Method for manufacturing tire mold

A manufacturing method and mold technology, which are applied in the field of tire mold manufacturing, can solve the problems of reduced manufacturing efficiency of tire molds, deviation of slit exhaust port width, deviation of pattern of mold pieces, etc., so as to achieve the effect of improving manufacturing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

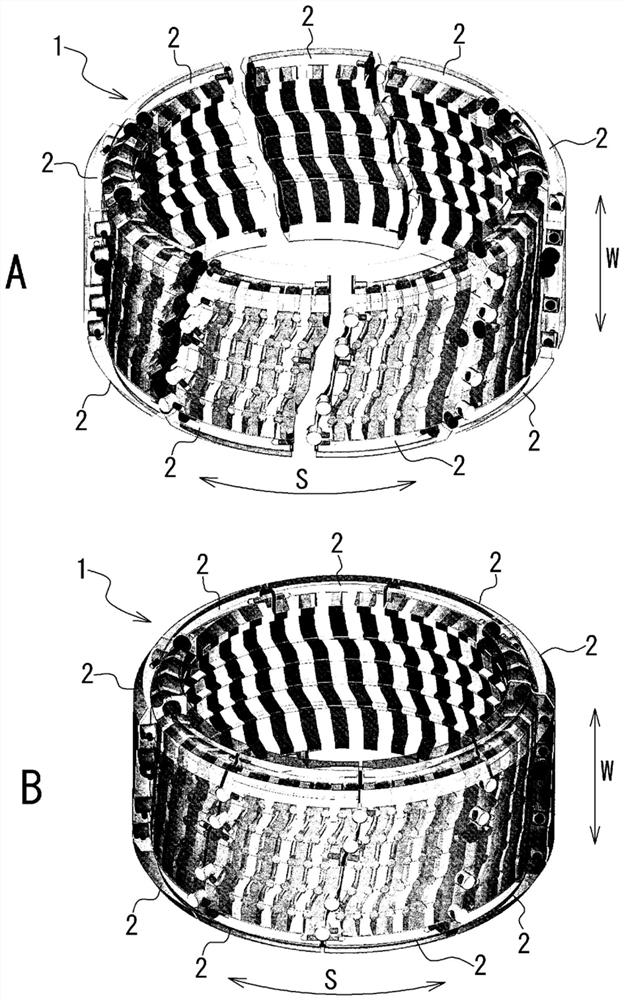

[0040] figure 1 It is a perspective view showing the tire mold 1 of the first embodiment, showing the structure of the tire mold 1 seen through. in addition, figure 1 A shows the tire mold 1 in an open state, figure 1 B shows the tire mold 1 in a closed state.

[0041] As shown in the figure, the tire mold 1 is an annular outer mold for molding the outer surface of a tire, and is provided in a tire molding device (tire vulcanizing device). The tire mold 1 surrounds an annular tire and molds the outer peripheral portion including the tread portion of the tire. Regarding the direction of the tire mold 1 , the width direction of the tire mold 1 (mold width direction W) coincides with the tire width direction, and the circumferential direction of the tire mold 1 (mold circumferential direction S) coincides with the tire circumferential direction. In addition, the radial direction of the tire mold 1 (mold radial direction) coincides with the tire radial direction.

[0042] ...

no. 2 Embodiment approach

[0074] Next, a method for manufacturing the tire mold 1 according to the second embodiment will be described. Regarding the manufacturing method of the tire mold 1 of the second embodiment, the description of the same items as those of the manufacturing method of the tire mold 1 of the first embodiment will be omitted. In addition, regarding the configuration of the second embodiment, the same names as those of the configuration of the first embodiment are used for configurations corresponding to the configuration of the first embodiment.

