Truck rear axle housing multi-procedure machining clamp and clamping and using method

A rear axle housing and multi-process technology, applied to workpiece clamping devices, manufacturing tools, workbenches, etc., can solve the problems of multi-process processing obstacles, angle change restrictions, and inconvenient fixing of rear axle housings, and achieve the goal of fixing clamps Convenient and fast holding, convenient angle adjustment, and the effect of meeting the needs of azimuth changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

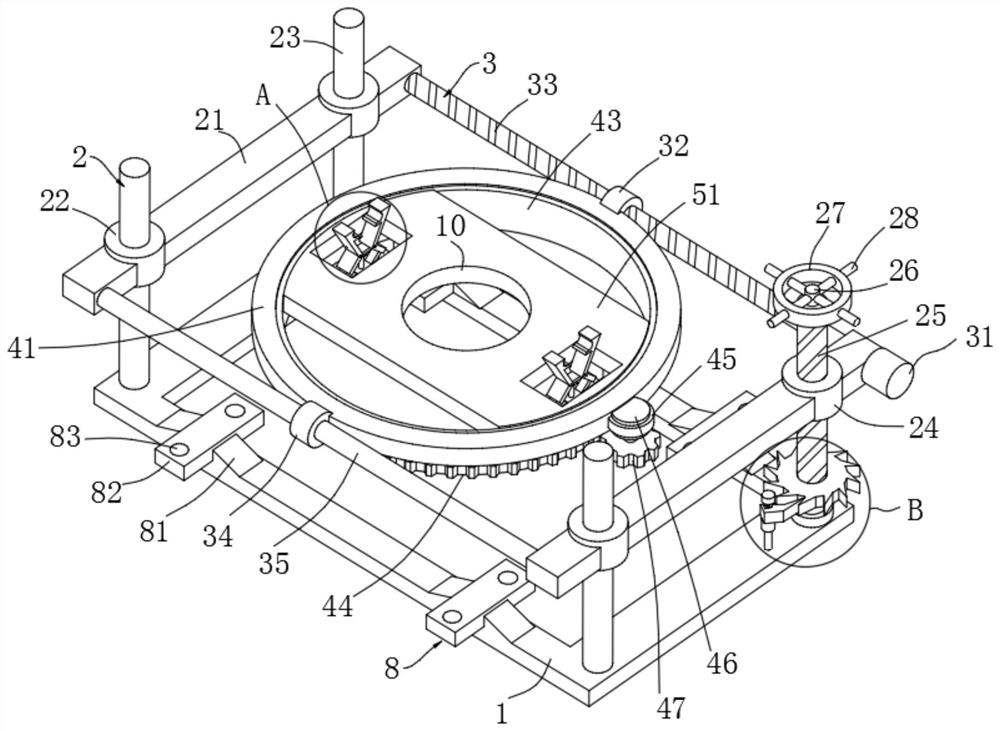

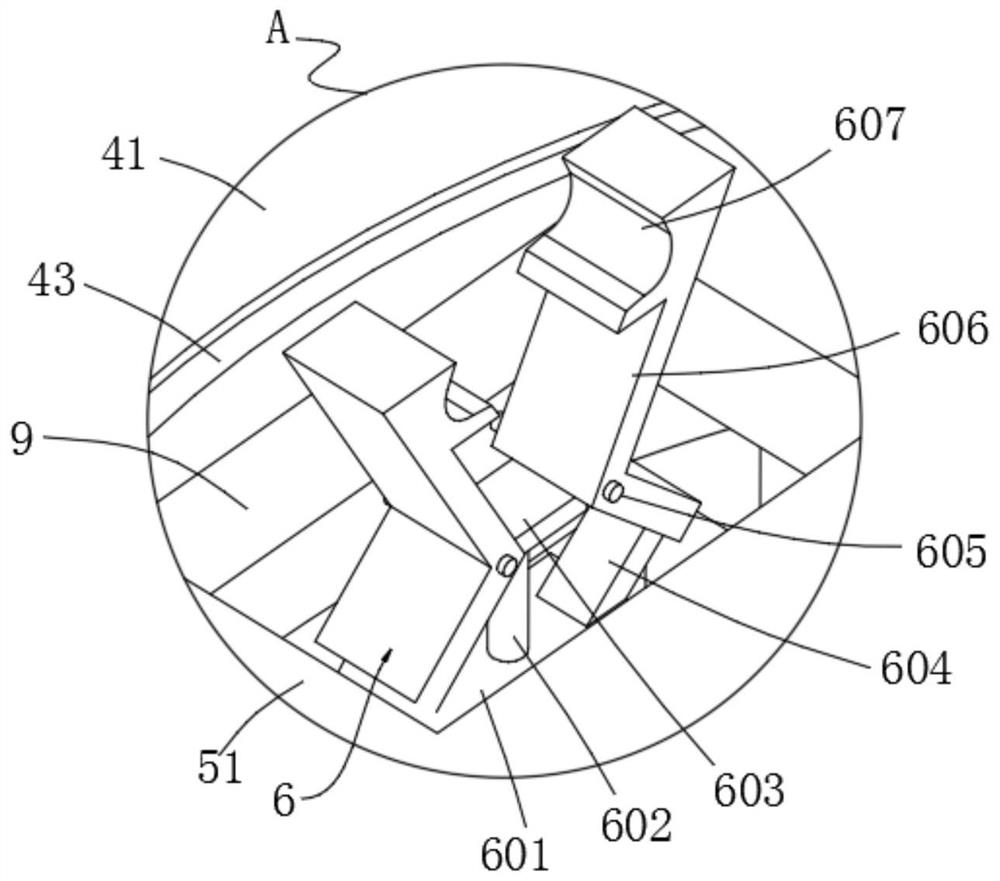

[0046] Example 1, please refer to Figure 1-8 , this embodiment provides a technical solution: a truck rear axle housing multi-process processing fixture, including a bottom frame 1, a lifting control unit 2, a lateral control unit 3, a rotation control unit 4, an overturning control unit 5 and a clamping unit 6;

[0047] A horizontal control unit 3 is installed on the bottom frame 1 through a lift control unit 2, a rotation control unit 4 is installed on the inner side of the lateral control unit 3, a turning control unit 5 is installed on the inner side of the rotation control unit 4, and two turning control units are installed on the turning control unit 5. clamping unit 6;

