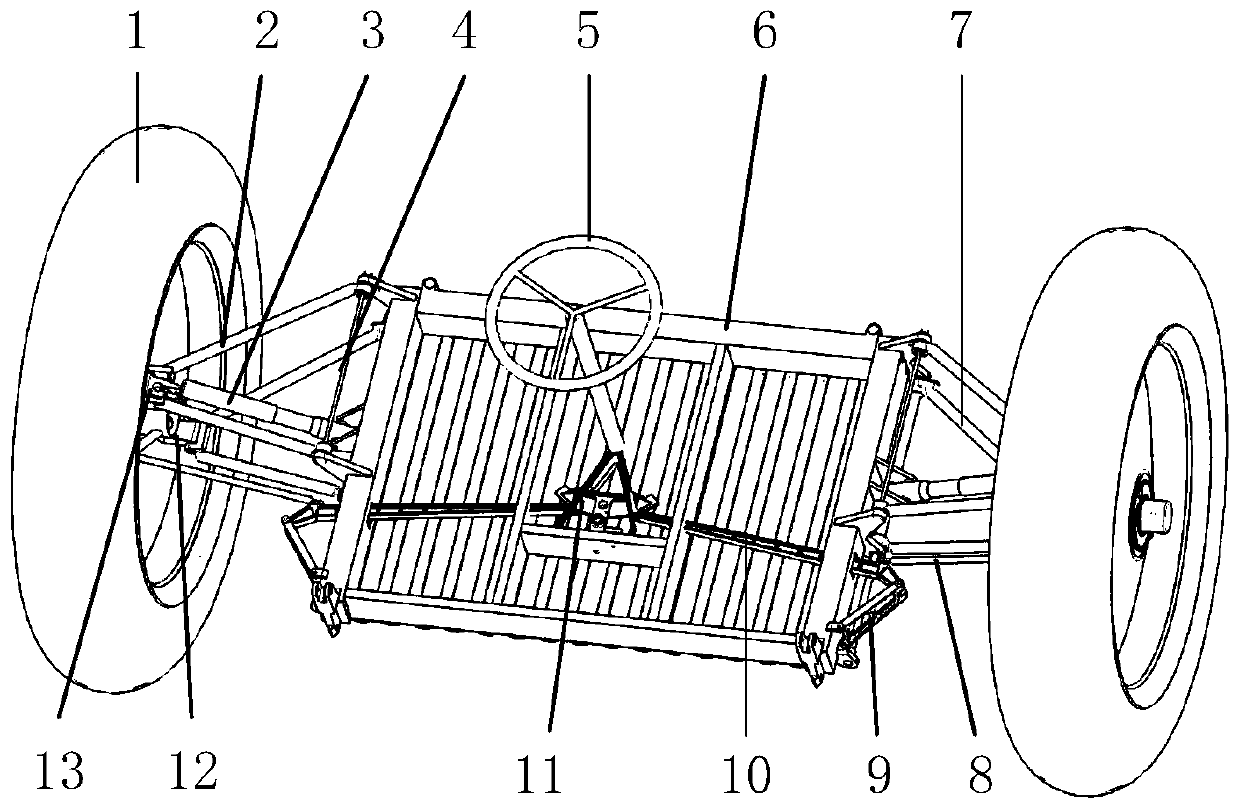

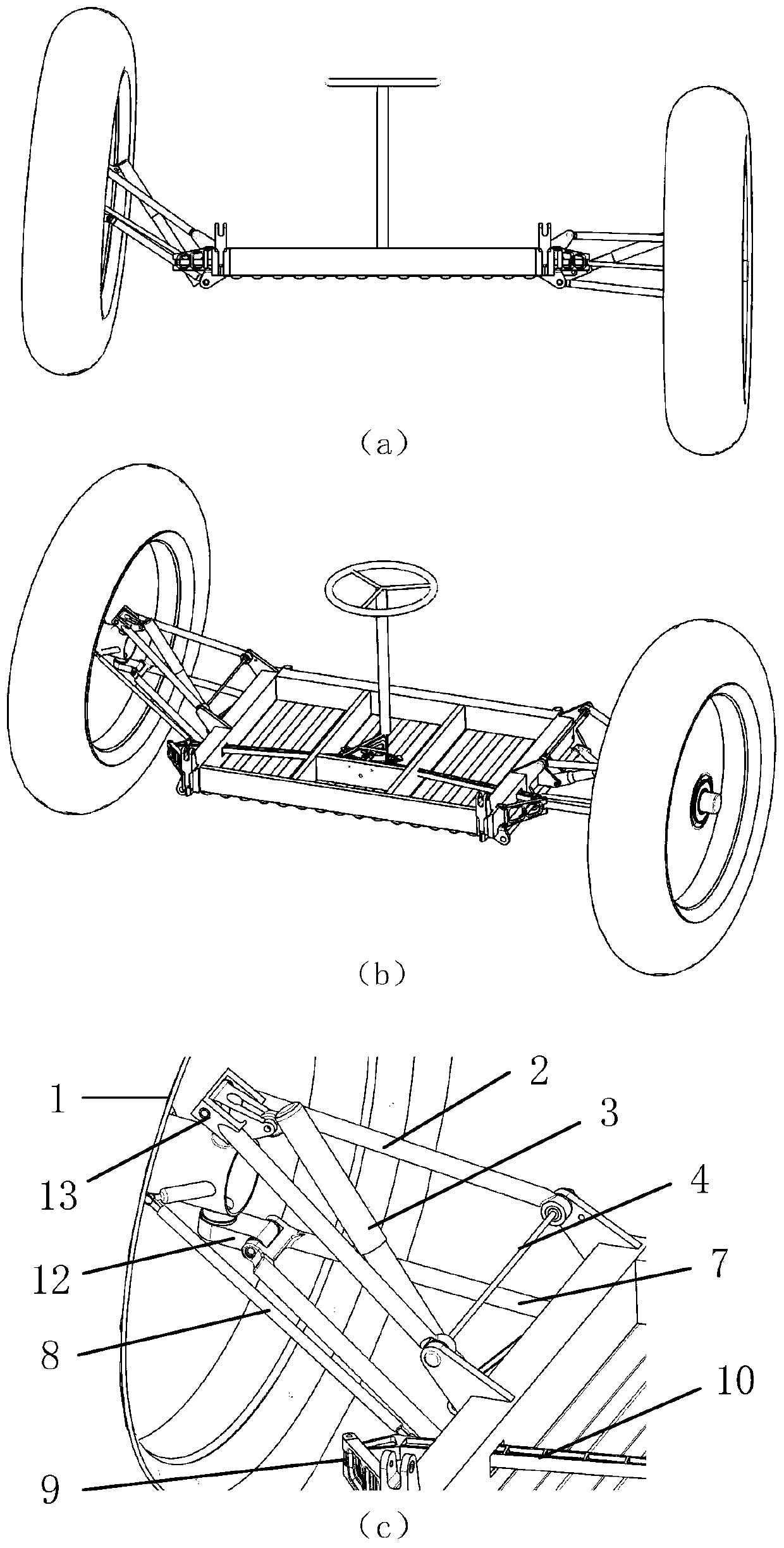

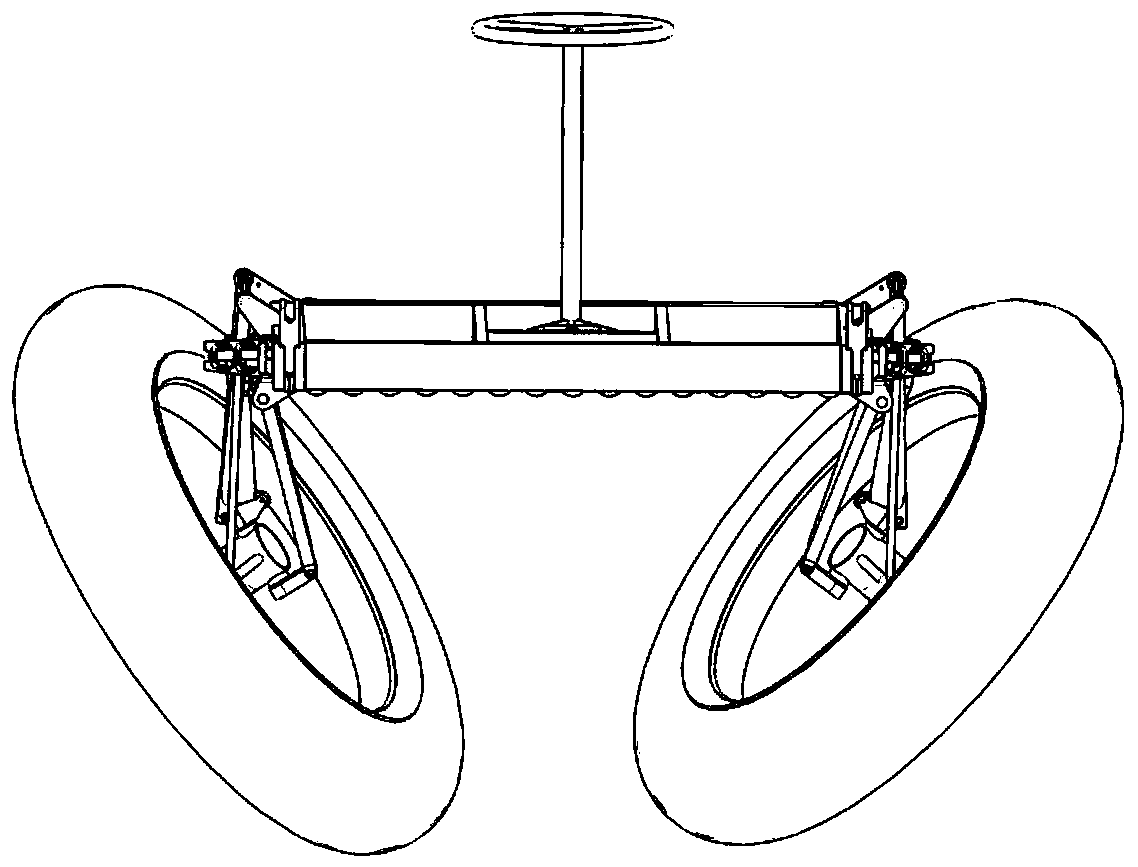

Multi-connecting-rod suspension mechanism with buffering, folding and steering functions

InactiveCN110001330ARealize the buffer functionImplement the folding functionResilient suspensionsPivoted suspension armsSteering wheelRotational degrees of freedom

The invention provides a multi-connecting-rod suspension mechanism with buffering, folding and steering functions. The multi-connecting-rod suspension mechanism with the buffering, folding and steering functions comprises an upper connecting rod structure, a lower connecting rod structure, an upper steering block, a lower steering block, a shock absorber, a torsion rod spring and a steering mechanism; one end of the upper connecting rod structure is connected with the upper side of a wheel hub shaft part through the upper steering block; the other end of the upper connecting rod structure is connected with a bottom plate; one end of the lower connecting rod structure is connected with the lower side of the wheel hub shaft part through the lower steering block; the other end of the lower connecting rod structure is connected with the bottom plate; the upper steering block and the lower steering block have two rotation freedom degrees; the normal direction of one rotation freedom degreeis perpendicular to to the axis of a wheel and points to the front; the normal direction of the other rotation freedom degree is perpendicular to to the axis of a wheel and points to the downside; oneend of the shock absorber is connected with the upper side of the wheel hub shaft part through the upper steering block; the other end of the shock absorber is connected with the bottom plate; the torsion rod spring is mounted in the axis directions in which the upper and lower connecting rod structures are connected with the bottom plate; the steering mechanism mainly comprises four connecting rod mechanisms; one end of the steering mechanism is connected to the lower end of a steering wheel; and one end of the steering mechanism is connected to the wheel hub shaft part.

Owner:SHANGHAI AEROSPACE SYST ENG INST

A multi-link suspension structure

ActiveCN103009951BEliminate large load shocksAvoid crackingResilient suspensionsPivoted suspension armsTrailing armControl arm