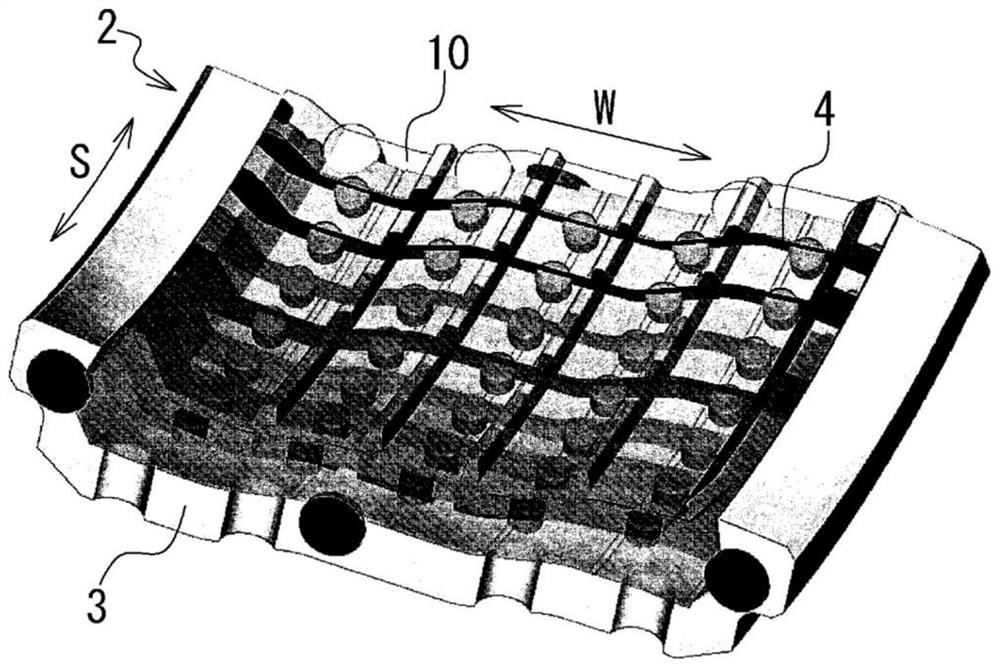

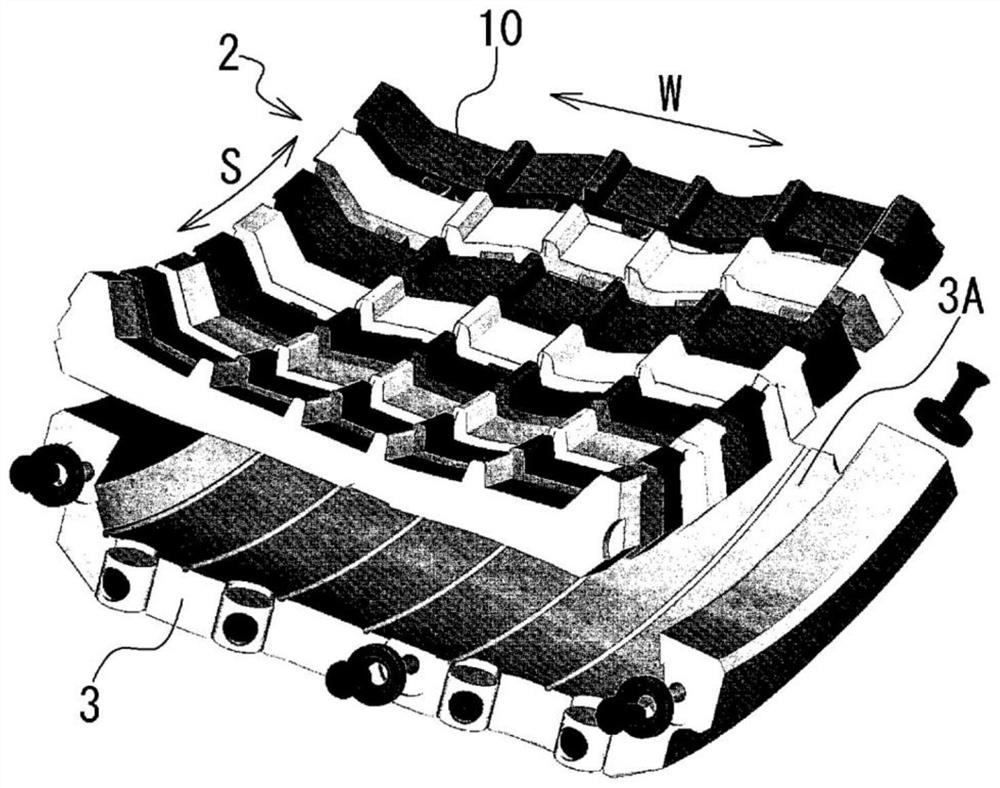

[0075] Figure 14 It is a perspective view showing the mold half 2 of the second embodiment, showing the structure of the mold half 2 through the mold half 2 . Figure 15 It is a disassembled perspective view showing the mold half 2 of the second embodiment. Figure 16 It is a perspective view showing the mold sheet 10 of the second embodiment, and shows a part of the mold sheets 10 among the plurality of mold sheets 10 provided in the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com