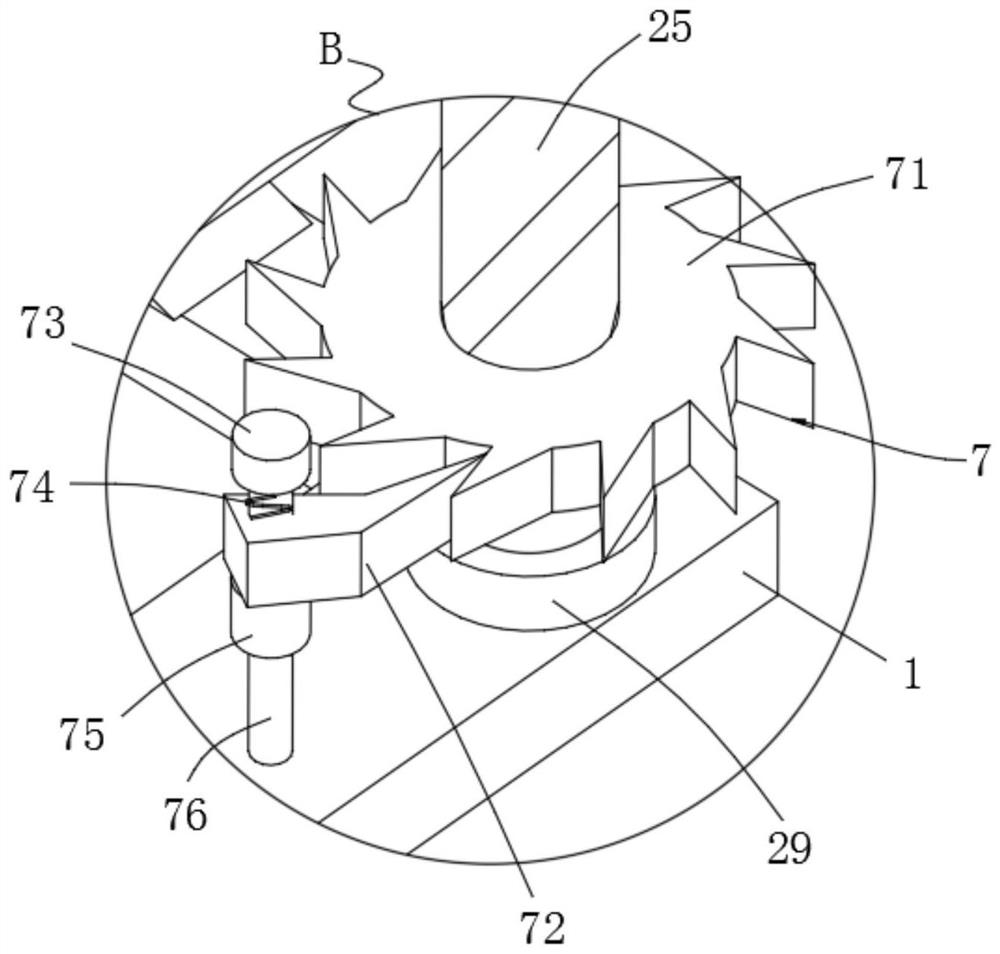

[0048] The lifting control unit 2 includes a longitudinal beam 21, a sliding sleeve 22, a sliding rod 23, a screw hole sleeve 24, a screw rod 25, a connecting column 26, a swivel 27, a torsion bar 28 and a horizontal bearing 29. The three corners of the bottom frame 1 are respectively A vertical slide...

Embodiment 2

[0062] Example 2, please refer to Figure 9 , this embodiment provides a technical solution: a multi-process processing fixture for the truck rear axle housing. The structure of this embodiment is roughly the same as that of Embodiment 1, except that the clamping unit 6 is different:

[0063]The clamping unit 6 includes a hydraulic cylinder 608, a U-shaped frame 611, a fixed block 612, an end plate 613, a through groove 614, a mounting plate 615, a gear shaft 616, a clamping gear 617, a double-sided rack 618 and a clamping rod 619, the two ends of flipping plate 51 are provided with square groove 9 respectively, and the position corresponding to square groove 9 is fixed on the bottom of flipping plate 51 with mounting plate 615, and the bottom of mounting plate 615 is connected with U-shaped frame 611 by end plate 613, and end plate A through groove 614 is opened in the middle of the 613, and a hydraulic cylinder 608 is fixed inside the U-shaped frame 611. The telescopic end o...

Embodiment 3

[0065] Embodiment three, please refer to Figure 10 , this embodiment provides a technical solution: multi-process processing fixture for truck rear axle housing, this embodiment is roughly the same structure as the above embodiment, the difference lies in the difference of the clamping unit 6:

[0066] The clamping unit 6 includes a hydraulic cylinder 608, a fixed plate 621, a sector gear 622, a sector gear shaft 623, a cylinder 624, a vertical bar 625, a slide rail fixing bar 626, a slide rail 627, a slide bar 628, a hinge support 629 and an arc Shaped clamp bar 630, the two ends of turning plate 51 are provided with square groove 9 respectively, the position corresponding to square groove 9 is fixed on the bottom of turning plate 51 with fixed plate 621, and the two ends of the side of fixed plate 621 are respectively connected by sector gear shaft 623 rotation. Cylinder 624, the side of two cylinders 624 is provided with corresponding sector gear 622, two sector gears 622 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com