Owner:CHERY AUTOMOBILE CO LTD

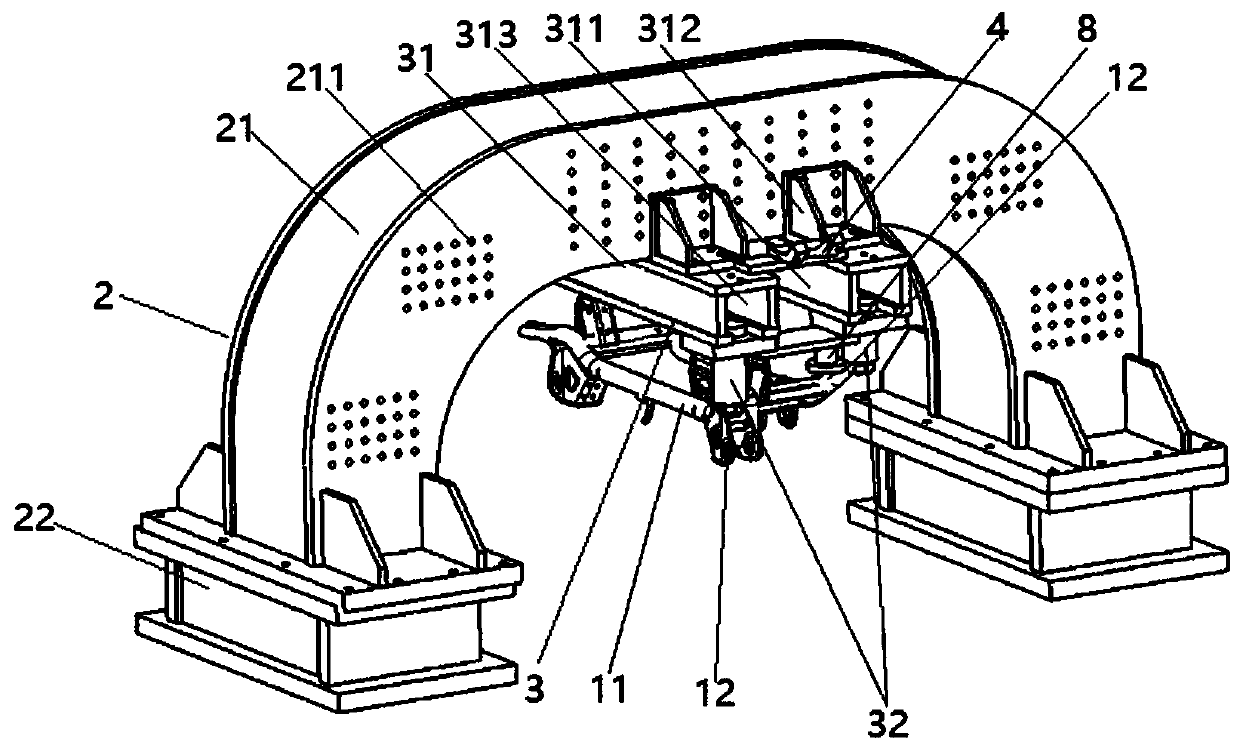

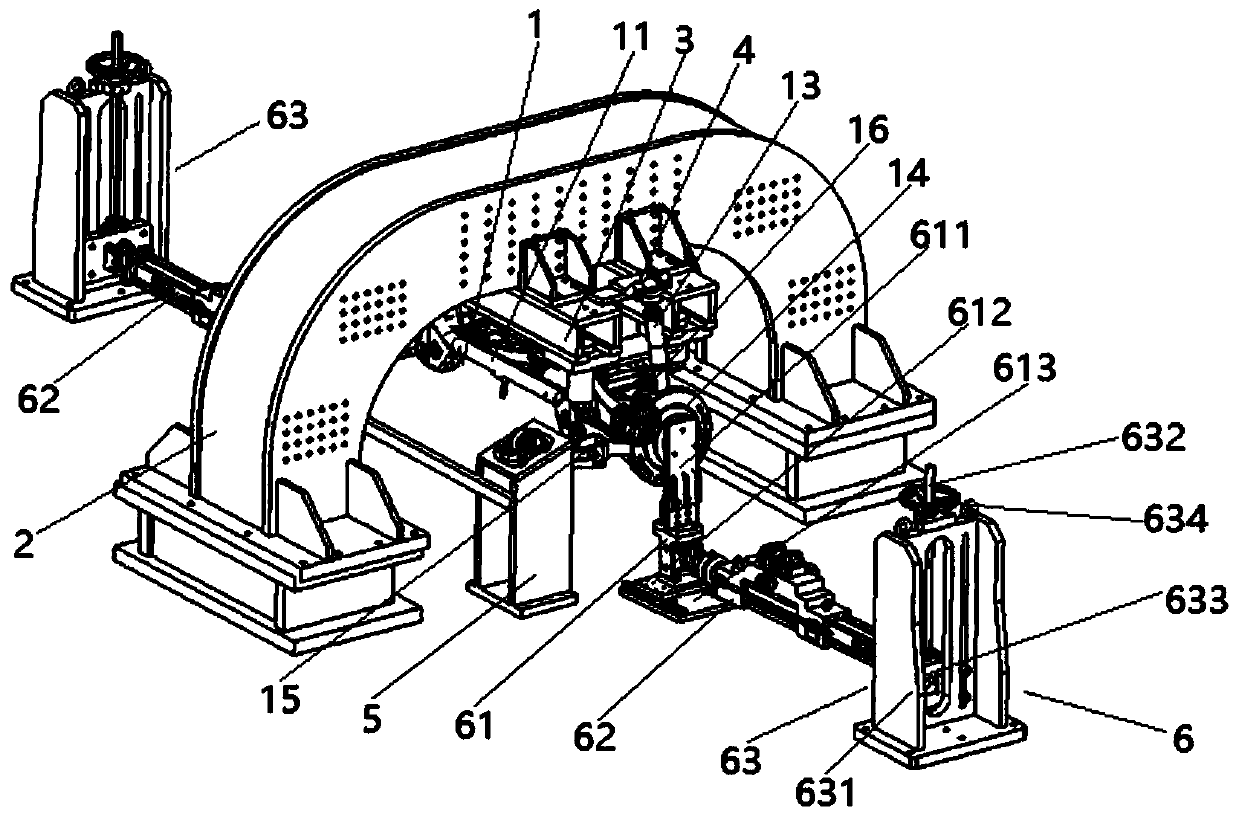

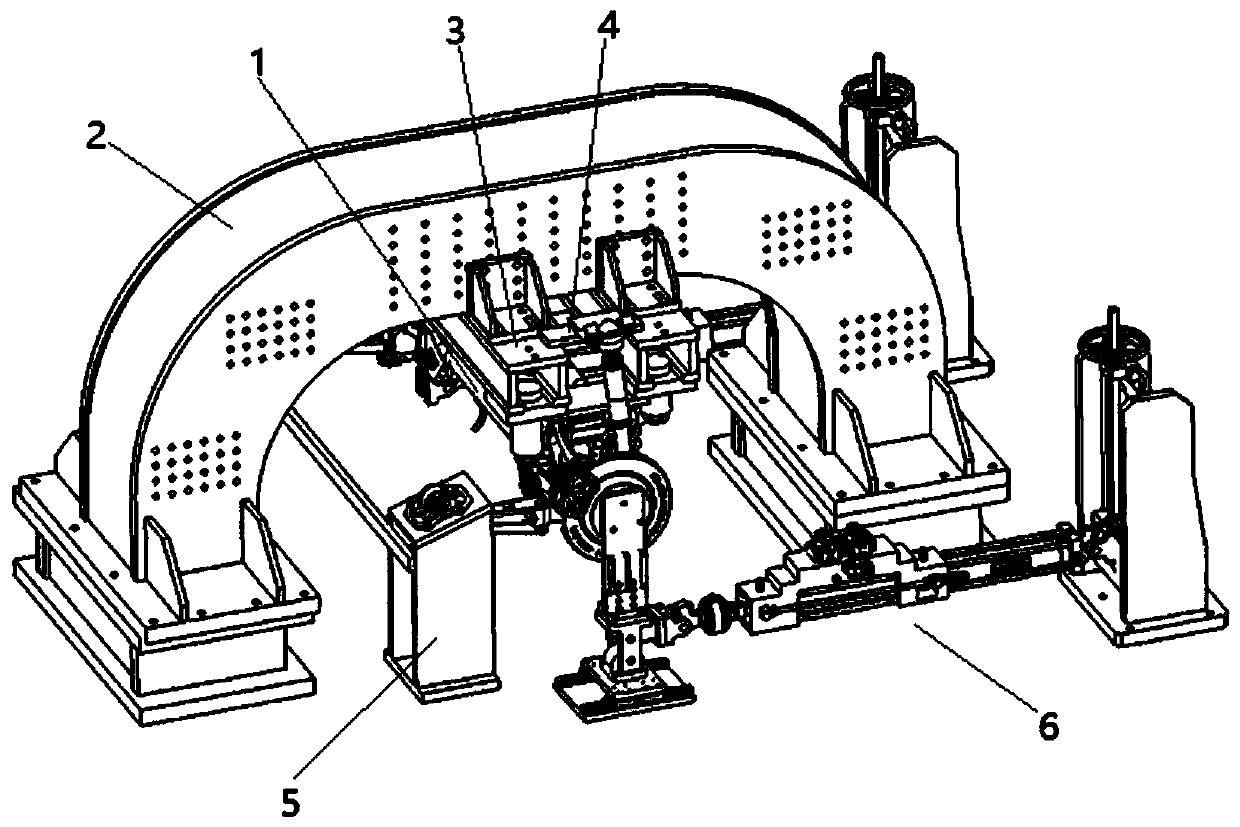

Bench test tool for automobile multi-link suspension system

InactiveCN110274775AGeneralizationReduce investmentVehicle suspension/damping testingTest efficiencyVehicle frame

The present invention provides a bench test tool for an automobile multi-link suspension system, belonging to the field of performance test equipment of automobile suspension systems. The test tool comprises a base component, wherein an auxiliary frame mounting bracket is connected to the base component, the lower end of the auxiliary frame mounting bracket is fixedly connected with a mounting point, a shock absorber mounting component is arranged on the auxiliary frame mounting bracket, a towing arm mounting seat and a loading component I for simulating the lateral force and the frictional resistance of a tire are arranged at the lower portion of the base component, and a loading component II for simulating the ground reaction force of the tire is arranged at the upper portion of the base component. The test bed achieves the suspension system that one set of test tool matches multiple specifications, clamping and location are performed according to the whole automobile gesture, multiple experiments can be performed in one-time clamping, the precision of a test result is higher, the tool universalization is achieved, the input of a special tool can be reduced, the test efficiency can be improved, and the test cost and the verification period can be reduced.

