Immediate dental implant manufacturing method

A production method and technology for dental implants, which are applied in the field of oral medicine, can solve the problems of long cycle and unfavorable oral recovery of patients, and achieve the effects of convenient operation, simple structure and shortened cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

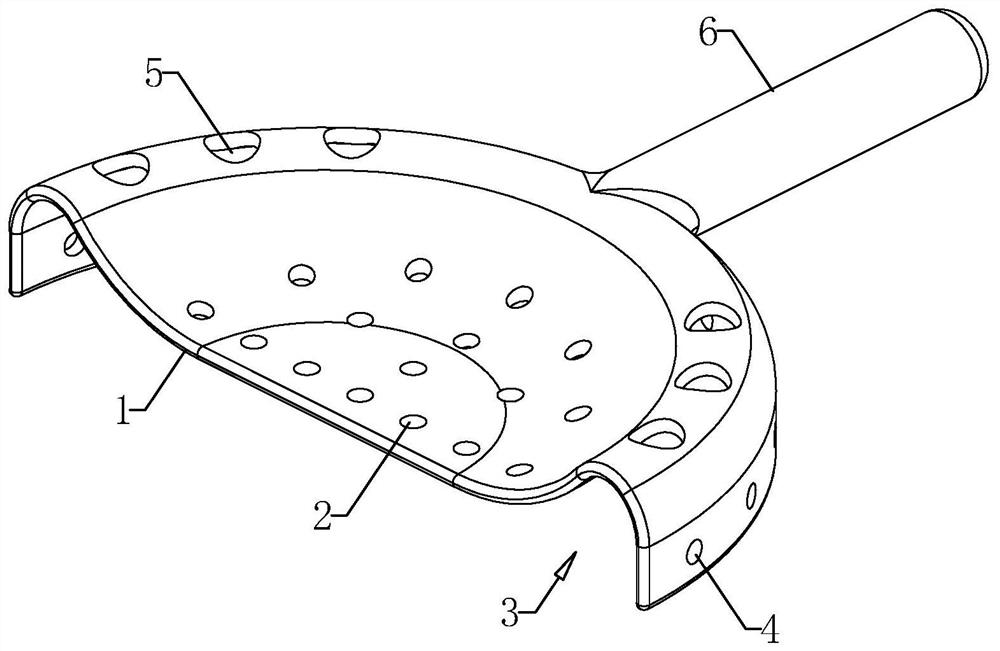

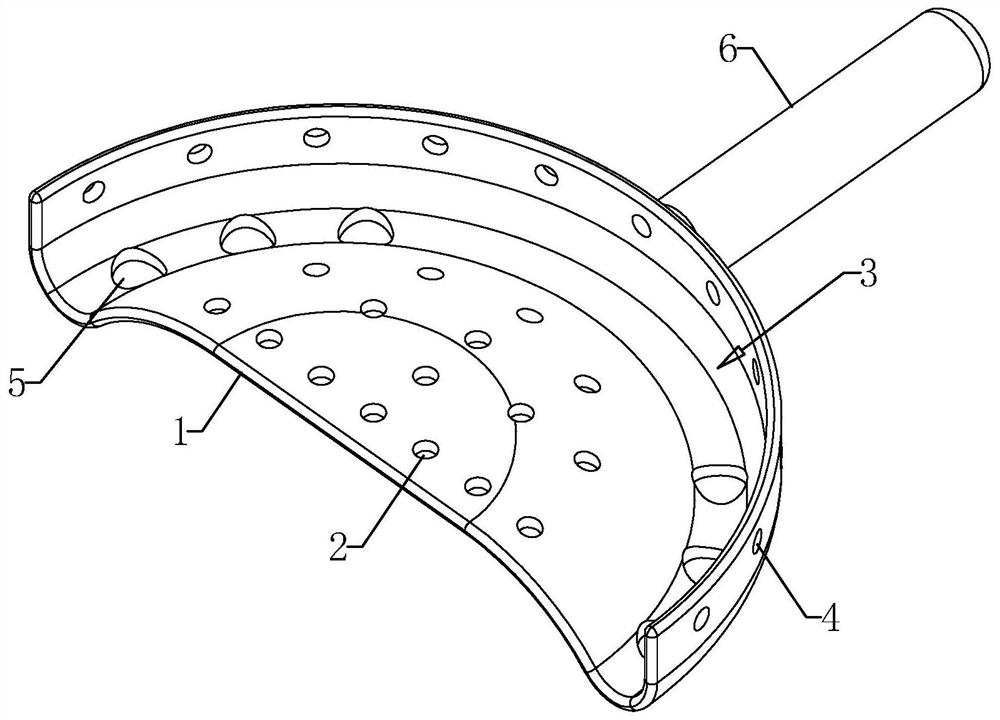

[0043] The following is attached Figure 1-3 The application is described in further detail.

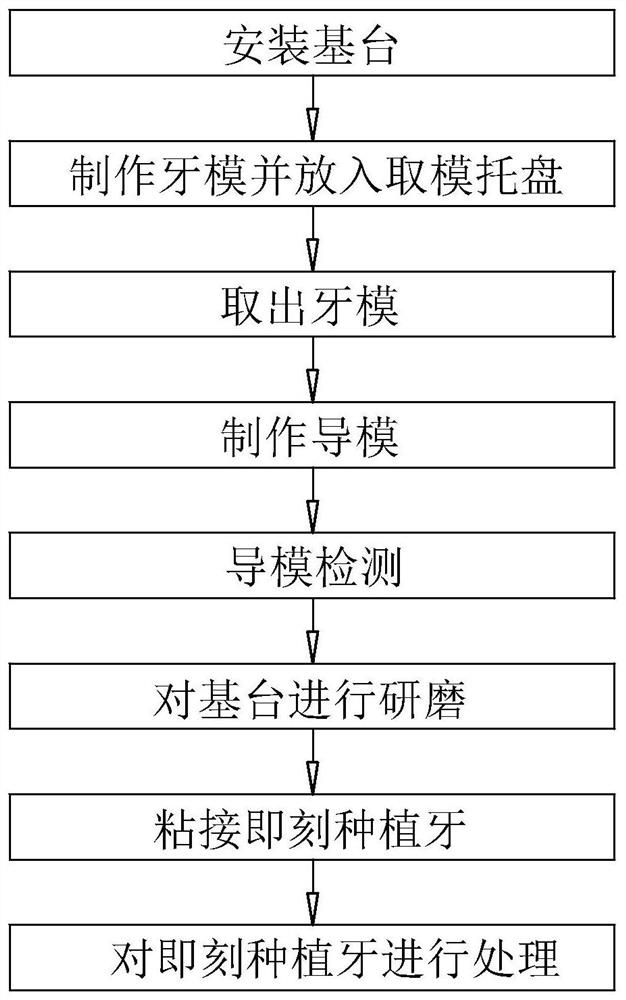

[0044] A kind of immediate dental implant manufacturing method disclosed in this application, refer to figure 1 , including the following steps:

[0045] Step 1. Temporarily install multiple abutments on the implant in the oral cavity, and fix the abutment to the implant;

[0046] Step 2. Use silica gel to make a dental model in the mouth and put it into the model taking tray;

[0047] combine figure 2 , image 3 The mold taking tray includes a baffle 1, a pressure groove 3 connected to the baffle 1, and a handle 6 connected to the pressure groove 3 at one end. 1 on one side.

[0048] The mold-taking tray is integrally formed with flexible materials, such as plastic, rubber, etc. The mold-taking tray made of flexible materials can produce a certain deformation under the premise of maintaining structural strength and stability, so that it is easy to put into the patient inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com