Multi-link suspension wheel rim drive system of wheel hub motor direct-drive electric vehicle

A technology for in-wheel motors and electric vehicles, applied in suspension, elastic suspension, steering mechanism, etc., can solve the problem of less suspension system, and achieve the effect of reducing the quality of the whole vehicle, meeting the power demand, and reducing the handling stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

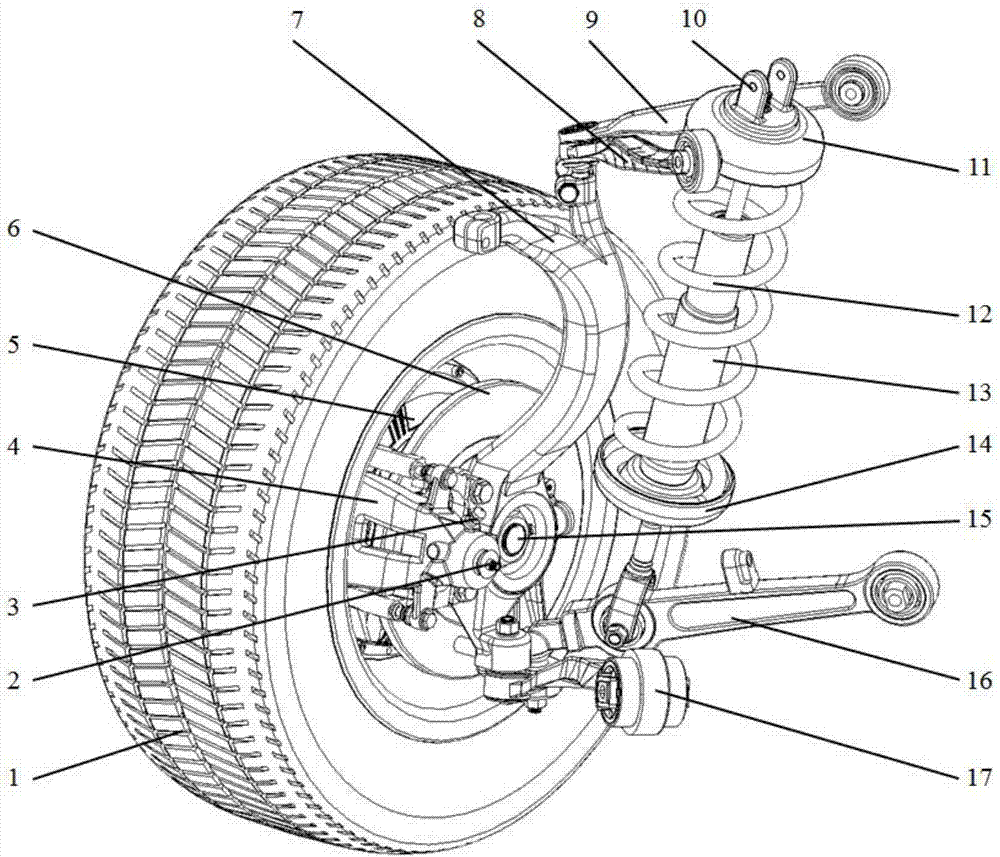

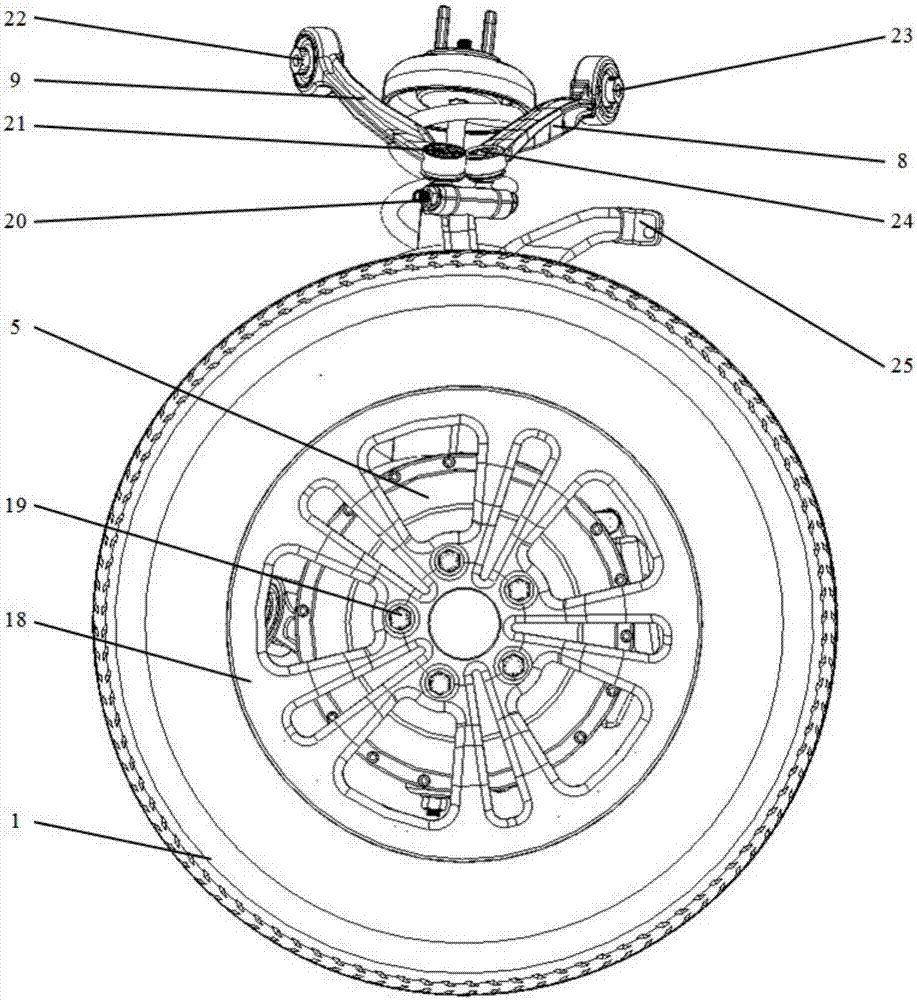

[0025] Embodiment 1: The multi-link suspension wheel side drive system of the hub motor direct drive type electric vehicle provided by the present invention is made up of two parts, one is the hub motor direct drive type drive system fixedly connected with the wheel hub, and