Owner:CHERY COMML VEHICLE ANHUI

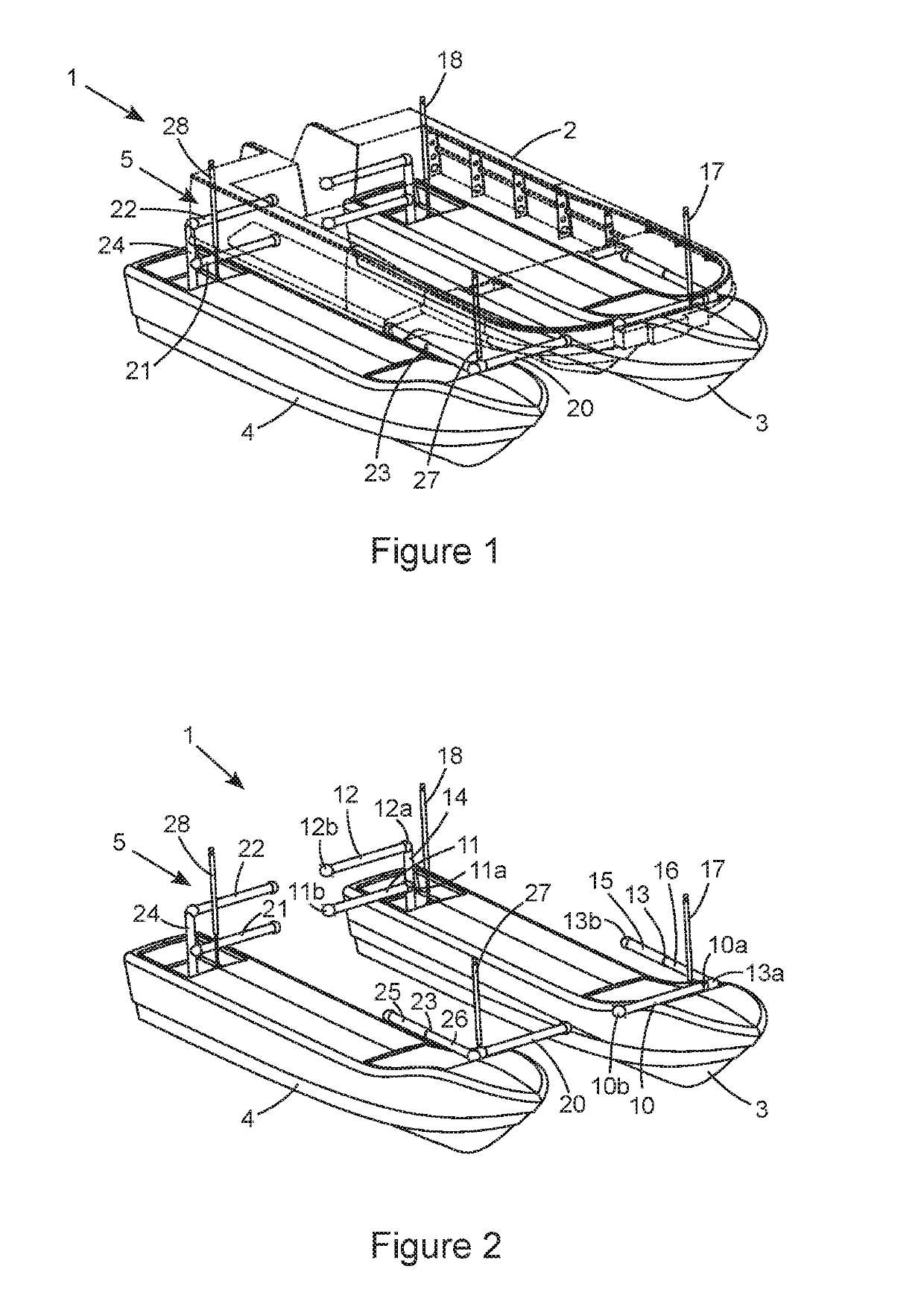

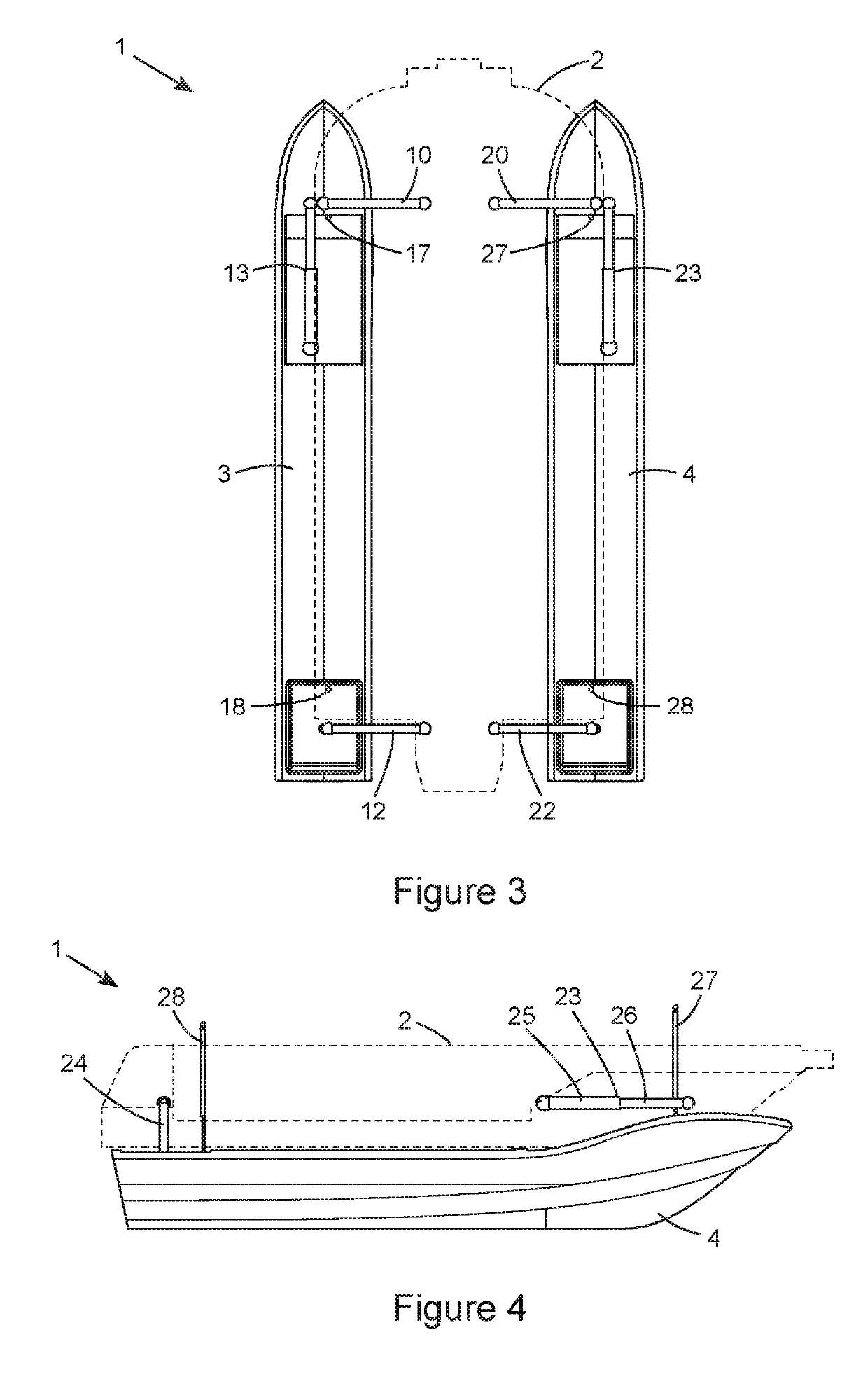

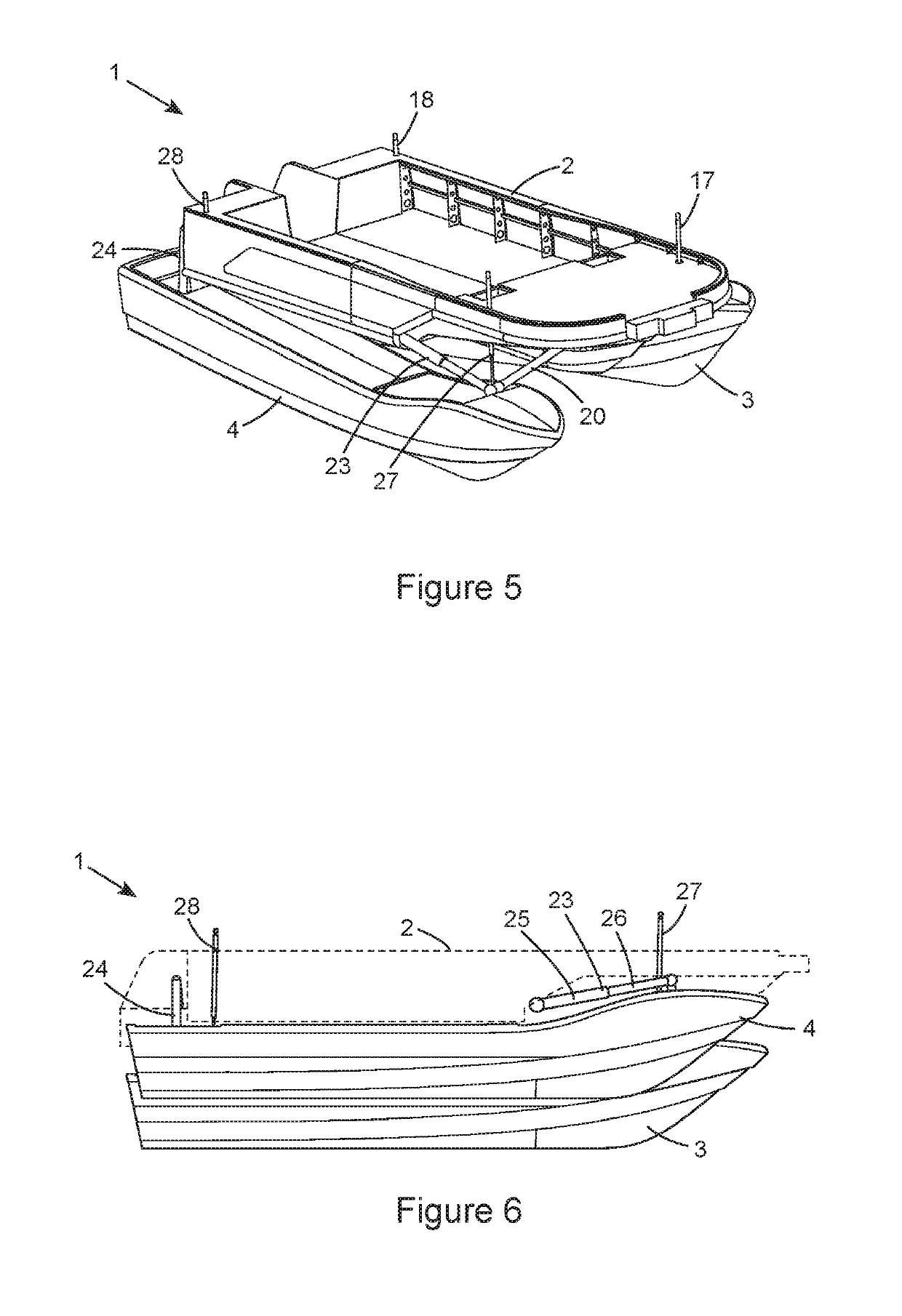

Multi-link suspension for multi-hulled vessels

ActiveUS20190092435A1Different stiffnessIncrease inclinationVessel partsShip vibration reductionMarine engineeringMulti-link suspension

A suspension system for a water craft, the water craft including a chassis which is at least partially suspended above or relative to at least a first hull and a second hull. The suspension system includes a first hull locating arrangement for at least partially constraining the first hull in a lateral, a yaw, a roll and a longitudinal direction relative to the chassis, the first hull locating arrangement comprising a first, a second, a third and a fourth link arranged to directly or indirectly connect between the hull and the chassis. The first, second and third links each extend in at least a lateral direction relative to the chassis and contribute to a lateral constraint on the first hull relative to the chassis. The second link is longitudinally spaced from the first link relative to the chassis to contribute to a hull yaw constraint on the first hull relative to the chassis. The third link is vertically spaced from the first and / or second link to contribute to a hull roll constraint on the first hull relative to the chassis. The fourth link extends in at least a longitudinal direction relative to the chassis to at least contribute to a longitudinal constraint on the first hull relative to the chassis and may be adjustable in length to vary the lateral spacing between the first and second hulls and thereby vary the overall width of the vessel.

Owner:NAUTI CRAFT PTY LTD

Sub-frame of multi-link suspension system

The invention relates to a sub-frame of a multi-link suspension system. The sub-frame comprises a V-shaped upper cross beam, a right longitudinal beam and a left longitudinal beam, and further comprises a first right mounting bracket, a first left mounting bracket and a U-shaped lower cross beam, wherein one end of the first right mounting bracket is connected to the other end of one side face of the right longitudinal beam and the other end of the first right mounting bracket is connected to the right of the upper cross beam; one end of the first left mounting bracket is connected to the other end of one side face of the left longitudinal beam and the other end of the first left mounting bracket is connected to the left of the upper cross beam; the right end of the lower cross beam is connected to the first right mounting bracket and the left end is connected to the first left mounting bracket; the sub-frame is characterized in that a trapezoidal rear ring beam component is composed of a first round steel pipe, a second round steel pipe, a third round steel pipe, a fourth round steel pipe and a base plate; and the rear ring beam component is connected to both the upper beam and the lower beam. The sub-frame disclosed by the invention can meet functional requirements, and also can be used for guaranteeing the precision of mounting point, reducing self-weight and saving cost.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