the other part is A suspension assembly device in which the hub motor shaft is fixedly connected to the steering knuckle and the multi-link.

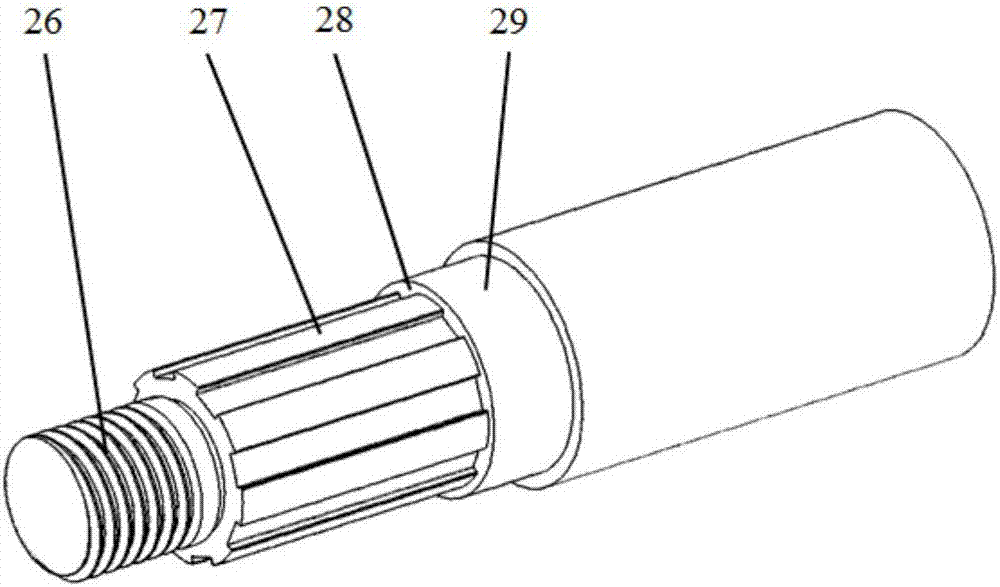

[0026] The in-wheel motor direct-drive drive system includes a tire 1, a wheel hub 18, a brake disc 6, a brake cylinder 4, and an in-wheel motor 5; the in-wheel motor 5 is fixed on the rim of the wheel hub 18 through a hub bolt 19, and the outer rotor of the in-wheel motor 5 The rotational torque is transmitted to the hub 18 and the tire 1 through the hub bolts 19, driving the tire 1 to rotate synchronously; the outer rotor of the hub motor 5 is fixedly connected with the brake disc 6 through the bolt 46 passing through the bolt hole 45, and the hub motor 5 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com