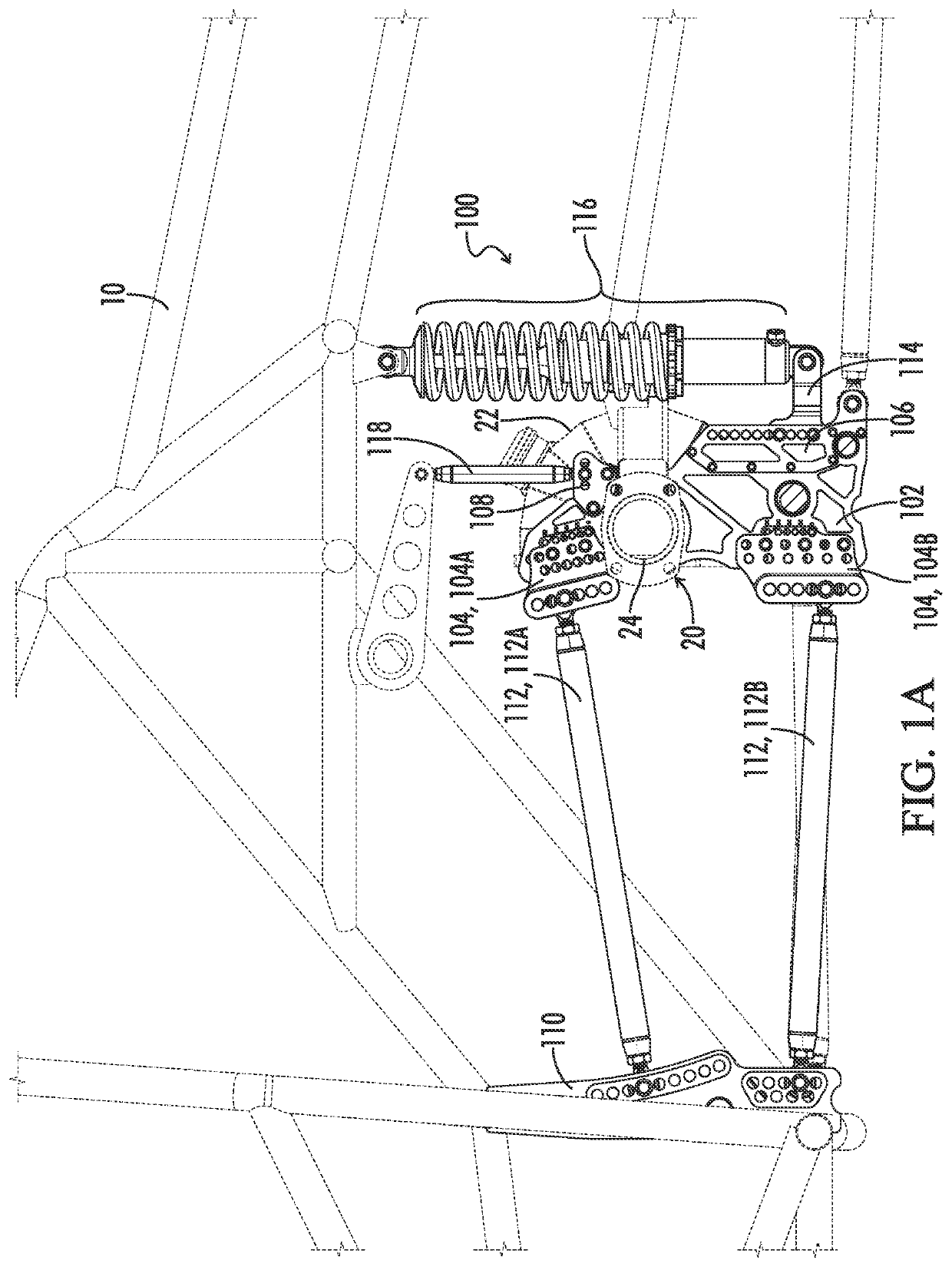

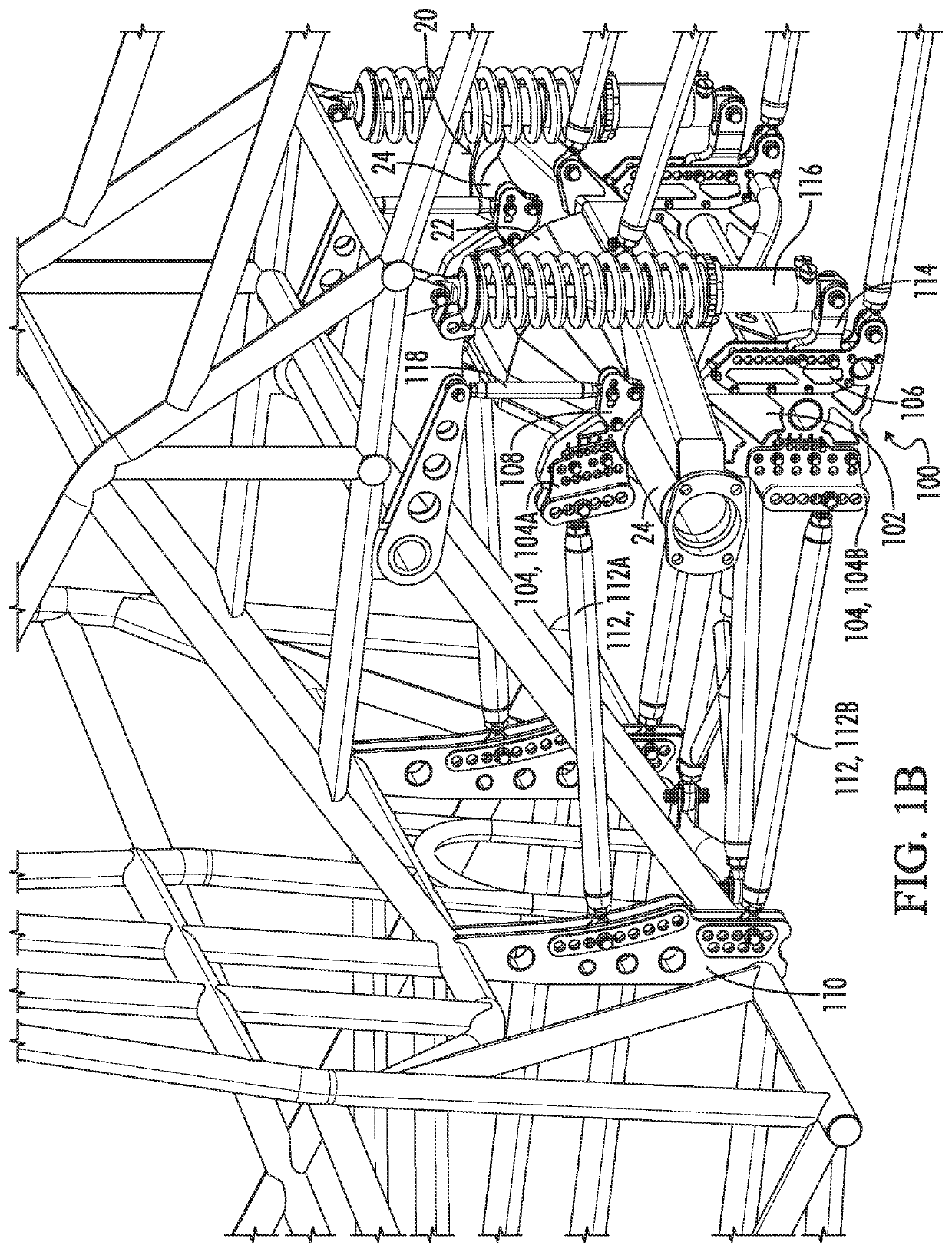

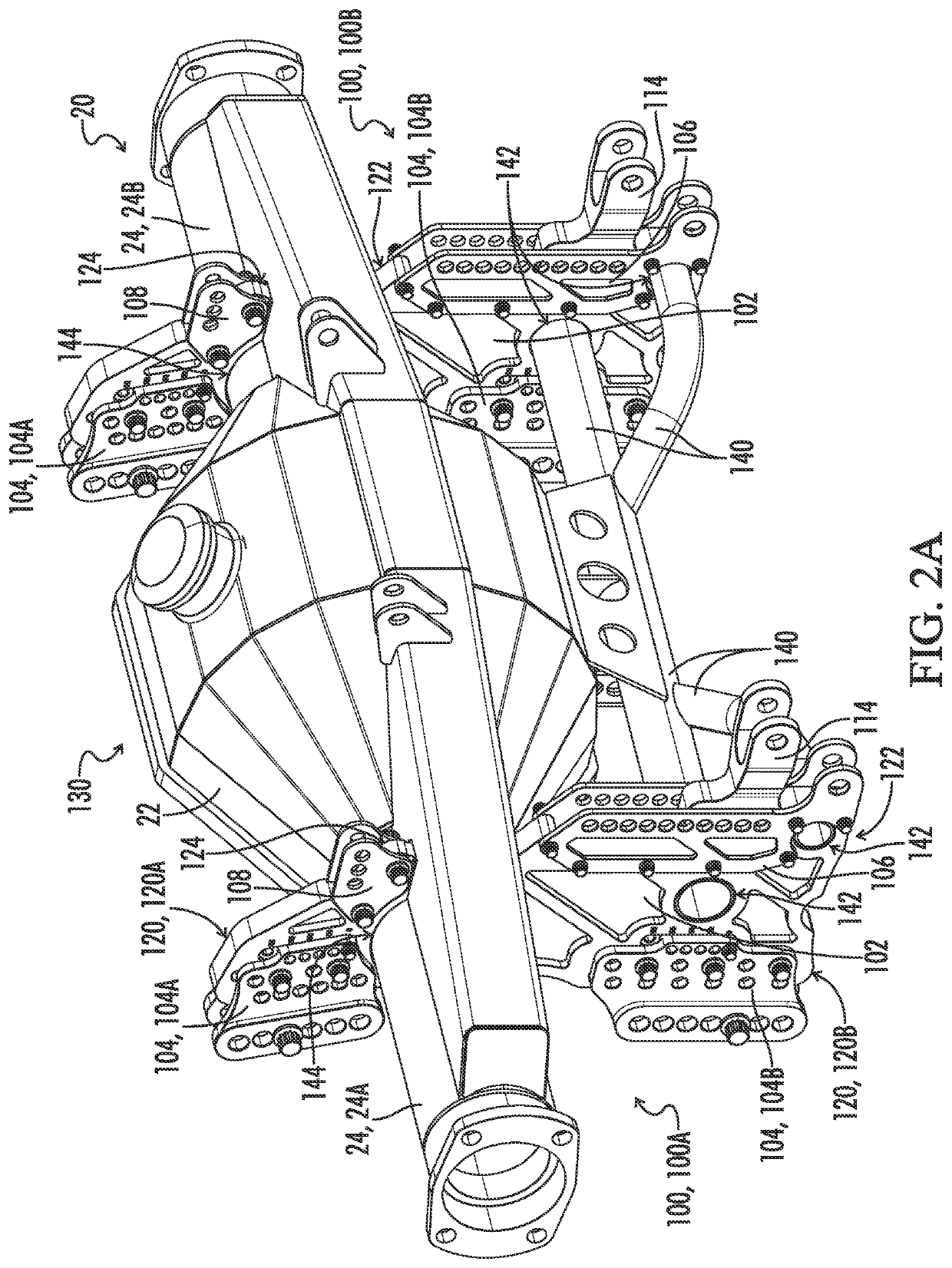

Bracket assembly for a multi-link suspension system

ActiveUS11396213B1Easy to replaceInterconnection systemsResilient suspensionsTrailing armMotorized vehicle

A bracket assembly for a multi-link suspension system is provided, said bracket assembly mounted to a housing of an automotive vehicle, as opposed to a chassis of the automotive vehicle, enabling modularity and ease of replacement of the housing and adjustability of suspensions system components. The bracket assembly may have a body, wherein the body includes: an axle tube hole; one or more cross tube support holes; at least one trailing arm attachment portion having a first plurality of adjustment holes and a second plurality of adjustment holes; an anti-roll bar attachment portion having one or more attachment holes; and a shock attachment portion having a plurality of attachment holes. Further, the bracket assembly may include one or more engagement points, configured to support a number of said suspension system components, such as at least one trailing arm, an anti-roll bar, a shock absorber coupler, and a shock absorber.

Owner:HAMMER CONCEPTS & DESIGNS LLC

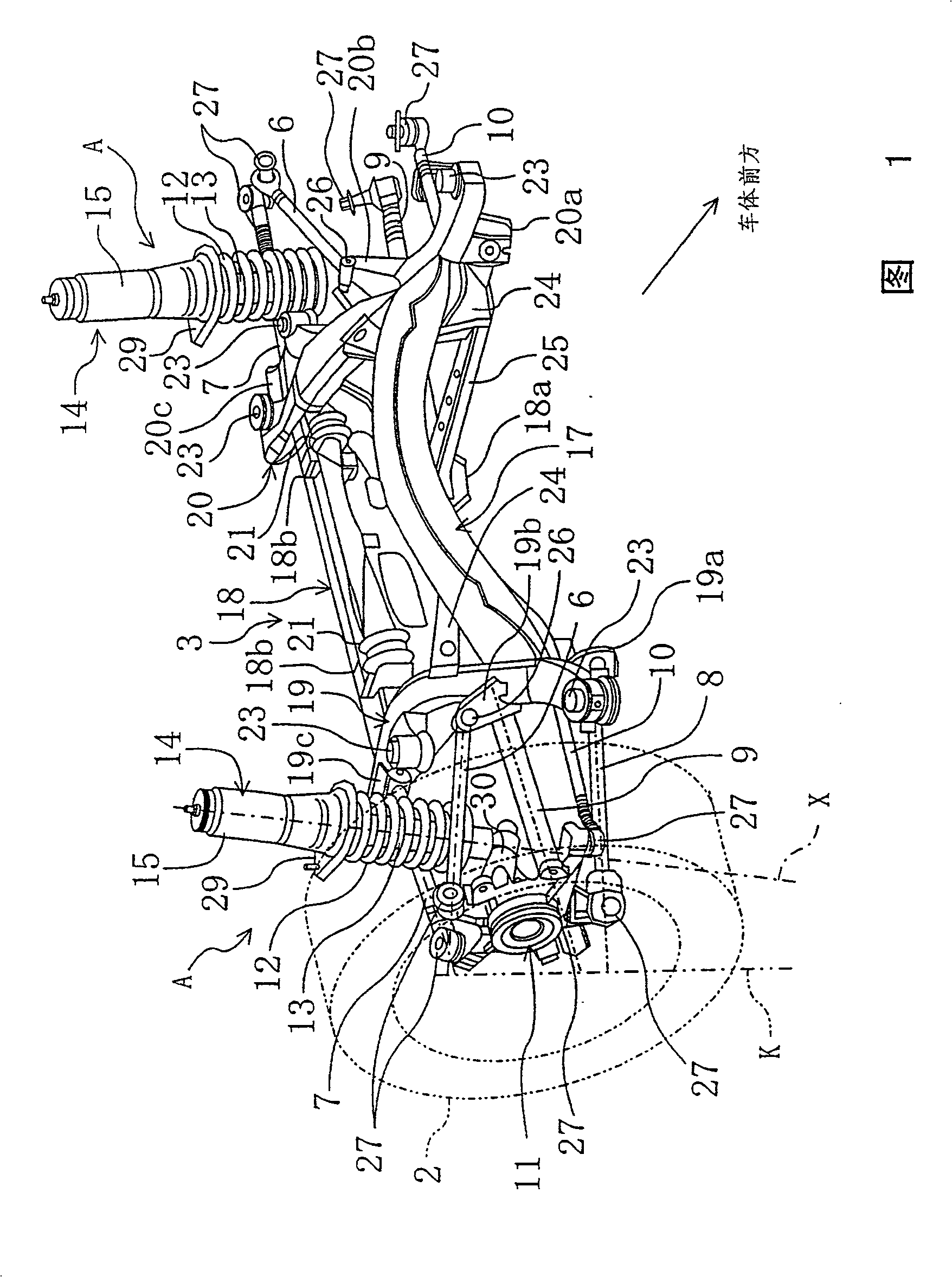

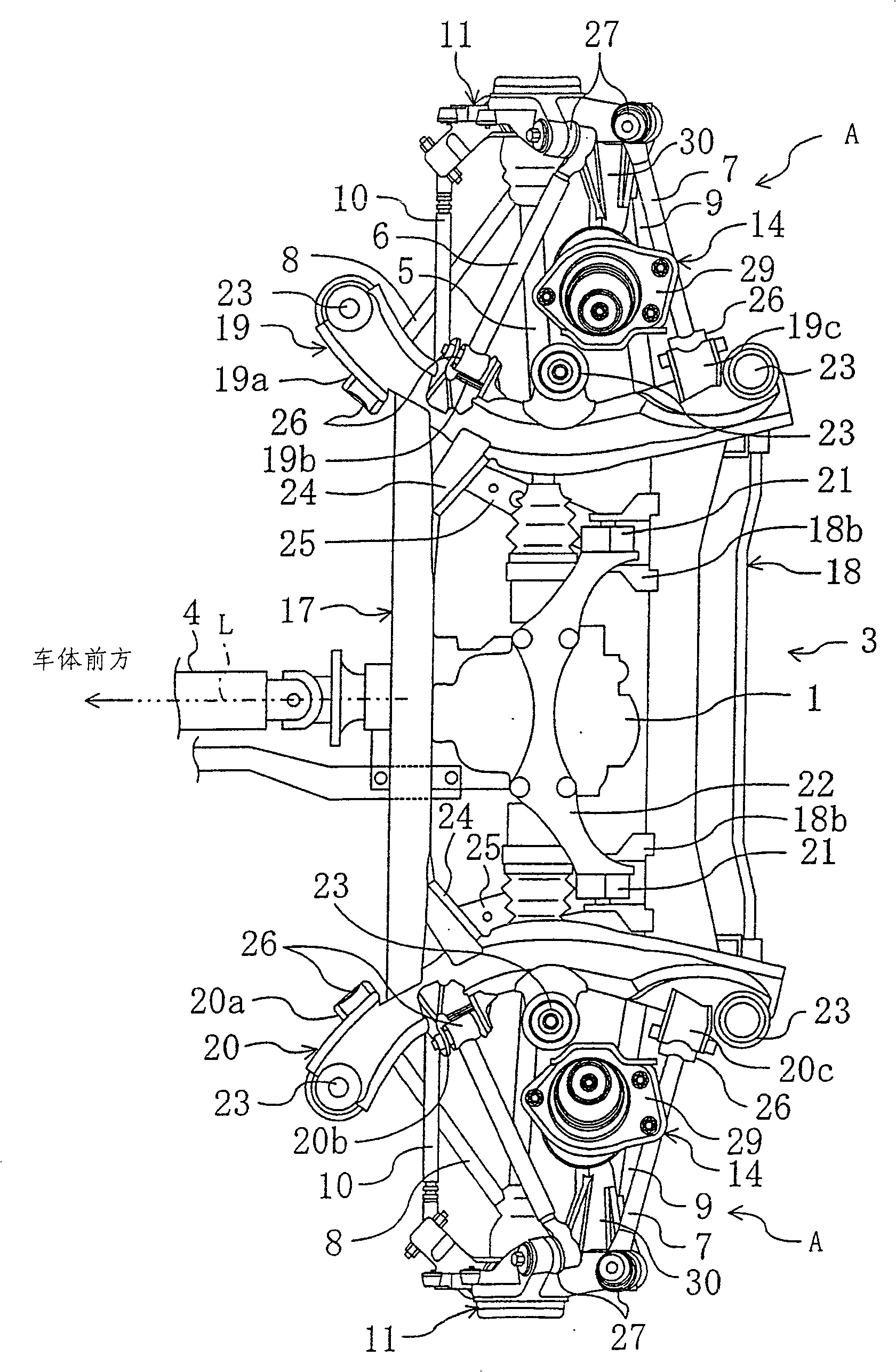

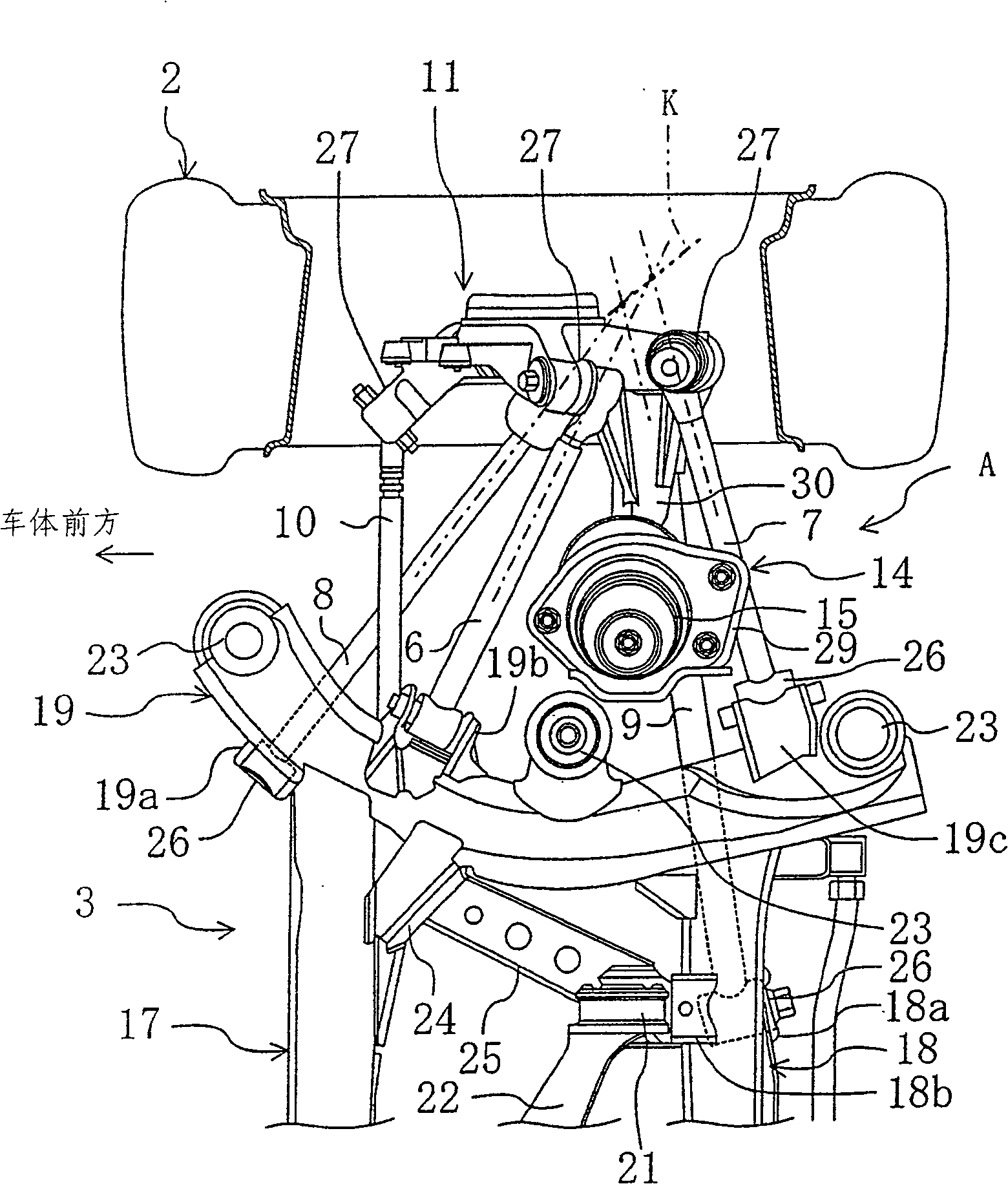

Rear wheel suspension for automobile

In a multi-link rear suspension ( A ) in which a wheel support ( 11 ) is connected to a vehicle body through five links ( 6-10 ) and vehicle body side ends of the links are provided with rubber bushes ( 26 ), respectively, the lower end of a damping device ( 14 ) formed by coaxially arranging a coil spring ( 12 ) and a damper ( 13 ) is pivoted to a portion of the wheel support ( 11 ) located toward the inside of the vehicle body so that the vertical reaction force of the damping device ( 14 ) produces a moment Mn toward negative camber on a rear wheel (2) . The moment Mn is set to be always larger than a moment Mp toward positive camber produced by a side force on the outside rear wheel. The damping device ( 14 ) is disposed with respect to a suppositive king pin axle K so that the vertical reaction force thereof produces a moment toward toe-in on the rear wheel ( 2 ). In this manner, the multi-link suspension provides a sharp driving feeling applicable even for a sports car while maintaining a good ride through the involvement of the rubber bushes (26).

Owner:MAZDA MOTOR CORP

Rear suspension for automobile

ActiveCN101186175ARealize coordinated controlImprove performanceResilient suspensionsHydraulic cylinderHarmonic control

The invention discloses a vehicle rear suspension, comprising a multi-linkage mechanism; wherein, the mechanism is provided with a guide arm which is a hydraulic mechanism, which comprises a hydraulic cylinder and a piston pulling rod. The multi-linkage suspension of the invention is provided with the guide arm which constitutes part of a suspension system and is also an execution element of a steering hydraulic loop, and implements the harmonic control between 4WS and the suspension, thus improving the performance of a chassis to most extent.

Owner:SHANGHAI BYD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com